Vacuum screen printing machine hole plugging pad plate jig and hole plugging method thereof

A technology for a screen printing machine and a backing plate, which is applied in the direction of screen printing machine, printing machine, rotary printing machine, etc., can solve the problems of cumbersome processing method of printing platen, increase cost, reduce efficiency, etc., and achieve simple structure and cost. low, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

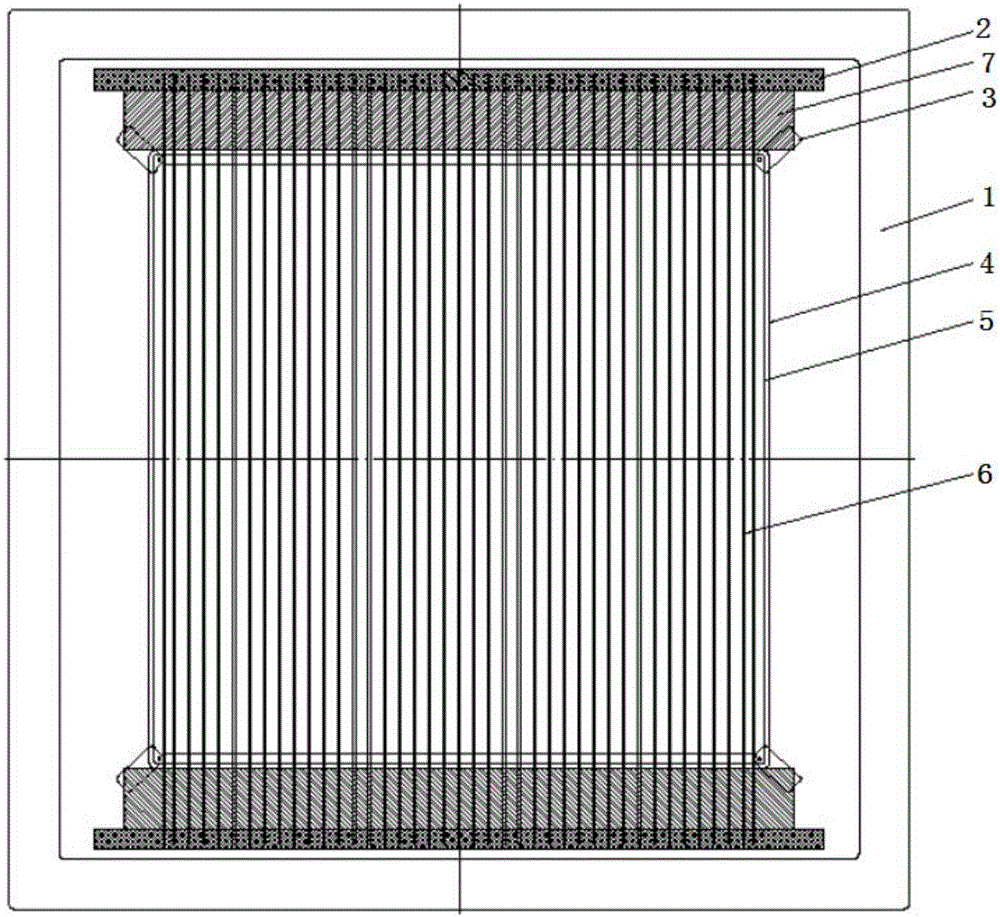

[0032] Embodiment 1 discloses a vacuum screen printing machine plug hole backing plate fixture, which is used in the plug hole printing process of the vacuum screen printing machine to prevent the ink in the hole from being depressed under the action of vacuum negative pressure when the hole is plugged .

