Patents

Literature

42results about How to "Eliminate pressure differentials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

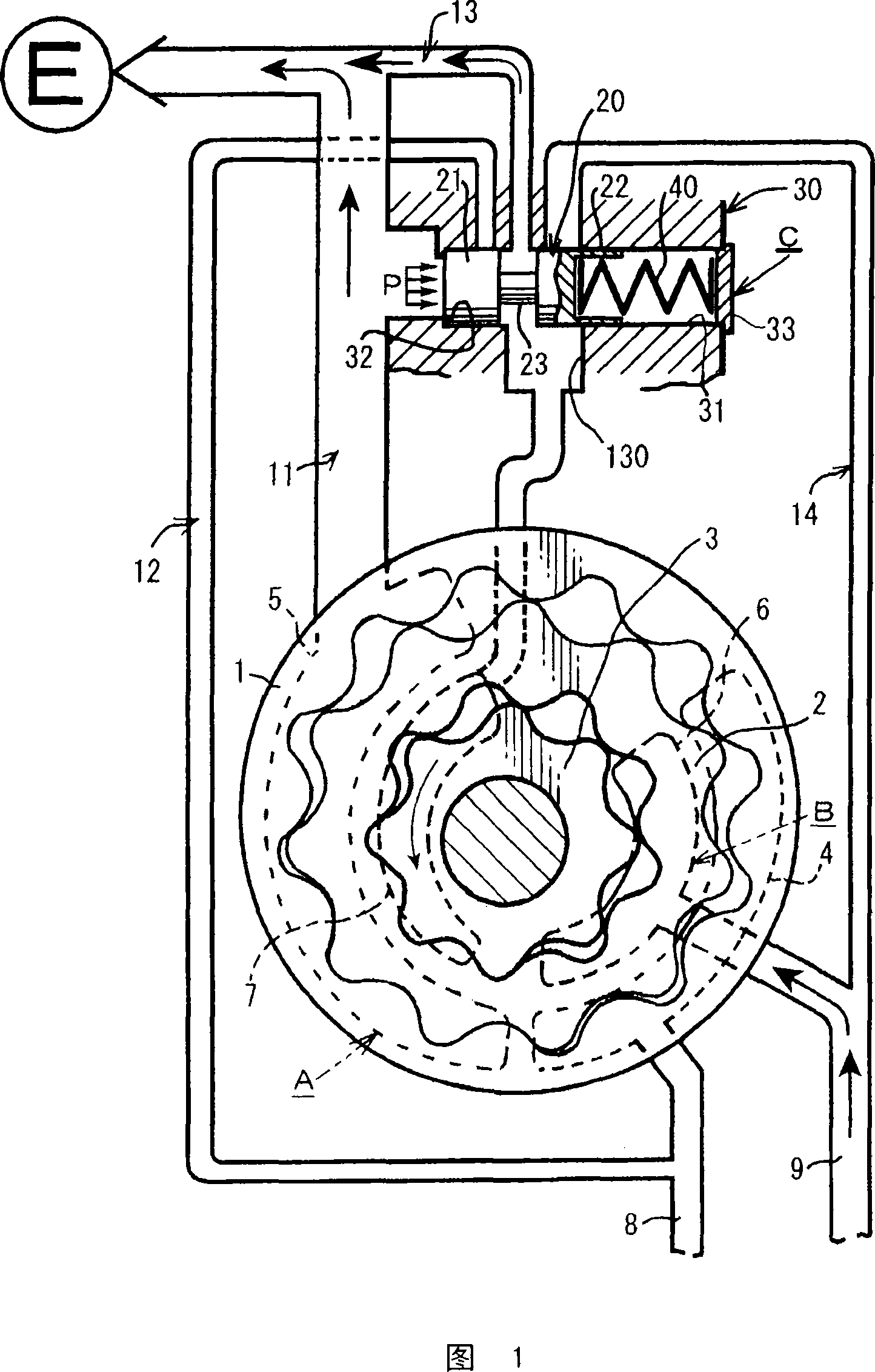

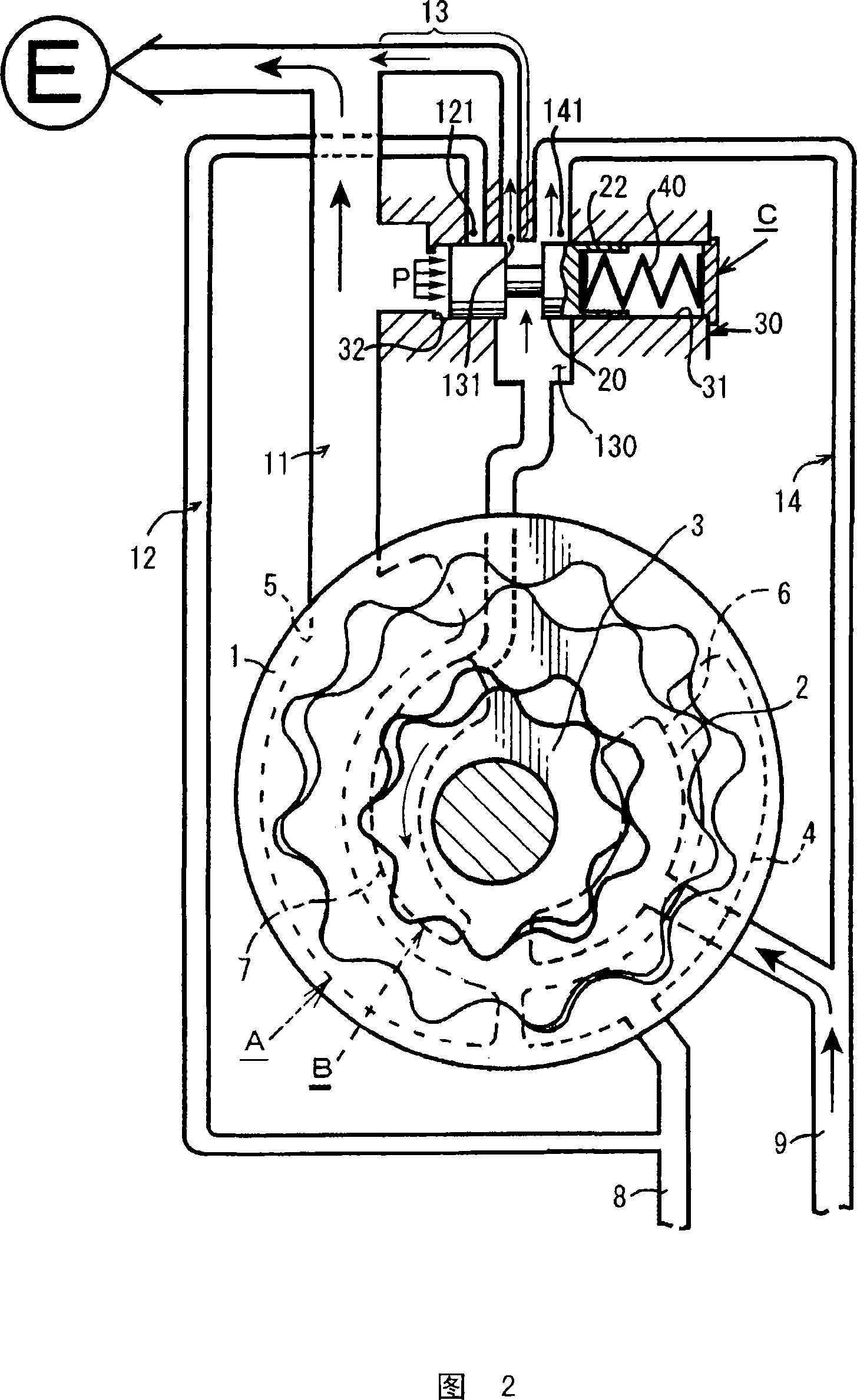

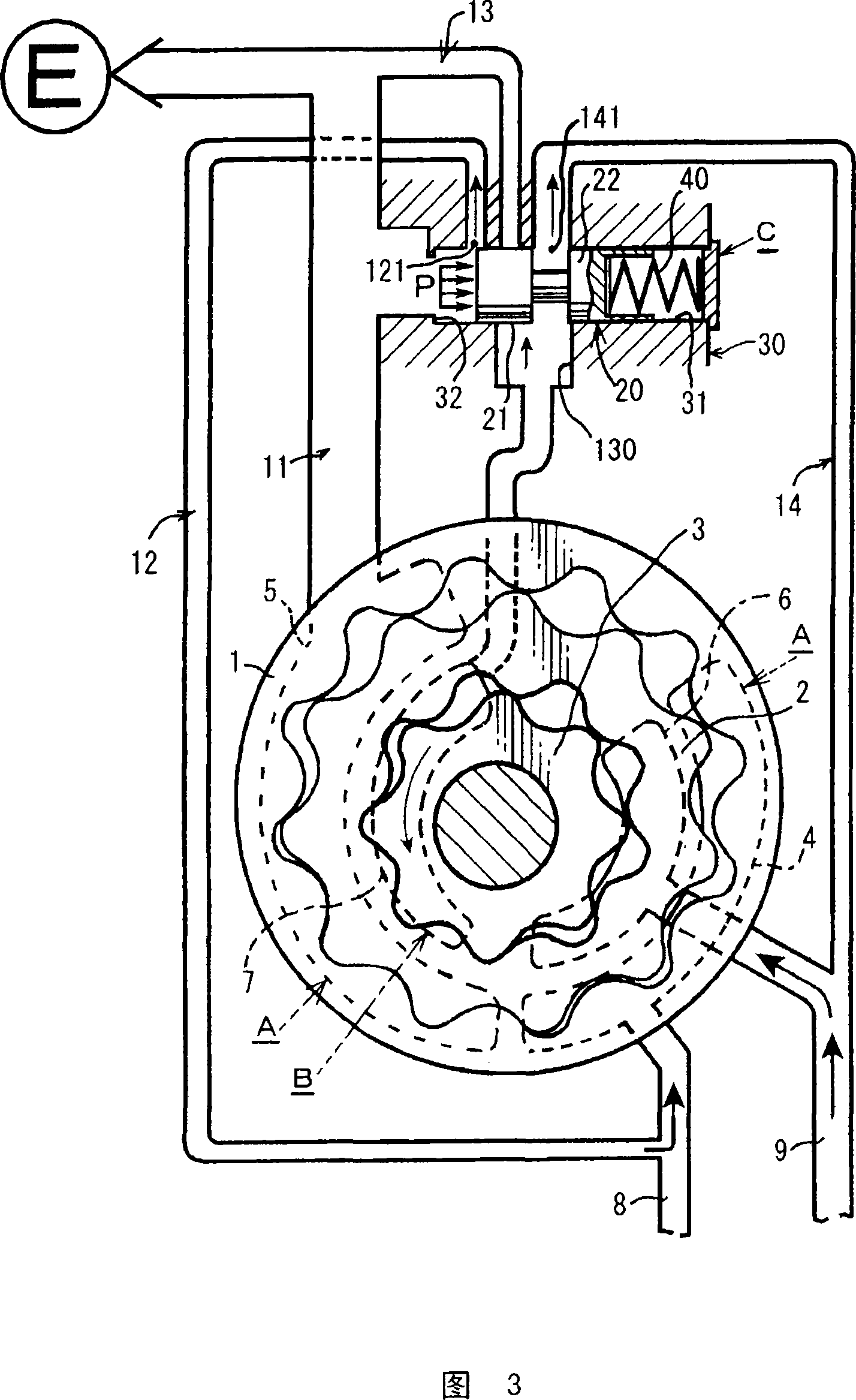

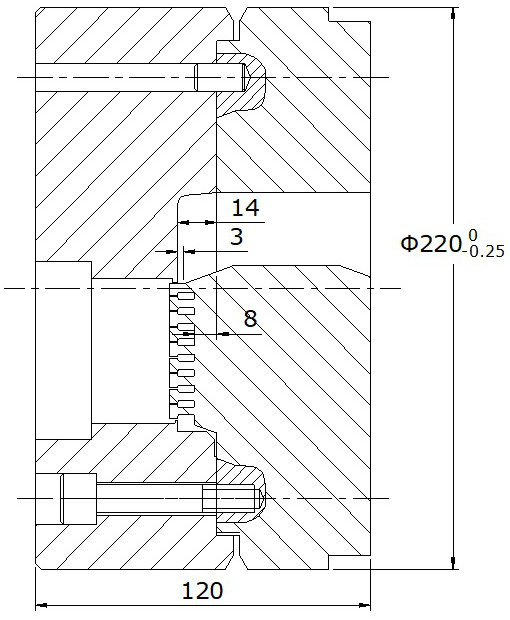

Oil pump pressure control device

InactiveCN101251108ARelieve pressureAvoid wear and tearRotary piston pumpsRotary/oscillating piston combinationsEngineeringControl valves

The invention provides a flow quantity variable oil pump having two discharge ports and using three rotors. The inventive oil pump maintains pressure property same with that of normal oil pumps and reduces friction at the same time. The inventive oil pump comprises a first discharge passage (11) for supply oil to the engine; a return passage (E) that returns to an intake side of an outer circumferential side rotor (A); a second discharge passage (13) for supplying oil to the engine; a return passage (E) that returns to an intake side of an inner circumferential side rotor (B); and a pressure control valve whose valve main body is provided between a discharge port from the inner circumferential side rotor and the first discharge passage. The first and second discharge passage are coupled, and a flow passage control is executed in each of: a low revolution range in a state in which only the first and the second discharge passage are open; an intermediate revolution range in a state in which the first and second discharge passage are open and a first intake side of the return passage is closed while a second intake side of the return passage is open; and a high revolution range in a state in which the second discharge passage is closed while the first discharge passage and the return passage are open.

