Fuel tank control valve

A technology for controlling valves and fuel tanks, which is applied in the direction of valve lifts, valve details, and valve devices. It can solve problems such as internal and external pressure differences, gaskets cannot be separated in time, and affect normal exhaust, and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

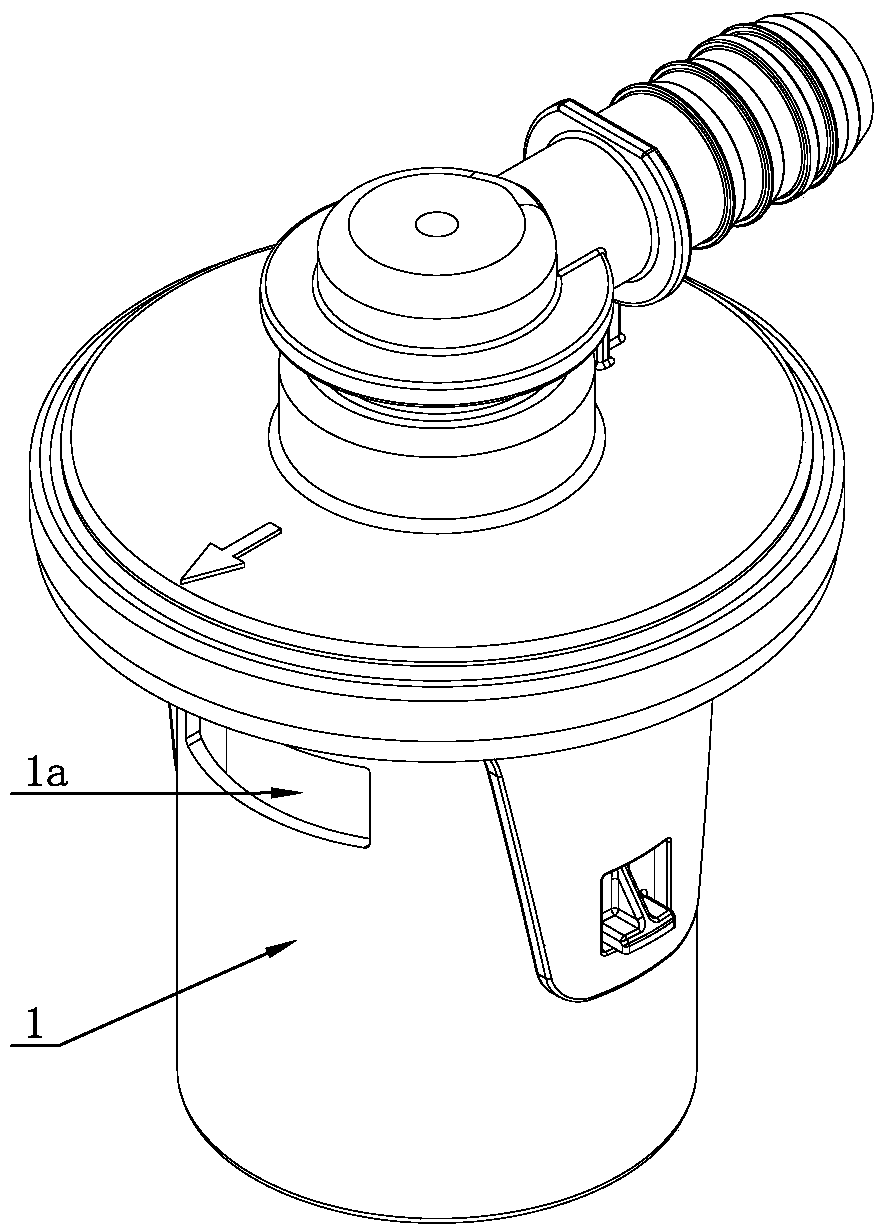

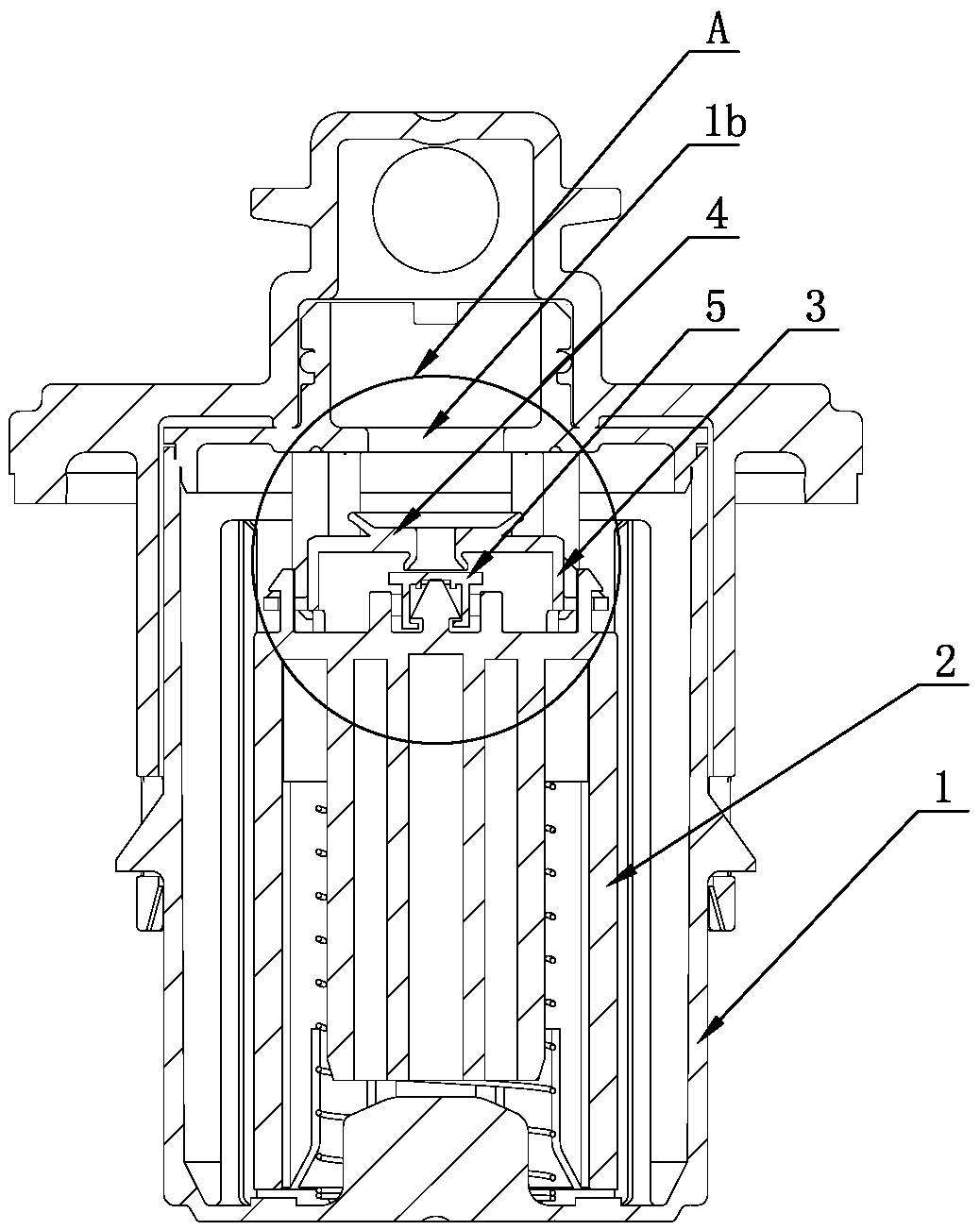

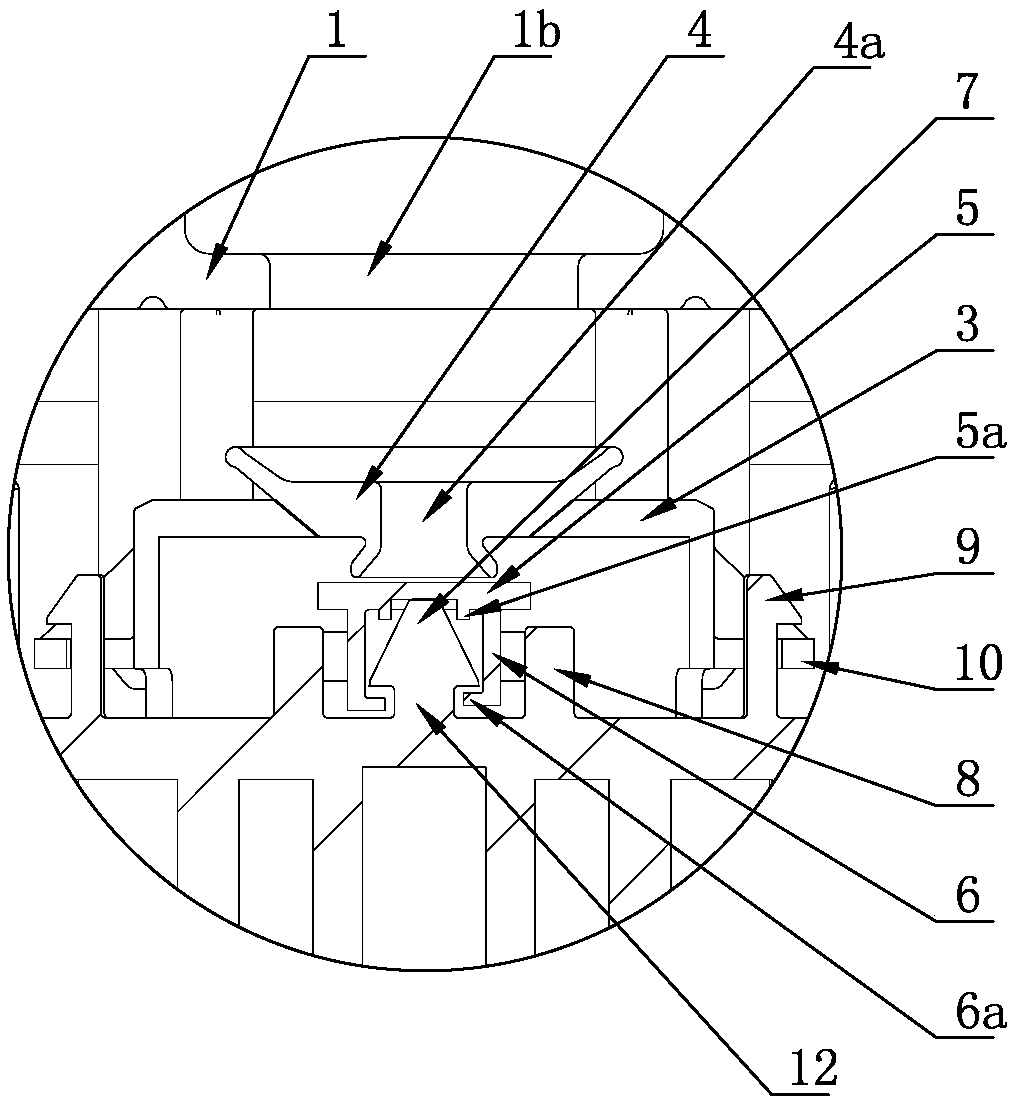

[0020] like Figure 1-6 The shown fuel tank control valve includes a float 2 arranged in the valve body 1, the top of the valve body 1 is provided with an exhaust hole 1b, the side of the valve body 1 is provided with a liquid inlet hole 1a, and the bottom of the valve body 1 is provided with a The oil discharge hole, the top surface of the float 2 is equipped