Worm-oblique gear transmission mechanism with load fitting characteristic and in form of dual-assistance mechanism

A technology of transmission mechanism and load characteristics, which is applied in the direction of electromechanical devices, electric components, and control of mechanical energy. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

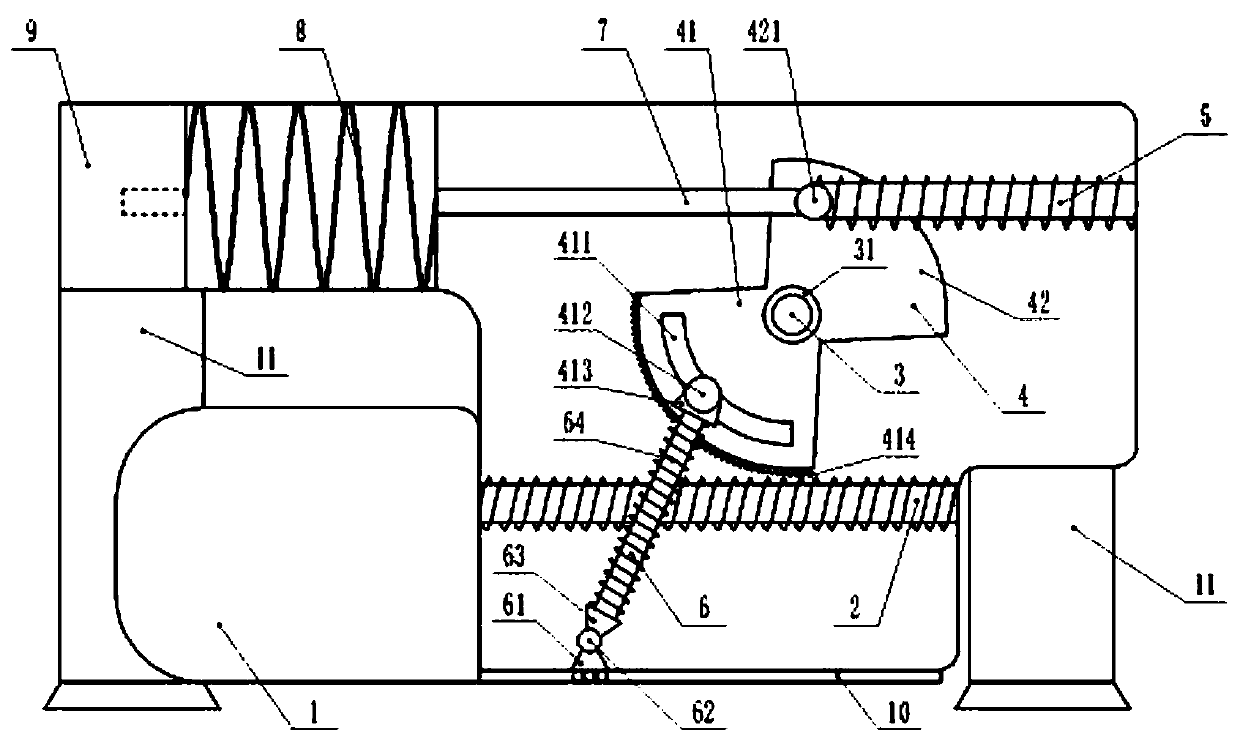

[0024] Such as figure 1 As shown, the worm-helical gear transmission mechanism in the form of a double booster mechanism that fits the load characteristics mainly includes a motor 1, a transmission screw 2, a mandrel 3, a turntable 4, a booster mechanism 1 5, a booster mechanism 2 6, and a transmission rod 7 , the buffer mechanism 8 and the external load 9, the motor 1 is arranged at the lower left part of the transmission mechanism, the motor 1 performs periodic forward and reverse rotation under the control of the control circuit, the transmission screw rod 2 is arranged at the inner lower part of the transmission mechanism, and the transmission screw rod 2 The left end of the motor is fixedly connected with the output end of the motor 1, the right end of the transmission screw 2 is movably connected with the inner wall of the transmission mechanism, the mandrel 3 is movably arranged inside the transmission mechanism above the transmission screw 2, and the turntable 4 is fixe...

Embodiment 2

[0027] Using the worm-helical gear transmission mechanism in the form of double booster mechanisms provided in Example 1 to study the specific influence of booster mechanism 1 and booster mechanism 2 on the transmission mechanism.

