Spiral separating device

A separation device and vortex technology, applied in swirl devices, devices whose axial direction can be reversed, etc., can solve problems such as being easily taken away by the airflow again, affecting the separation effect, and increasing the system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

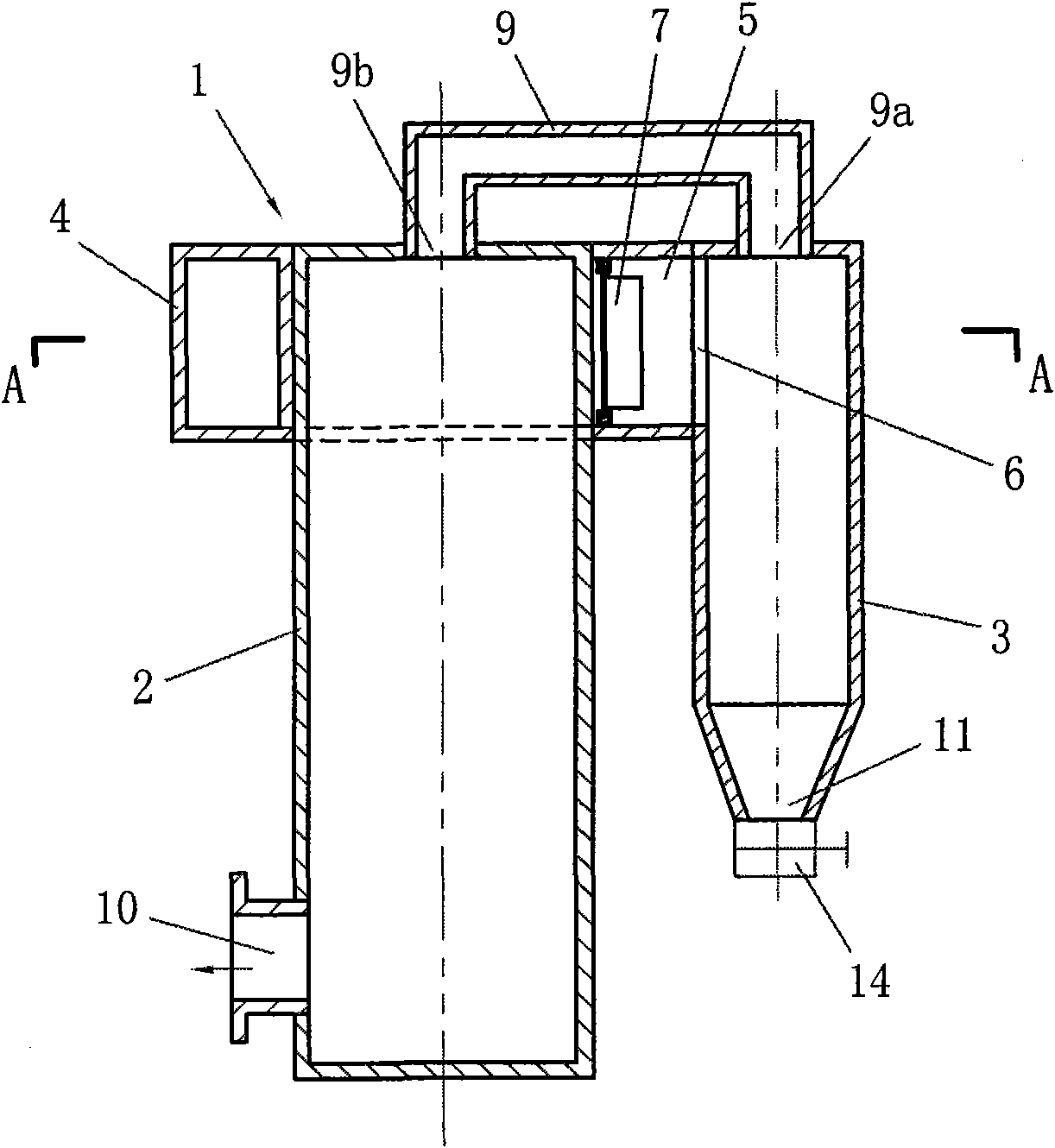

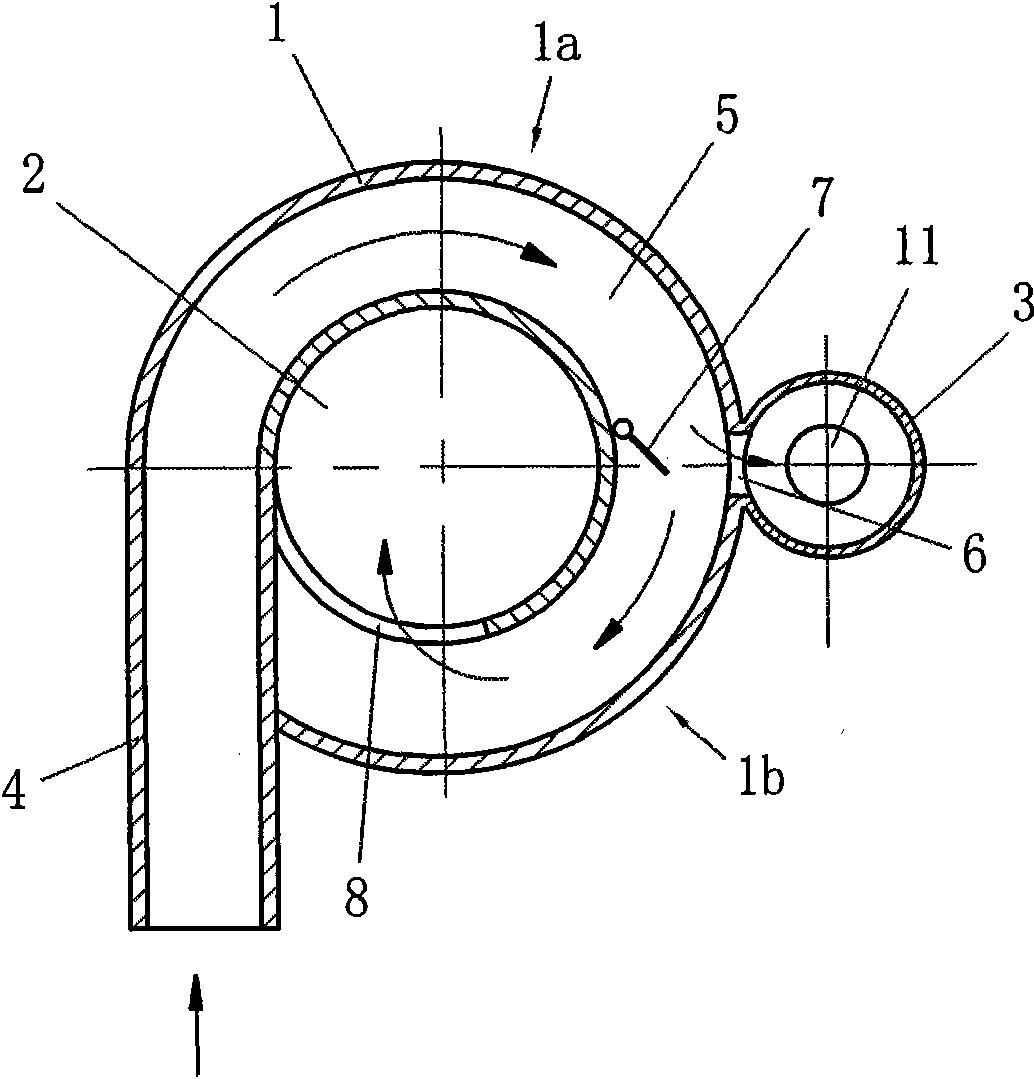

[0021] Example 1, see figure 1 , figure 2 .

[0022] A volute case 1, a main cylinder 2, and an auxiliary cylinder 3 are provided. The volute case 1 is provided with an air inlet pipe section 4, and the volute case 1 has a volute swirl air passage 5. The pipe hole of the air inlet pipe section 4 is connected to the The spiral swirl air passage 5 communicates; the upper part of the auxiliary cylinder 3 is located outside the volute case 1, and the upper part of the main cylinder 2 is located in the volute case 1. In this example, the upper wall of the main cylinder 2 forms a spiral spiral The inner wall of the flow air channel 5 and the outer wall of the middle section of the volute swirl air channel 5 are provided with a channel 6 communicating with the inner cavity of the auxiliary cylinder 3, and at least one deflector 7 is provided at the position of the channel 6 in the volute swirl air channel 5, The deflector 7 can swing freely under the action of the air flow, and re...

