Metering and distributing assembly and coating system comprising same

A technology of components and gear sets, applied in the field of coating systems, can solve problems such as adverse effects on product quality, time-consuming and laborious maintenance of coating systems, and unsatisfactory appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments according to the present invention will hereinafter be described in detail with reference to the accompanying drawings. In the description of the drawings, the same or corresponding parts are denoted by the same numerals and symbols, and repeated descriptions will be omitted.

[0049] In the following description, the terms "upper", "lower", "left", "right", "front", "rear", etc. (if any) indicating directions are only used to describe the accompanying drawings, and do not constitute the essence of the present invention. sex restrictions.

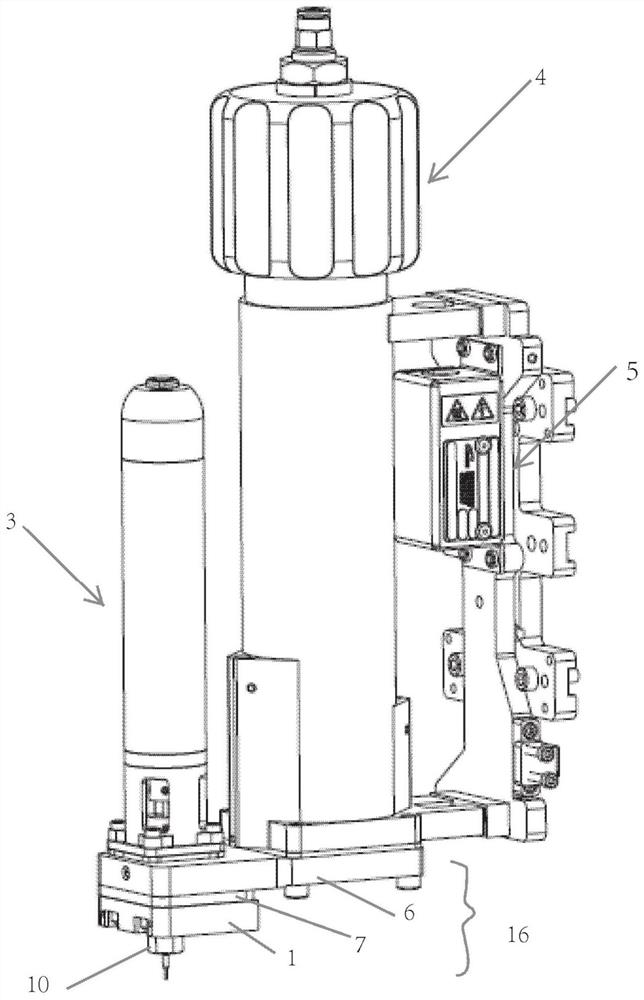

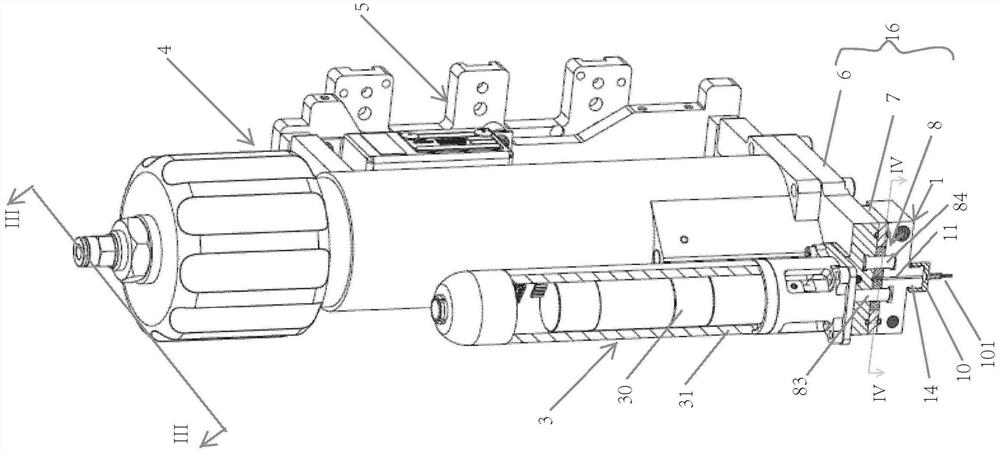

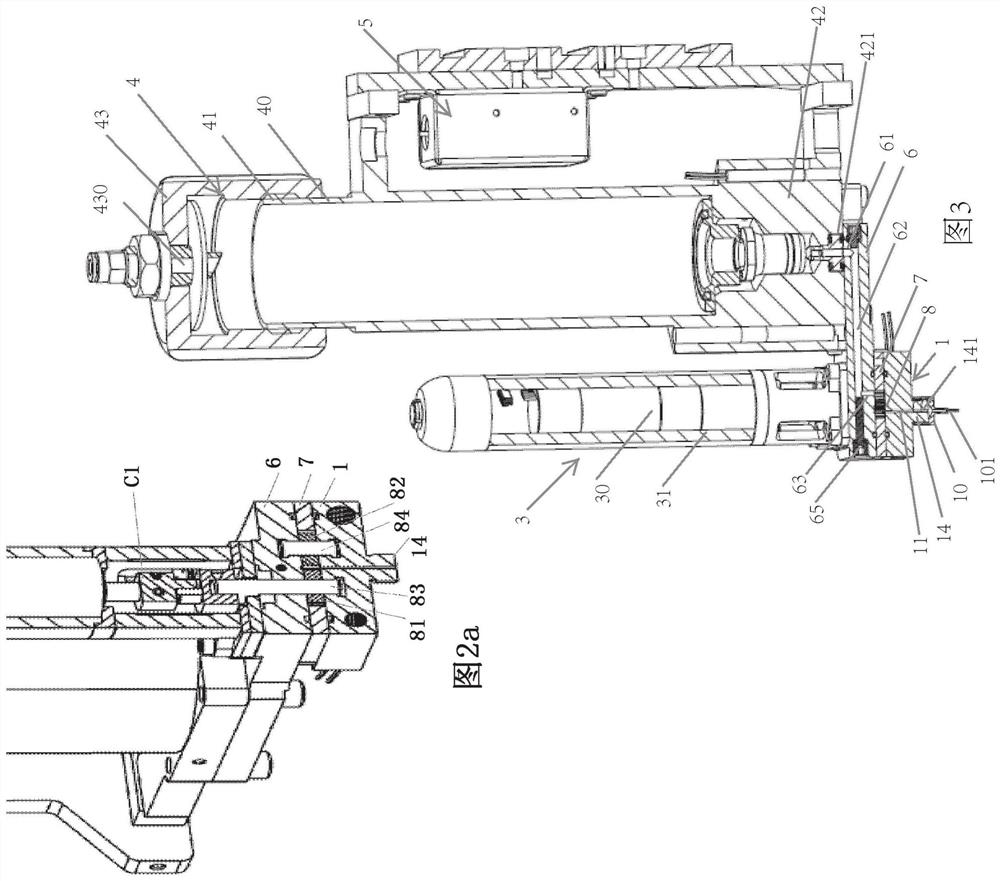

[0050] figure 1 is a perspective view of a VCP-embedded coating system according to a first embodiment of the present invention, and figure 2 is a view showing the drive assembly of the coating system and the VCP in cross-section. A VCP-embedded coating system according to the present invention is used for dispensing fluids. refer to figure 1 , the coating system generally includes a cartridge assembly 4 and a meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com