Owner:YAMADA SEISAKUSHO KK

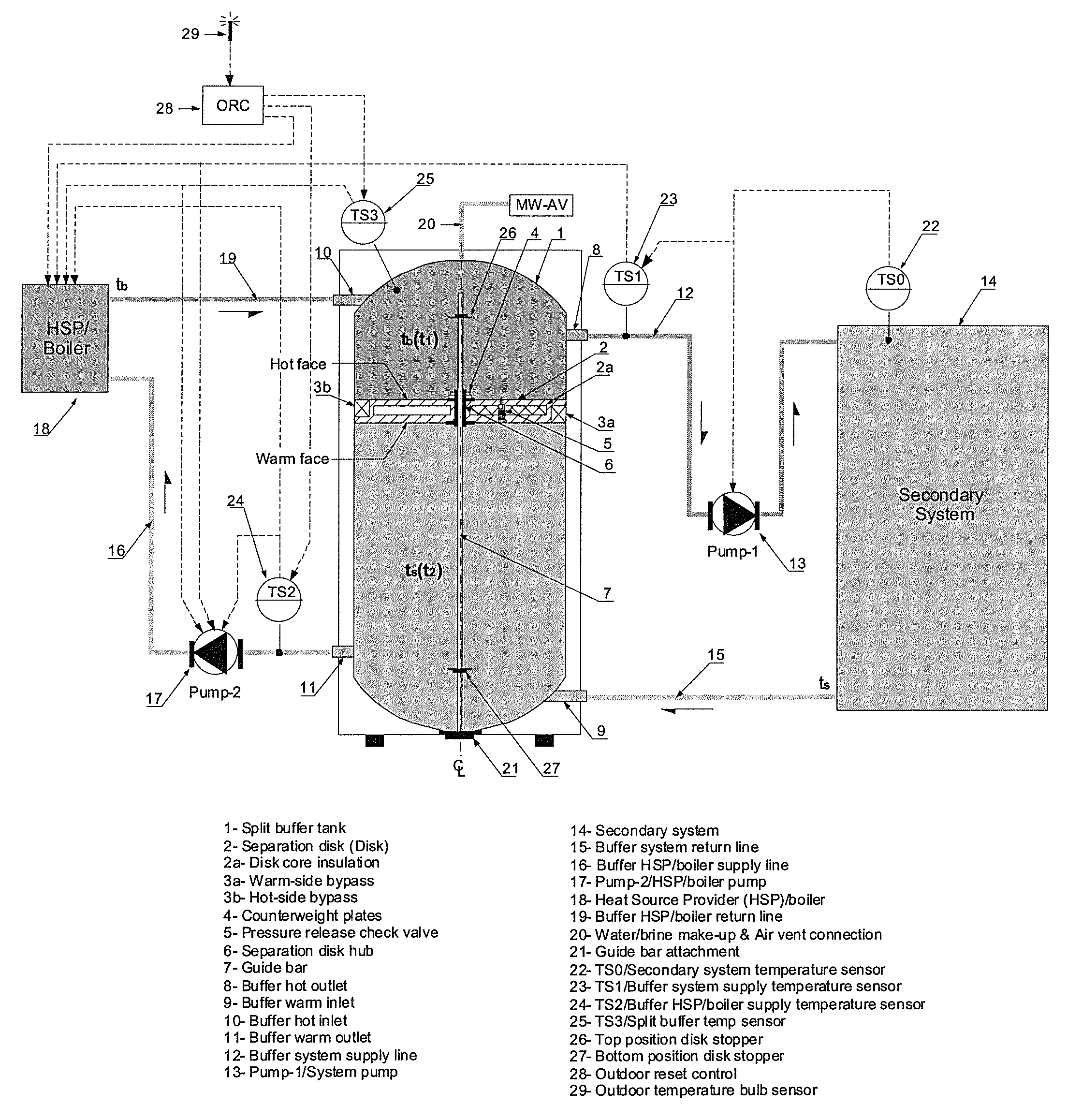

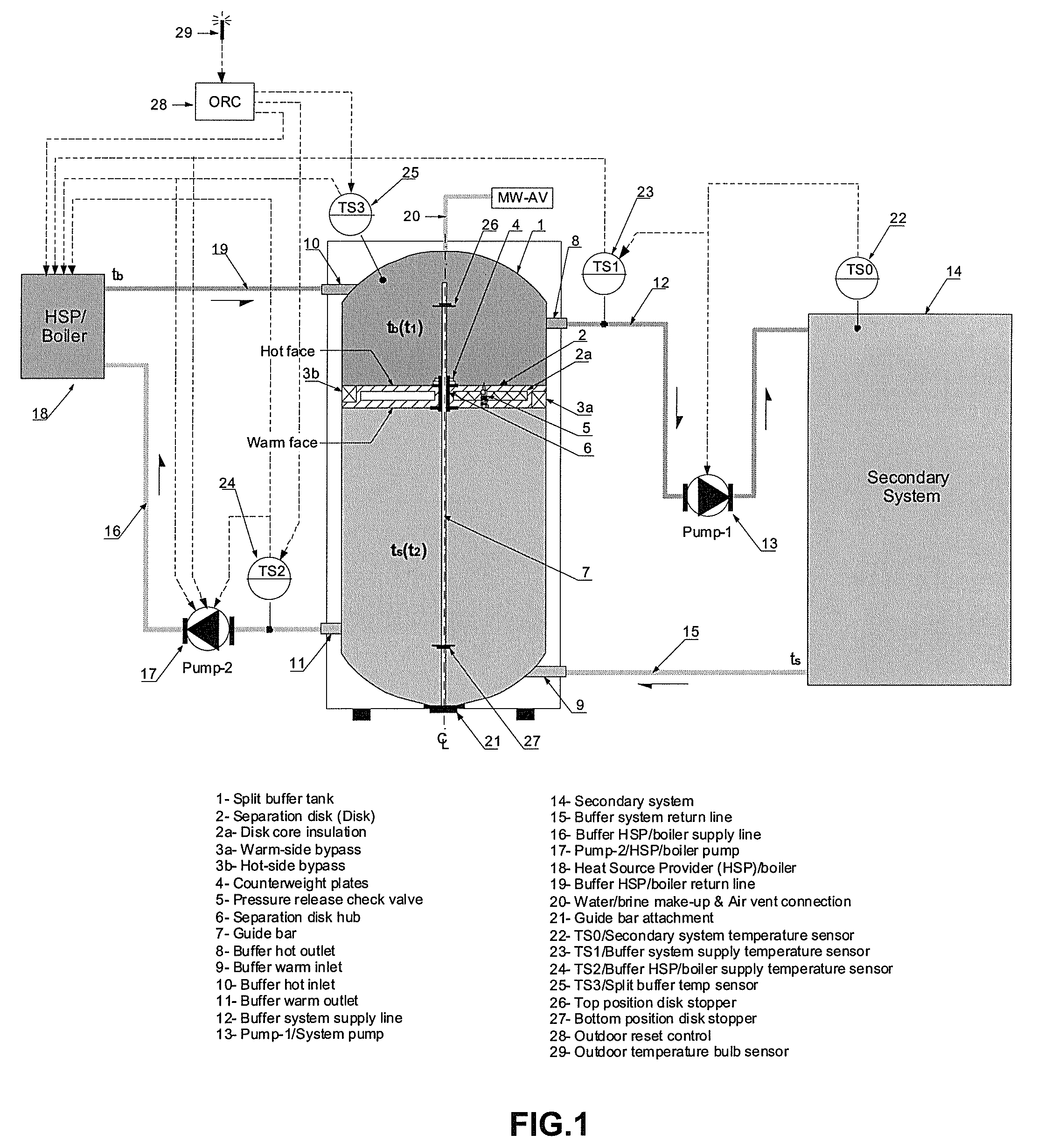

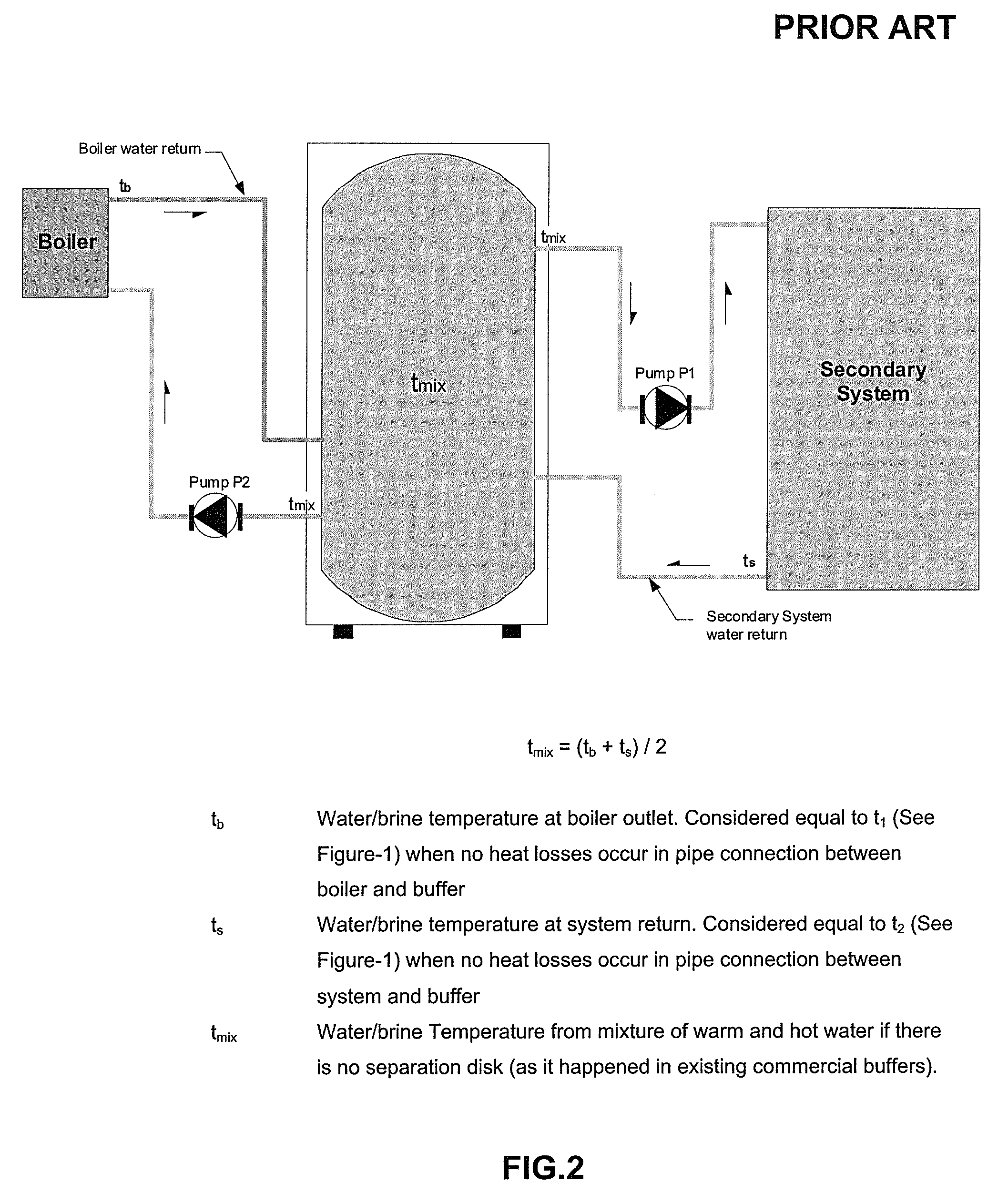

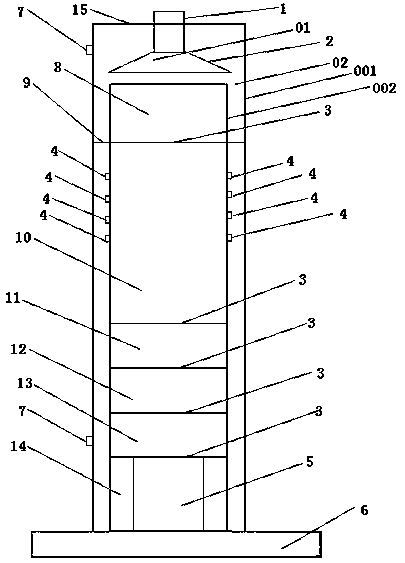

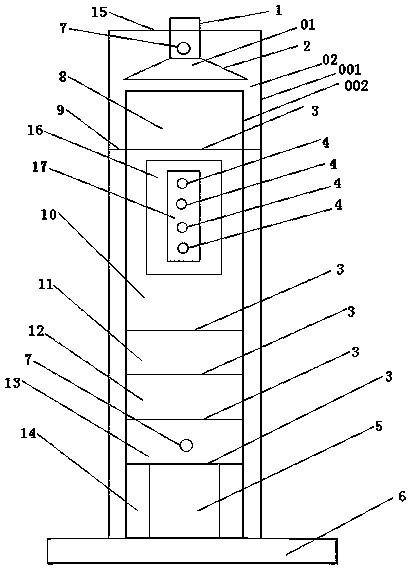

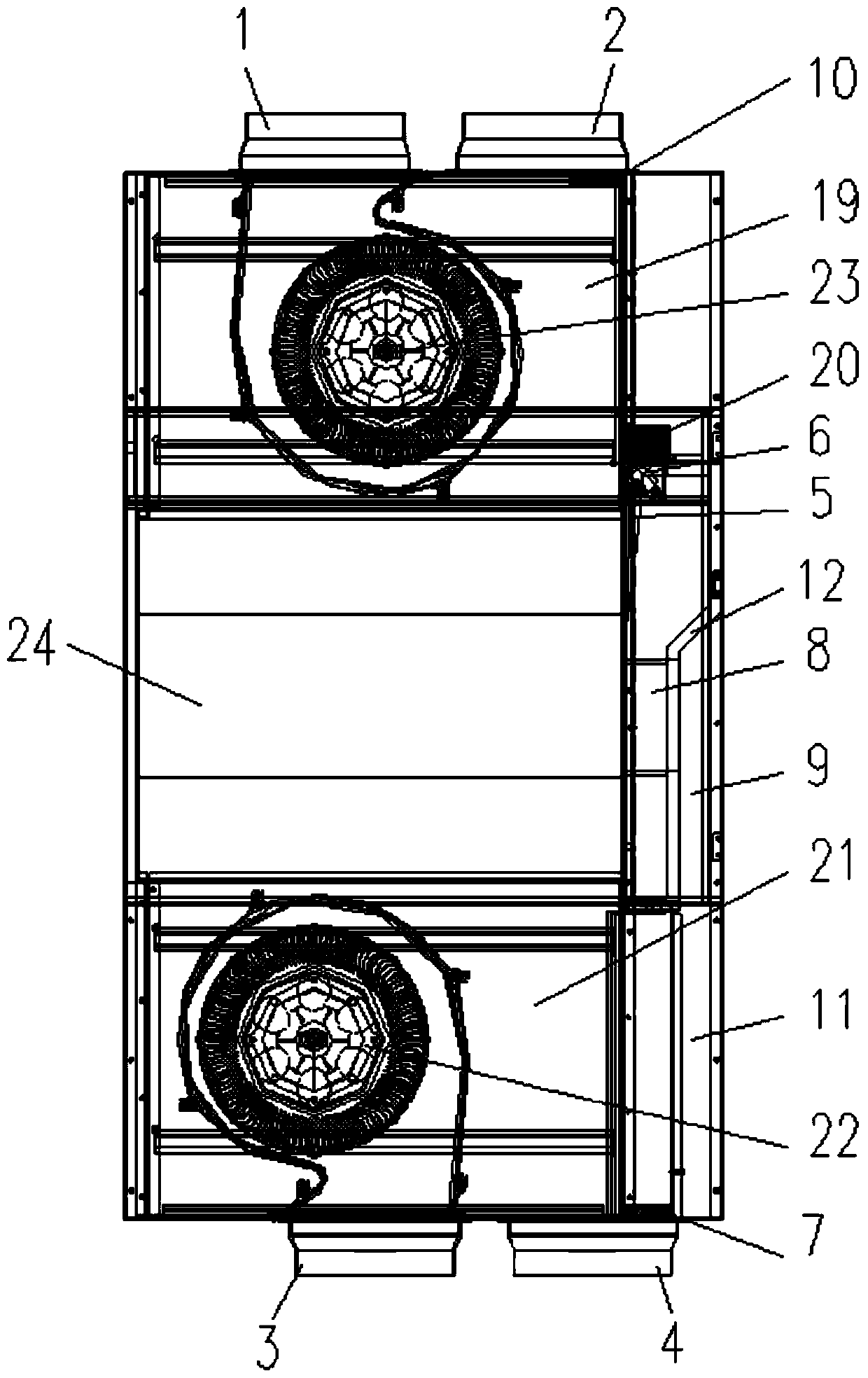

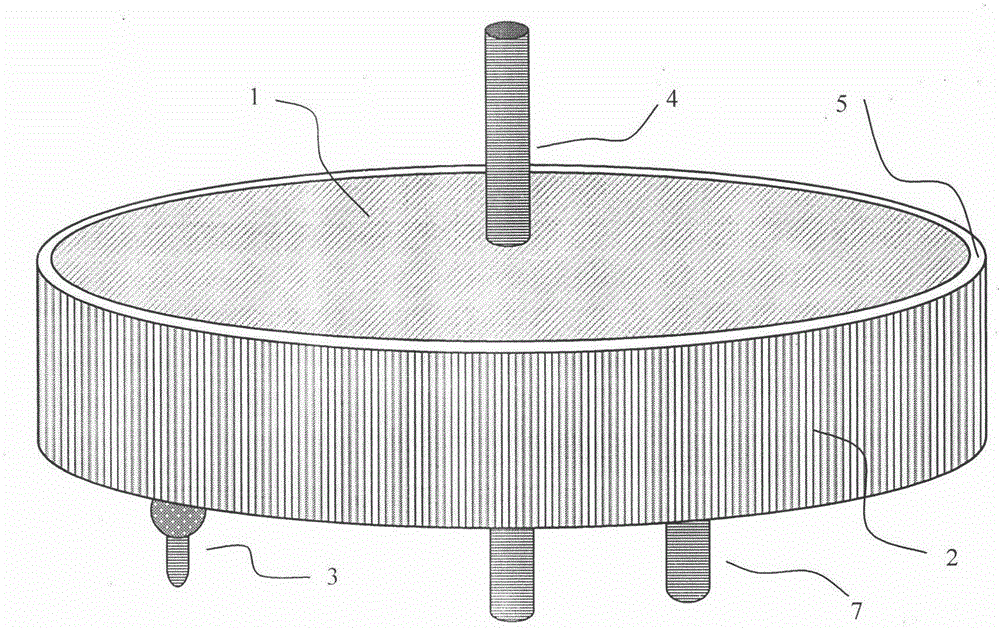

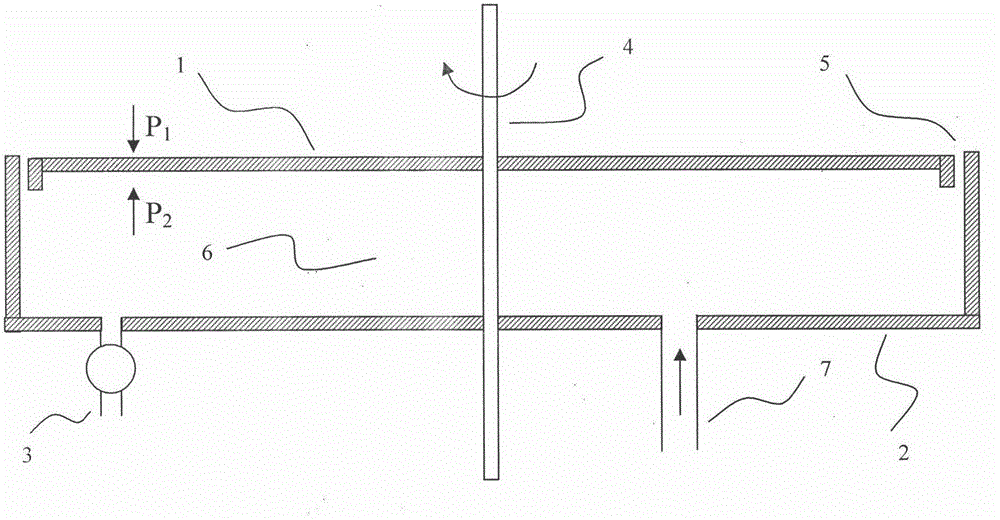

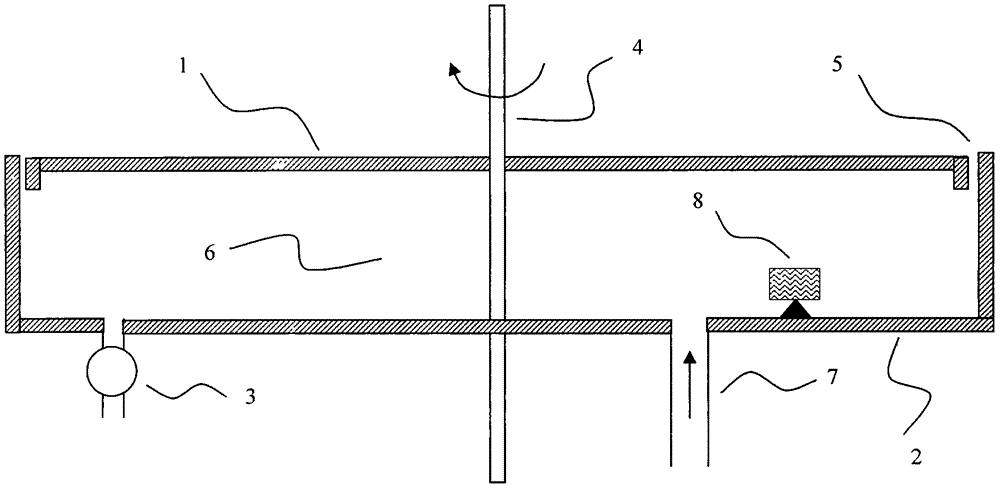

Heating or cooling system featuring a split buffer tank

ActiveUS8997511B2Eliminate differential pressurePrevent rotationMechanical apparatusCentral heating with accumulated heatThermodynamicsWarm water

This invention relates to a heating / cooling system operating on the basis of a novel SPLIT BUFFER TANK; representing an efficiency improvement alternative to HVAC systems functioning with existing commercial buffer tanks. Currently, commercial buffers have the heat source provider (HSP)-return and system-return discharging to a common buffer / vessel. Novel SPLIT BUFFER is provided with a SEPARATION DISK placed inside the tank as mechanical way of separating the hot water inflow from the HSP from the warmer water inflow from system return. The disk moves up and down along the tank driven by demanded water supply and return. Pump-1 circulates hot water from the hot section of the buffer to the secondary system claiming for heat. Pump-2 circulates warmer water from the warmer section of the buffer through the HSP where it is reheated, and subsequently stored in the hot section of the buffer to reinitiate this cycle again.

Owner:BERRIO DENERING

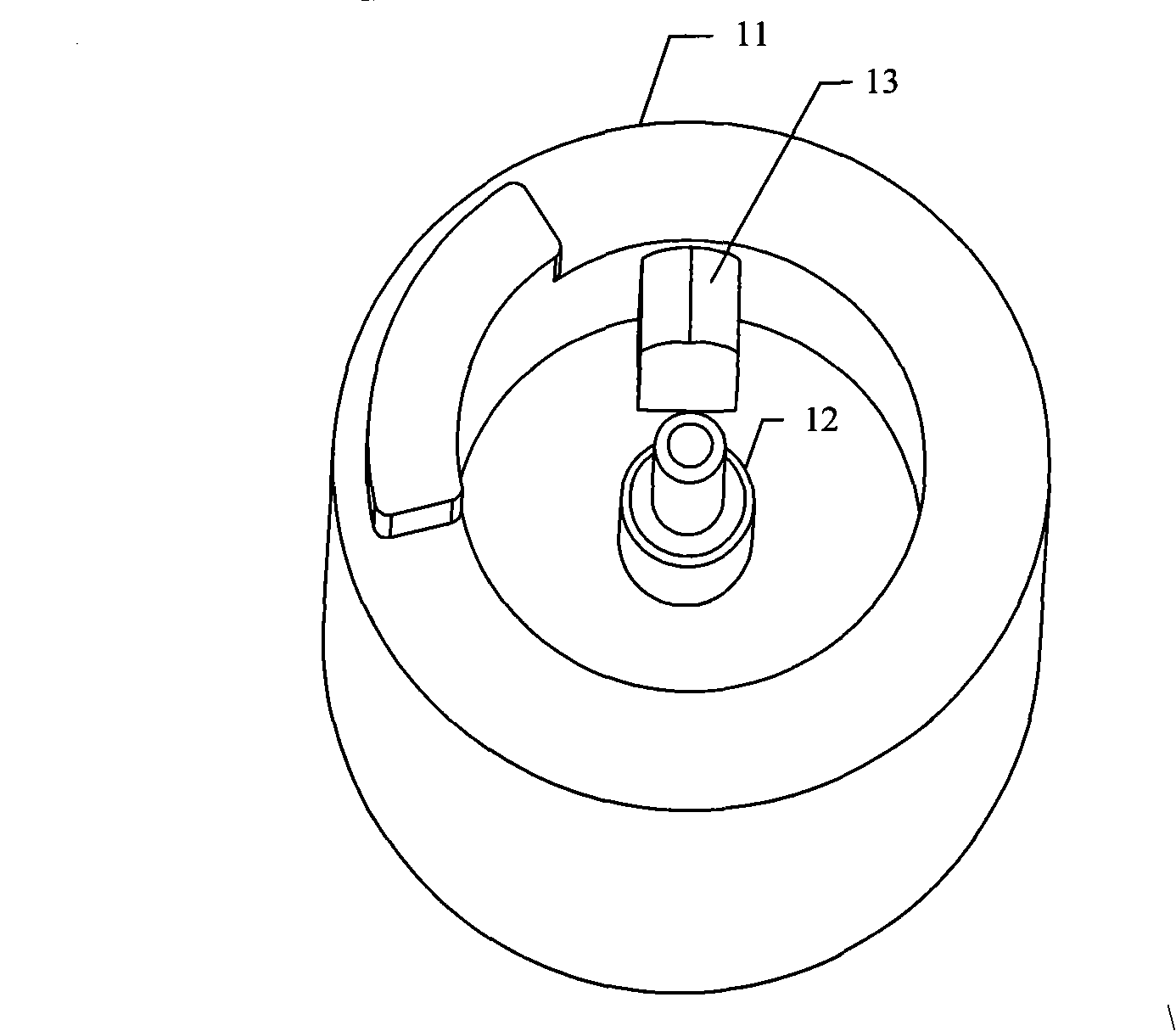

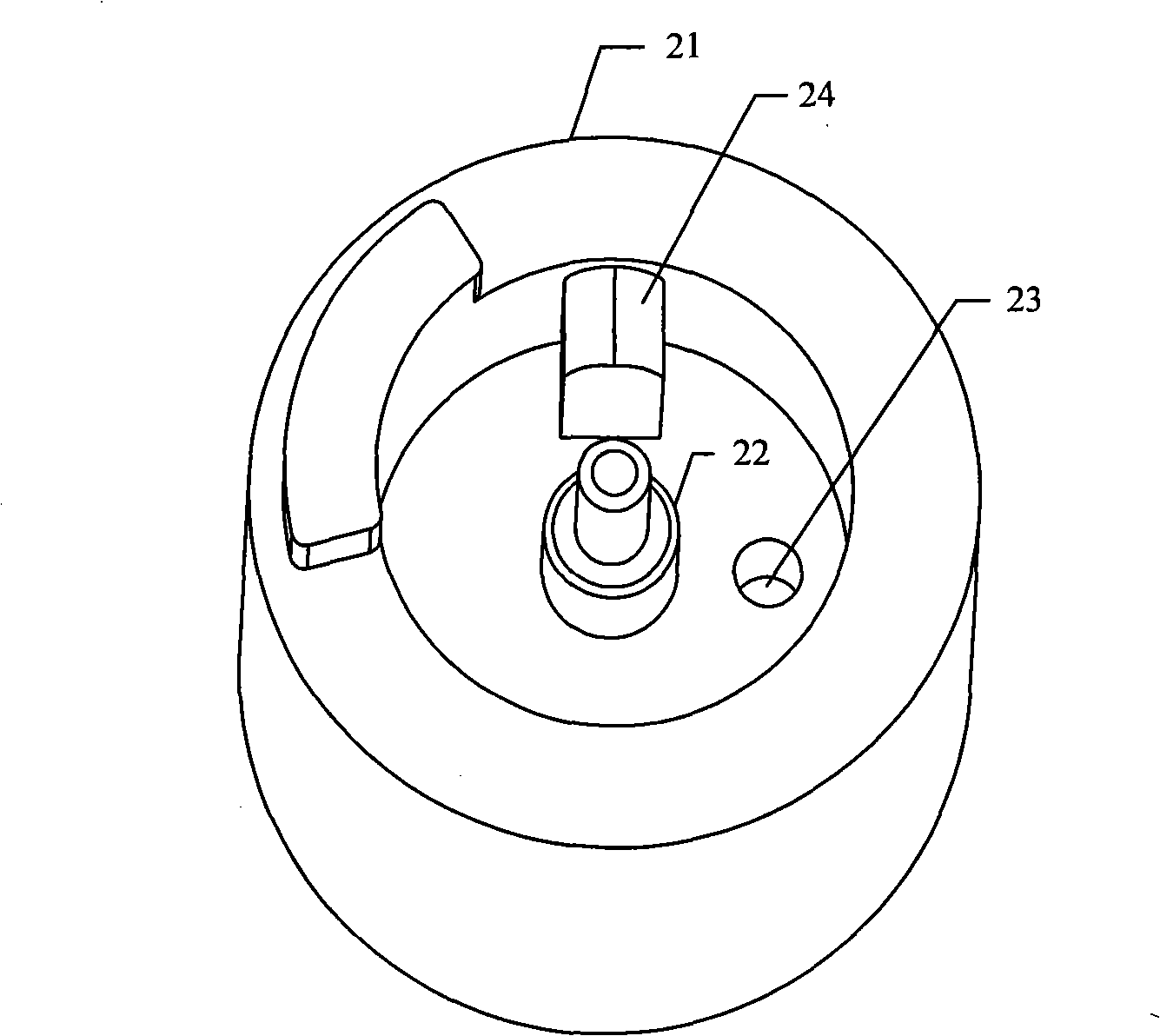

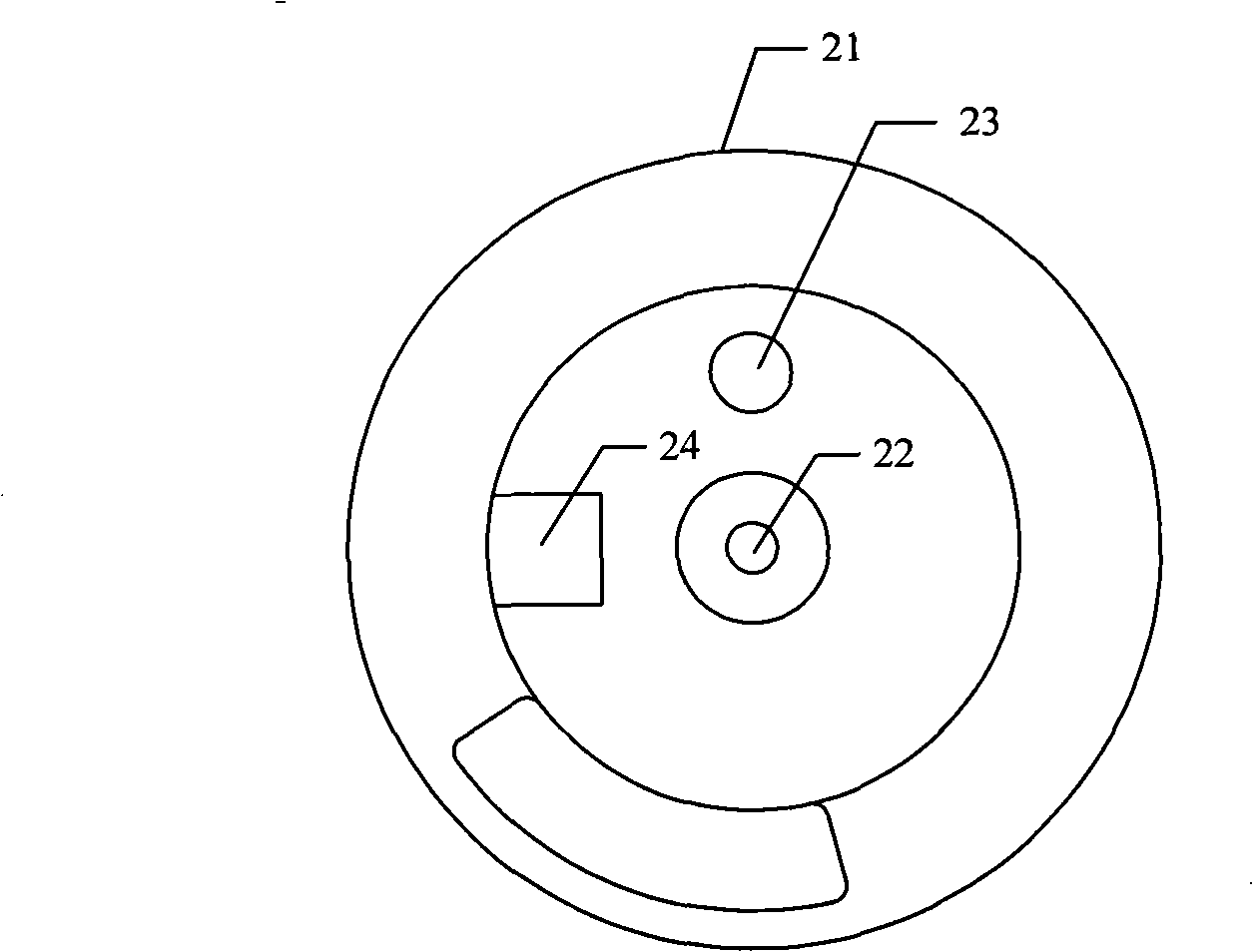

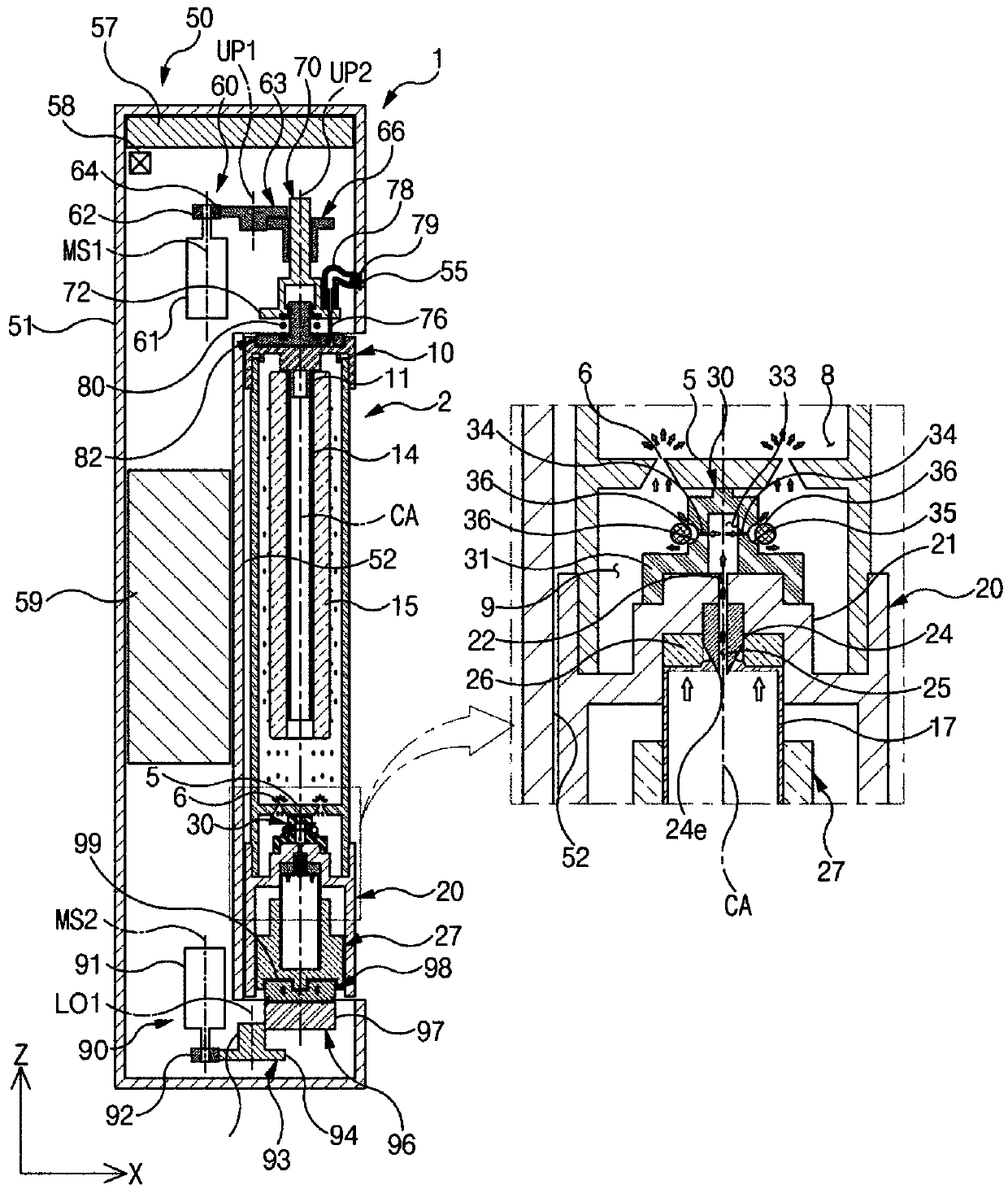

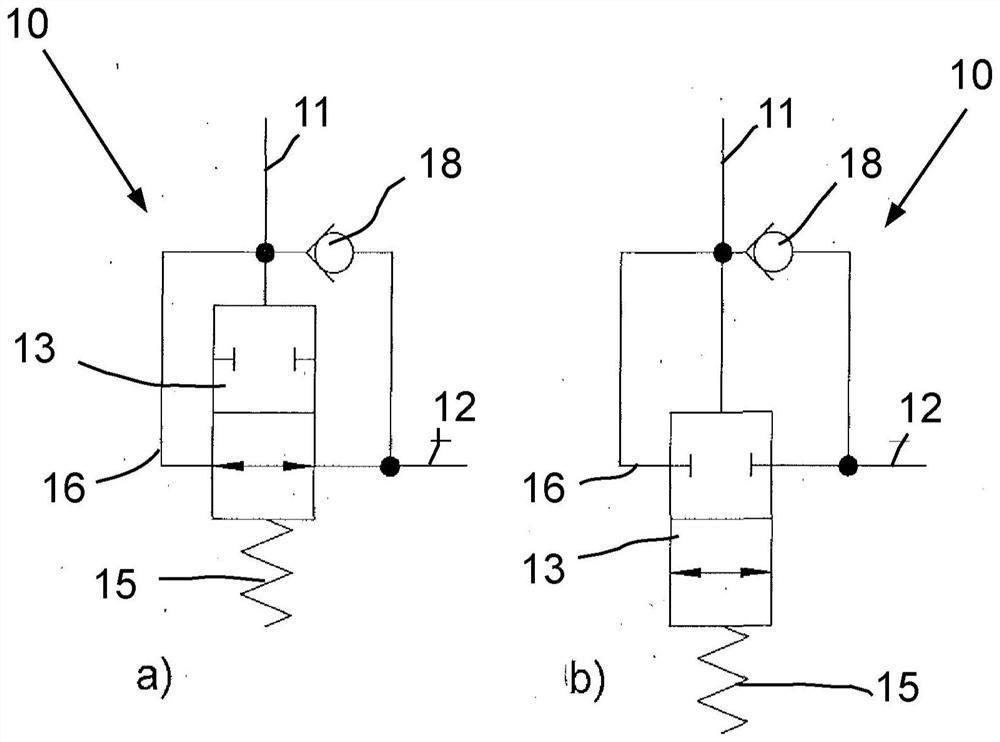

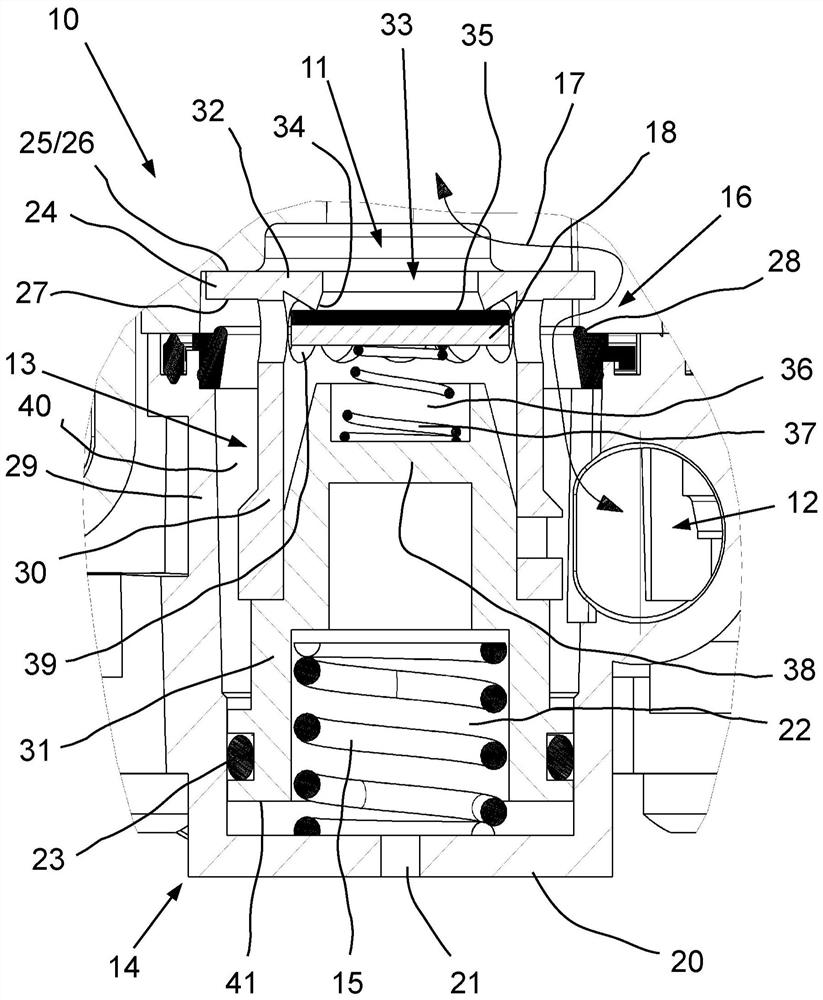

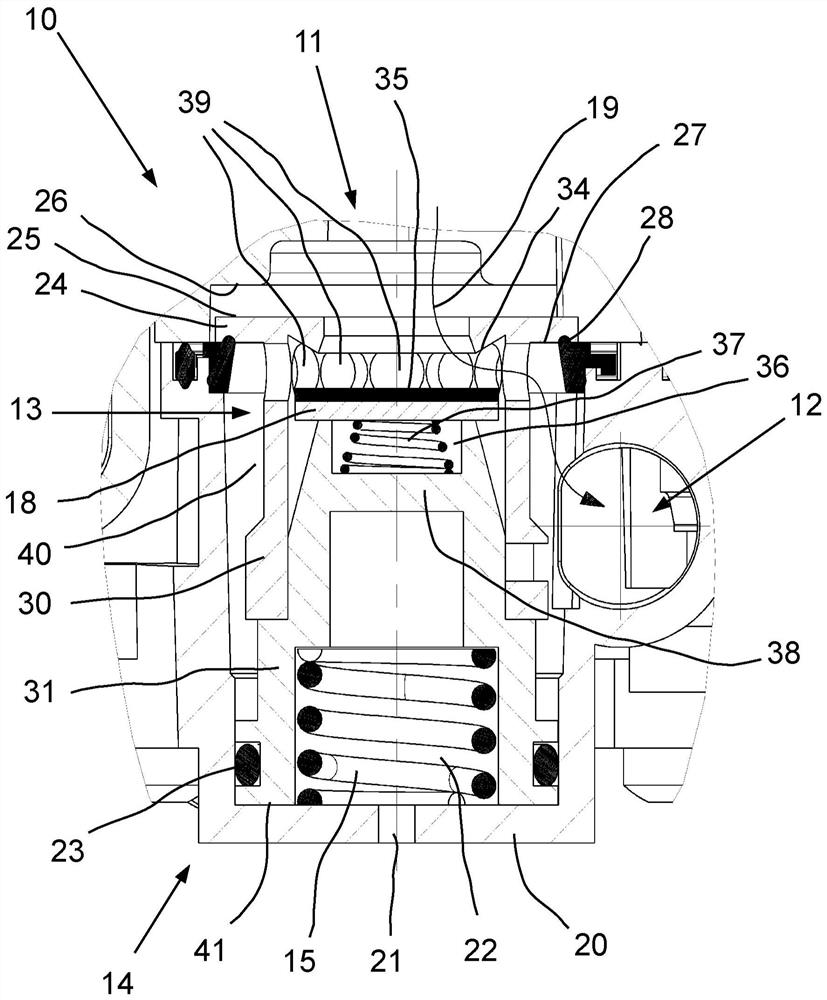

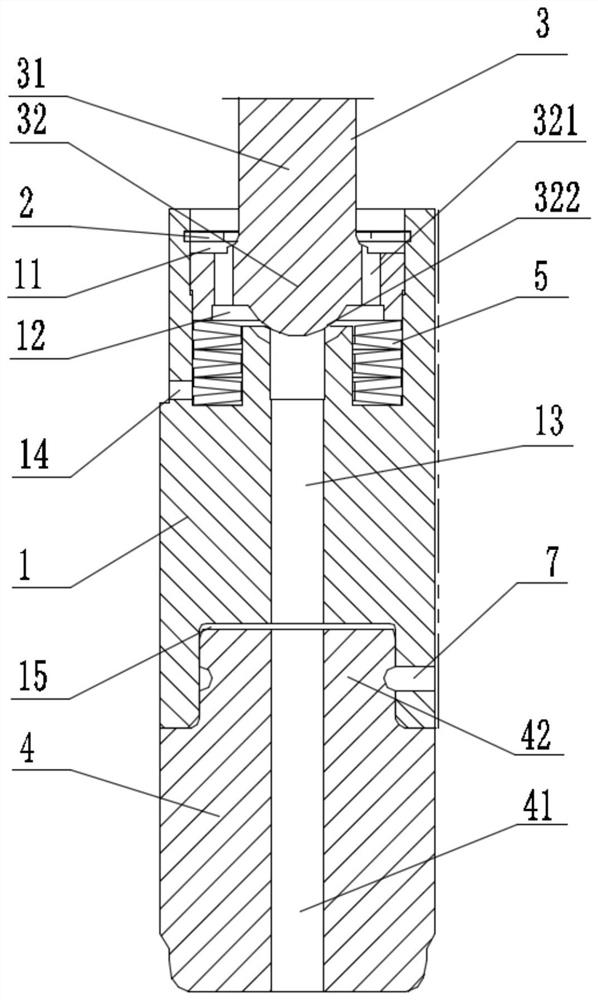

Magnetic rotor structure and power-driven switching valve

InactiveCN102116382AEliminate pressure differentialsEnsure normal valve openingOperating means/releasing devices for valvesMultiple way valvesValve openingElectrical and Electronics engineering

The invention provides a magnetic rotor structure and a power-driven switching valve, wherein the power-driven switching valve comprises a magnetic rotor structure, a valve seat, a slide block, and an outer cover sleeve of the power-driven switching valve; the magnetic rotor structure comprises a magnetic rotor, a shaft and a key; one end of the shaft is arranged in a valve seat bottom hole of the valve seat; the key is used for clamping with a key groove of the slide block; the outer cover sleeve of the power-driven switching valve is sleeved on the valve seat, wherein the distance between the magnetic rotor and the inner wall of the outer cover of the power-driven switching valve is 0.2mm-1.0mm. According to the technical scheme provided by the invention, through the arrangement of the distance of 0.2mm-1.0mm between the magnetic rotor and the inner wall of the outer cover of the power-driven switching valve, and through the arrangement of at least one through hole which is arranged on the magnetic rotor and is communicated with the upper part and the lower part of the magnetic rotor, the technical defect that the normal valve opening of the power-driven switching valve is influenced because of the pressure difference of a medium existing between the upper part and the lower part of the magnetic rotor in the prior art is overcome.

