A Pressure Balance Control Method for Coal Injection System of Blast Furnace

A technology of blast furnace coal injection and balance control, applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as large pressure differences in injection tanks, and achieve the effects of low cost, simple process, and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

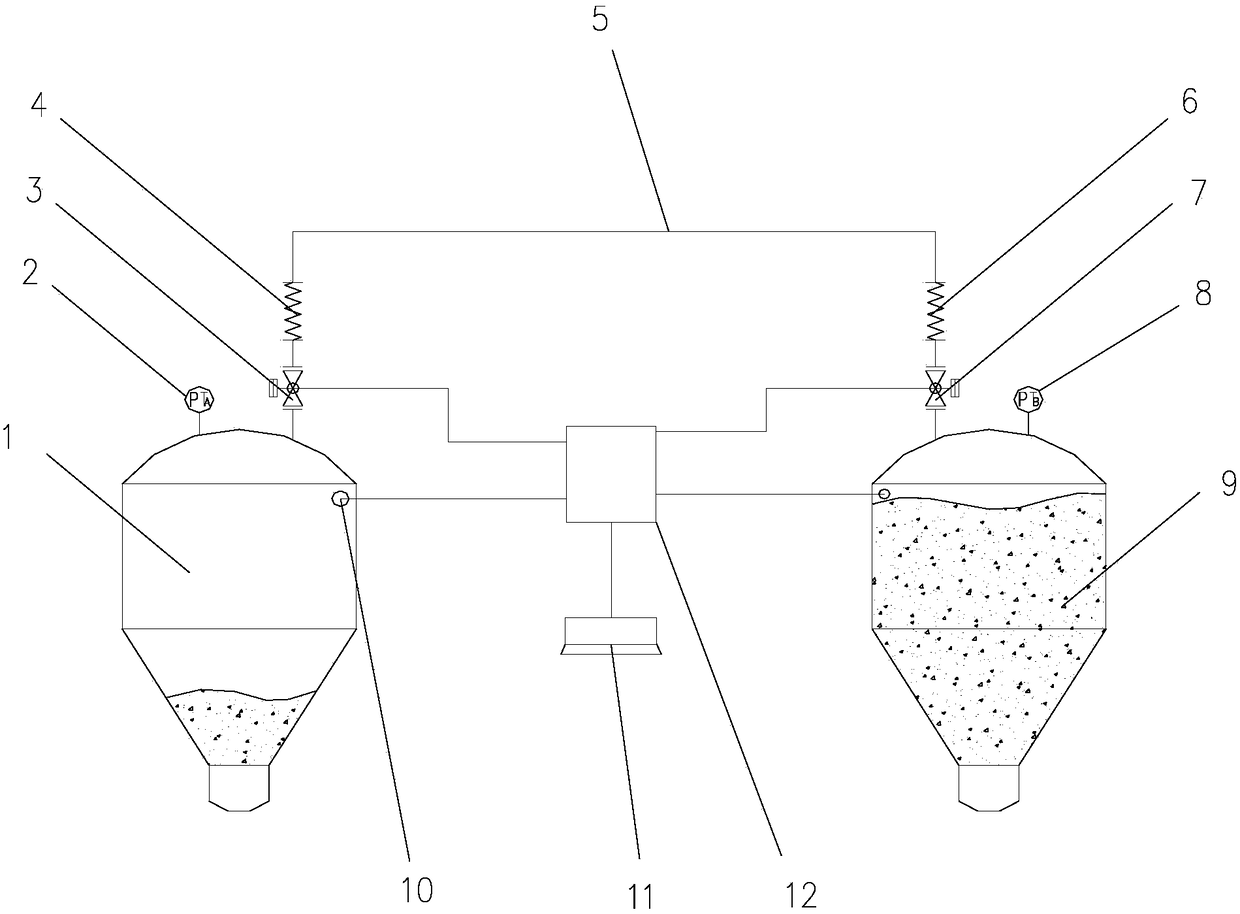

[0026] As shown in the figure, it is a structural diagram of related devices of a pressure balance control method of a blast furnace coal injection system according to the present invention. The device adopted in the present embodiment comprises the A spray tank 1 and the B spray tank 9 connected successively with the connecting pipe 5, and the first shut-off valve 3, the first metal hose 4, the second The metal hose 6 and the second shut-off valve 7 ; the A spray tank 1 and the B spray tank 9 are respectively provided with a first pressure gauge 2 and a second pressure gauge 8 .

[0027] In the present embodiment, also comprise control system, control system comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com