Underwater redundant hydraulic mechanical arm and work method thereof

A technology of hydraulic machinery and mechanical arms, applied in the field of underwater mechanical robots, which can solve problems such as limited rotation angle, complicated operation, and inability to expand the mechanical arm conveniently and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

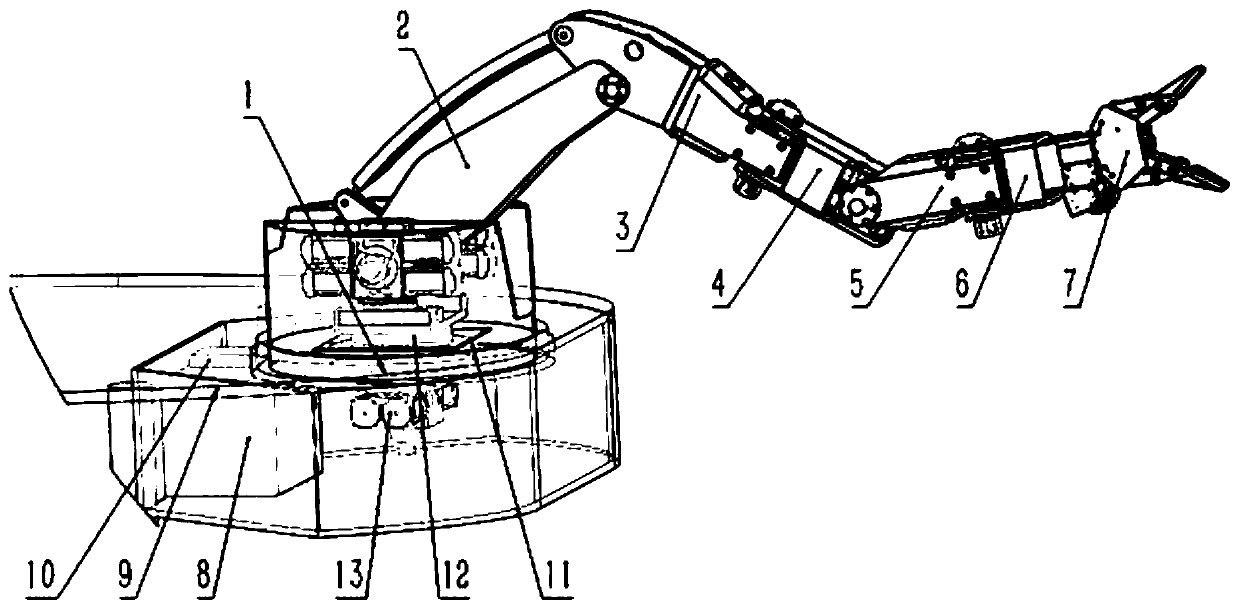

[0091] An underwater redundant hydraulic manipulator, such as Figure 1-11 As shown, including swivel arm 1, big arm 2, middle arm 3, small arm A4, small arm B5, wrist arm 6, gripper 7, hydraulic system 8 and STM32 control board 10, swivel arm 1, big arm 2, middle Arm 3, forearm A4, forearm B5, wrist arm 6 and gripper 7 are connected in sequence, the hydraulic system 8 provides power for the entire robotic arm, and the STM32 control board 10 is used to control the movement of the robotic arm;