Owner:ZHEJIANG SANHUA CO LTD

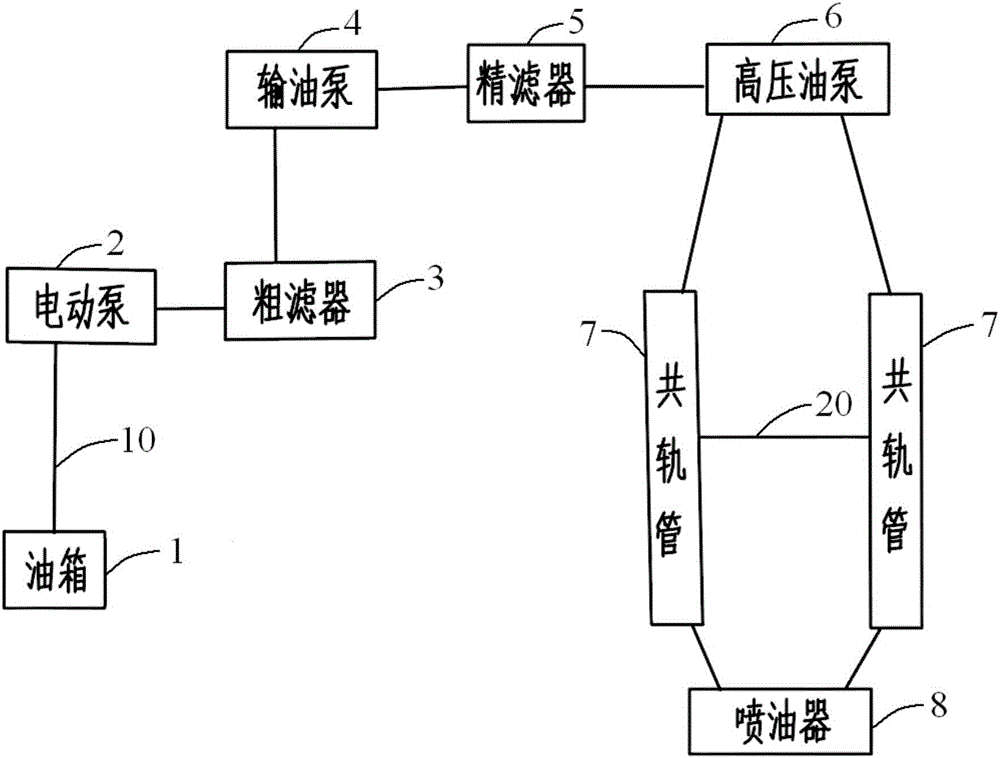

Diesel engine and high pressure common rail fuel injection system thereof

InactiveCN105927440AEliminate pressure differentialsImprove stabilityFuel injection apparatusMachines/enginesRail pressurePressure difference

The invention relates to the technical field of diesel engines, in particular to a high pressure common rail fuel injection system. The high pressure common rail fuel injection system comprises a high pressure fuel pump, a fuel atomizer and a plurality of common rail pipes; the common rail pipes communicate with one another through the high pressure fuel pump and the fuel atomizer; the high pressure common rail fuel injection system further comprises a high pressure fuel pipe; and the common rail pipes communicate with the high pressure fuel pipe. The invention further relates to a diesel engine comprising the high pressure common rail fuel injection system. The common rail pipes communicate with one another through the high pressure fuel pipe, so that on the one hand, the pressure difference between the common rail pipes caused by uneven fuel supply of two cylinders of a fuel injection pump can be eliminated; on the other hand, rail pressure oscillation caused by fuel pumping of the fuel injection pump and fuel injection of the fuel atomizer can be eliminated, and accordingly the purposes of enhancing the stability of a hydraulic system, improving smoothness of operation of the whole engine, lowering the noise and improving emission consistency are achieved.

Owner:WEICHAI POWER CO LTD

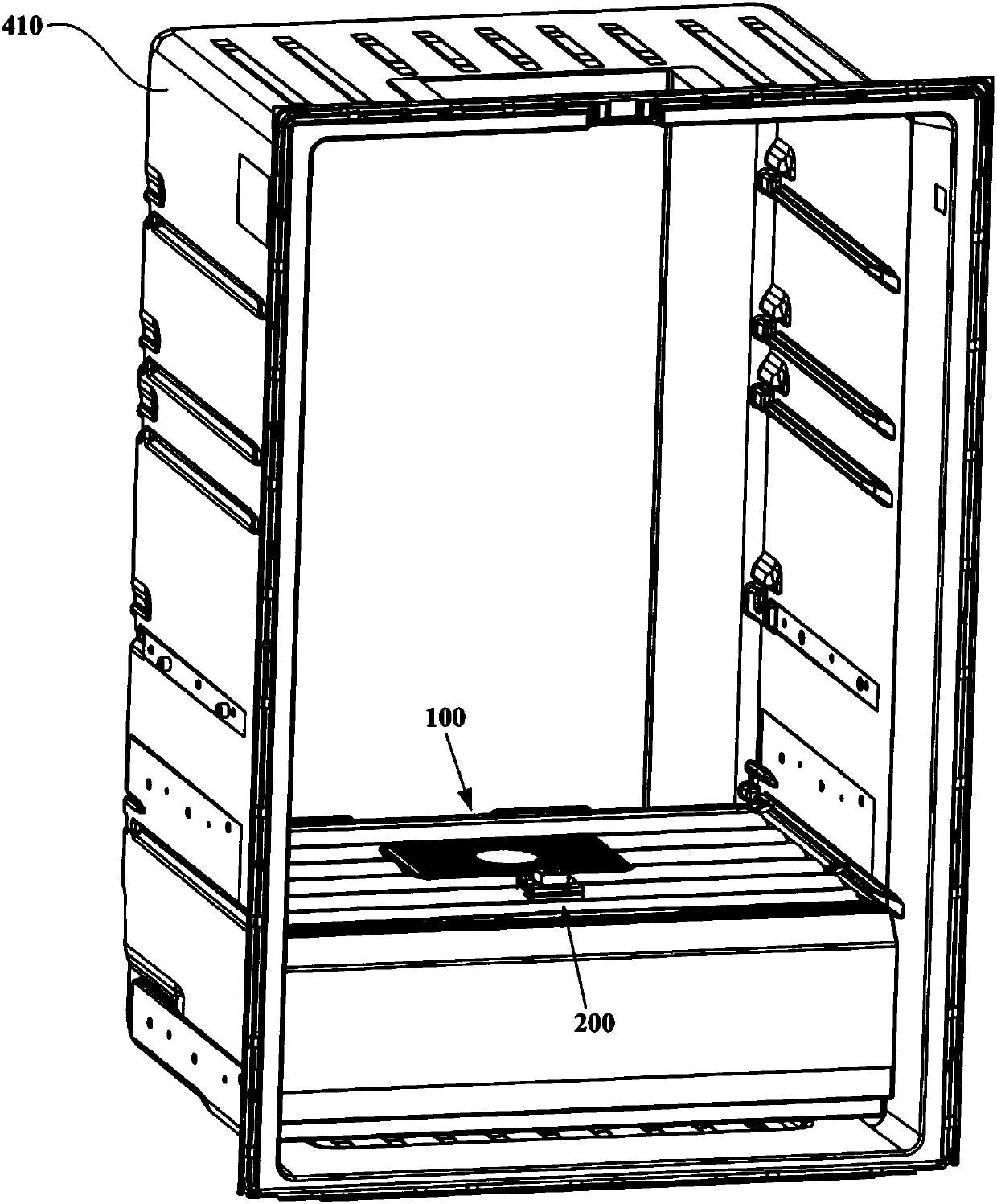

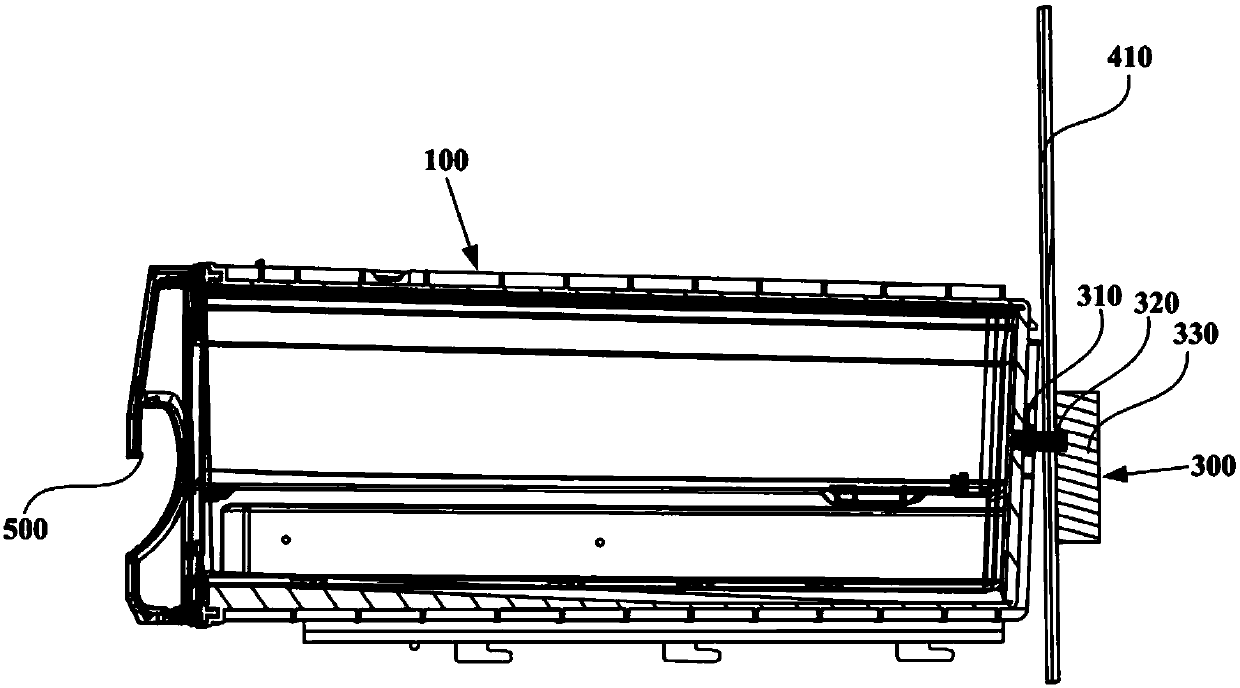

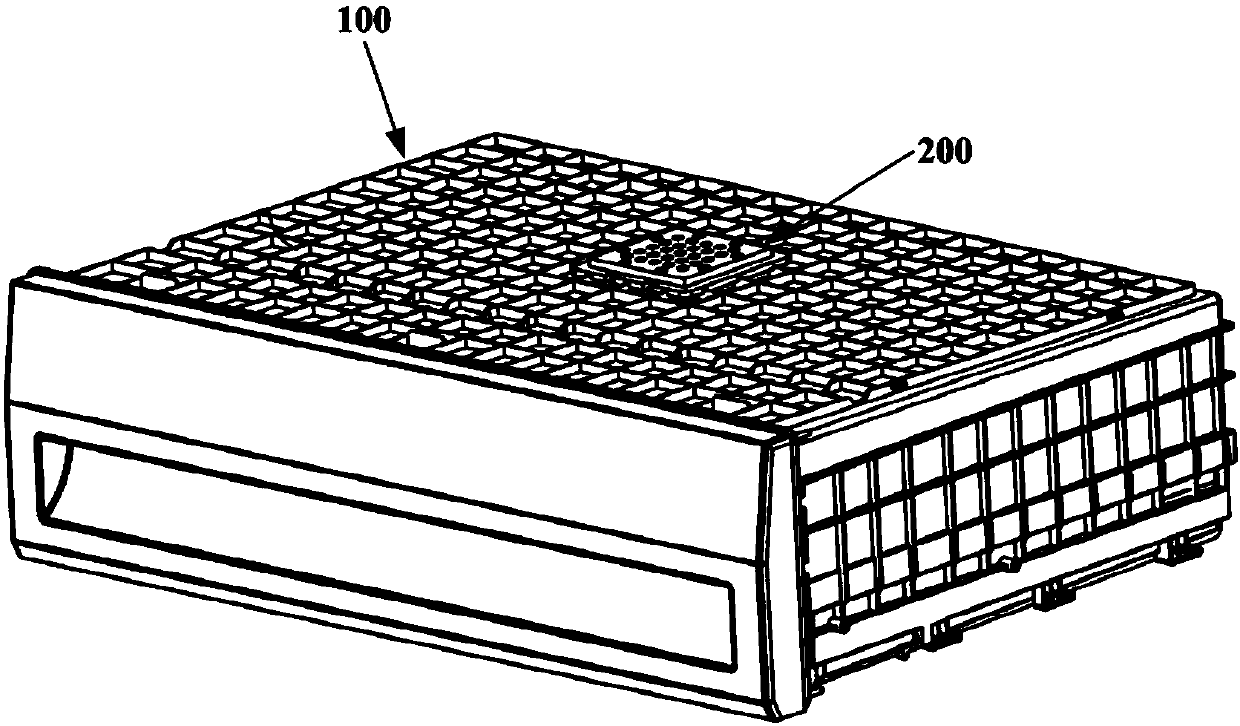

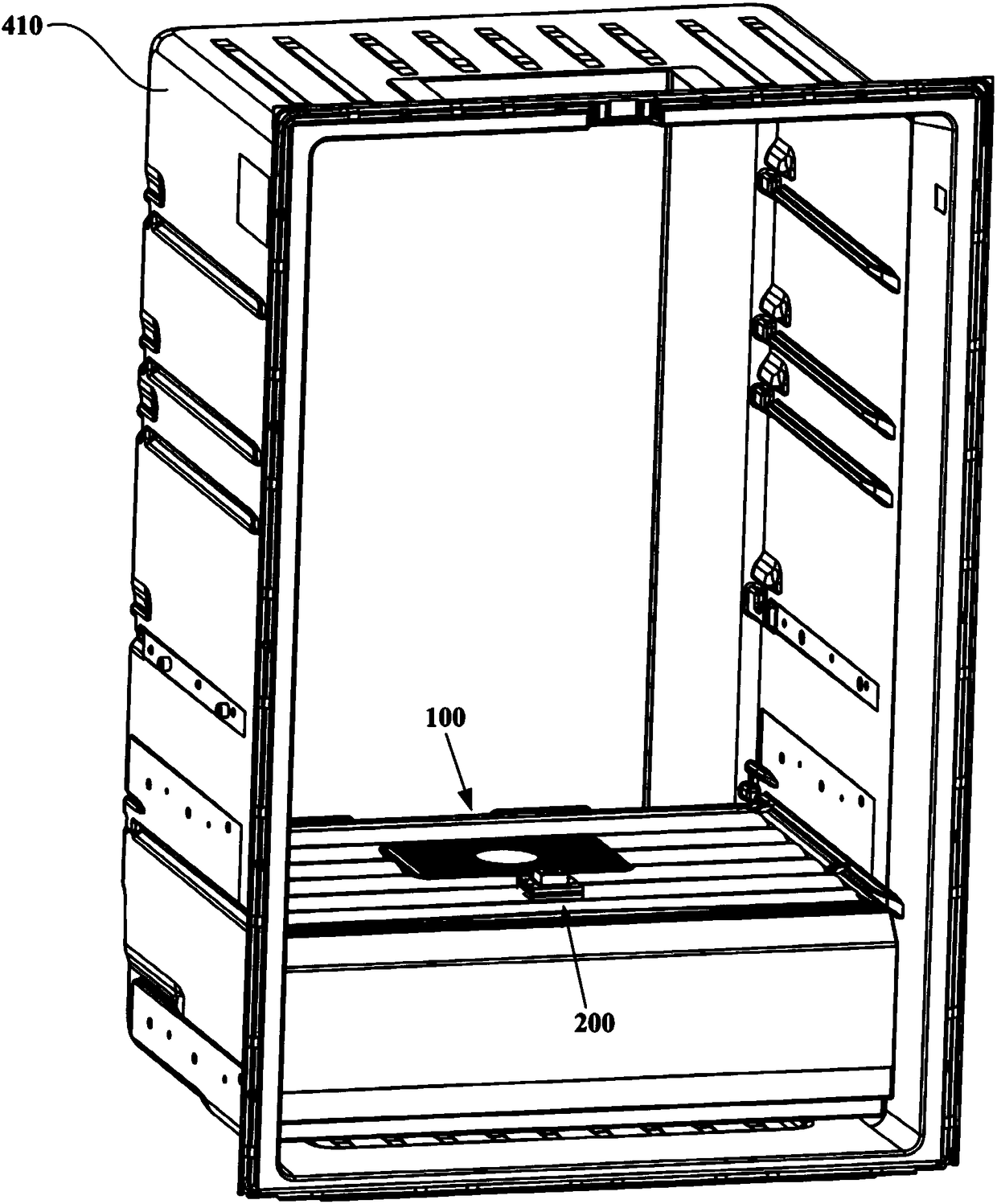

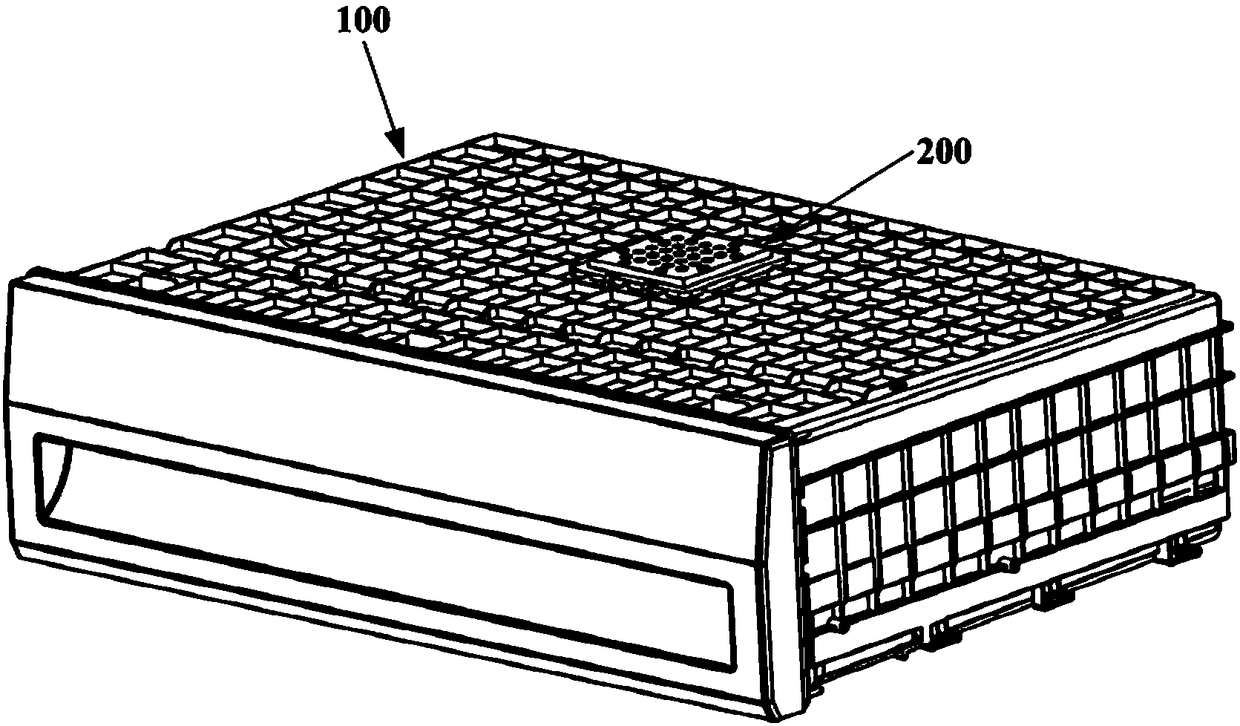

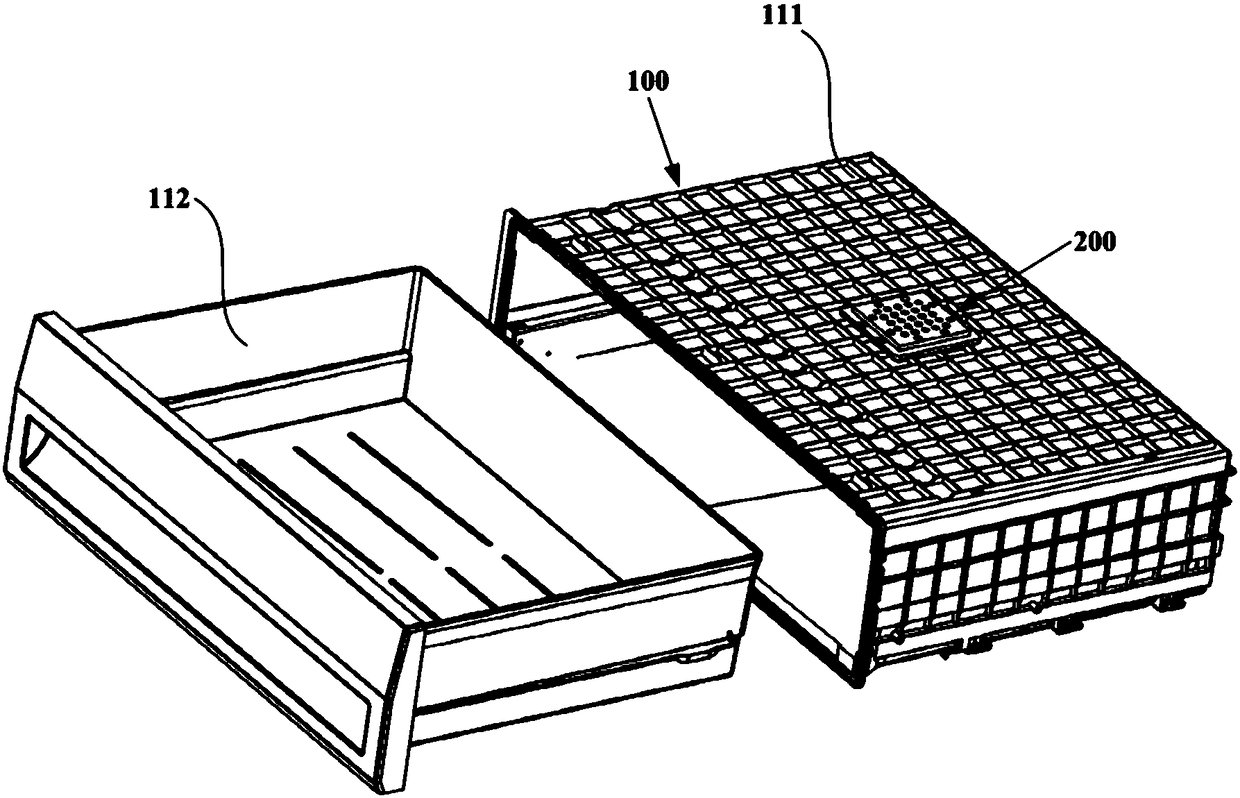

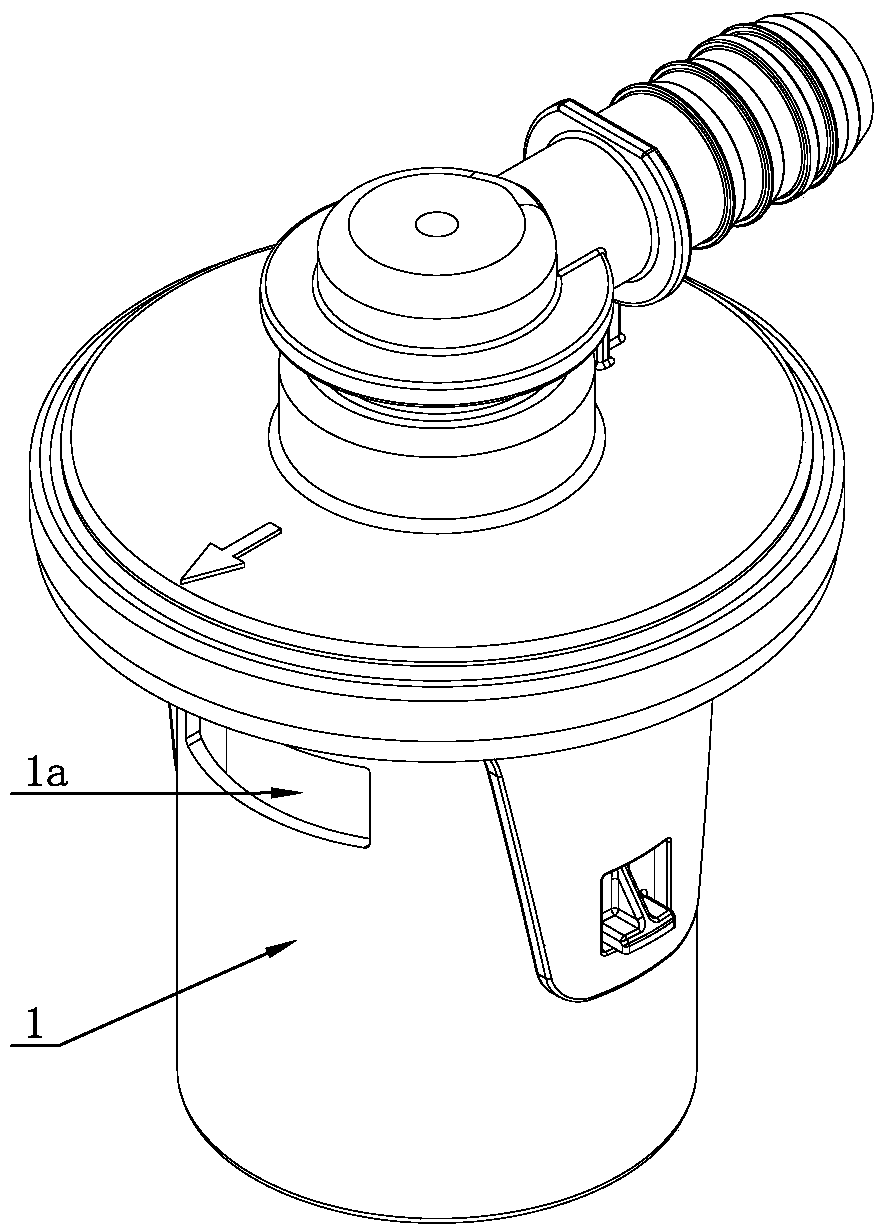

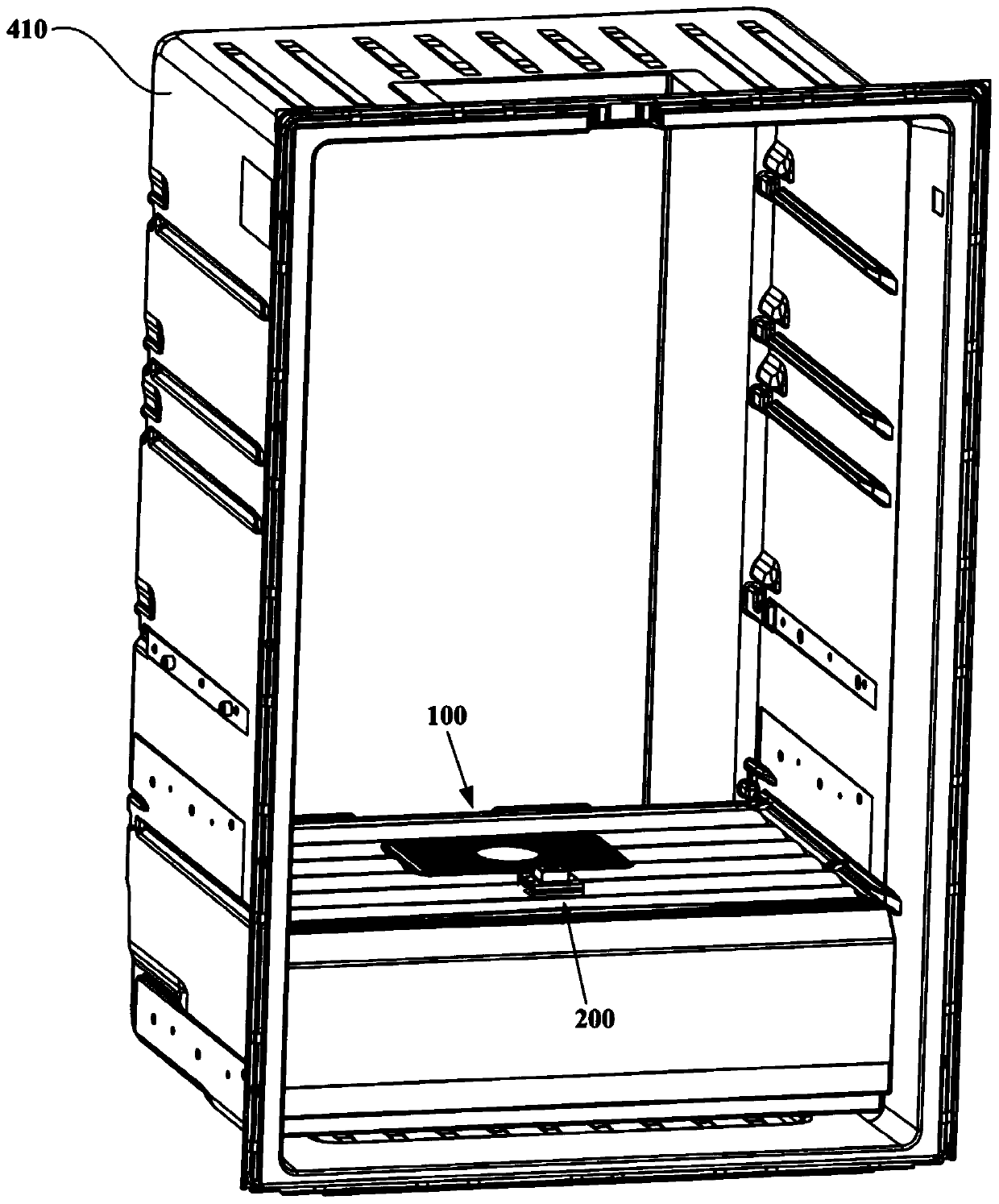

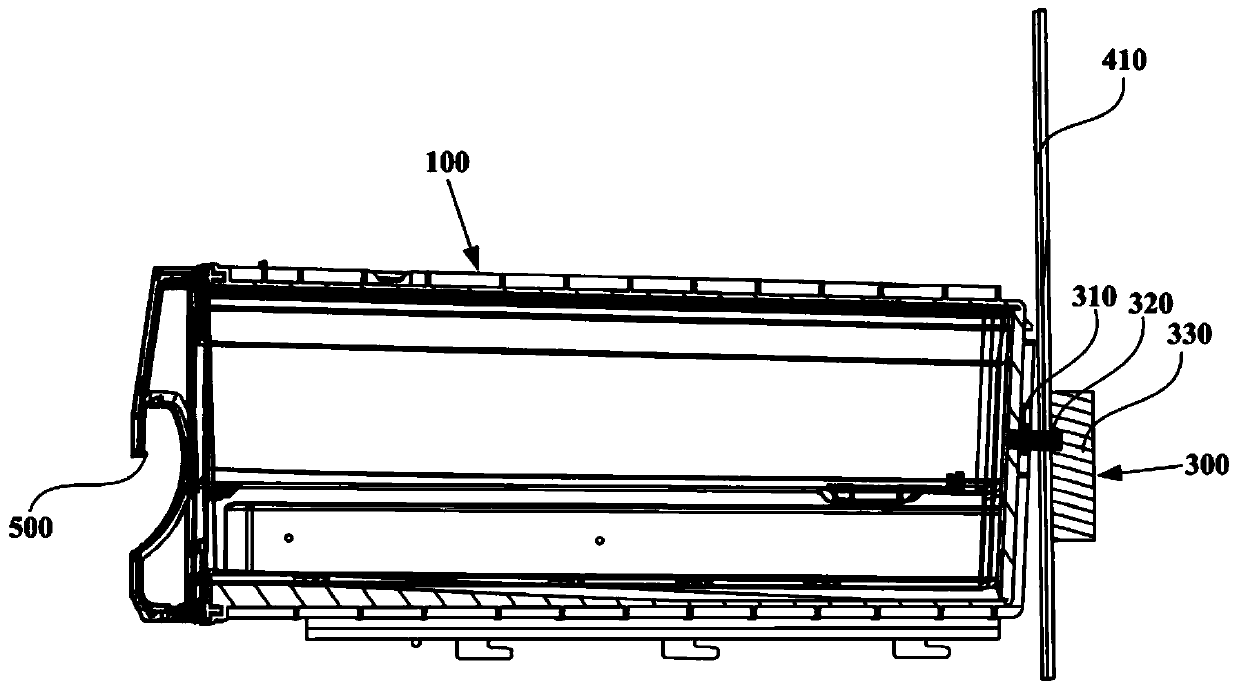

Refrigerating device for cold storage

ActiveCN109855348AEasy to disassembleEasy to installLighting and heating apparatusDomestic refrigeratorsCellular respirationAnaerobic respiration

