Eye drop filling control device without pollution source

A control device and technology of eye drops, applied in liquid bottling, packaging, bottle filling and other directions, can solve the problems of eye drop contamination and pollution sources, and achieve the effect of ensuring output and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

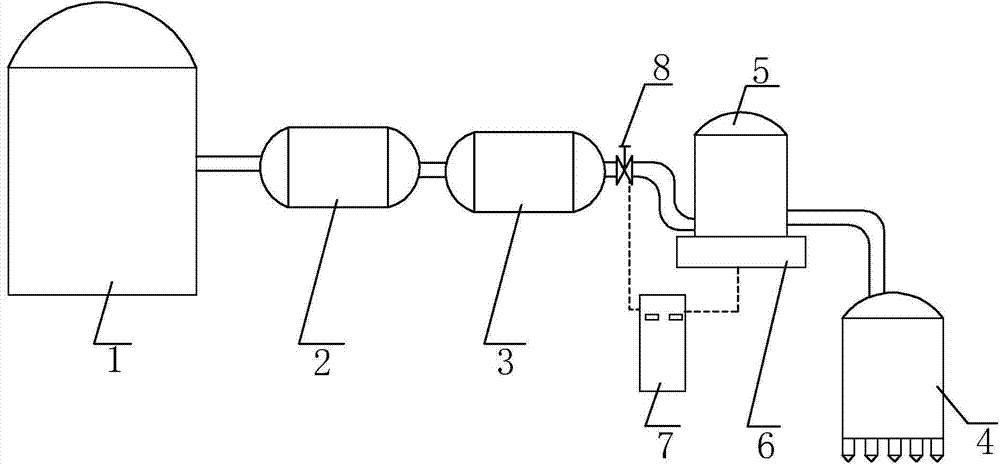

[0017] The present invention is a pollution-free eye drop filling control device, such as figure 1 , 2 As shown, it includes a large tank 1 , a first filter 2 , a second filter 3 , and a filling machine 4 sequentially connected through a delivery pipe, as well as a controller 7 , an electronic scale 6 and a buffer tank 5 . The buffer tank 5 is arranged on the electronic scale 6, and is connected between the second filter 3 and the filling machine 4, and the input port of the buffer tank 5 is provided with a solenoid valve 8, and the input of the electronic scale 6 and the controller 7 Terminals are electrically connected, and the solenoid valve 8 is electrically connected with the output terminal of the controller 7. The lower limit and the upper limit of the stock of eye drops are provided in the controller 7, and the stock of eye drops in the buffer tank 5 detected by the electronic scale 6 is sent to the controller 7 from time to time, when the electronic scale 6 When the...

Embodiment 2

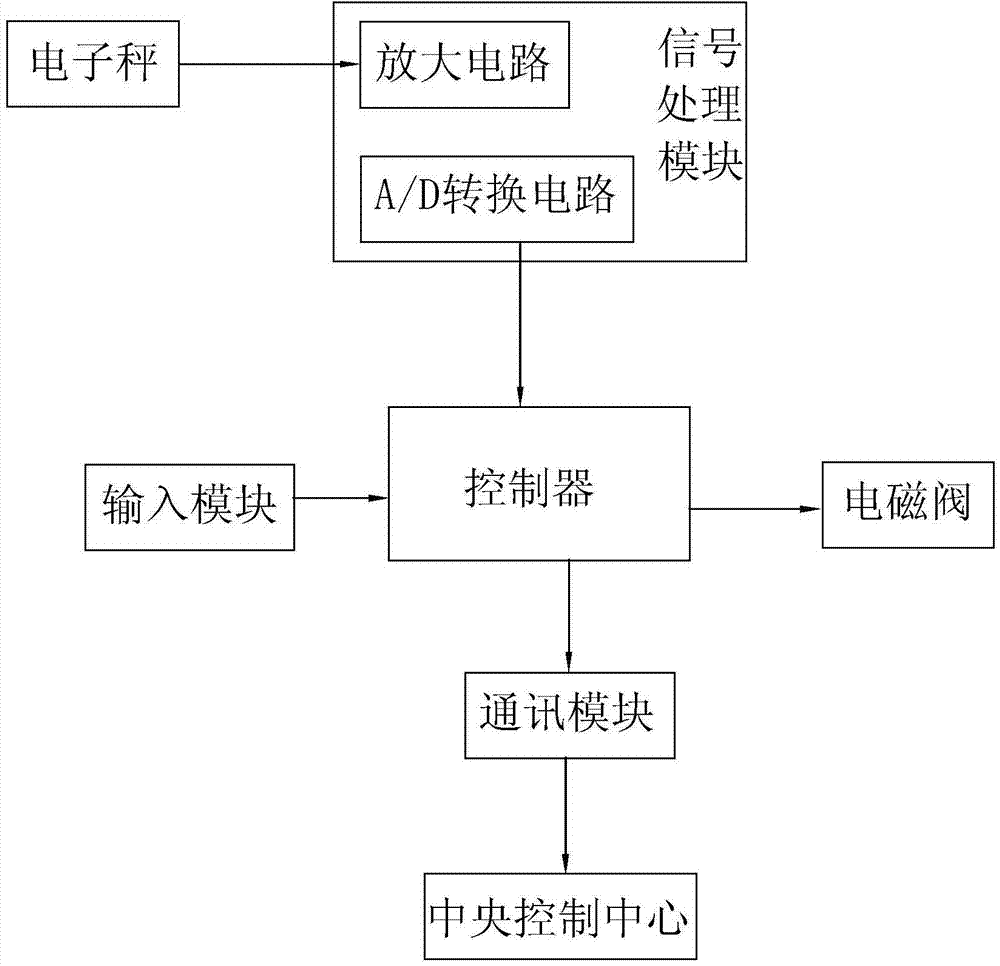

[0019] The difference between this embodiment and Embodiment 1 is that it further includes an input module, and the input module is electrically connected to the input end of the controller 7 . When the buffer tank 5 needs to be replaced, or the filling speed of the filling device is changed, in order to make the pressure difference between the second filter 3 and the filling device zero, it is necessary to change the eye drops set in the controller 7 It is more convenient and faster to set these two values by the input module.

Embodiment 3

[0021] The difference between this embodiment and Embodiment 2 is that it also includes a signal processing module electrically connected between the electronic scale 6 and the controller 7, and the signal processing module includes an amplification circuit and an A / D conversion circuit connected in sequence. The signal processing module amplifies the signal detected by the electronic scale 6 to make the controller 7 more accurate in operation processing, and performs analog-to-digital conversion on the signal through the A / D conversion circuit to reduce the processing pressure of the control, making it The processing speed is faster, and the opening or closing of the solenoid valve 8 can be controlled more accurately, thereby making the filling more accurate, and also avoiding the occurrence of bubbles in the buffer tank 5 due to large pressure changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com