Laser ablation sampling system

A sample introduction system and laser ablation technology, which are used in the preparation of test samples, material analysis by electromagnetic means, instruments, etc., can solve problems such as gas path effects, and achieve the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

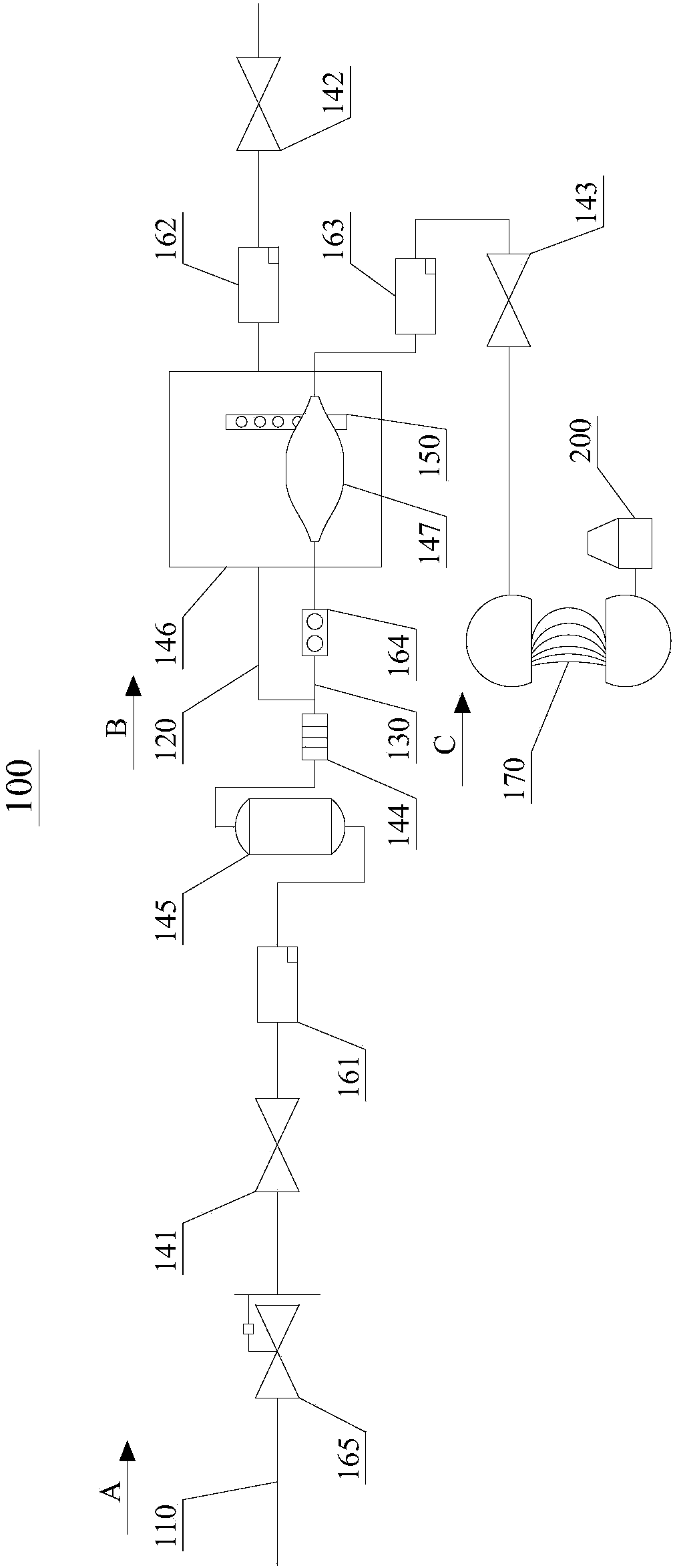

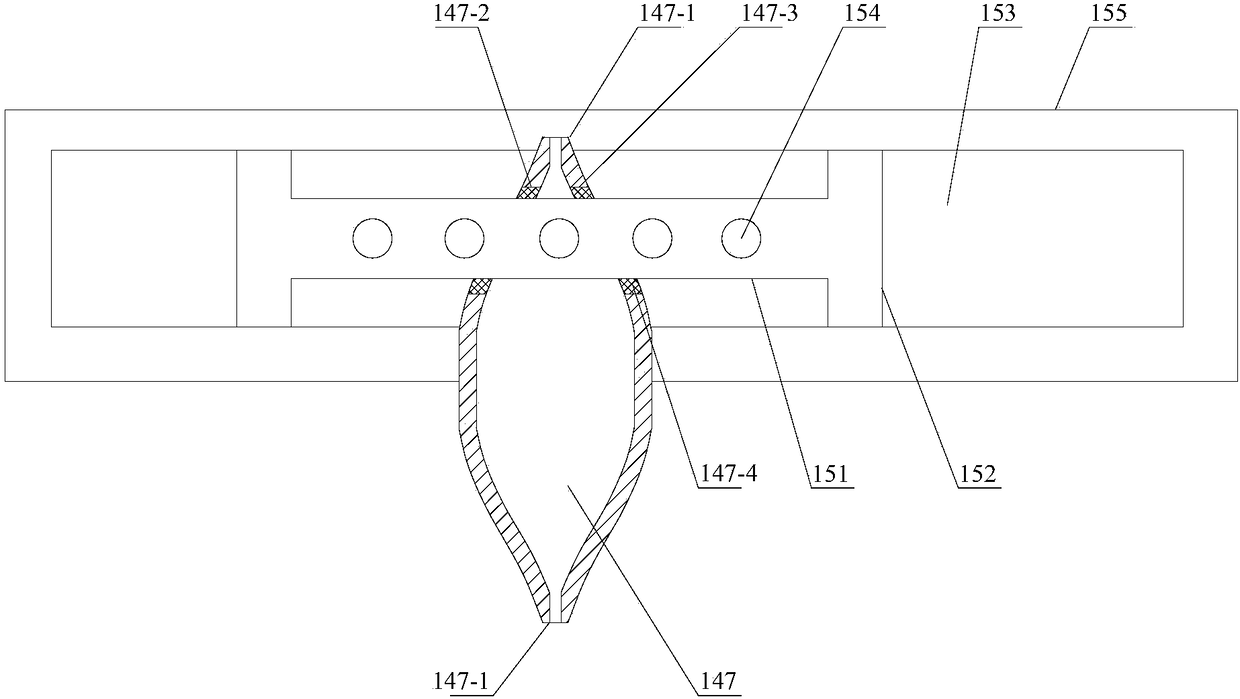

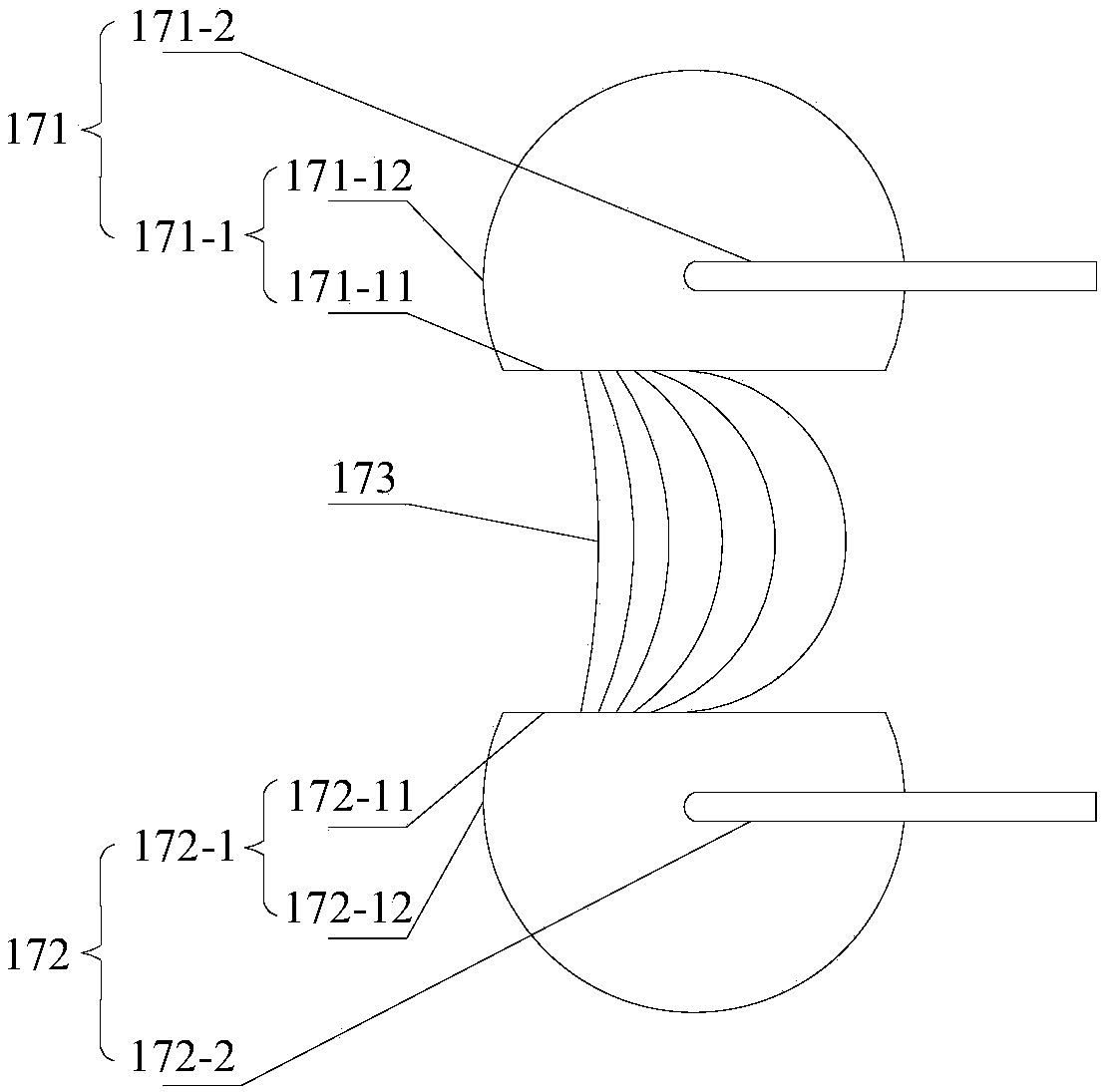

[0037] refer to figure 1 , figure 1 It is a schematic structural diagram of a laser ablation sample introduction system 100 in an embodiment of the present invention. The laser ablation sampling system 100 includes a main pipeline 110 , a first branch pipeline 120 and a second branch pipeline 130 . The main pipe 110 has a beginning and an end. During operation, the gas flows from