The invention provides a refrigerating device for cold storage. The refrigerating device comprises a storage drawer, an electrolytic oxygen removal component, a touch sensing device and an electric-air valve. The electrolytic oxygen removal component is used for consuming oxygen in air in a storage space, so that nitrogen-rich and oxygen-lean gas atmosphere benefiting food preservation is obtainedin the space. Through reduction of the oxygen content in the gas atmosphere of the storage space, the aerobic respiration intensity of food (especially fruits and vegetables) is reduced, and meanwhile the basic respiration is ensured; anaerobic respiration of the food is avoided, so that the purpose of the long-time preservation of the food is achieved. When the touch sensing device detects thata user is to open the storage drawer, a through hole in the drawer is opened through the electric-air valve, so that the interior and exterior of the storage space communicate with each other; and thedifference between internal pressure and external pressure of the drawer is eliminated, and the problem that the drawer is hard to open due to installation of the electrolytic oxygen removal component is solved. The refrigerating device enables the user to conveniently open the storage drawer in a labor-saving manner, and the user experience is improved.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

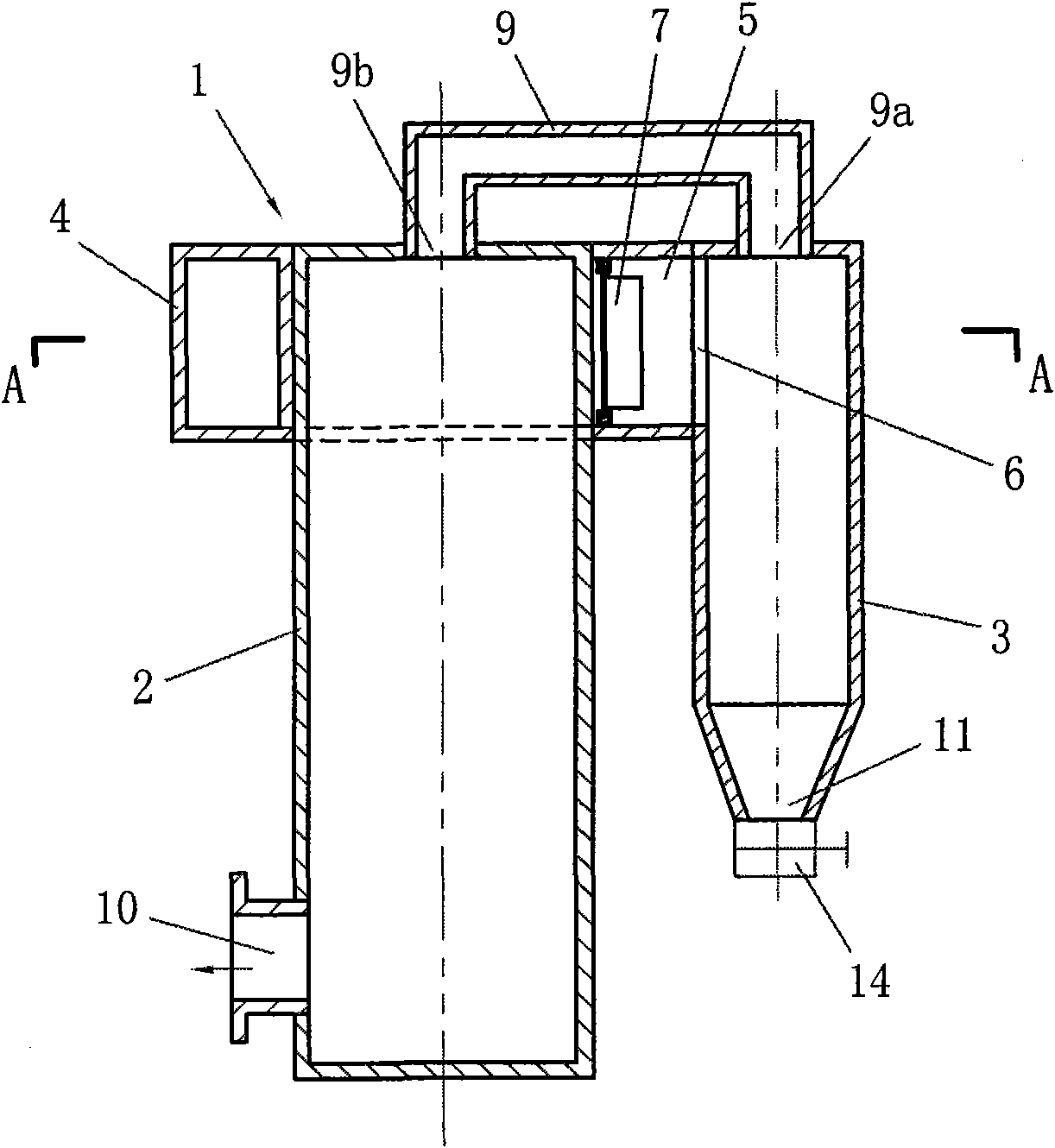

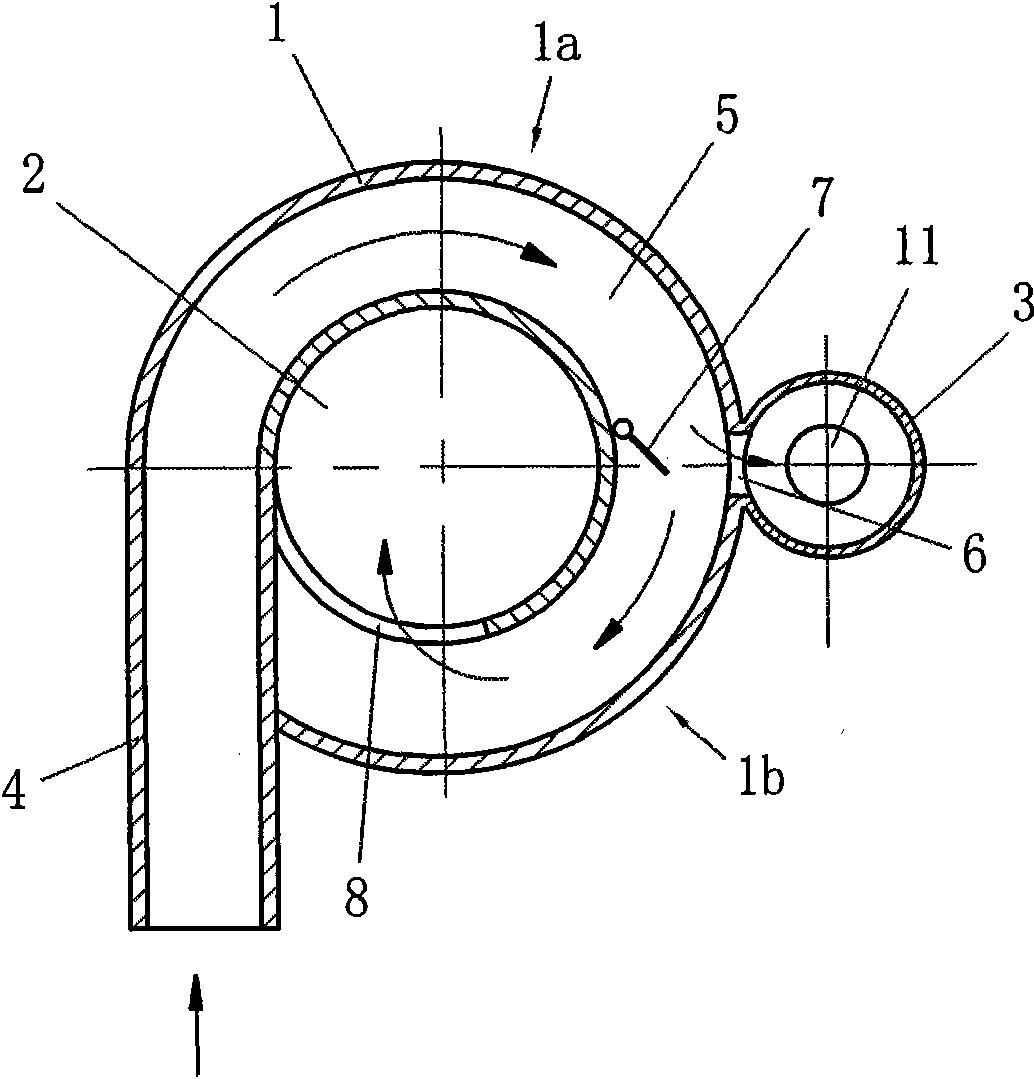

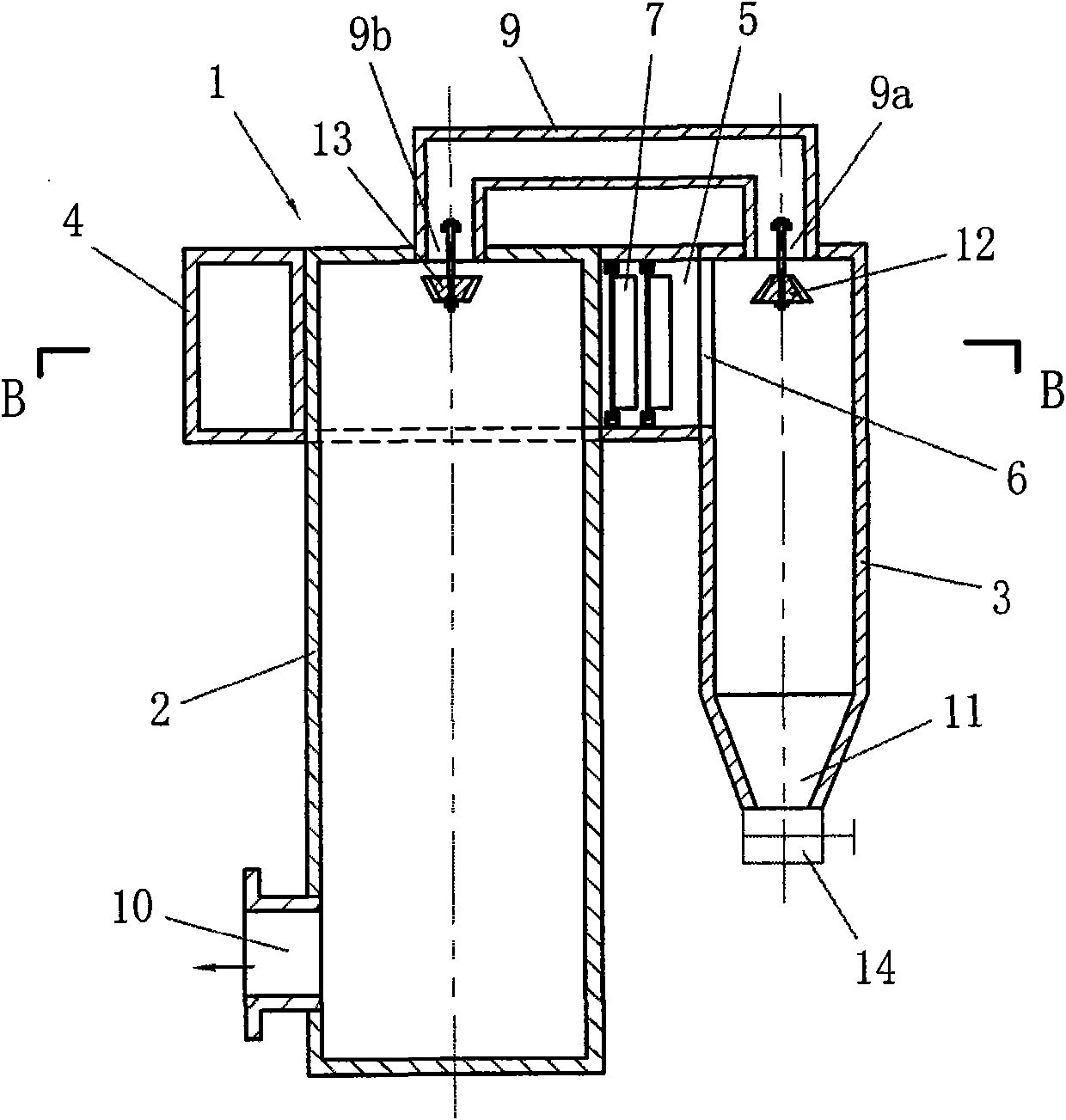

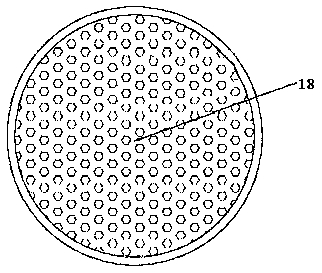

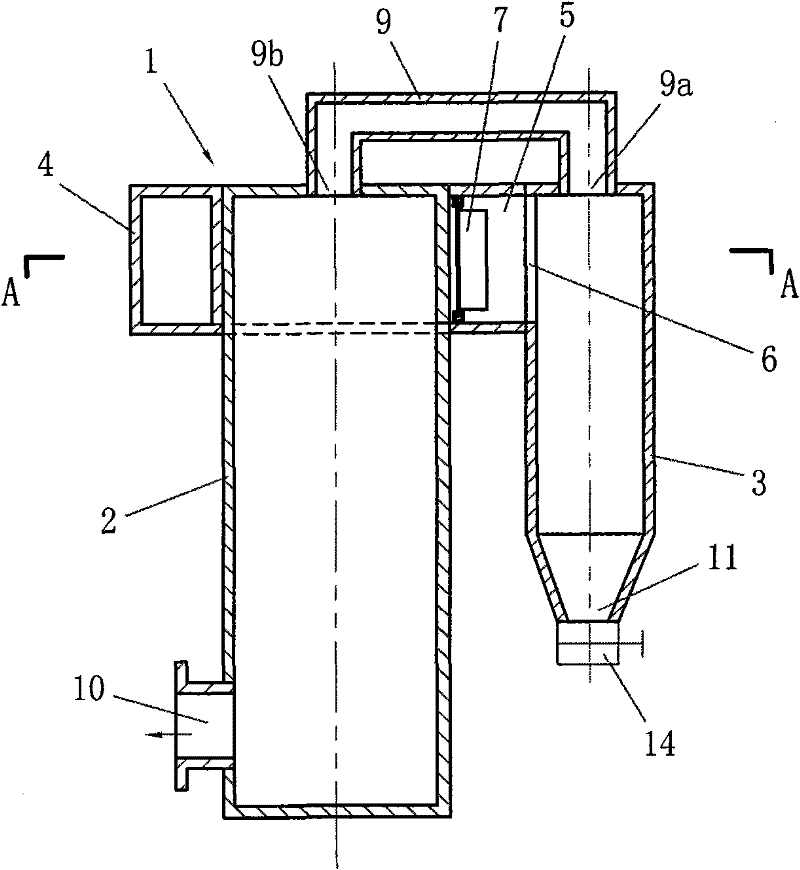

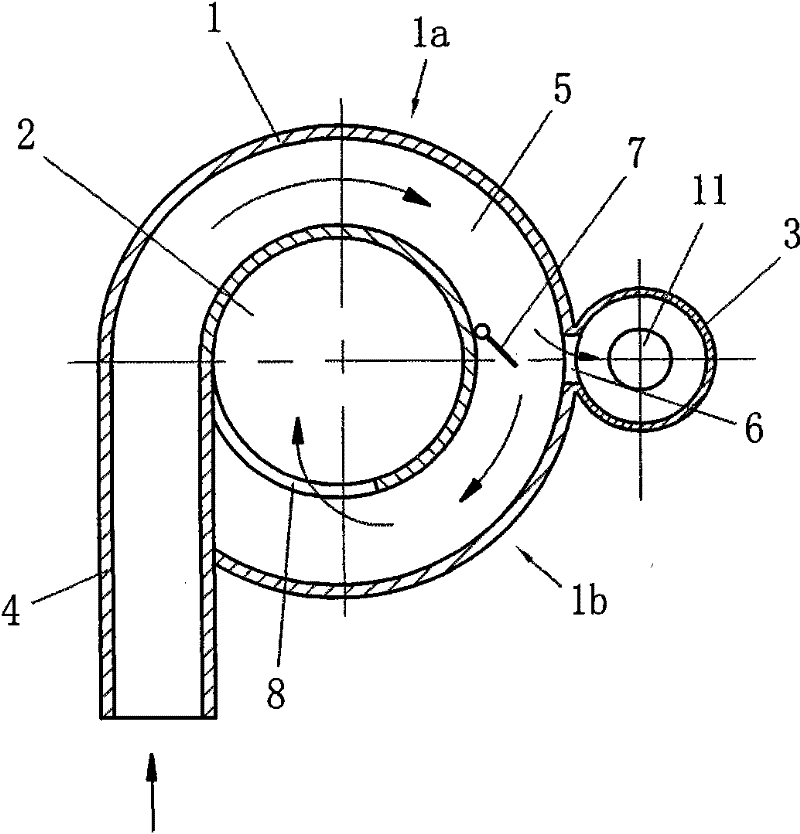

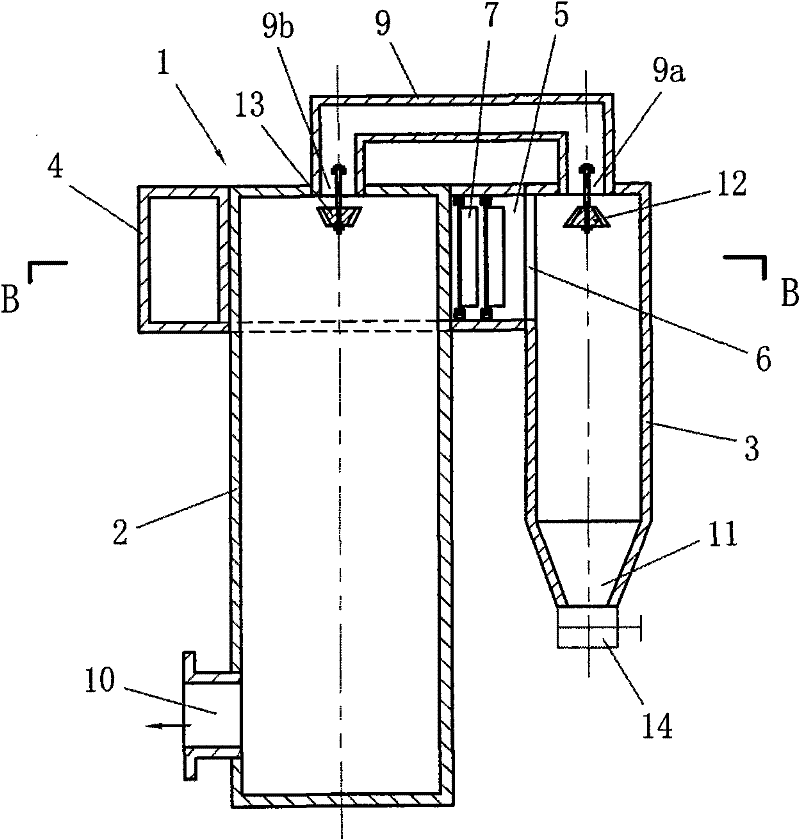

Spiral separating device

The invention discloses a spiral separating device. An air inlet tube section (4) is arranged on a spiral casing (1) and a spiral swirl air flue (5) is arranged in the spiral casing (1); the upper part of an assistant cylinder (3) is positioned outside the spiral casing (1) and the upper part of a main cylinder (2) is positioned inside the spiral casing (1); a passage (6) communicated with the inner cavity of the assistant cylinder (3) is arranged on the outer wall of the middle section of the spiral swirl air flue, at least one deflector (7) is arranged in the spiral swirl air flue and at the part of the passage (6), and an air flue (8) communicated with the inner cavity of the main cylinder (2) is arranged on the inner wall of the end section of the spiral swirl air flue; the nozzle (9a) of a pressure balancing air flue tube (9) is communicated with the upper part of the inner cavity of the assistant cylinder (3) and the nozzle (9b) is communicated with the upper part of the inner cavity of the main cylinder (2); an air outlet (10) is arranged at the lower part of the main cylinder (2) and a discharge hole (11) is arranged at the lower part of the assistant cylinder (3); a secondary separator (12) is arranged at the nozzle (9a) and a pressure balancer (13) is arranged at the nozzle (9b).

Owner:长沙奥邦环保实业有限公司

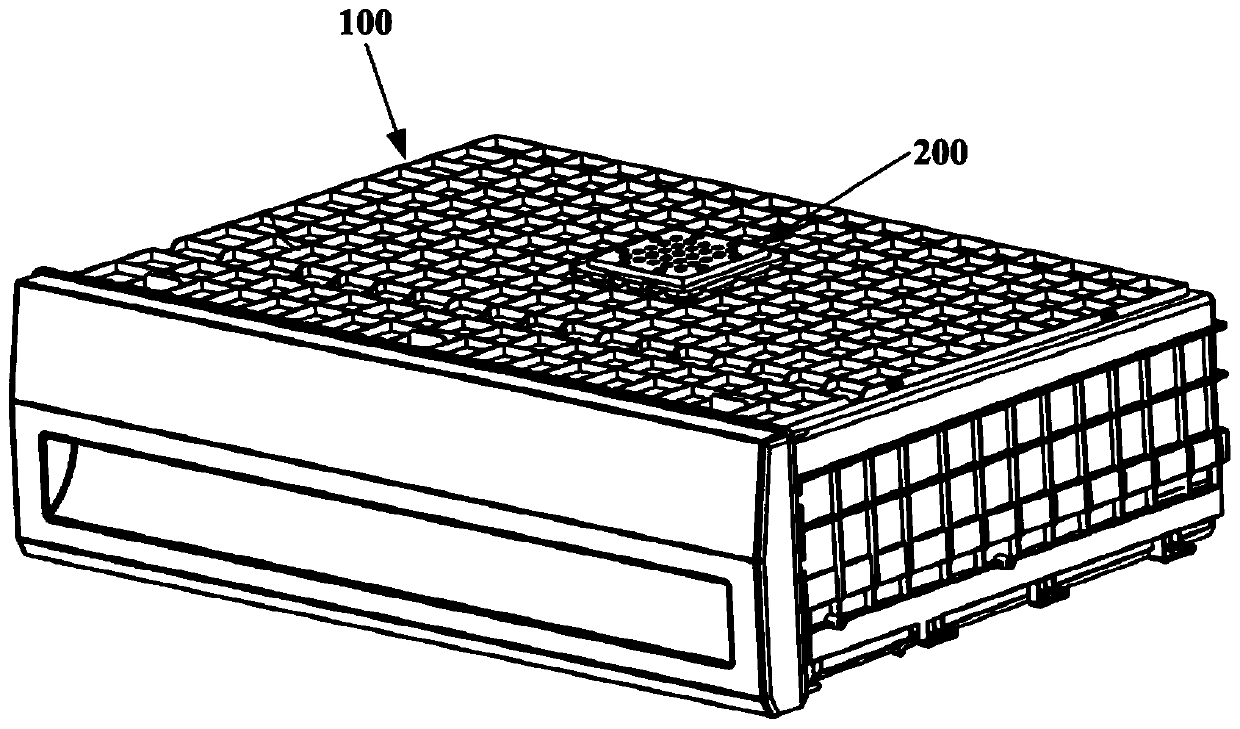

Refrigerating and freezing device

ActiveCN108514066AEasy to disassembleEasy to installLighting and heating apparatusFood preservationChemistryNitrogen

The invention provides a refrigerating and freezing device. The refrigerating and freezing device comprises a storage drawer, an electrolysis oxygen removal assembly and a pore opening and closing device. The electrolysis oxygen removal assembly is used for consuming oxygen in the air in a storage space, so that rich nitrogen and poor oxygen can be obtained in the space to benefit the gas atmosphere for food preservation. The gas atmosphere can reduce the intensity of aerobic aspiration of food (particularly fruits and vegetables) by decreasing the content of oxygen in the storage space, ensure basic respiratory action and prevent anaerobic respiration of the food, so that the purpose of long-term preservation of the food is achieved. According to the refrigerating and freezing device, when a user is about to open the storage drawer, the pore opening and closing device can open a pore, arranged in a grabbing groove, of the device, so that the inside and the outside of the storage spacecan be communicated, the pressure difference between the inside and the outside of the drawer can be eliminated, and the problem that the drawer is difficult to open due to mounting of the electrolysis oxygen removal assembly is solved. The user can open the storage drawer more effortlessly, and the use experience of the user is improved.