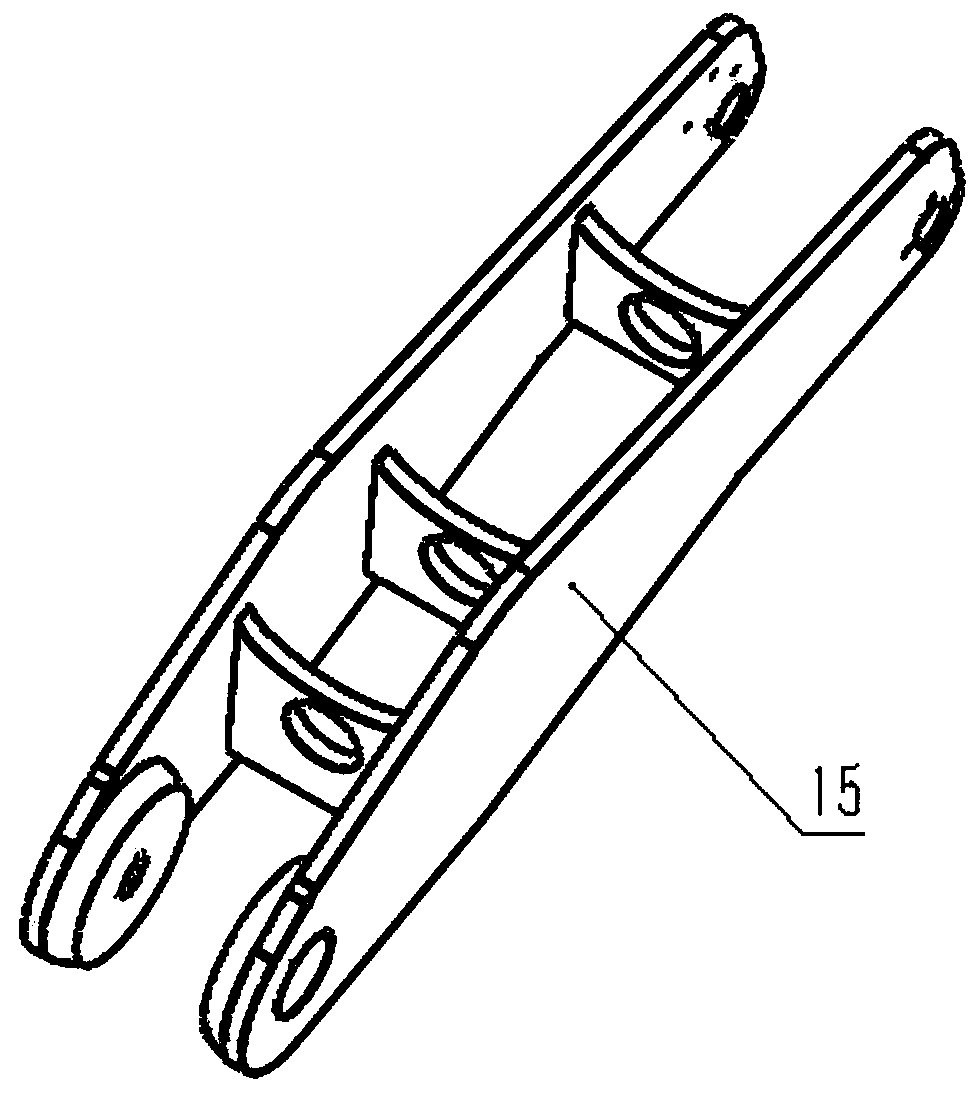

[0092] The slewing arm 1 is installed on the underwater mobile platform 9 to support the entire hydraulic mechanical arm, and realize the fixation and rotation of the entire mechanical arm. The large arm 2 and the middle arm 3 realize the pitching of the mechanical arm in a large range, and the small arm A4 realizes the vertical movement of the mechanical arm. For yaw, the small arm B5 realizes the pitching of the mechanical arm in a small range, the wrist arm 6 realizes the yaw and rot...