the beginning of the main pipe 110 to the end of the main pipe 110, that is, the gas flows figure 1 Flow in the direction of A. The first branch pipeline 120 also has a beginning and an end, and the beginning of the first branch pipeline 120 is connected to the end of the main pipeline 110 . The gas flowing out from the end of the main pipeline 110 enters the first branch pipeline 120, and flows from the beginning of the first branch pipeline 120 to the end of the first branch pipeline 120, that is, the gas is figure 1Flow in the B direction. The second branch pipeline 130 also has a start end an...

Embodiment 2

[0065] refer to Figure 4 , Figure 4 It is another structural schematic diagram of the laser ablation sample introduction system 100 in the embodiment of the present invention. This embodiment also provides a laser ablation sample introduction system 100, which adds a vacuum pump 180 and a three-way valve 190 on the basis of Embodiment 1.

[0066] The three-way valve 190 has a first port 191 , a second port 192 and a third port 193 . The third interface 193 is connected to the end of the second branch pipeline 130 , and the first interface 191 is connected to the vacuum pump 180 .

[0067] The working process is as follows:

[0068] A plurality of samples are fixed on the sample holder bar 151 , and the samples are evenly arranged in the length direction of the sample holder bar 151 .

[0069] Close the second on-off valve 142 , the third on-off valve 143 and the fourth on-off valve 144 , and open the first on-off valve 141 . Carrier gas (inert gas, such as helium) is fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com