Owner:HAIER SMART HOME CO LTD

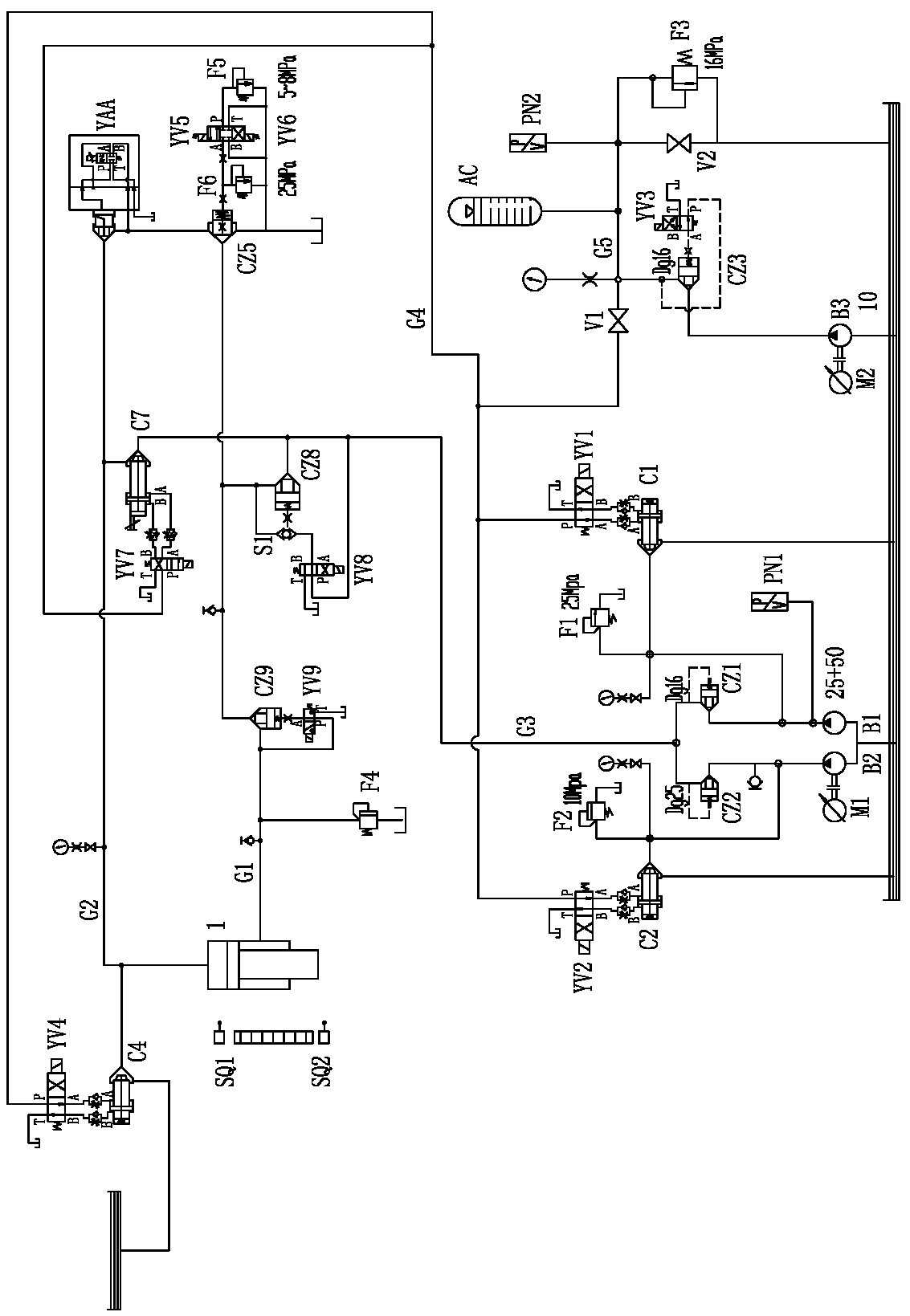

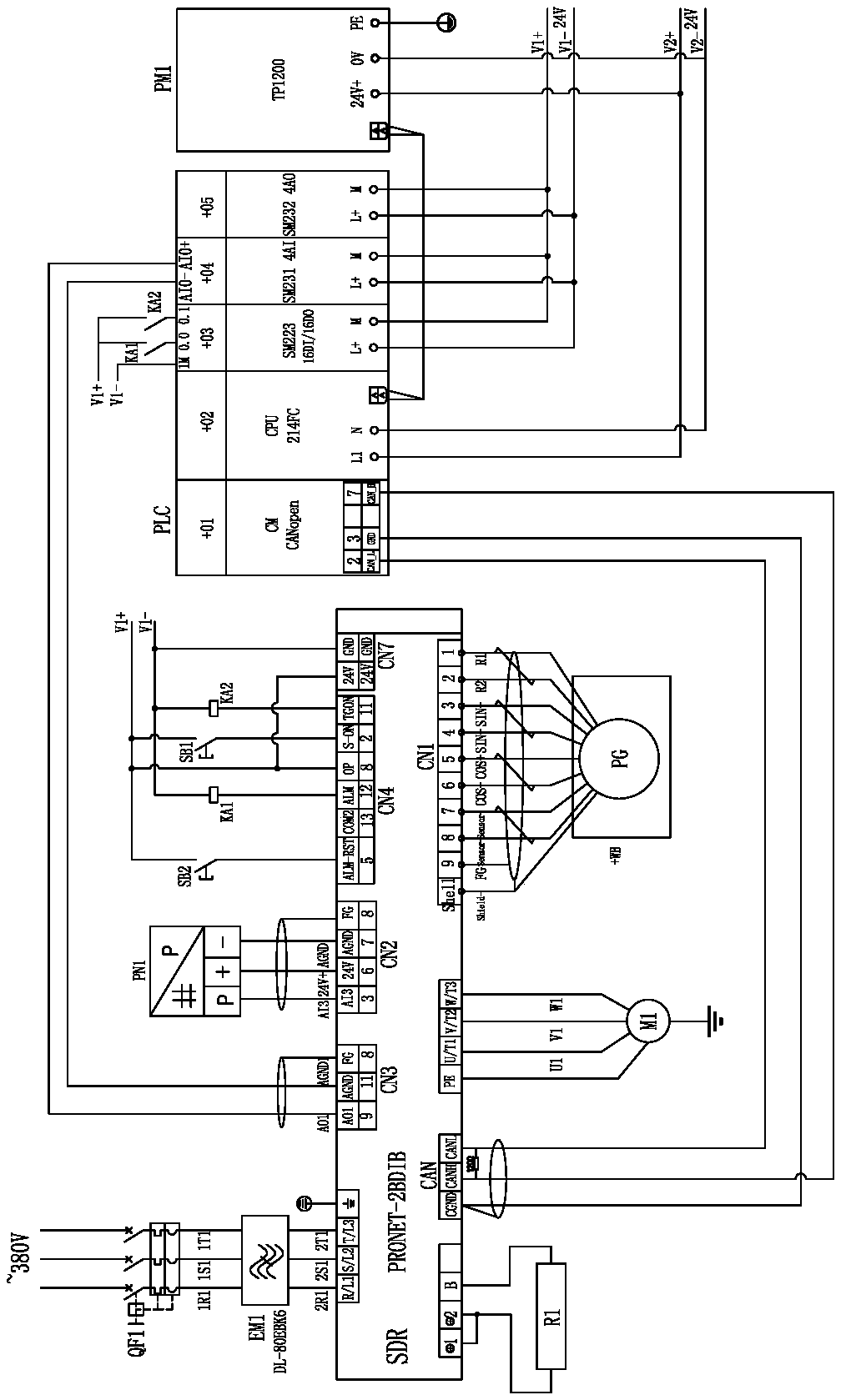

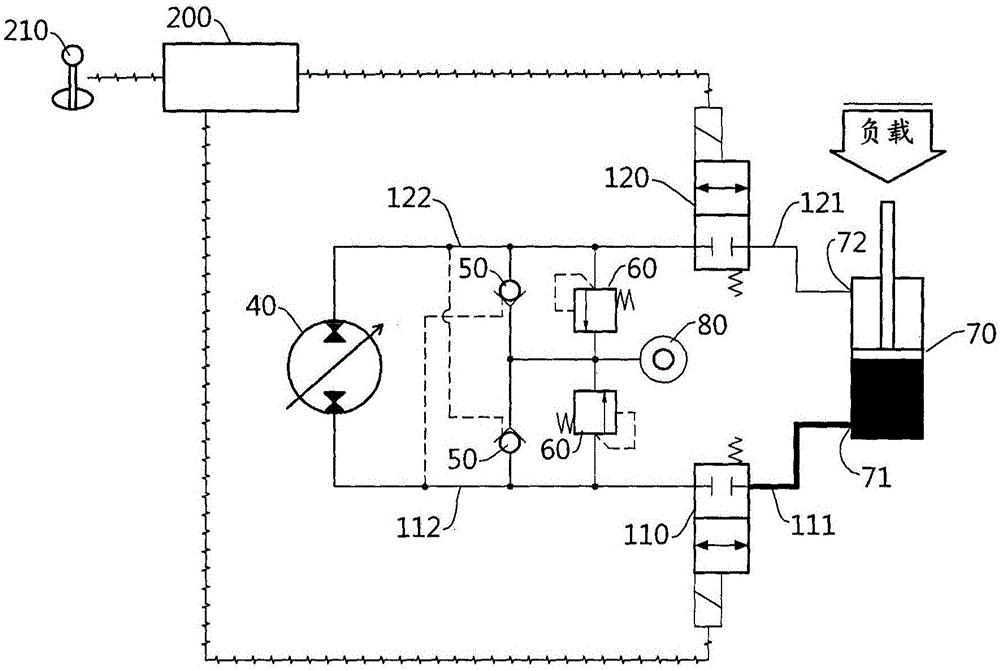

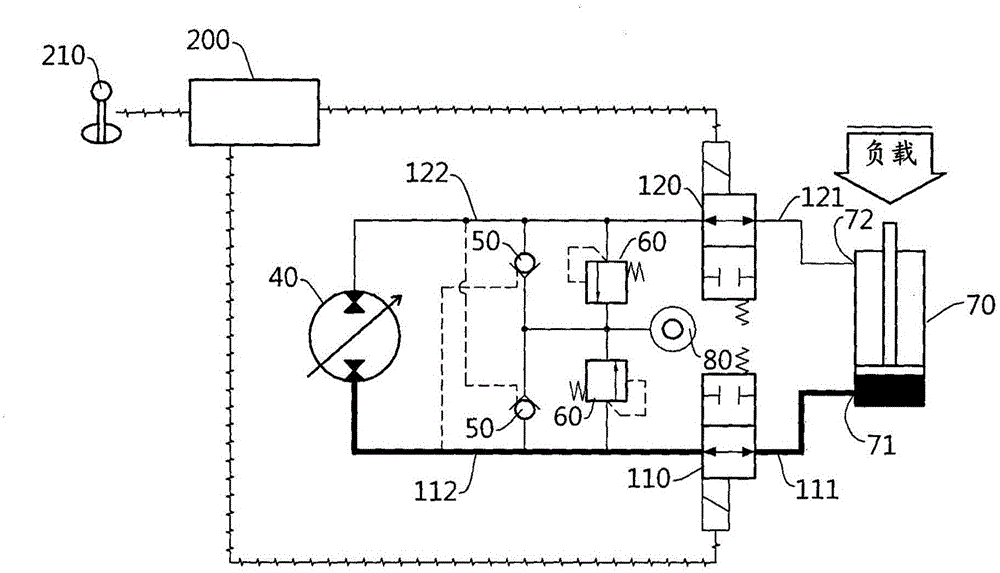

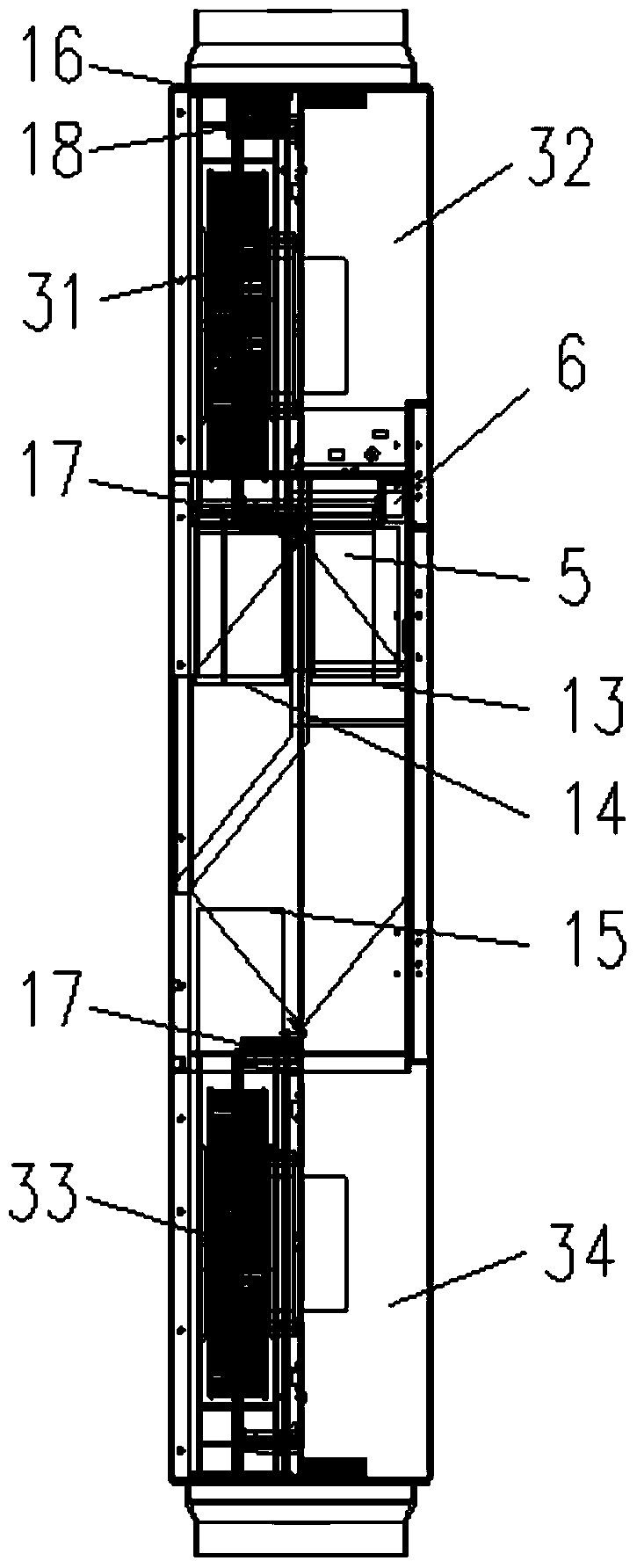

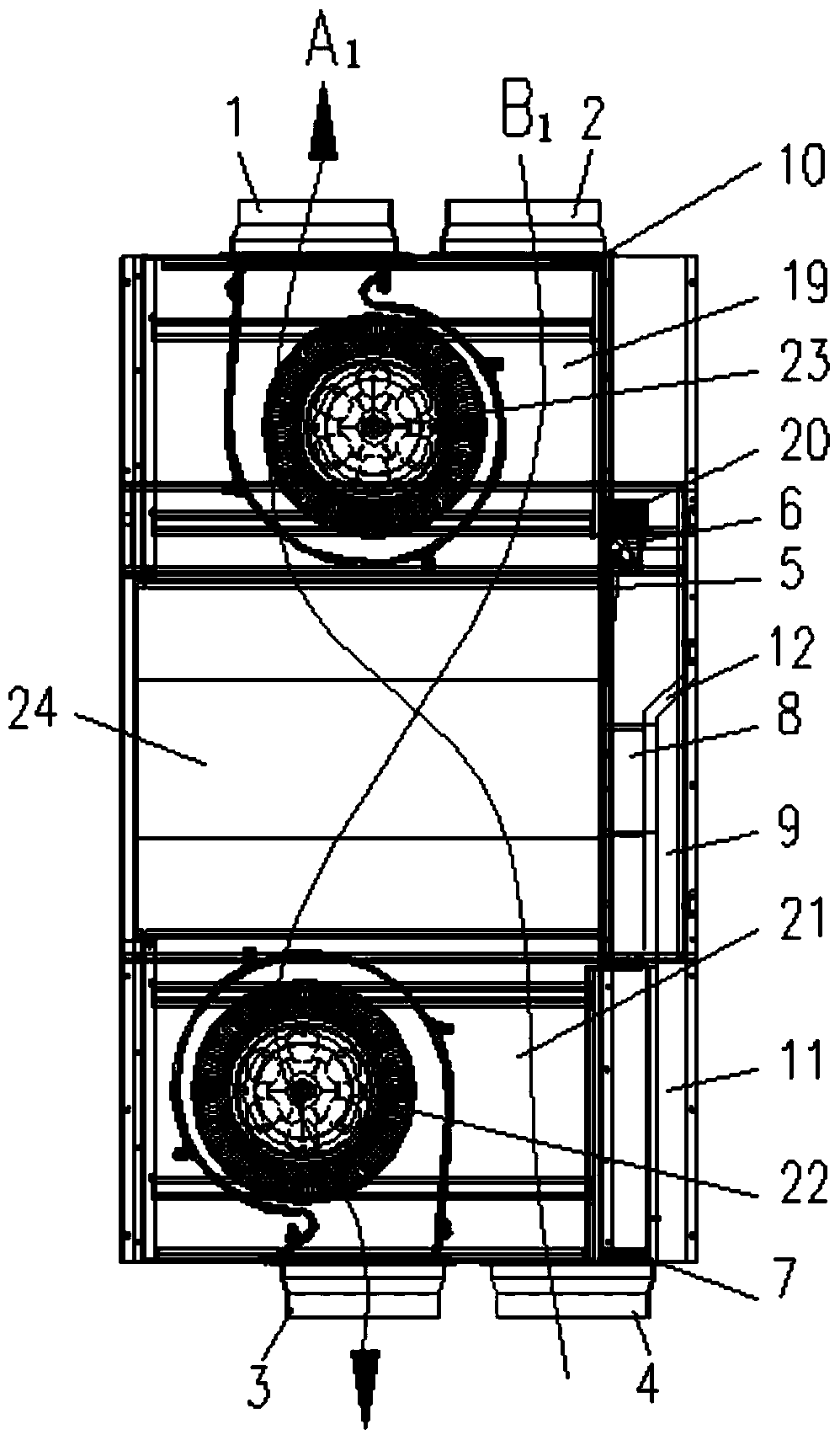

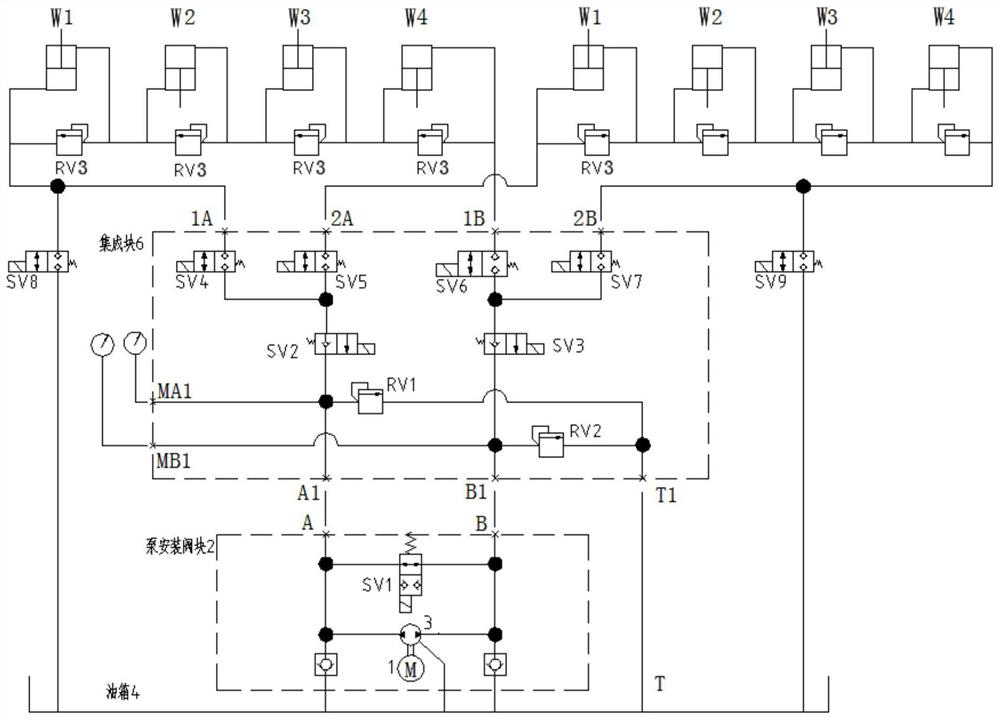

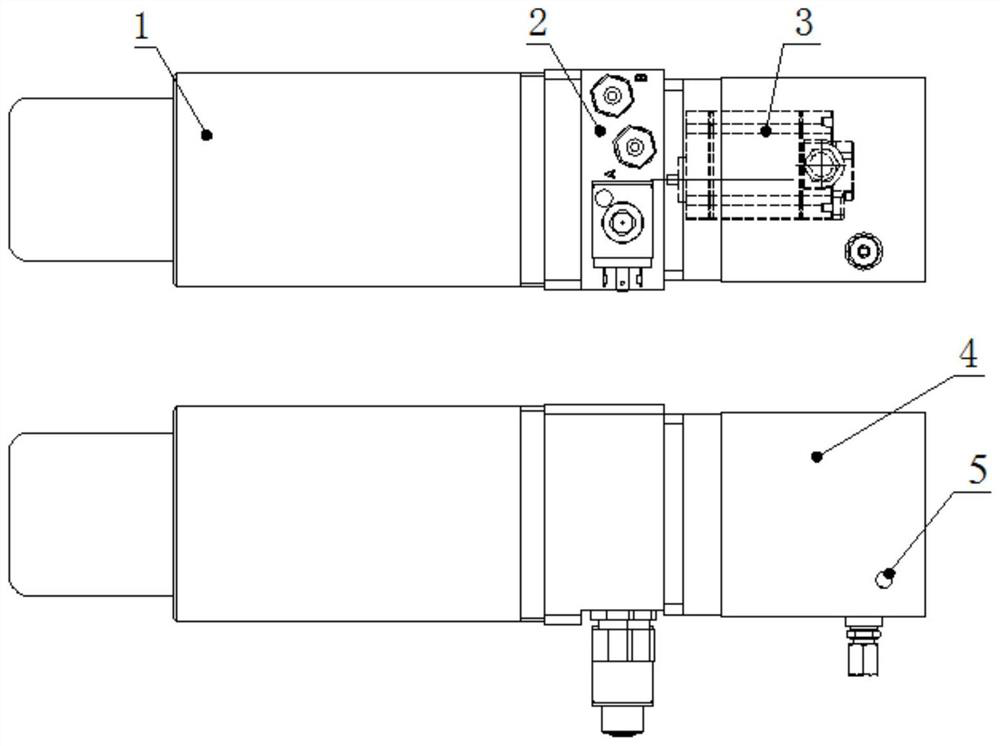

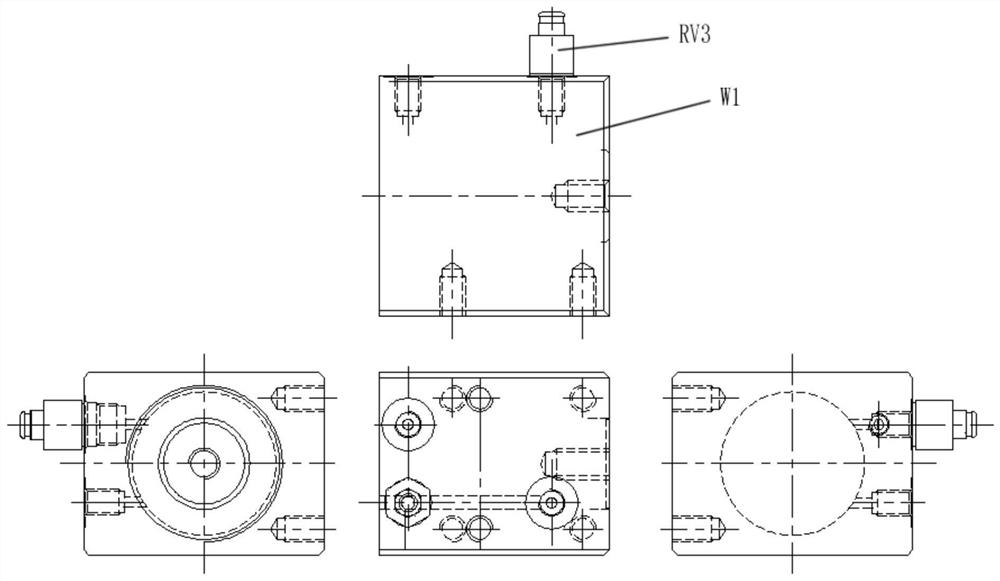

Precision pressure control system and hydraulic machining method of servo pump control hydraulic machine

ActiveCN108561346AEliminate pressure differentialsReliable return to seatServomotorsServometer circuitsControl systemWork cycle

The invention relates to a precision pressure control system and a hydraulic machining method of a servo pump control hydraulic machine. The hydraulic machine comprises a medium-flow servo pump and alarge-flow servo pump driven by a servo motor, outlet pipelines of two pumps are connected with a main cylinder upper cavity oil way through a seventh dynamic valve, and the main cylinder upper cavityoil way is further connected with an oil tank through a fourth dynamic valve and a proportional valve; a main cylinder lower cavity pipeline is connected with an outlet of a ninth cartridge valve, aninlet of the ninth cartridge valve is connected with the oil tank through a fifth cartridge valve and an eighth cartridge valve, the fifth cartridge valve supplies supporting force during deceleration and pressurization through an overflow valve, and the eighth cartridge valve is turned on during the return stroke. In hydraulic machining, each working cycle comprises the following actions of automatic pressure compensation for an energy accumulator, pressure supplementation stopping for the energy accumulator, rapid descending of a sliding block, deceleration pressurizing of the sliding block, pressure maintaining of the sliding block, pressure relief of the sliding block, and return and stopping of the sliding block. The servo driver is switched in two modes of flow control and PID regulation control, stable pressurization of the sliding block is achieved, the phenomenon that a part deforms due to pressurization overshoot is avoided, and pressure relief is stable.

Owner:江苏扬力液压装备有限公司

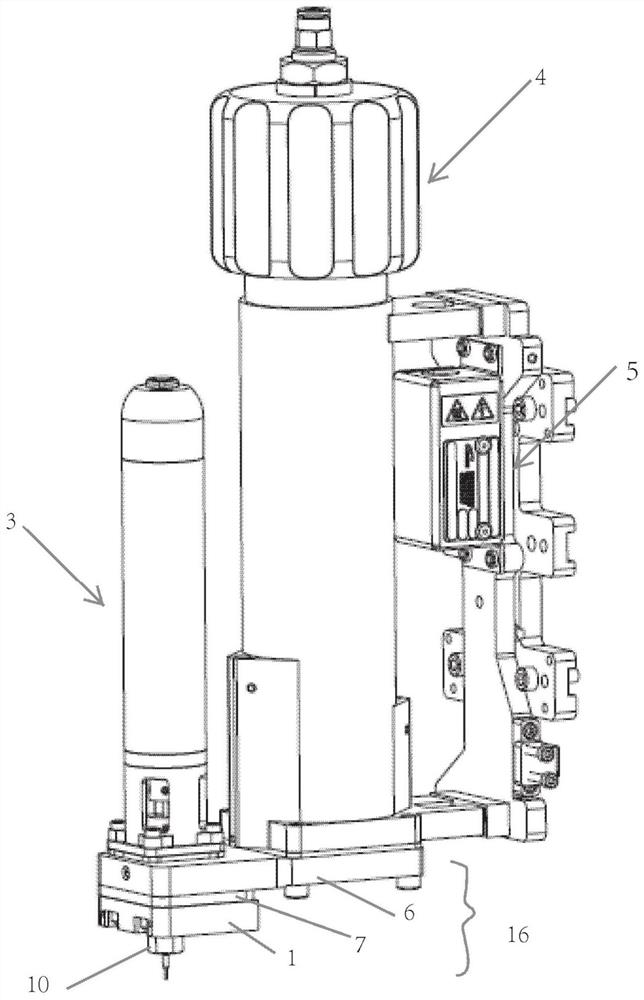

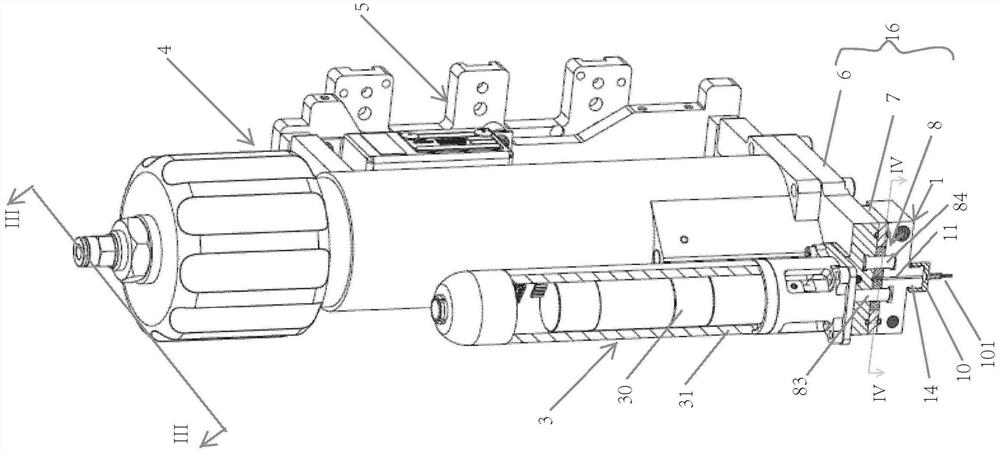

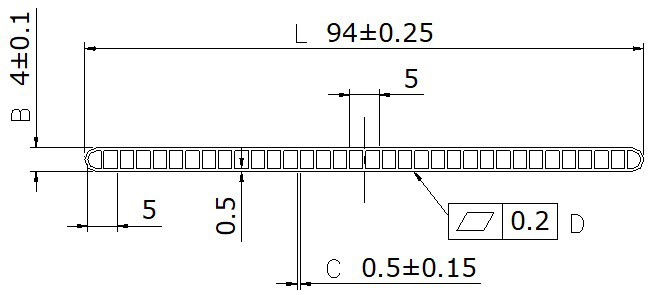

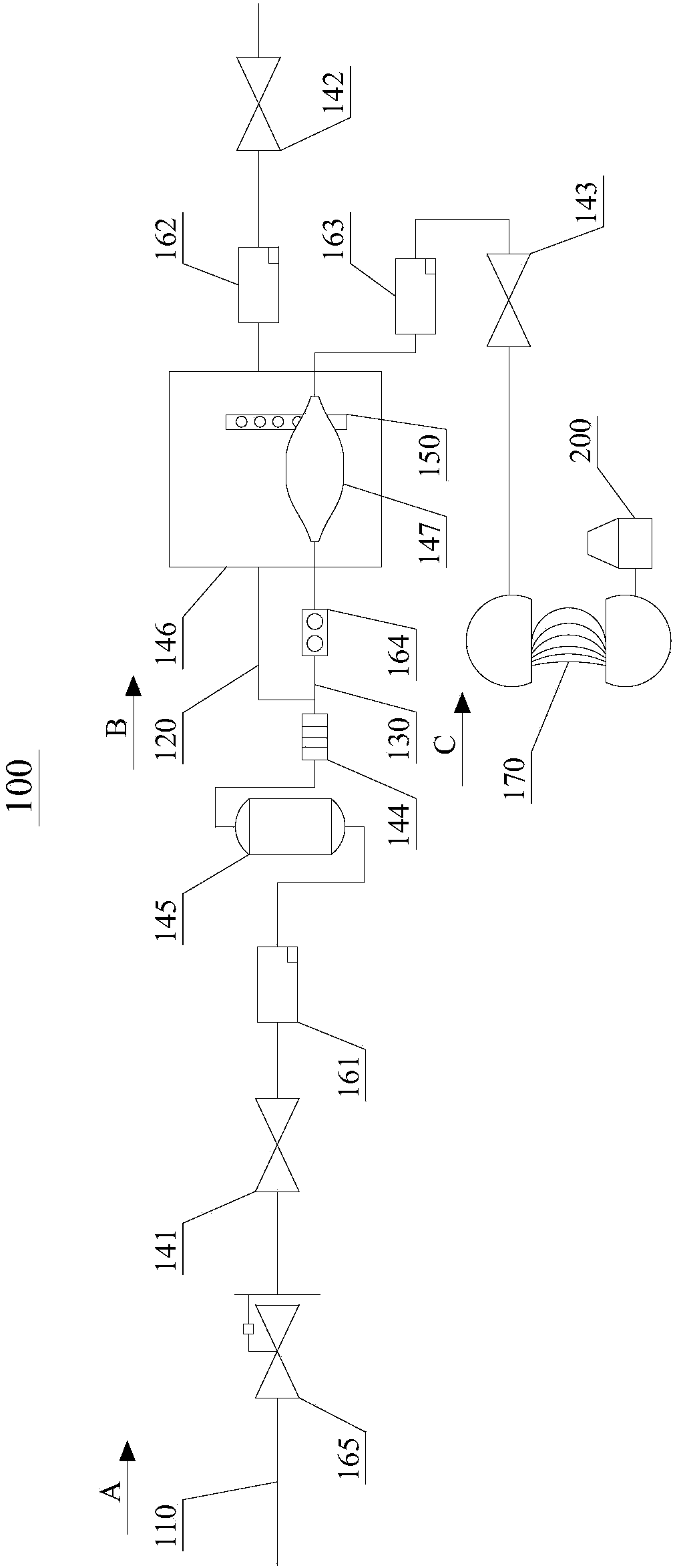

Laser ablation sample feeding system

ActiveCN105954089APrevent leakageRealize automatic replacementPreparing sample for investigationMaterial analysis by electric/magnetic meansEngineeringBuffer tank