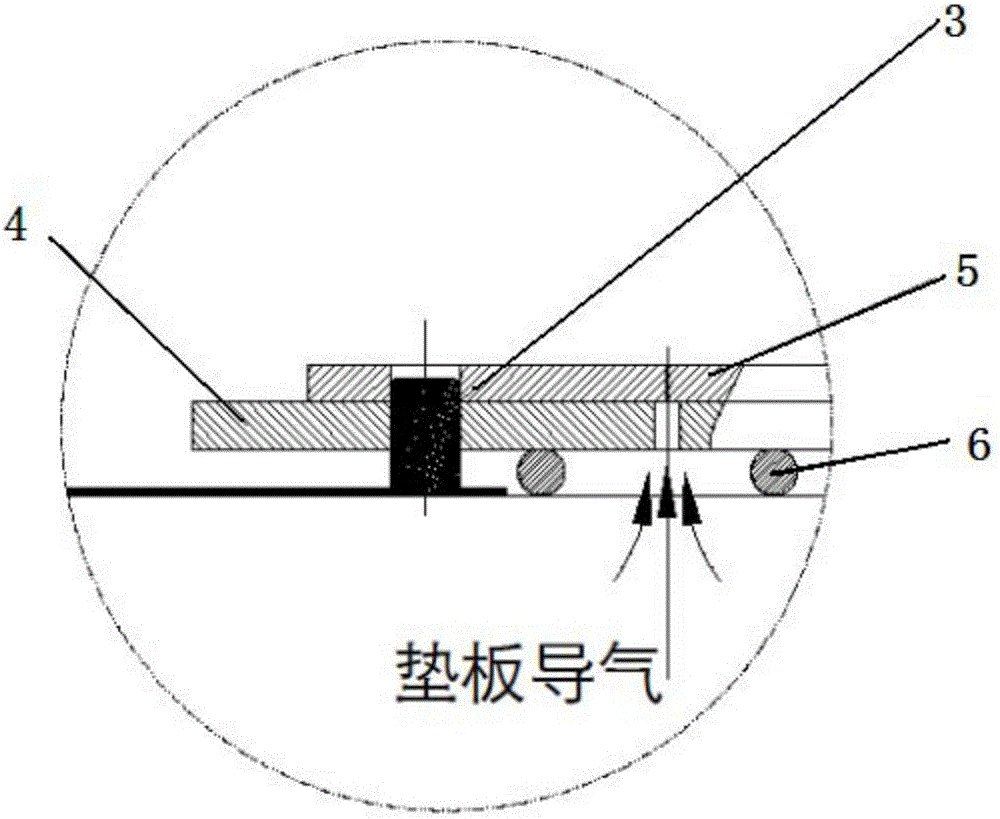

[0033] The structure of the fixture is as Figure 1-2 As shown, the jig is mainly used on the printing platen 1, the above-mentioned printing platen 1 is arranged in the printing chamber of the vacuum screen printing machine, and the two ends of the above-mentioned printing platen 1 are provided with double-sided adhesive tape 2, The above-mentioned double-sided adhesive tape 2 is arranged on the front and rear ends of the above-mentioned printing platen 1. In this embodiment, the positions of the front and rear ends of the above-mentioned printing platen 1 are based on the operator's work position. There are several aluminum pads 6 arranged between the two, and the above-m...

Embodiment 2

[0040] The vacuum screen printing machine plug hole backing plate jig disclosed in embodiment 2 is basically the same in structure as the jig in embodiment 1, the difference is that in embodiment 2, the aluminum spacer 6 is fixed on the above-mentioned printing platen 1 The method is different. In Embodiment 2, a number of aligned aluminum bar slots are provided at both ends of the above-mentioned printing platen 1 , and the distance between the above-mentioned aluminum bar slots is 10-15 mm.

[0041] The above-mentioned aluminum pads 6 are directly engaged between the above-mentioned aluminum strip slots, and the aluminum pads 6 are equally spaced on the above-mentioned printing platen 1 to form a printing area on the above-mentioned printing platen 1 .

[0042] In other embodiments, the distance between the above-mentioned aluminum pads 6 can be improved according to actual design needs, which is not limited here.

Embodiment 3

[0044] A kind of plug hole method is disclosed in embodiment 3, comprises the following steps:

[0045] Step 1. Paste the double-sided tape on the front and rear ends of the printing plate, and then evenly arrange the aluminum pads between the above-mentioned double-sided tapes according to the spacing of 10-15mm. The aluminum pads are perpendicular to the above-mentioned double-sided tapes on the horizontal plane. Adhesive tape, the above-mentioned aluminum pads form the printing area, and the left and right sides of the printing area are 5mm smaller than the two sides of the air guide plate.

[0046] Step 2. Place the air guide plate flatly on the aluminum pad, and secure the four corners of the above air guide plate with double-sided pins.

[0047] Step 3. During the printing operation, place the PCB board in the above-mentioned double-sided pins for positioning. When replacing different types of PCB boards, you only need to replace the above-mentioned air guide pad.

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com