with a sealing cover 5, the outer periphery of the top of the float 2 is provided with a support frame 3, and the center of the support frame 3 is installed with a sealing gasket 4 that cooperates with the sealing cover 5 and the exhaust hole 1b, and the center of the sealing gasket 4 is There is a vent hole 4a, the top and bottom of the gasket 4 are processed into a trumpet-shaped structure, the top of the gasket 4 is matched with the vent hole 1b, the bottom of the gasket 4 is matched with the sealing cover 5, and the sealing cover 5 is passed through the push-pull assembly It is movably installed on the top of the flo...

Embodiment 2

[0022] like Figure 1-5 A fuel tank control valve shown in . There is an oil discharge hole, a sealing cover 5 is installed on the top surface of the float 2, a support frame 3 is set on the outer periphery of the top of the float 2, and a sealing gasket 4 is installed in the center of the support frame 3 to cooperate with the sealing cover 5 and the exhaust hole 1b. 4 is provided with a ventilation hole 4a in the center, the top and bottom of the gasket 4 are processed into a trumpet-shaped structure, the top of the gasket 4 is matched with the vent hole 1b, the bottom of the gasket 4 is matched with the sealing cover 5, and the sealing cover 5 is The push-pull assembly is movably installed on the top of the float 2. The push-pull assembly is used to push the seal cover 5 to move upward when the float 2 rises. When the float 2 descends, one side of the seal cover 5 pulls it down. The push-pull assembly includes a Pillar 12, a boss 7 is arranged on the pillar 12, a pair of gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com