The invention discloses a laser ablation sample feeding system which comprises a first on-off valve, a buffer tank and a fourth on-off valve. The first on-off valve, the buffer tank and the fourth on-off valve are sequentially arranged on a main pipeline from the starting end to the tail end. The laser ablation sample feeding system further comprises an outer chamber and a second on-off valve which are sequentially arranged in a first branch pipeline from the starting end to the tail end. The laser ablation sample feeding system further comprises a sample chamber and a third on-off valve which are sequentially arranged on a second branch pipeline from the starting end to the tail end. The sample chamber is located inside the outer chamber. A sample inlet and a sample outlet opposite to the sample inlet are formed in the sample chamber. The laser ablation sample feeding system further comprises a sample feeding device arranged inside the outer chamber. The sample feeding device comprises a sample supporting strip which penetrates through the sample chamber in a slidable mode through the sample inlet and the sample outlet and a driving device connected with the sample supporting strip and used for driving the sample supporting strip to slide on a straight line where the sample inlet and the sample outlet are located. According to the laser ablation sample feeding system, automatic replacement of samples is achieved, the sample chamber does not need to be opened frequently, and therefore influences caused when the sample chamber is frequently opened on air ways in the laser ablation sample feeding system are avoided.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

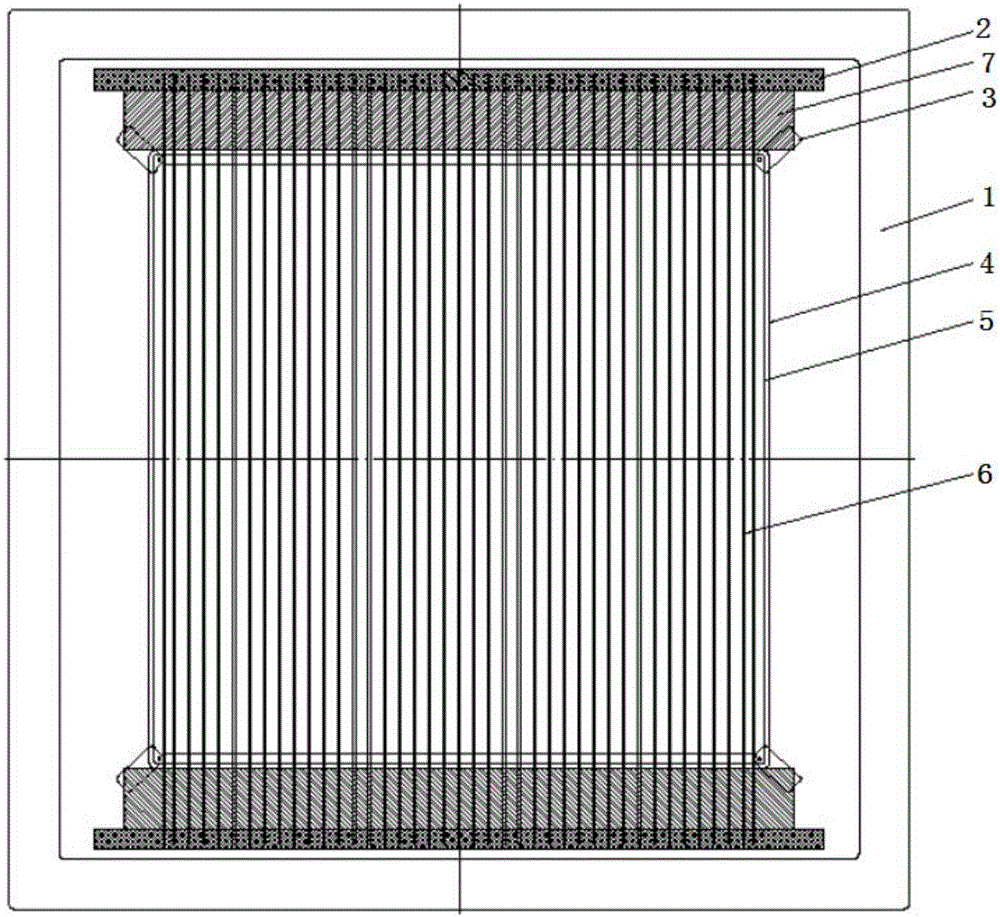

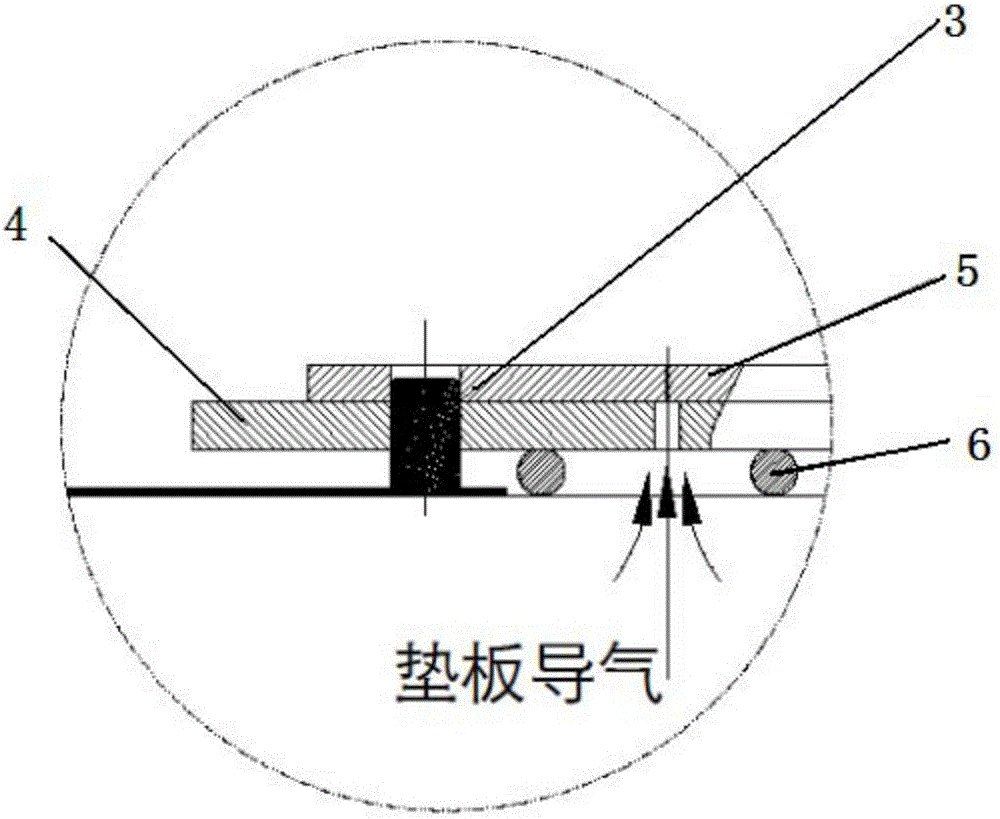

Vacuum screen printing machine hole plugging pad plate jig and hole plugging method thereof

The invention discloses a vacuum screen printing machine hole plugging pad plate jig. The vacuum screen printing machine hole plugging pad plate jig comprises a printing table plate and an air guide pad plate; the printing table plate is arranged in a printing cavity of a vacuum screen printing machine, a plurality of aluminum pad strips are arranged on the printing table plate, and a printing area is formed by the aluminum pad strips; a plurality of air guide holes are formed in the air guide pad plate, the air guide pad plate is placed on the aluminum pad strips, the four corners of the air guide pad plate are fixed through double-face pins, and a PCB is sleeved with the double-face pins to be positioned; the air guide pad plate is supported by the aluminum pad strips, an air guide channel is formed between every two aluminum pad strips, air enters the air guide holes from the air guide channels, and the pressure difference of the two faces of the PCB is removed. Compared with an existing printing table plate adopting a special air guide pad plate or provided with an air guide groove, the jig is simple in structure, convenient to use and low in cost, the jig is shared by PCBs of different types, efficiency is high, and operation is convenient; and the jig can further be directly used in common with a non-vacuum hole plugging air guide pad plate.

Owner:昆山晟丰精密机械有限公司

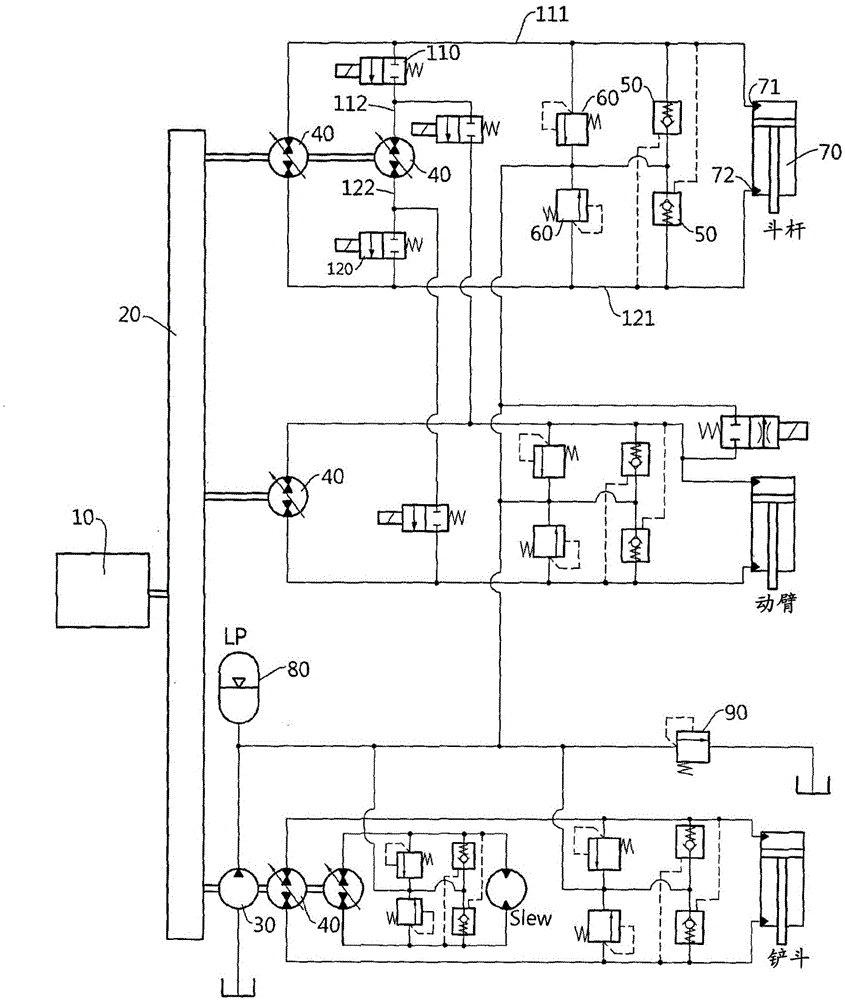

Hydraulic system for construction equipment

ActiveCN105074096AImprove economyImprove operational controlServomotor componentsServomotorsActuatorPressure difference

The present invention relates to a hydraulic system for construction equipment and, more specifically, to a hydraulic system of which an actuator is controlled by a pump / motor. The hydraulic system for construction equipment according to the present invention includes logic valves respectively provided to first and second hydraulic lines provided to the actuator. In addition, when the actuator must be operated in a state in which the operation of the actuator is stopped by the closing of the logic values, a pressure difference can be resolved by increasing the pressure in the pump / motor and logic value sections in advance even if a load is applied to the actuator, and thus the actuator can implement a desired operation without being affected by the load. That is, operation controllability of the actuator can be improved.

Owner:HYUNDAI DOOSAN INVIGORATE CORP

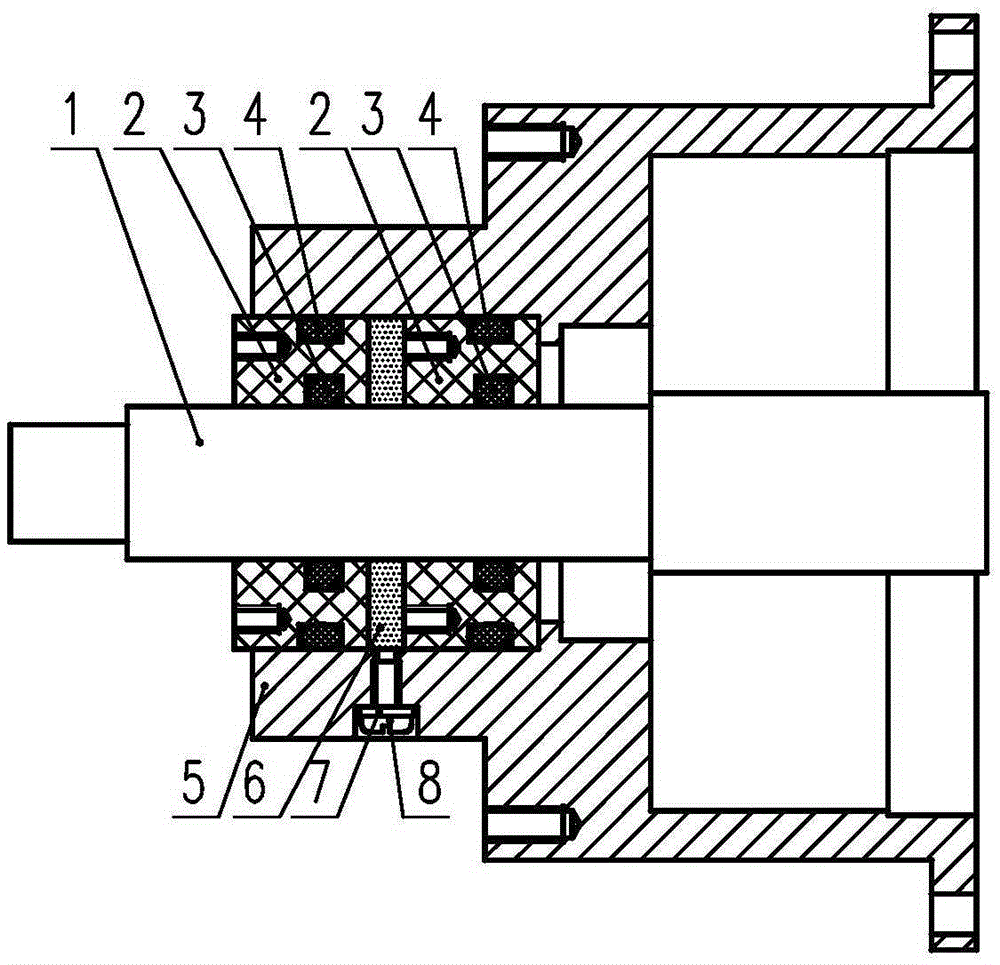

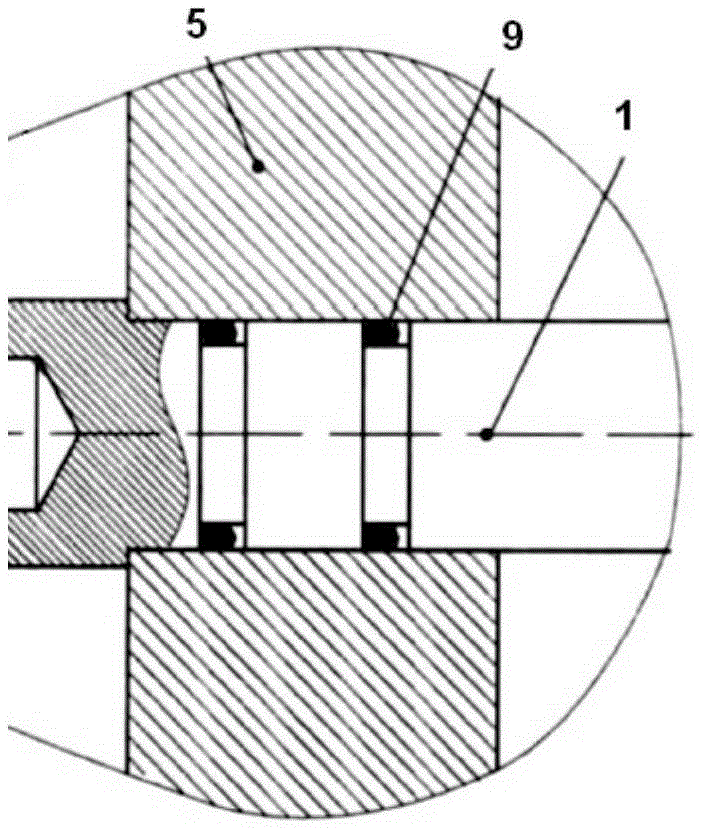

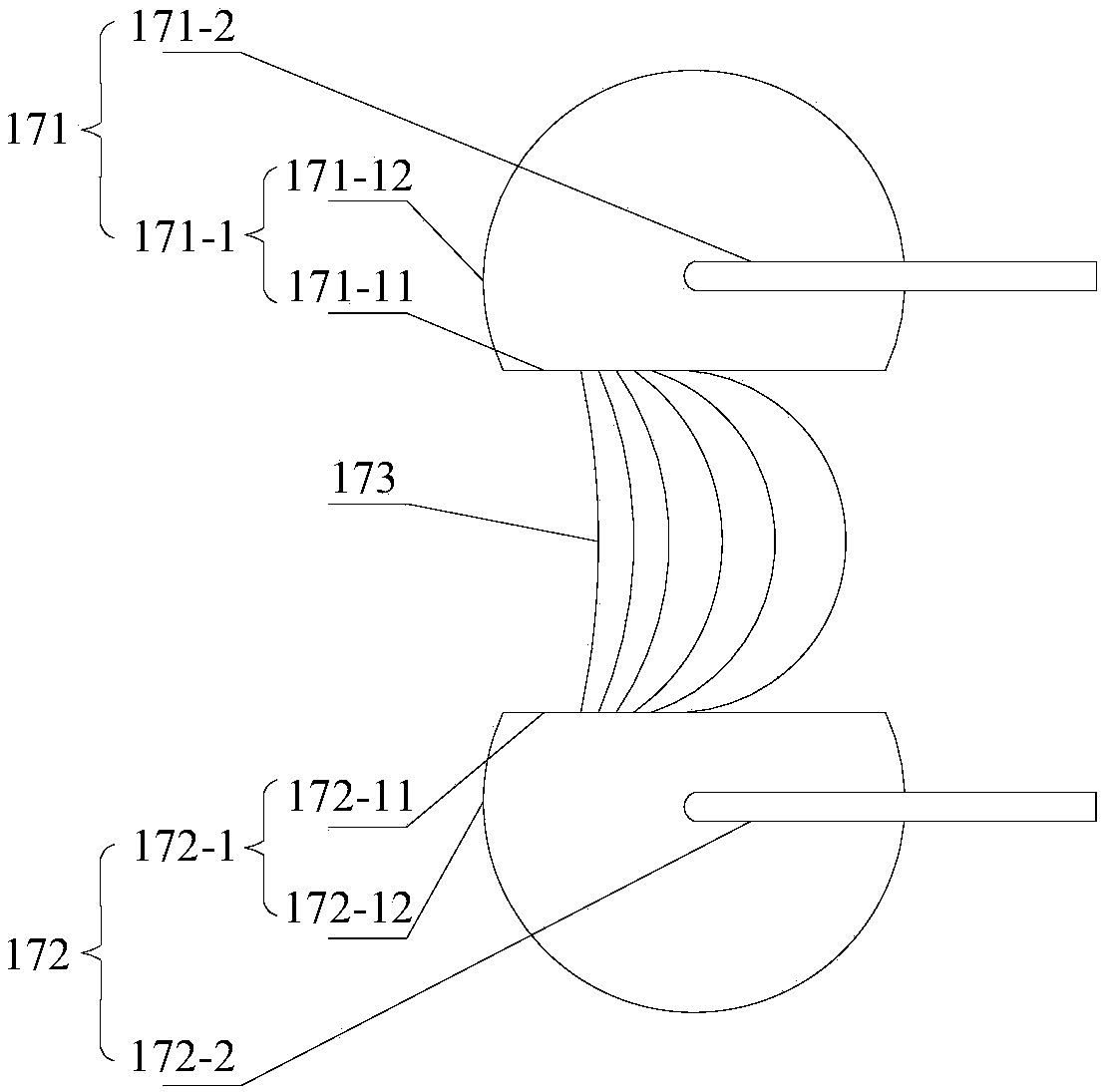

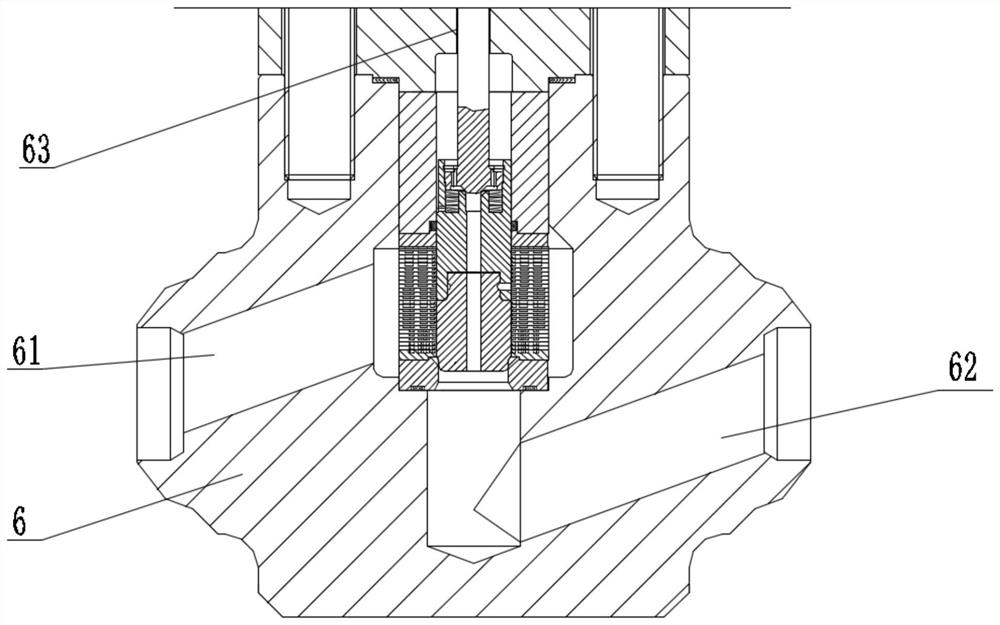

Self-balance floating sealing device

InactiveCN105402417AEliminate pressure differentialsGuaranteed reliabilityEngine sealsEngineeringPressure difference

The invention discloses a self-balance floating sealing device for solving the technical problem of weak sealing performance of a traditional sealing device. The self-balance floating sealing device comprises a rotating shaft, sealing rings, outer O-shaped rings, inner O-shaped rings, a shell, hydraulic oil, a red copper pad and a screw. The number of the sealing rings is two; the outer O-shaped rings are positioned in inner clamping grooves of the sealing rings; the inner O-shaped rings are positioned in outer clamping grooves of the sealing rings; the two sealing rings are arranged between the rotating shaft and the shell in a sleeving manner; the sealing rings can move along the axis of the rotating shaft; a sealing cavity is defined by the two sealing rings, the shell and the rotating shaft, and is communicated with an oil injecting hole in the shell; the oil injecting hole is sealed by the red copper pad and the screw; and the hydraulic oil is injected in the sealing cavity through the oil injecting hole in the shell. Along with the pressure change, the volume of the sealing cavity is changed through the translation of the sealing rings to form self-balance with external water pressure, so that the pressure difference of the two sides of the outer O-shaped rings and the inner O-shaped rings is eliminated, and the sealing reliability is guaranteed.

Owner:中国船舶重工集团公司第七〇五研究所

Fuel tank control valve

PendingCN109944952AImprove reliabilityOut of Stability RealizationOperating means/releasing devices for valvesLarge containersPush and pullFuel tank

The invention discloses a fuel tank control valve, and belongs to the field of valves. The fuel tank control valve comprises a floater arranged in a valve body, an exhaust hole is formed in the top ofthe valve body, a liquid inlet hole is formed in the side part of the valve body, a sealing cover is arranged on the top surface of the floater, a supporting frame is arranged on the periphery of thetop of the floater in a sleeve mode, a sealing gasket matched with the sealing cover and the exhaust hole is arranged in the center of the supporting frame, a vent hole is formed in the center of thesealing gasket, the top and the bottom of the sealing gasket are both machined into a trumpet-shaped structure, the top of the sealing gasket is matched with the exhaust hole, the bottom of the sealing gasket is matched with the sealing cover, the sealing cover is movably arranged at the top of the floater through a push-and-pull assembly, and the push-and-pull assembly is used for pushing the sealing cover to move upwards when the floater rises, and pulling one side of the sealing cover to descend when the floater descends. According to the fuel tank control valve, the sealing gasket can bestably separated from the exhaust hole through the designed push-and-pull assembly, so that influence from the internal and external pressure difference is avoided, the use reliability of the valve body is improved, and the control valve can be used in a fuel tank.

Owner:JIANGSU AOLIWEI SENSING TECH

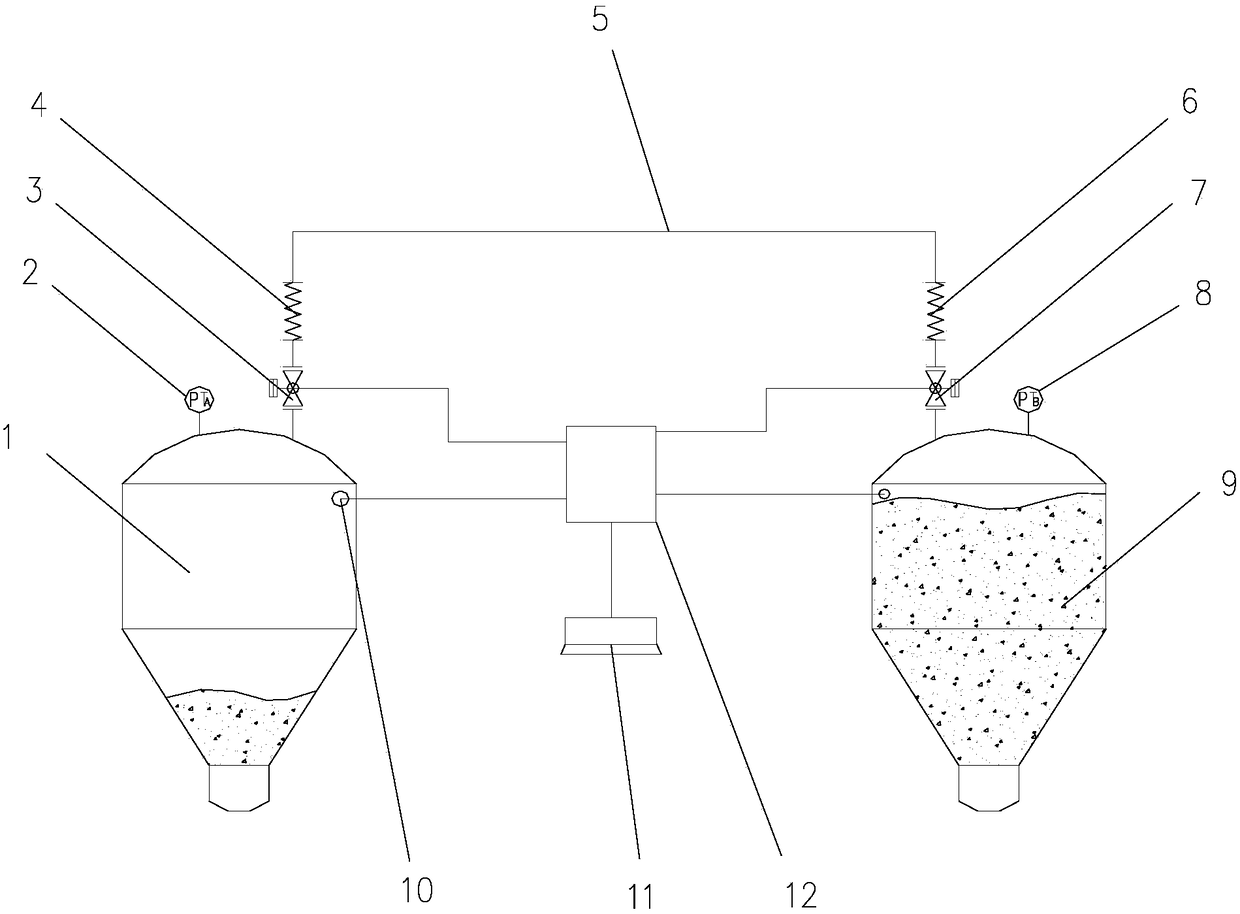

Pressure balance control method and device for blast furnace coal injection system

ActiveCN105695648ASolve the hysteresisAvoid pressure differenceBlast furnace detailsEconomic benefitsEngineering

The invention discloses a pressure balance control method and device for a blast furnace coal injection system. The method includes the steps that a blowing tank A at the last phase in the braize blowing sub-process stable blowing state is connected with a blowing tank B in a blowing waiting state through a connecting pipe by opening a first stop valve and a second stop valve at the same time; and when the pressure difference deltaP between the blowing tank A and the blowing tank B is extremely small, the absolute value of a difference of PTA and PTB is smaller than or equal to deltaP, the first stop valve and the second stop valve are closed at the same time, and pressure balance control is completed. The pressure balance control device comprises the blowing tank A and the blowing tank B which are sequentially communicated through the connecting pipe, and the connecting pipe is sequentially provided with the first stop valve and the second stop valve. According to the pressure balance control method and device, the pressure difference between the blowing tank A and the blowing tank B is controlled through the first stop valve and the second stop valve, pressure balance between the blowing tank A and the blowing tank B is achieved, shortcomings such as pressure fluctuation, the hysteretic nature, overregulation or under-regulation in the prior art can be eliminated, and the pressure balance control method and device have the remarkable economic benefit on stable production of a blast furnace.

