Hydraulic system for construction equipment

A hydraulic system and engineering machinery technology, applied in the field of hydraulic systems, can solve problems such as low energy efficiency and pressure loss, and achieve the effects of eliminating pressure differences, improving fuel economy, and improving operational controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

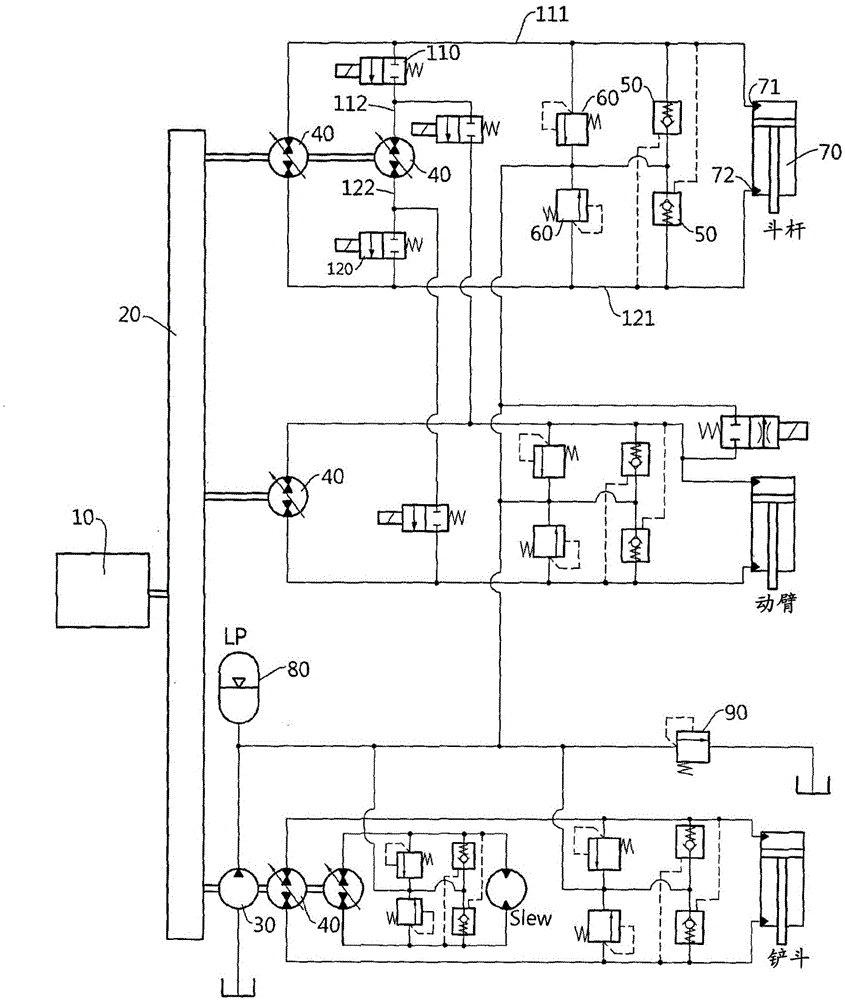

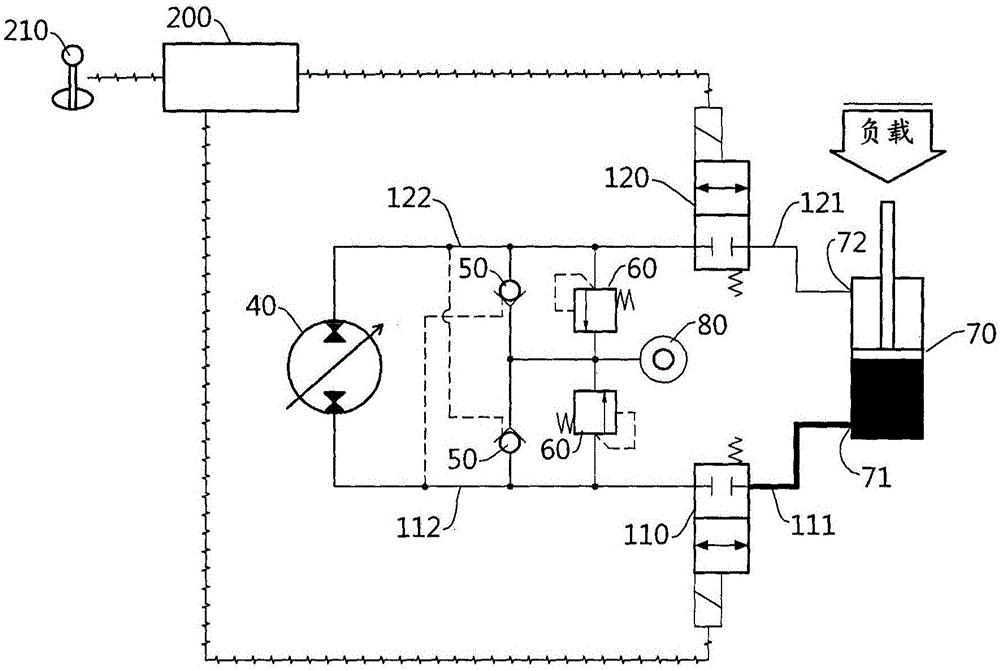

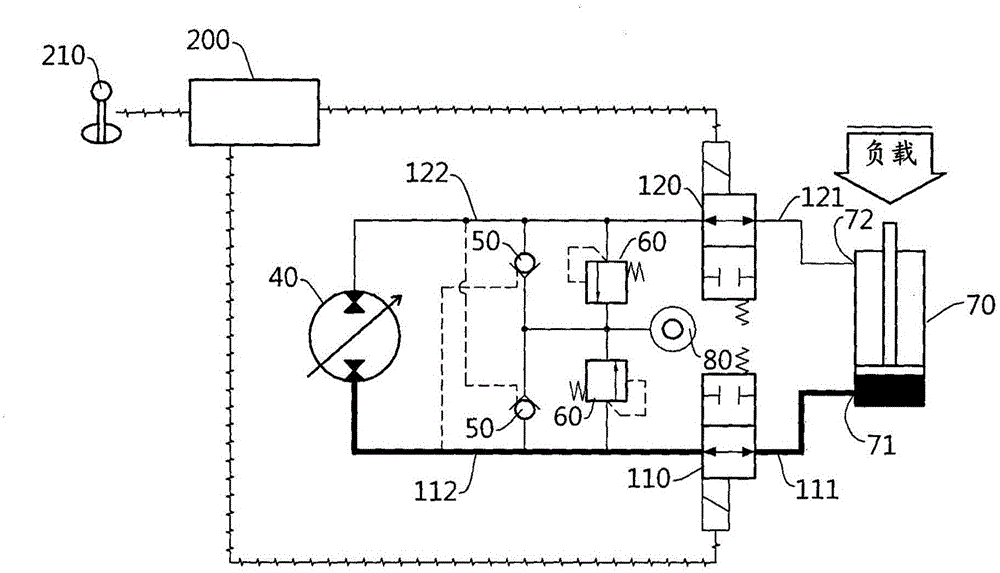

[0029] If referring to the following and attached Figure 1 With the detailed description of the embodiments, the advantages and characteristics of the present invention and the method for achieving them will be clarified.

[0030] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The embodiments described below are exemplified to facilitate understanding of the present invention, and it should be understood that the present invention can be variously modified and implemented differently from the embodiments described here. However, in describing the present invention, when it is judged that the specific description of related known functions or components may unnecessarily obscure the gist of the present invention, the detailed description and specific illustrations will be omitted. In addition, the drawings are not shown on an actual scale to facilitate understanding of the invention, and the size of some com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com