Embodiment 2

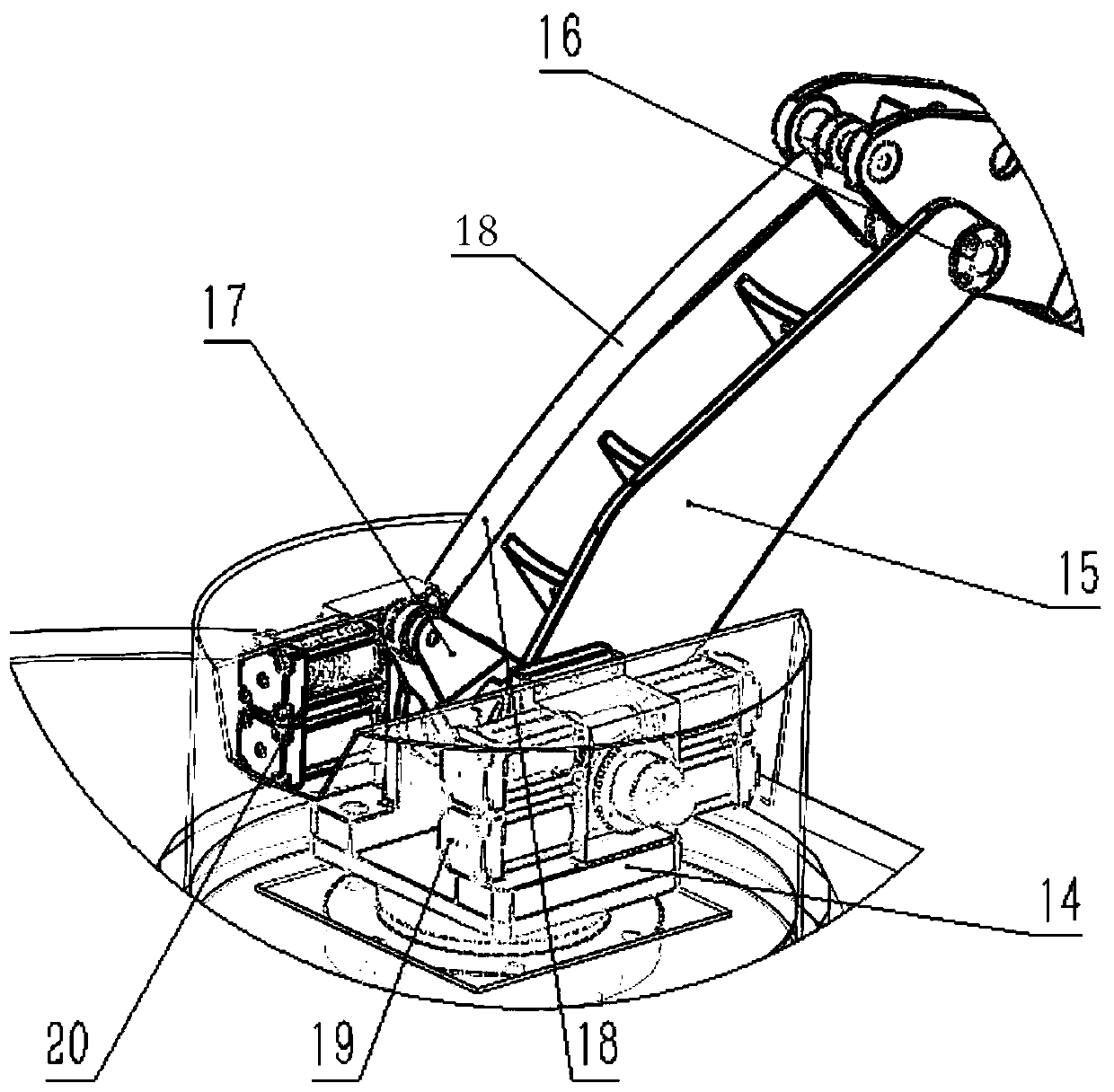

[0094] An underwater redundant hydraulic mechanical arm, the structure of which is shown in Embodiment 1, the difference is that the rotary arm 1 includes a fixed base 11, a rotary seat 12 and a rotary hydraulic cylinder A13, and the fixed base 11 and the underwater mobile platform 9 is fixedly connected by bolts, and the upper part of the fixed base 11 is connected with the revolving base through double bearings. The double bearings are two bearings installed in series and parallel to support the rotation of the revolving base. The revolving base 12 is equipped with a boom base 14 and The protective cover, the bottom of the revolving seat 12 is connected with the revolving hydraulic cylinder A13 through the spline gear shaft A42, and the revolving hydraulic cylinder A13 is installed on the underwater mobile platform through the revolving hydraulic cylinder block 39.

Embodiment 3

[0096] A kind of underwater redundant hydraulic mechanical arm, the structure is as shown in embodiment 2, the difference is, as Figure 10 As shown, two rotary hydraulic cylinders 40 are also installed on the rotary hydraulic cylinder block 39 of the rotary hydraulic cylinder A13, and the two ends of the two rotary hydraulic cylinders 40 are respectively equipped with an oil inlet and an oil outlet. A double-headed rack piston 41 is installed in the 40, and the double-headed rack piston 41 and the spline gear shaft A42 are installed in cross-staggered meshing, the spline end of the spline gear shaft A42 is meshed with the rotary seat 12, and the other end is installed with an angle sensor 43 and torque sensor 44 are used to measure the rotation angle and torque of the spline gear shaft on the spline gear shaft A42 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com