Embodiment 2

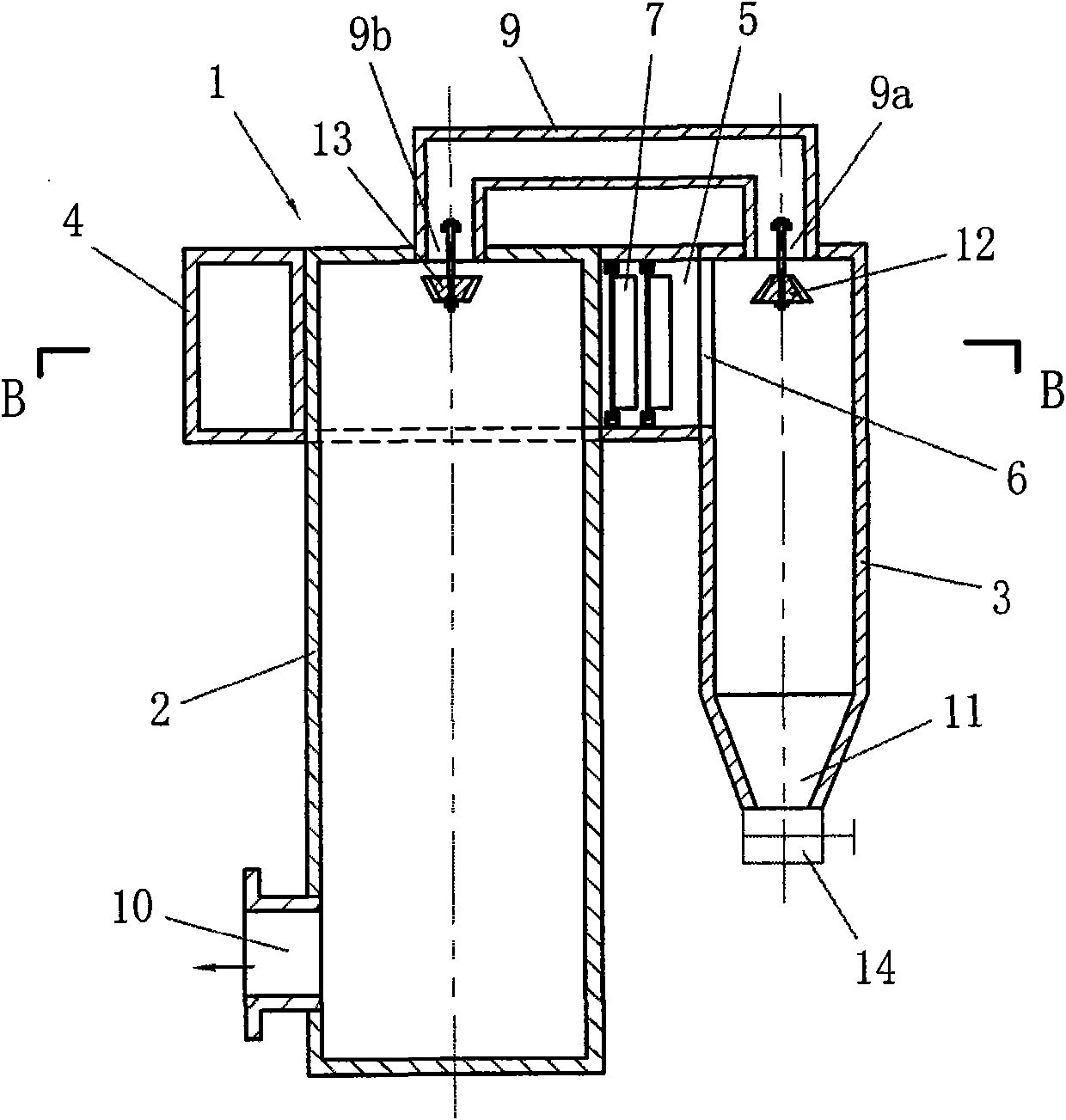

[0025] Example 2, see Figure 3 to Figure 6 .

[0026] This embodiment is based on the structure of Embodiment 1. A secondary separator 12 is provided at the nozzle 9a of the pressure balance air duct pipe 9 communicating with the inner cavity of the auxiliary cylinder 3 to perform secondary separation on the particles entering the auxiliary cylinder. , the secondary separator 12 in this example is an upper cone secondary separator, and the secondary separator 12 can also be a separator of other structural forms, and the diameter of the lower part of the cone 12a of the upper cone separator is greater than or equal to The diameter of the nozzle 9a of the pressure balance air duct pipe 9, during implementation, the diameter of the lower part of the cone 12a is preferably slightly larger than the nozzle diameter of the pressure balance air duct pipe 9, and the diameter of the upper part of the cone 12a is less than the diameter of the nozzle 9a, and the diameter of the cone 12a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com