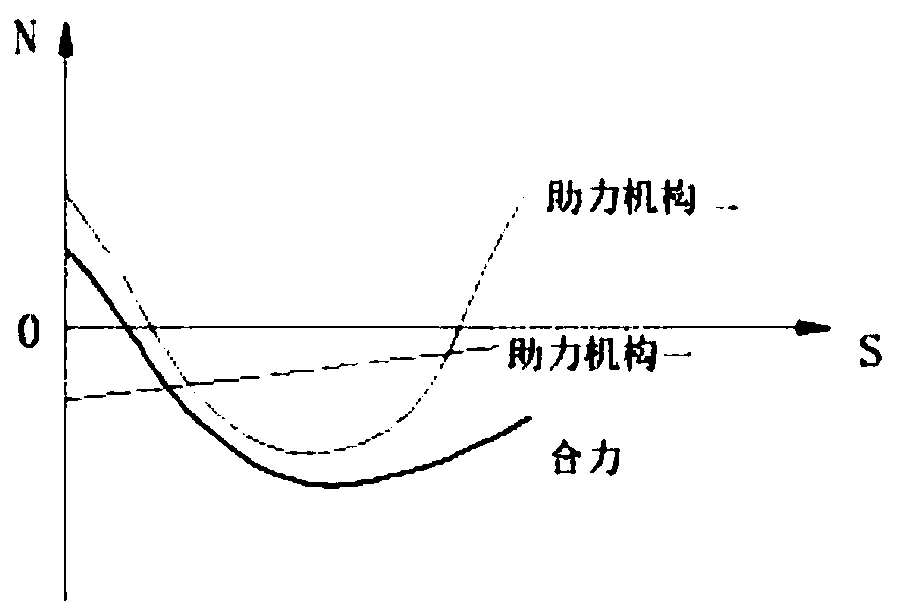

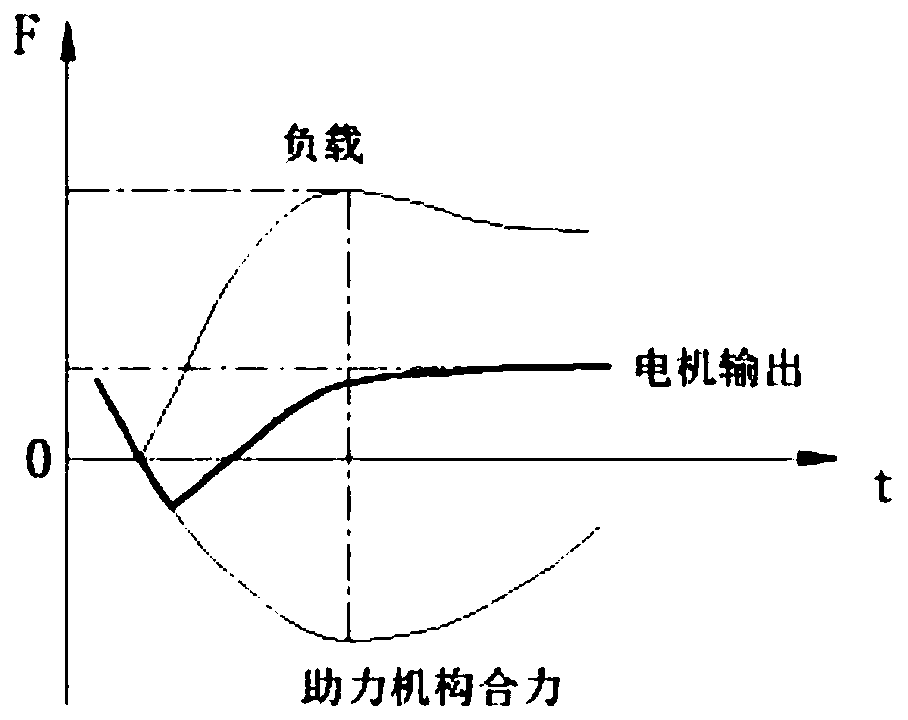

[0028] Firstly remove the booster mechanism 2, and measure the linearity of the boosting characteristics provided by the booster mechanism 1 when the turntable reciprocates, then remove the booster mechanism 1, install the booster mechanism 2, and measure the booster mechanism 2 when the turntable reciprocates. , the boost characteristics provided are sinusoidal, such as figure 2As shown, the first and second booster mechanisms are installed at the same time, and the force value, force point and booster direction of the first booster mechanism and the second booster mechanism are respectively adjusted. The resultant force of the booster mechanism is opposite to the direction of the load, and the characteristics are similar. Such as image 3 shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com