Owner:CISDI ENG CO LTD

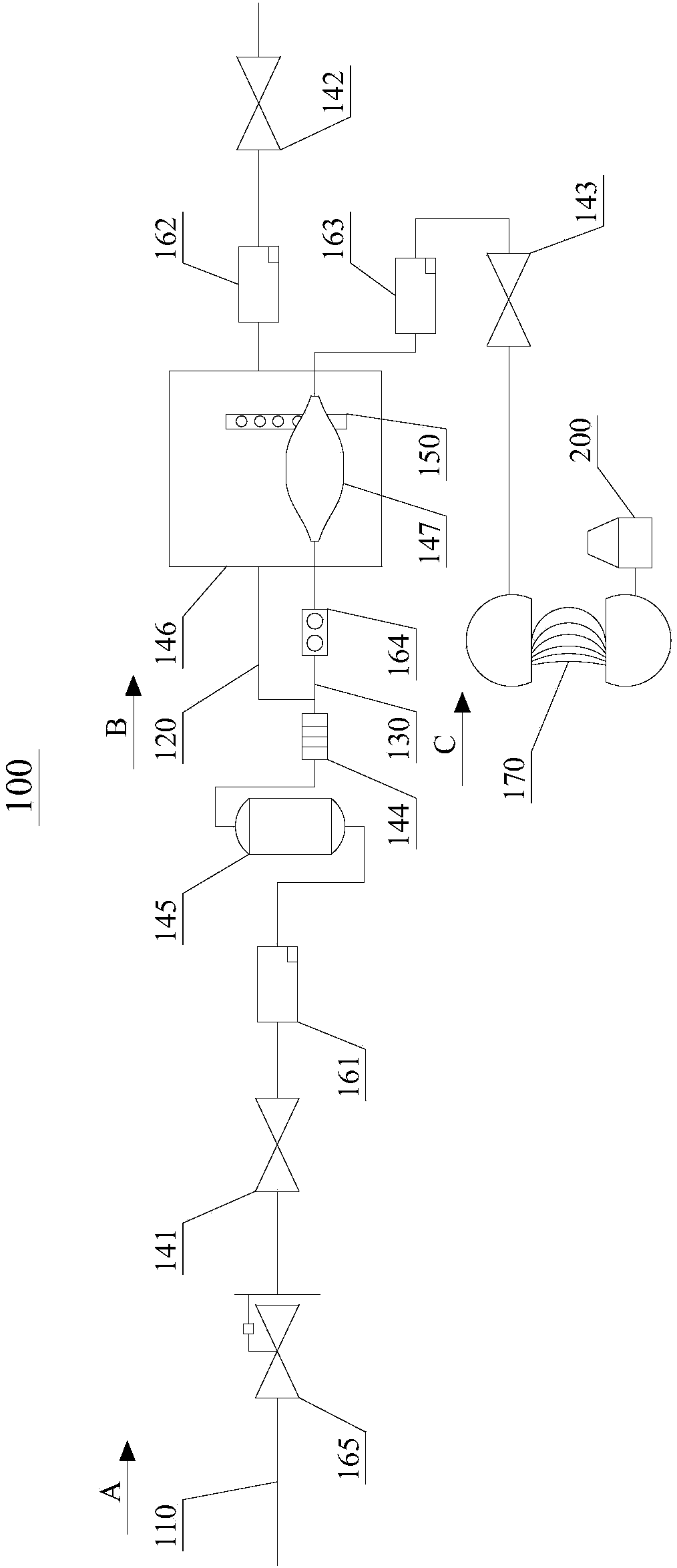

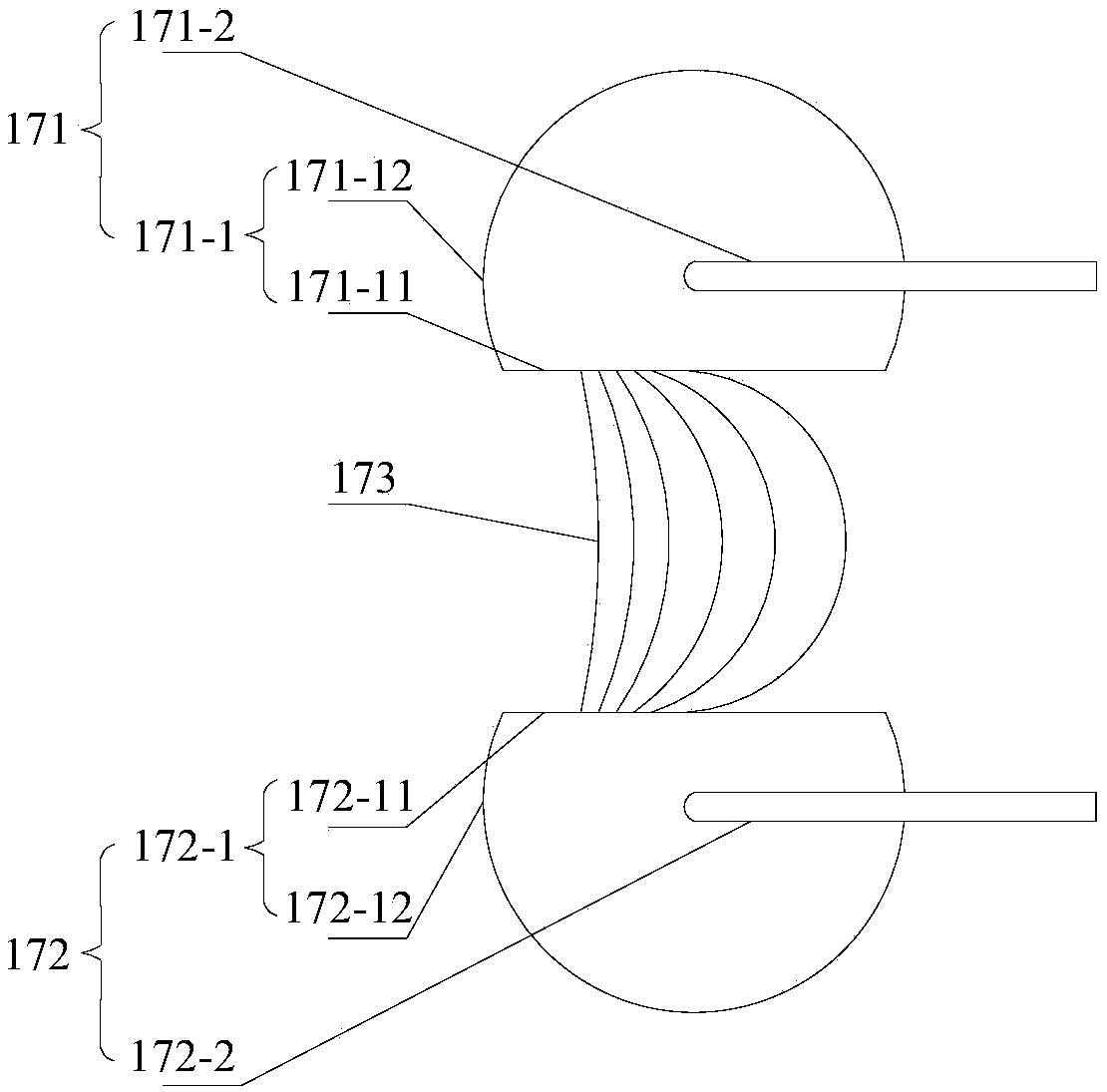

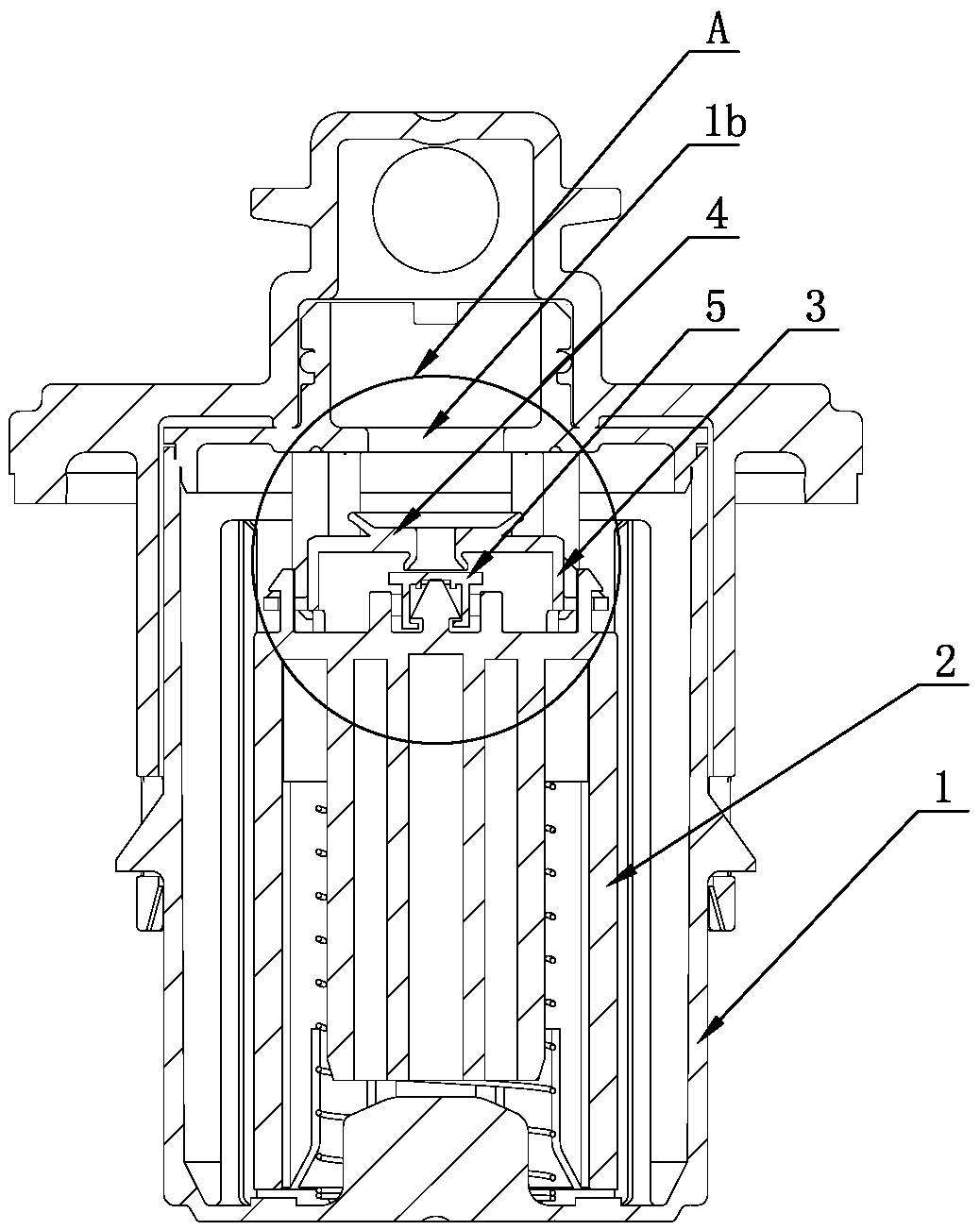

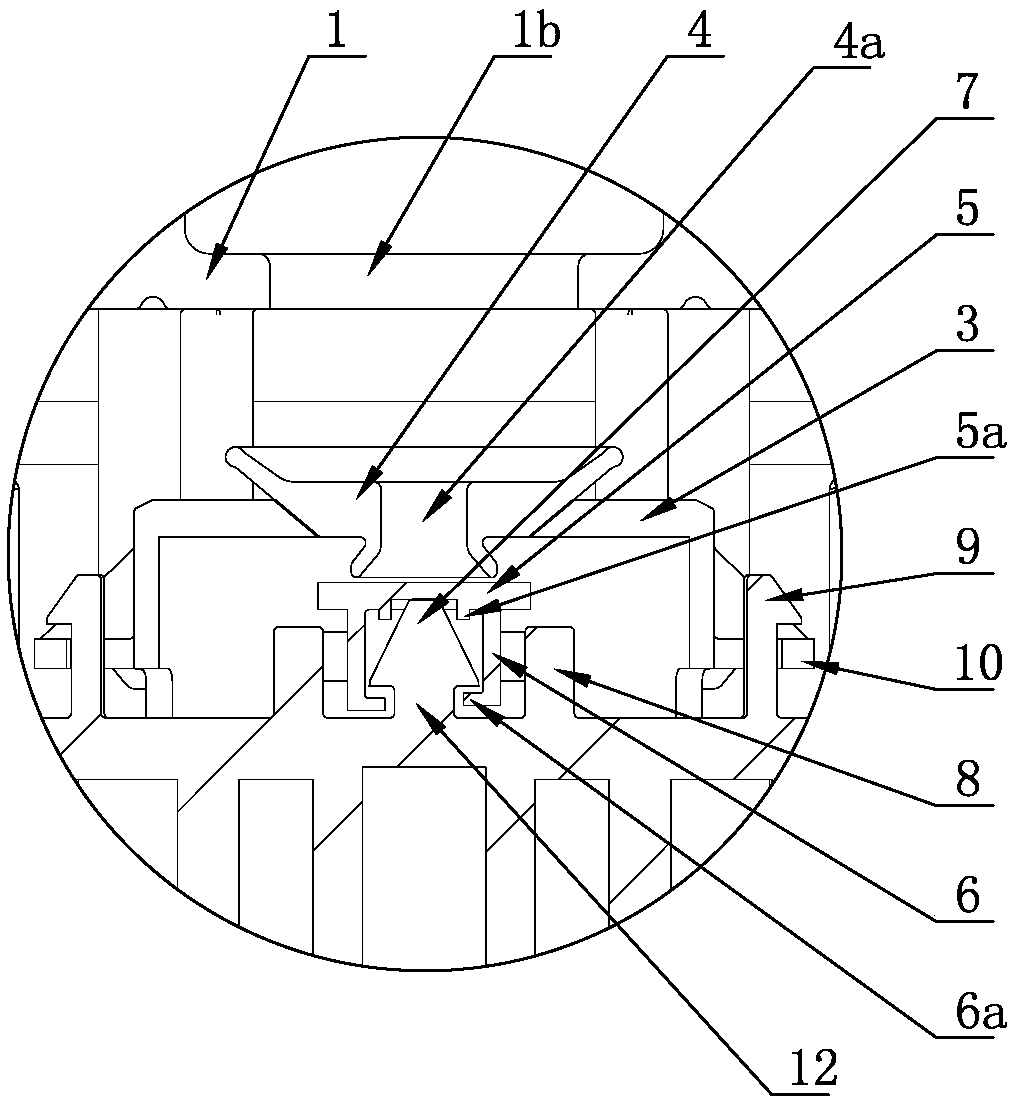

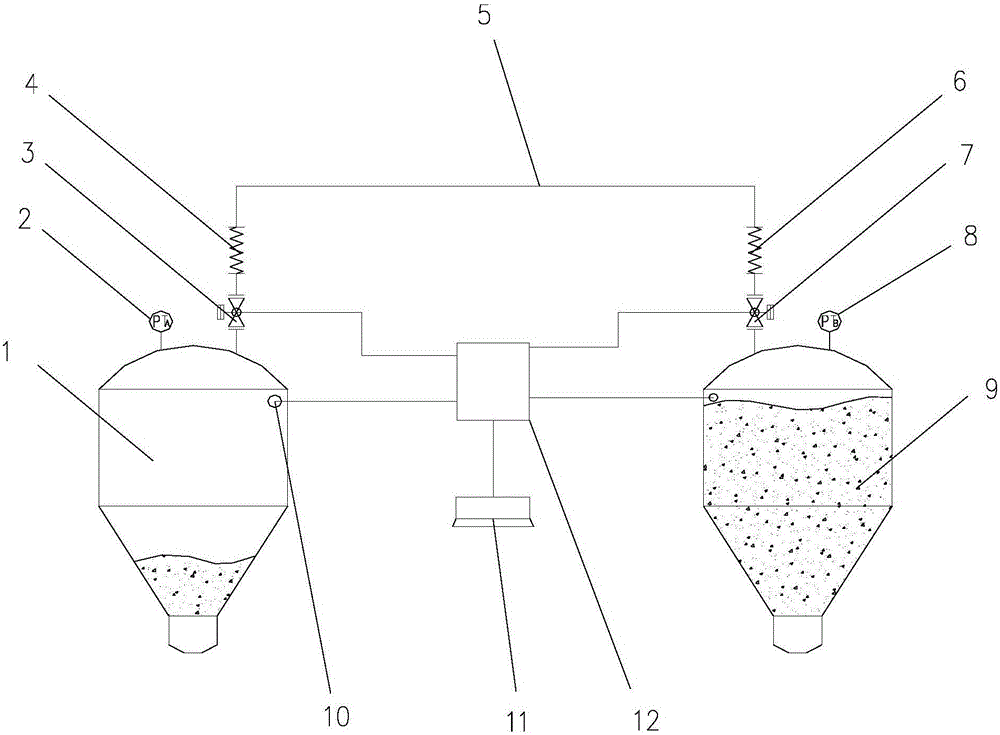

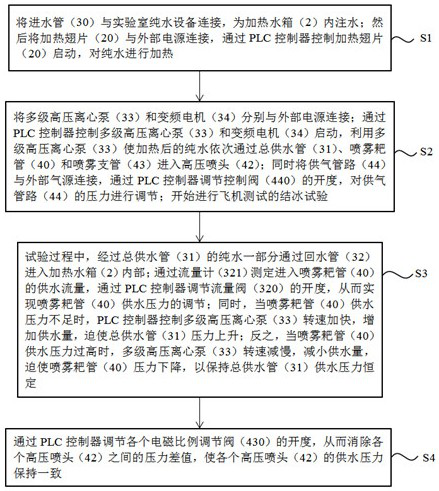

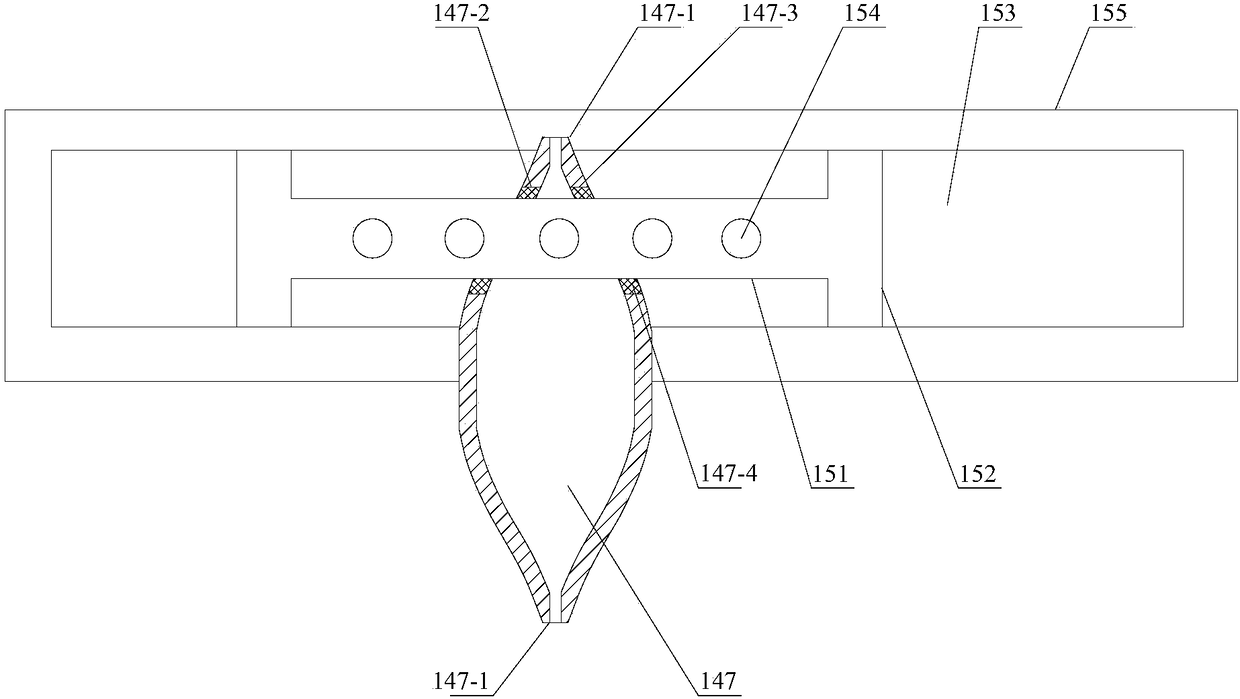

Icing test water supply system and water supply method for aircraft testing

ActiveCN114459791BEliminate pressure differentialsConsistent water pressureStructural/machines measurementService pipe systemsConnection controlAirplane

The invention discloses an icing test water supply system and a water supply method for aircraft testing, and relates to the technical field of aircraft testing. The water supply system includes an incubator, a heating water tank, a water supply component, a spray component and a control cabinet; , the water supply component includes the water inlet pipe, the main water supply pipe, the return water pipe, the multi-stage high-pressure centrifugal pump and the frequency conversion motor. The frequency conversion motor provides power for the multi-stage high-pressure centrifugal pump. The multi-stage high-pressure centrifugal pump is connected, and the return pipe is respectively connected with the main water supply pipe and the heating water tank; the spray assembly includes a spray rake pipe and a high-pressure nozzle. , and is connected with the spray rake pipe; the control cabinet is electrically connected with each electrical equipment; the system has a reasonable structure design, can realize constant pressure water supply, improve the spray effect of the icing test, and thus improve the aircraft test efficiency.

