Forming method and extrusion die for harmonica-shaped tube of heat exchanger

A technology for extrusion dies and harmonica tubes, applied in the direction of metal extrusion dies, etc., can solve the problems of difficult forming and high scrap rate of hot extrusion dies, and achieve the effects of improving service life, shortening processing cycle, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

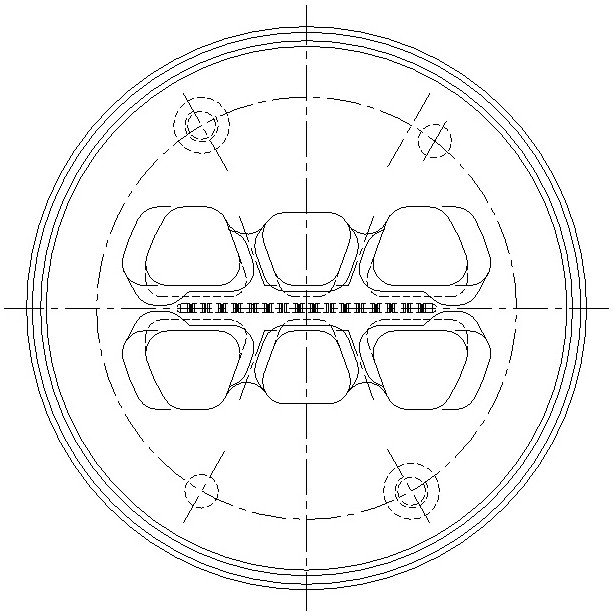

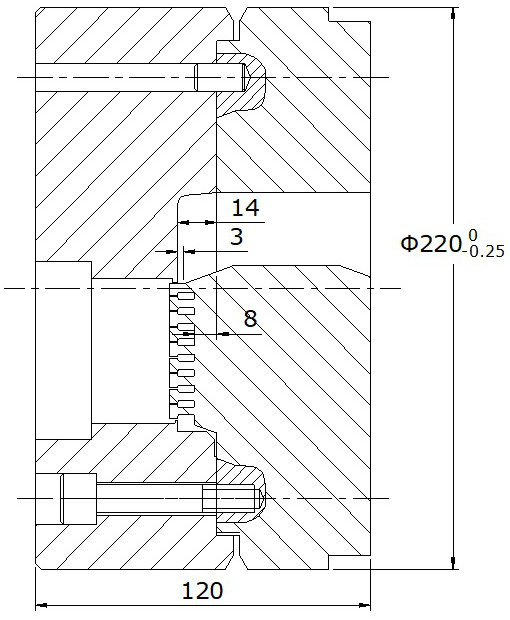

[0038] The specific embodiments and examples of the present invention will be described in detail below in conjunction with the accompanying drawings. The described specific embodiments are only used to explain the present invention, and are not intended to limit the specific embodiments of the present invention.

[0039]After an in-depth investigation of the relevant manufacturers, it is found that the current difficulty and pain point in the production of the enterprise is the strength and stiffness of the hot-extruded harmonica tube aluminum profile mold. The average service life is mostly below 2 tons; through careful analysis, there are certain defects in the production methods adopted by the enterprise and the molds used. Deformation or breakage.

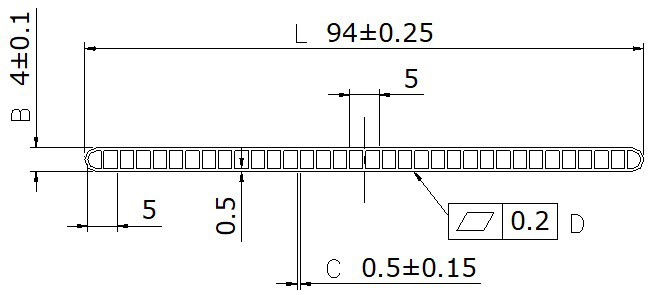

[0040] First, in terms of production methods, enterprises currently adopt the traditional production method of the original form of products, that is, carry out mold design and production according to the original shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com