Owner:CHINA AIRPLANT STRENGTH RES INST

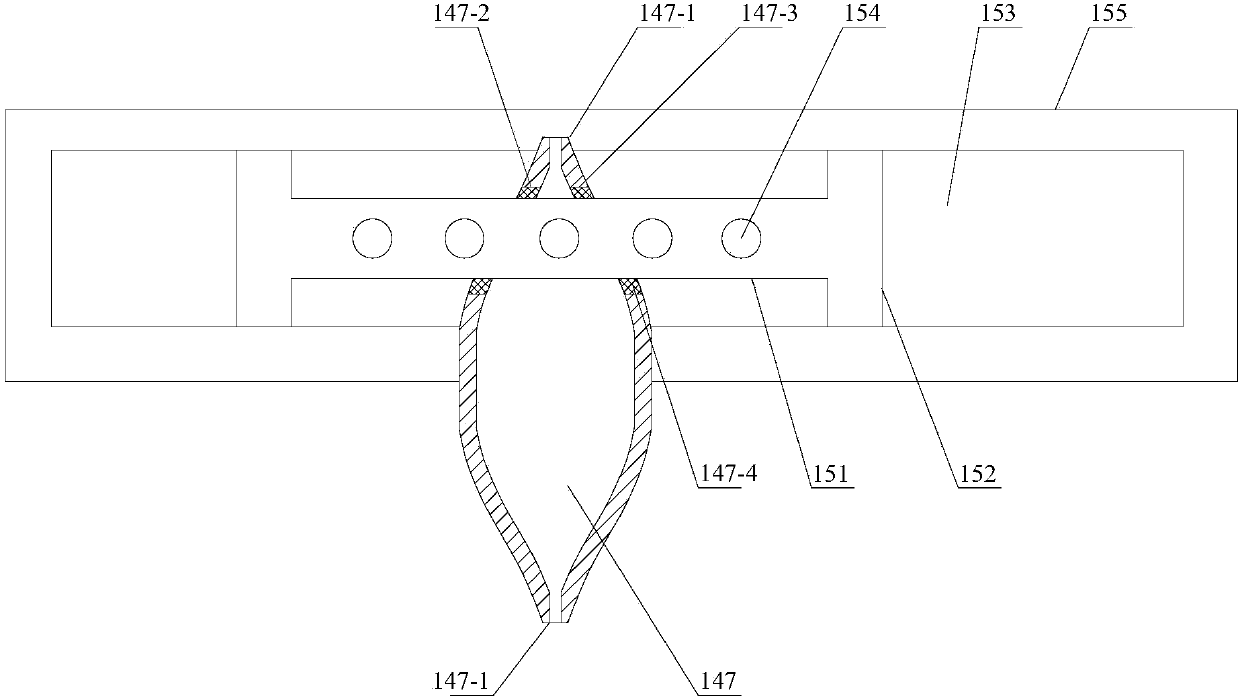

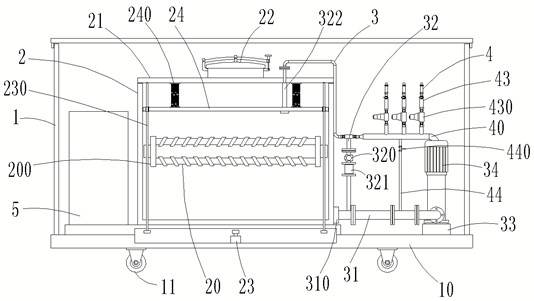

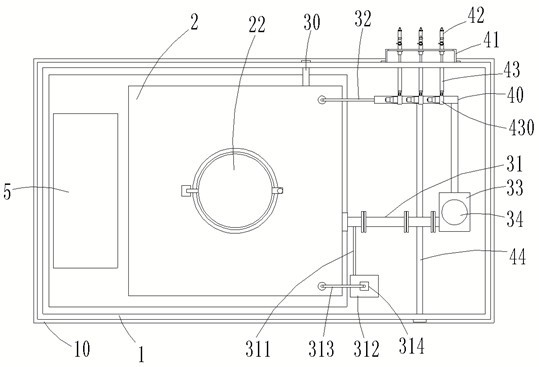

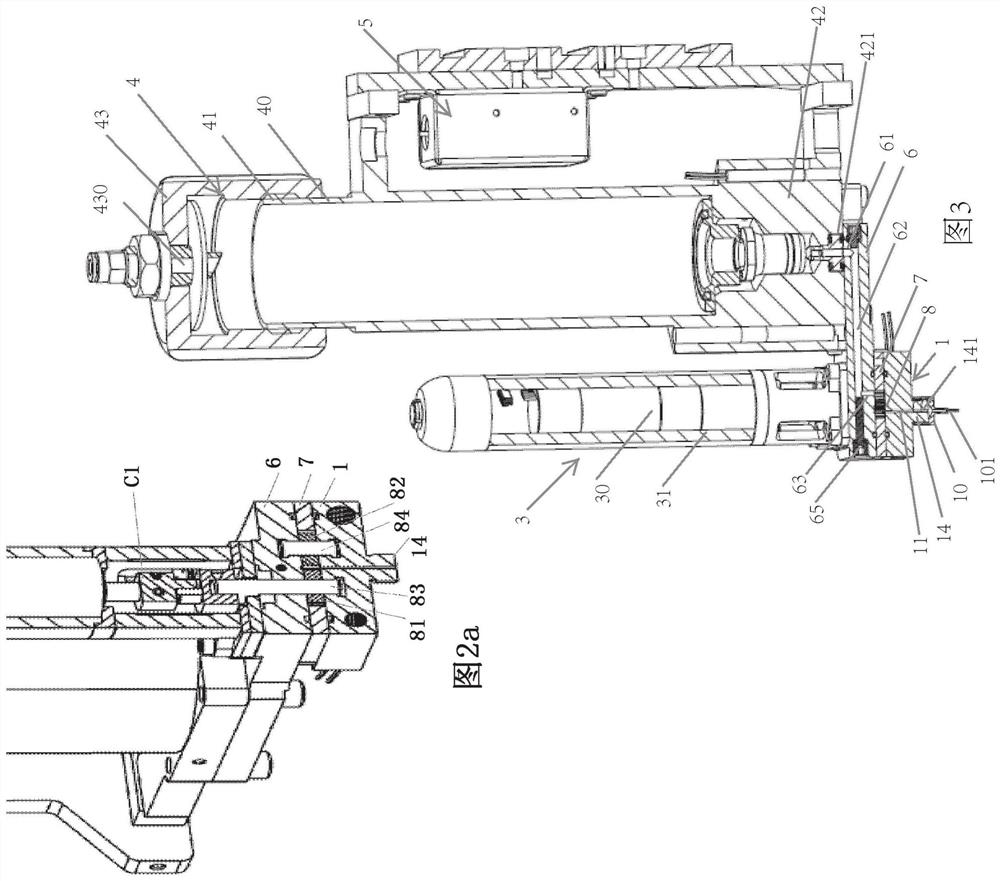

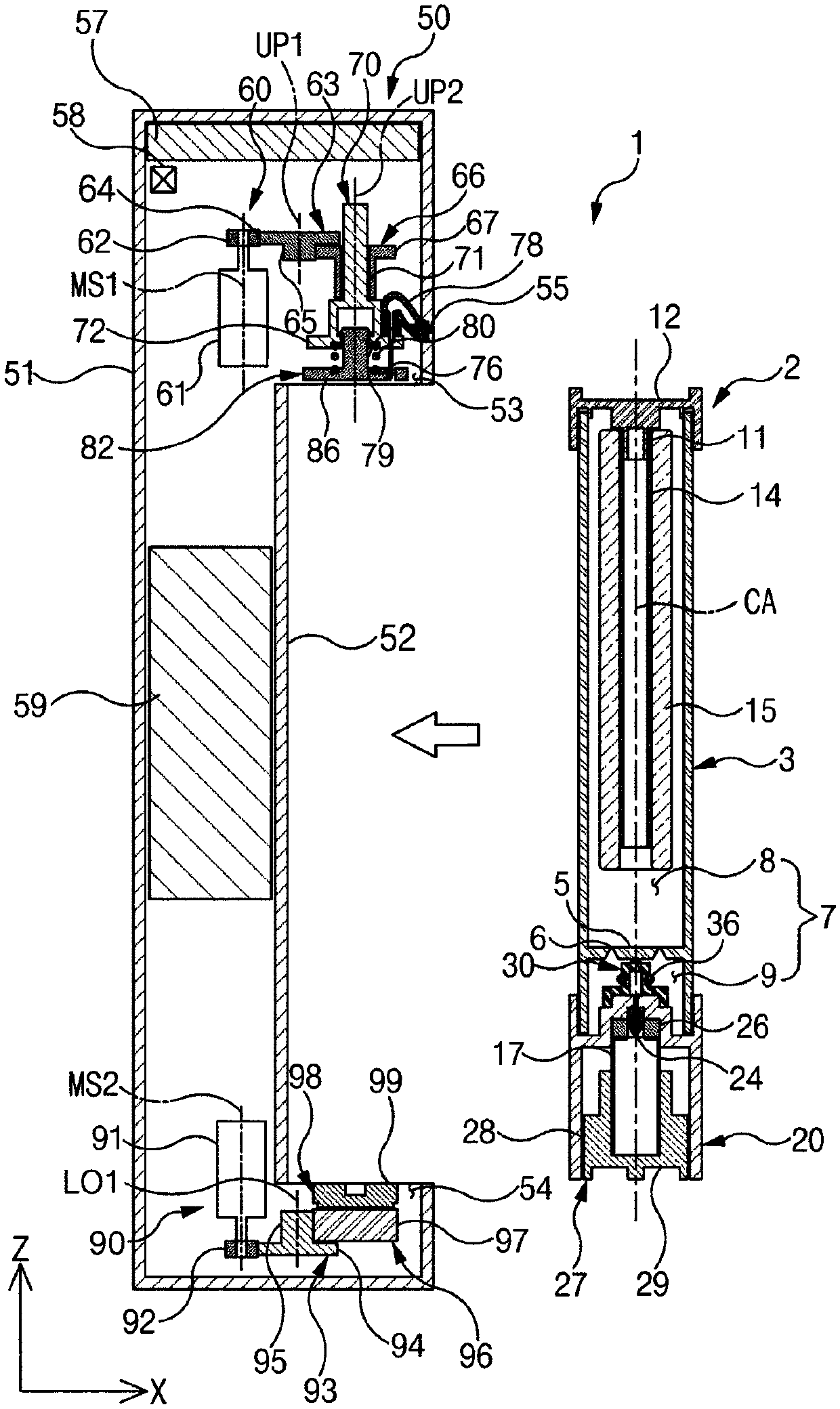

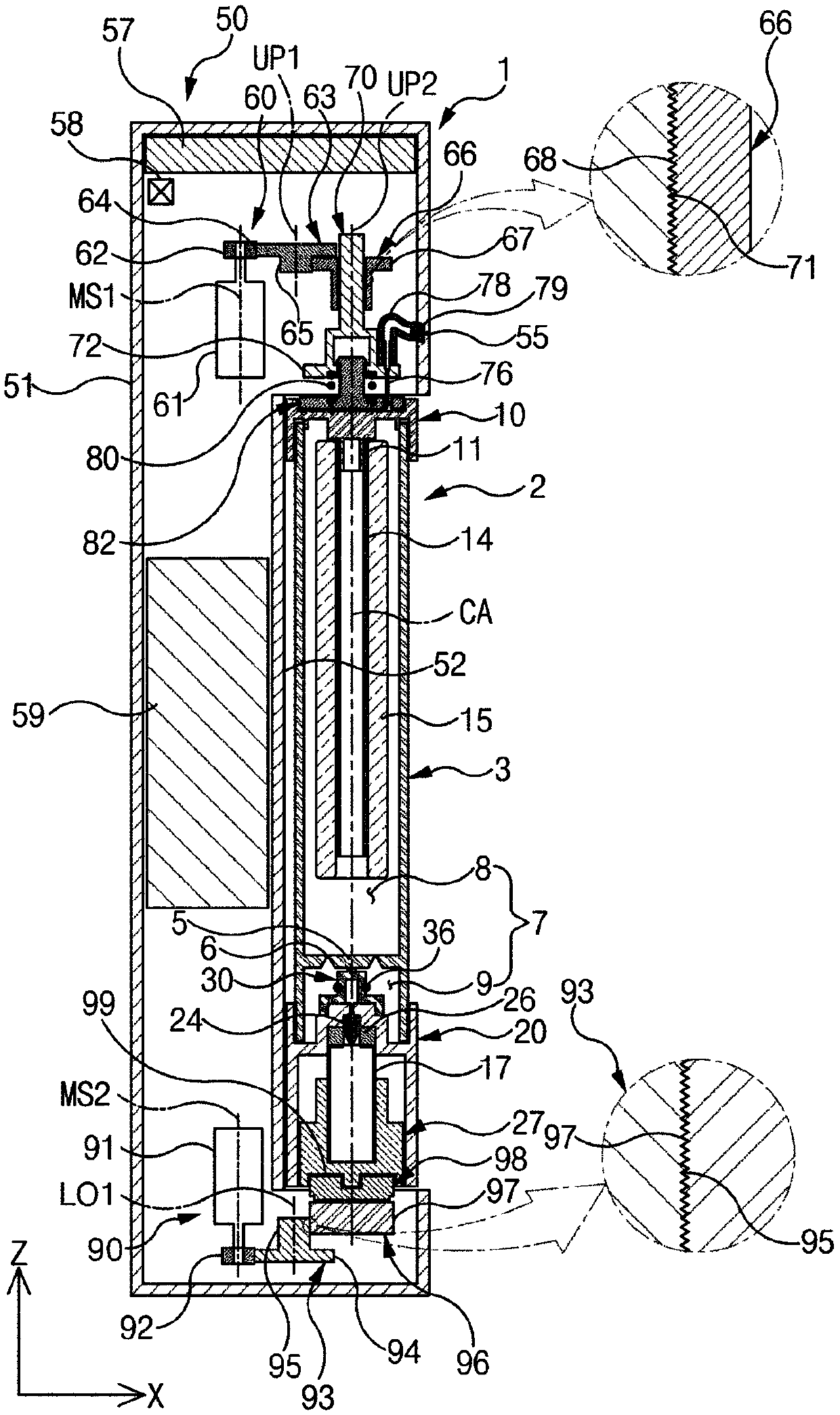

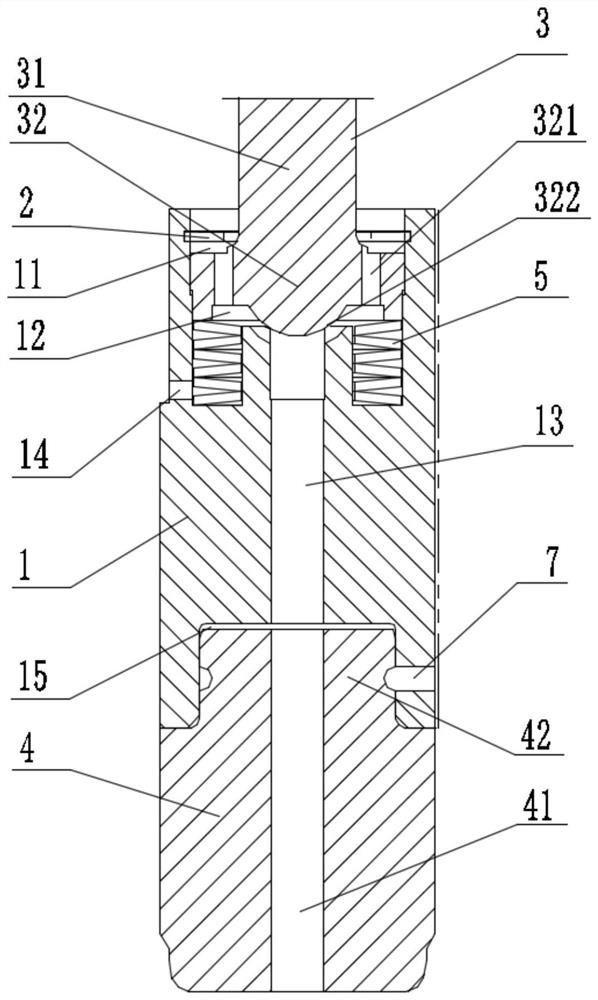

Metering and distributing assembly and coating system comprising same

PendingCN114074059AEliminate pressure differentialsAvoid crossingLiquid surface applicatorsMovable measuring chambersRotational axisCoating system

The invention provides a metering and distributing assembly and a coating system comprising the same. The metering and distributing assembly is composed of a positive displacement pump, and the positive displacement pump comprises a flow channel plate (6) provided with a flow channel for fluid to flow, a nozzle plate (1) provided with a flow channel penetrating through the nozzle plate (1), a gear fixing plate (7) attached between the flow channel plate (6) and the nozzle plate (1) and having an orifice (71), and a gear set (8) located in the orifice of the fixing plate (7); and the gear set has a fluid inlet (85) in fluid communication with the flow channel of the flow channel plate (6) and a fluid outlet (86) on an opposite side of the fluid inlet (85) with respect to the gear set (8), and the fluid outlet is in fluid communication with the flow channel of the nozzle plate, wherein a portion of the flow channel of the flow channel plate, which is in direct fluid communication with the fluid inlet, extends in a direction parallel to a rotational axis of the gear set.

Owner:NORDSON CORP

A soil column leaching device

ActiveCN107247129BReduce collapseShorten the timeWithdrawing sample devicesEarth material testingPressure differenceDistributor

A soil column leach device includes a support base, a leach pipe, and a water distributor. The leach pipe is placed on the support base, and the leach pipe and the support base are connected through threads. The water distributor is connected to the top of the leach pipe; The leach tube is composed of an inner tube and an outer tube, and the inner tube is placed inside the outer tube. The outer pipe of the leach pipe is divided into two upper and lower parts that are not connected to each other. When the air inlet on the upper part of the outer pipe of the leach pipe is connected to the pump, the pressure of the inner pipe of the leach pipe of the soil column leach device can be increased according to the experimental needs. , thereby effectively reducing the time required to perform soil column leach experiments; a soil column leach device of the present invention can be used to sample the soil layer while pressurizing the inner tube of the leach pipe of the soil column leach device. The air inlet at the lower part of the outer tube is connected to the pump, which increases the pressure outside the soil layer sampling port, which can effectively reduce or even eliminate the pressure difference between the inside and outside of the sampling port. At this time, sampling through the sampling window can reduce the phenomenon of wall flow and The occurrence of soil column collapse.

Owner:张豫 +1

Spiral separating device

InactiveCN101767068BAchieve separationEasy to separateReversed direction vortexDispersed particle separationPressure balanceFlue

The invention discloses a spiral separating device. An air inlet tube section (4) is arranged on a spiral casing (1) and a spiral swirl air flue (5) is arranged in the spiral casing (1). The upper part of an assistant cylinder (3) is positioned outside the spiral casing (1) and the upper part of a main cylinder (2) is positioned inside the spiral casing (1). A passage (6) communicated with the inner cavity of the assistant cylinder (3) is arranged on the outer wall of the middle section of the spiral swirl air flue. At least one deflector (7) is arranged in the spiral swirl air flue and at the part of the passage (6), and an air flue (8) communicated with the inner cavity of the main cylinder (2) is arranged on the inner wall of the end section of the spiral swirl air flue. A first nozzle (9a) of a pressure balancing air flue tube (9) is communicated with the upper part of the inner cavity of the assistant cylinder (3) and a second nozzle (9b) is communicated with the upper part of the inner cavity of the main cylinder (2). An air outlet (10) is arranged at the lower part of the main cylinder (2) and a discharge hole (11) is arranged at the lower part of the assistant cylinder (3). A secondary separator (12) is arranged at the first nozzle (9a) and a pressure balancer (13) is arranged at the second nozzle (9b).

Owner:长沙奥邦环保实业有限公司

Freezer

ActiveCN109855348BOpen to save effortFix hard-to-open problemsLighting and heating apparatusDomestic refrigeratorsAnaerobic respirationEngineering

A refrigeration and freezing device, comprising a storage drawer (100), an electrolytic oxygen removal assembly (200), a touch sensing device (500) and an electric air valve (300). The electrolytic oxygen removal assembly (200) is used for consuming oxygen in a storage space so that nitrogen-rich oxygen-deficient air is obtained in the space so as to benefit a gas atmosphere for food preservation. The intensity of the aerobic respiration of food, particularly fruits and vegetables, is decreased by means of decreasing the content of oxygen in the storage space, simultaneously ensuring basic respiratory action and preventing the anaerobic respiration of the food, thereby achieving the goal of long-term preservation of the food. When the touch sensing device (500) detects that a user is about to open the storage drawer (100), the electric air valve (300) opens a through hole on the drawer (100) so that the interior and exterior of the storage space communicate, the pressure difference between the interior and exterior of the drawer being eliminated, and thus the problem in which a drawer is difficult to open due to the mounting of the electrolytic oxygen removal assembly (200) is solved; a user may open the storage drawer (100) with less effort, and the usage experience of the user is thus improved.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Face mask box, oxygen injector, and face mask kit comprising both

InactiveCN110742813AEasy to useEliminate pressure differentialsCosmetic preparationsClosuresEngineeringMechanical engineering

The invention discloses a face mask box, an oxygen injector, and a face mask kit comprising both. The face mask box includes: a face mask container provided with an internal space; a face mask sheet,placed in the internal space of the face mask container and has a shape corresponding to the face; gel essence liquid, filling the internal space of the face mask container for soaking the face mask;a box base, which seals one side of the face mask container and is combined with same; a lid, sealing the other side of the face mask container and being detachably combined with same; an oxygen supplying needle, which is fixed by and supported on the box base and is provided with a central hole; an oxygen capsule bracket, which is combined movably in the direction of closed to the oxygen supplying needle and the direction opposite to the same; and an oxygen capsule which is loaded on the oxygen capsule bracket by facing to the oxygen supplying needle, air filling the oxygen capsule under highpressure.

Owner:金赞洙

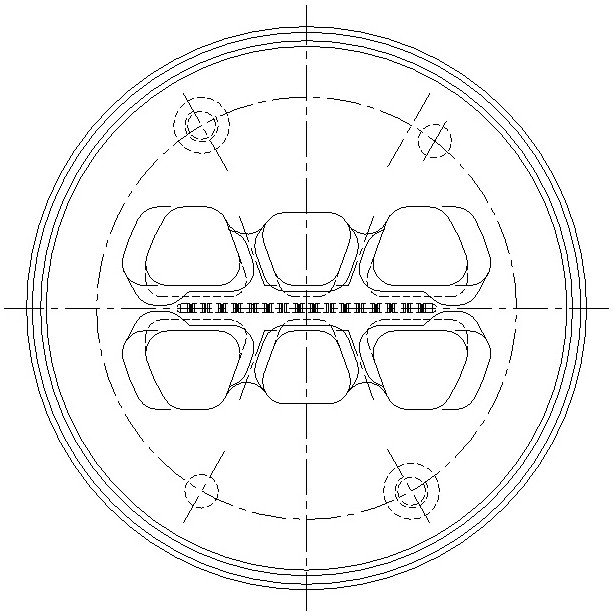

Forming method and extrusion die for harmonica-shaped tube of heat exchanger

PendingCN113634614AHigh strengthIncrease stiffnessExtrusion diesUltimate tensile strengthMechanical engineering

The invention discloses a forming method and an extrusion die for a harmonica-shaped tube of a heat exchanger. Firstly, a bent arc-shaped harmonica-shaped tube profile is extruded, and then a linear harmonica-shaped tube profile is extruded; the extrusion die comprises a straightening plate arranged at one side of a lower die, and the straightening plate straightens and deforms the arc harmonica-shaped tube profile into the linear harmonica-shaped tube profile; the curvature radius Ra of a central layer of the bent arc-shaped harmonica-shaped tube profile and the length L of the initial section of the linear harmonica-shaped tube profile meet the equation that Ra=(0.525-0.55) L; due to the adoption of a production mode of firstly extruding into the arc harmonica-shaped tube and then deforming into the linear harmonica-shaped tube by the straightening plate, die cores are positioned on the circumference with the same diameter, the pressure difference of an extrusion cylinder in the radial direction is eliminated, the strength and the rigidity of the die are greatly improved, the service life of the die is obviously prolonged, the machining period of the die is shortened, the cost is reduced, meanwhile, extrusion forming is stable, metal flow is uniform, and the production efficiency is remarkably improved.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

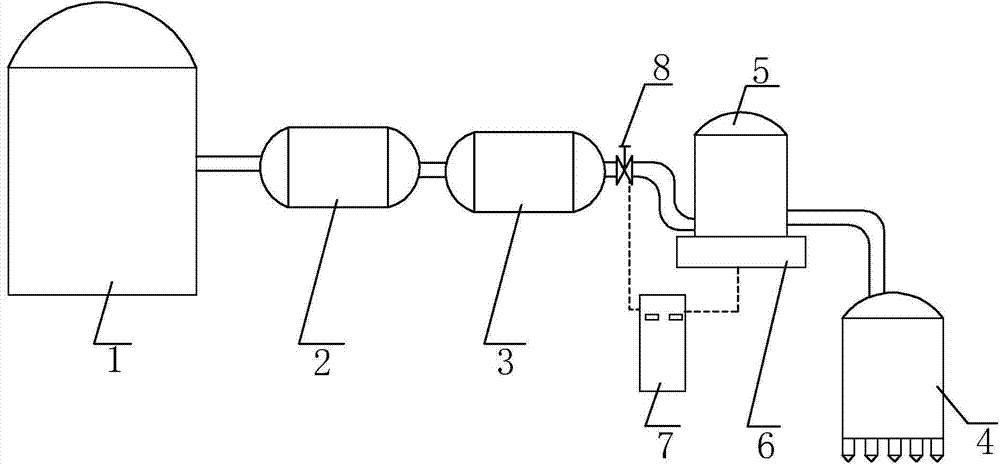

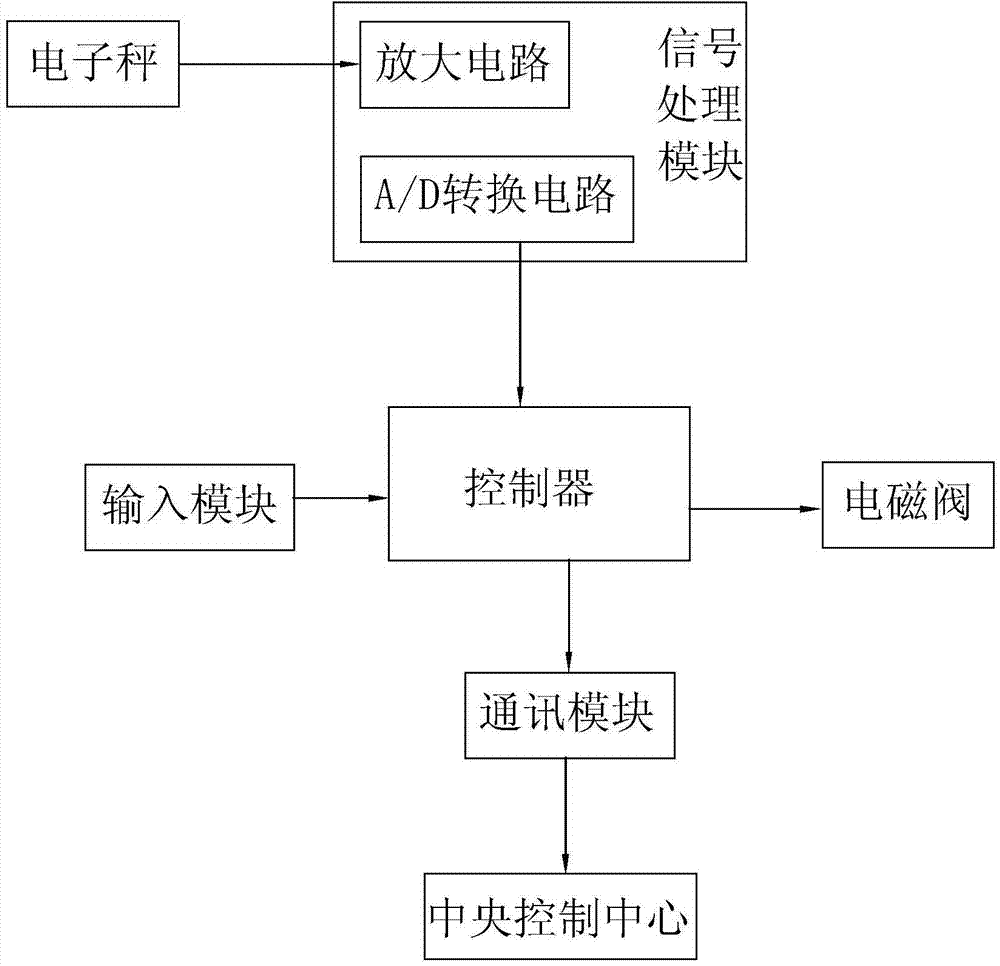

Eye drop filling control device without pollution source

InactiveCN104743488AEliminate pressure differentialsGuaranteed accuracyLiquid bottlingSterile environmentPollution

The invention discloses an eye drop filling control device without a pollution source. The eye drop filling control device comprises a large tank, a first filter, a second filter and a filling machine which are connected in sequence by a conveying pipe, and further comprises a controller, an electronic balance and a buffering tank, wherein the buffering tank is arranged on the electronic balance and is connected between the second filter and the filling machine, a solenoid valve is arranged at the input port of the buffering tank, the electronic balance is electrically connected with the input end of the controller, and the solenoid valve is electrically connected with the output end of the controller; and the controller is internally provided with an eye drop stock upper limit value for enabling the controller to send out a signal to switch on the solenoid valve when the weighing value of the electronic balance is smaller than the value, and an eye drop stock upper limit value for enabling the controller to send out a signal to switch off the solenoid valve when the weighing value of the electronic balance is greater than the value. The electronic balance arranged at the bottom of the buffering tank is used for metering eye drops in the buffering tank, so that the pollution source generated by adding a metering device is avoided, and the eye drops are filled under a sterile environment.

Owner:GUILIN PAVAY GENE PHARMA

A Pressure Balance Control Method for Coal Injection System of Blast Furnace

ActiveCN105695648BSolve the hysteresisAvoid pressure differenceBlast furnace detailsEconomic benefitsEngineering

The invention discloses a pressure balance control method and device for a blast furnace coal injection system. The method includes the steps that a blowing tank A at the last phase in the braize blowing sub-process stable blowing state is connected with a blowing tank B in a blowing waiting state through a connecting pipe by opening a first stop valve and a second stop valve at the same time; and when the pressure difference deltaP between the blowing tank A and the blowing tank B is extremely small, the absolute value of a difference of PTA and PTB is smaller than or equal to deltaP, the first stop valve and the second stop valve are closed at the same time, and pressure balance control is completed. The pressure balance control device comprises the blowing tank A and the blowing tank B which are sequentially communicated through the connecting pipe, and the connecting pipe is sequentially provided with the first stop valve and the second stop valve. According to the pressure balance control method and device, the pressure difference between the blowing tank A and the blowing tank B is controlled through the first stop valve and the second stop valve, pressure balance between the blowing tank A and the blowing tank B is achieved, shortcomings such as pressure fluctuation, the hysteretic nature, overregulation or under-regulation in the prior art can be eliminated, and the pressure balance control method and device have the remarkable economic benefit on stable production of a blast furnace.

Owner:CISDI ENG CO LTD

Valves and Pneumatic Braking Equipment

ActiveCN109552302BAchieve conductionEliminate pressure differentialsApplication and release valvesPiping arrangementsIn vehicleEngineering

Owner:WABCO GMBH

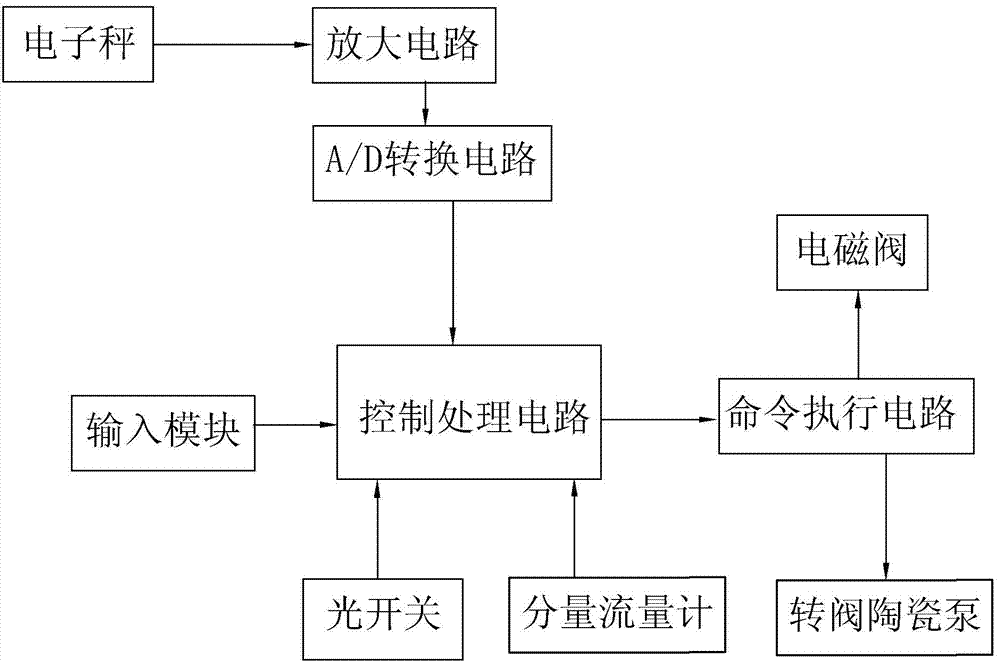

Eye drop sub-packaging control system

ActiveCN104773688AAvoid wastingAvoid pollutionSafety device in filling machineryControl systemSolenoid valve

The invention discloses an eye drop sub-packaging control system, comprising a control and processing circuit, a command executing circuit, a buffer tank, a photoelectric switch and a sub-packaging flowmeter, wherein a solenoid valve is arranged at a liquid inlet of the buffer tank, the buffer tank is arranged on an electronic scale, the electronic scale, the sub-packaging flowmeter and the command executing circuit are all connected with an input terminal of the control and processing circuit, the solenoid valve is connected with an output terminal of the control and processing circuit, a sub-packaging pump of a sub-packaging machine is a rotary-valve ceramic pump capable of carrying out secondary sub-packaging, and the control and processing circuit controls opening or closing of the rotary-valve ceramic pump according to the metered value of the sub-packaging flowmeter. The photoelectric switch arranged at a bottle-feeding and wheel-moving place of the sub-packaging machine can detect lack of bottles and prevent maloperation, so waste and pollution of eye drops are avoided.

Owner:GUILIN PAVAY GENE PHARMA

Bypass structure, ventilation equipment and ventilation method

ActiveCN105352105BSolve the problem of low bypass efficiencyImprove ventilation efficiencyDucting arrangementsMechanical apparatusFresh airEngineering

Disclosed are a bypass structure, a ventilation device, and a ventilation method, wherein the bypass structure is used for the ventilation device. The bypass structure is disposed in parallel with a primary ventilation structure in the ventilation device. The bypass structure comprises a fresh air bypass passage (8) and a discharge air bypass passage (9), which are independent from each other. The fresh air bypass passage (8) is configured to provide a flow passage for outdoor fresh air flowing through the ventilation device from the outdoor side to the indoor side, and the discharge air bypass passage (9) is configured to provide a flow passage for indoor discharge air flowing through the ventilation device from the indoor side to the outdoor side. A first airflow gate (51) is provided in the fresh air bypass passage (8) and a second airflow gate (52) is provided in the discharge air bypass passage (9), for opening or closing the fresh air bypass passage (8) and the discharge air bypass passage (9), respectively. With the bypass structure, the bypass ventilation efficiency is improved, and a pressure difference between the indoor side and the outdoor side can be eliminated, avoiding unfiltered air from directly entering the indoor side and reducing wear and tear of the primary ventilation structure. The ventilation device and method use the bypass structure in ventilation, reducing wear and tear of the primary ventilation structure.

Owner:GREE ELECTRIC APPLIANCES INC

Closed synchronous control hydraulic system and four-way shuttle

ActiveCN110701123BRealize automatic oil replenishmentImprove synchronicityFluid-pressure actuator safetyServomotor componentsHydraulic cylinderSynchronous control

The invention provides a closed synchronous control hydraulic system and a four-way shuttle, including: a hydraulic pump, the hydraulic pump includes a first oil outlet / oil inlet interface and a second oil outlet / oil inlet interface; a first hydraulic cylinder group and a second oil outlet interface; Two hydraulic cylinder groups, the first hydraulic cylinder group and the second hydraulic cylinder group both include two or more synchronously operating hydraulic cylinders, and the hydraulic cylinders in the same hydraulic cylinder group are connected in series; the oil inlet end of each hydraulic cylinder The oil circuit of the oil return end is also connected through the oil circuit with a relief valve; the first main oil circuit connected with the first oil outlet / inlet interface of the hydraulic pump; the second oil outlet / inlet interface of the hydraulic pump The second main oil circuit connected; the fifth oil circuit connecting the first oil circuit or the third oil circuit and the fuel tank; the sixth oil circuit connecting the second oil circuit or the fourth oil circuit and the fuel tank; the fifth Pressure relief valves are respectively provided on the oil circuit and the sixth oil circuit. The hydraulic system includes pressure relief valves and overflow valves for automatic oil replenishment to each hydraulic cylinder, improving the synchronization of the multi-cylinder system.

Owner:SHANGHAI SURAY INFORMATION TECH CO LTD

Device for efficiently obtaining air lift through low-density gas

InactiveCN105667792AEasy Density DifferencesEliminate pressure differentialsAircraftsMiniaturizationLow density

The invention discloses a device for efficiently obtaining air lift through low-density gas. The device can be used for upgrading lift systems of airships and fire balloons and promoting the large-lift and miniaturization development of the airships and the fire balloons. According to the device, the influence of density parameters on moving fluid pressure intensity changes is emphasized substantially, and the natural quality of the low-density gas is used for easily achieving the airflow density difference between the upper face and the lower face of a rotary part, so that excellent conditions are created for generating lift for the rotary part. When the rotary part rotates at a high speed, the lift is naturally formed. The effect is achieved through cooperative operation of the rotary part, a wind blocking part, an air pressure adjuster, an internal heater, an external heater and other parts.

Owner:徐珑洋

Laser ablation sampling system

ActiveCN105954089BRealize automatic replacementPrevent leakagePreparing sample for investigationMaterial analysis by electric/magnetic meansBuffer tankEngineering

The invention discloses a laser ablation sampling system, which comprises a first on-off valve, a buffer tank and a fourth on-off valve which are sequentially arranged in the main pipeline from the beginning to the end; The outer chamber and the second on-off valve in the branch pipeline; it also includes a sample chamber and a third on-off valve arranged in the second branch pipeline in sequence from the beginning to the end; the sample chamber is located in the outer chamber; the sample chamber is provided with Relative sample inlet and sample outlet; also includes a sample delivery device arranged in the outer chamber, the sample delivery device includes a sample holder that slidably passes through the sample chamber through the injection inlet and the sample outlet, and is connected with the sample holder And it is used to drive the driving device that the sample support bar slides on the straight line where the sample inlet and the sample outlet are located. The invention realizes the automatic replacement of samples without frequently opening the sample chamber, thus avoiding the influence of frequent opening of the sample chamber on the gas path in the laser ablation sample feeding system.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Balanced valve element structure and regulating valve

PendingCN113958720ASmall output torqueReduce stressPressure relieving devices on sealing facesValve members for absorbing fluid energyEngineeringMechanical engineering

Owner:SHANGHAI POWER EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com