Direction determining device in drilling hole for crustal stress testing according to hydrofracturing method

A technology of orientation device and in-situ stress, applied in the directions of surveying, earth-moving drilling, and fluid mining, etc., can solve the problems of loosening and deflection, error, large positioning, etc., and achieve the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

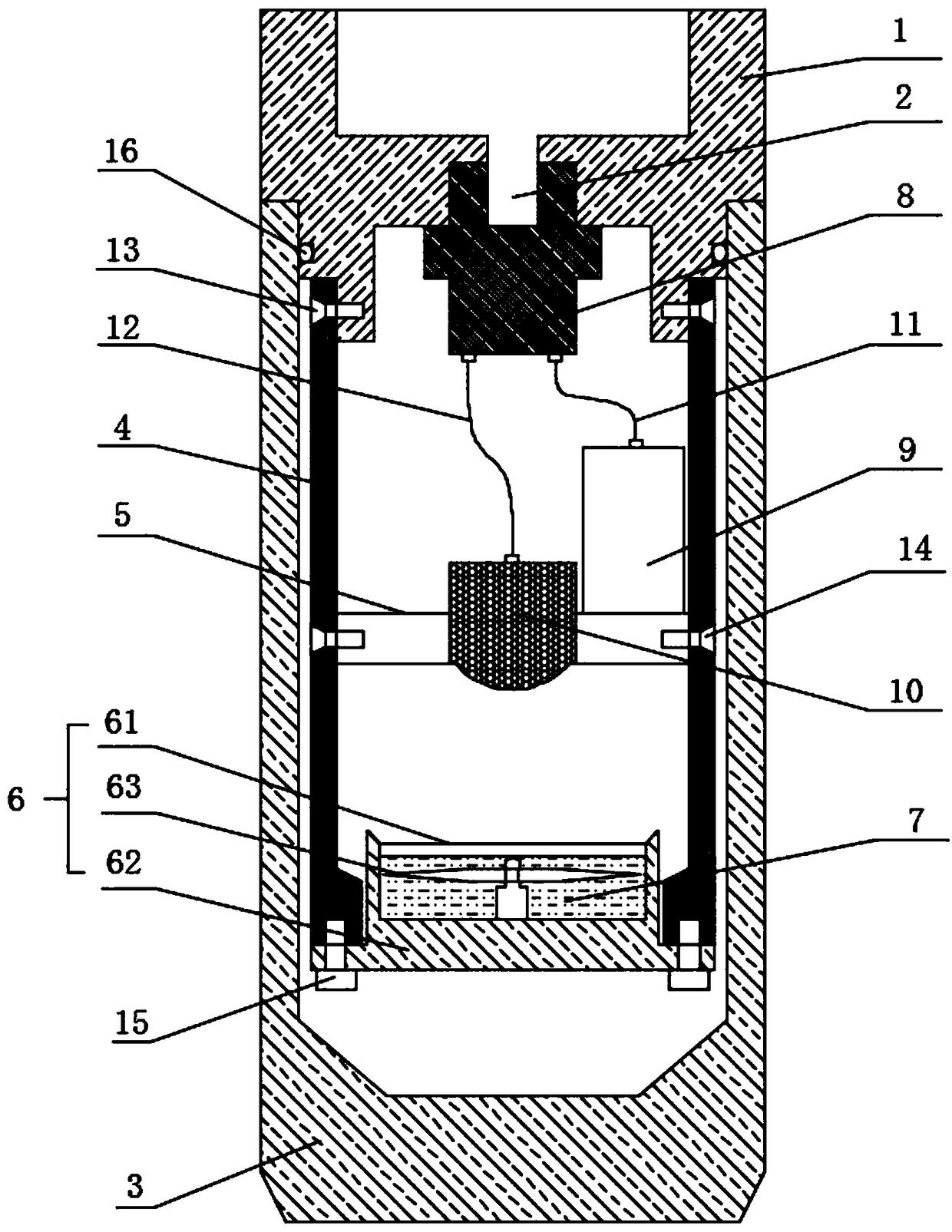

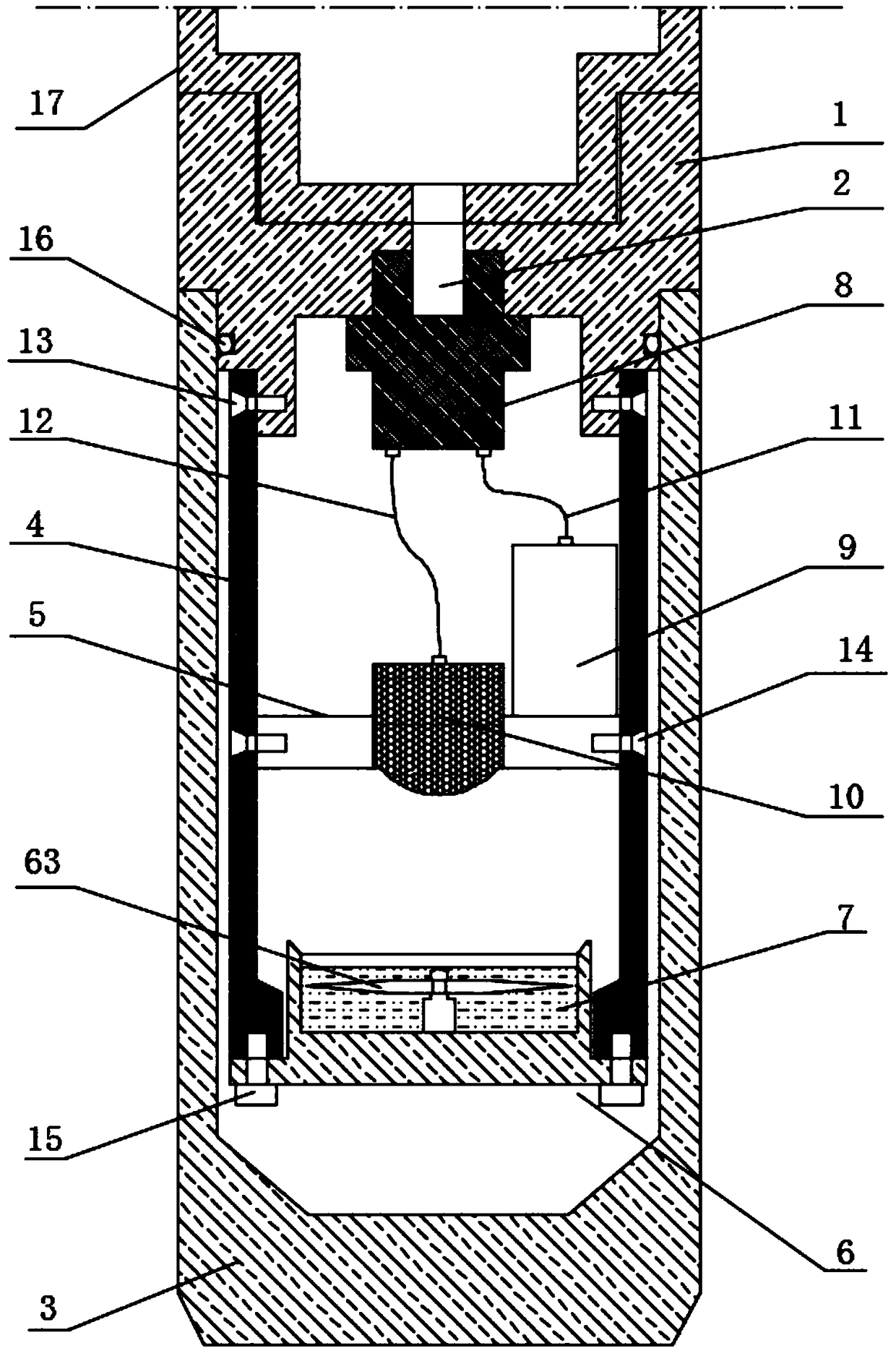

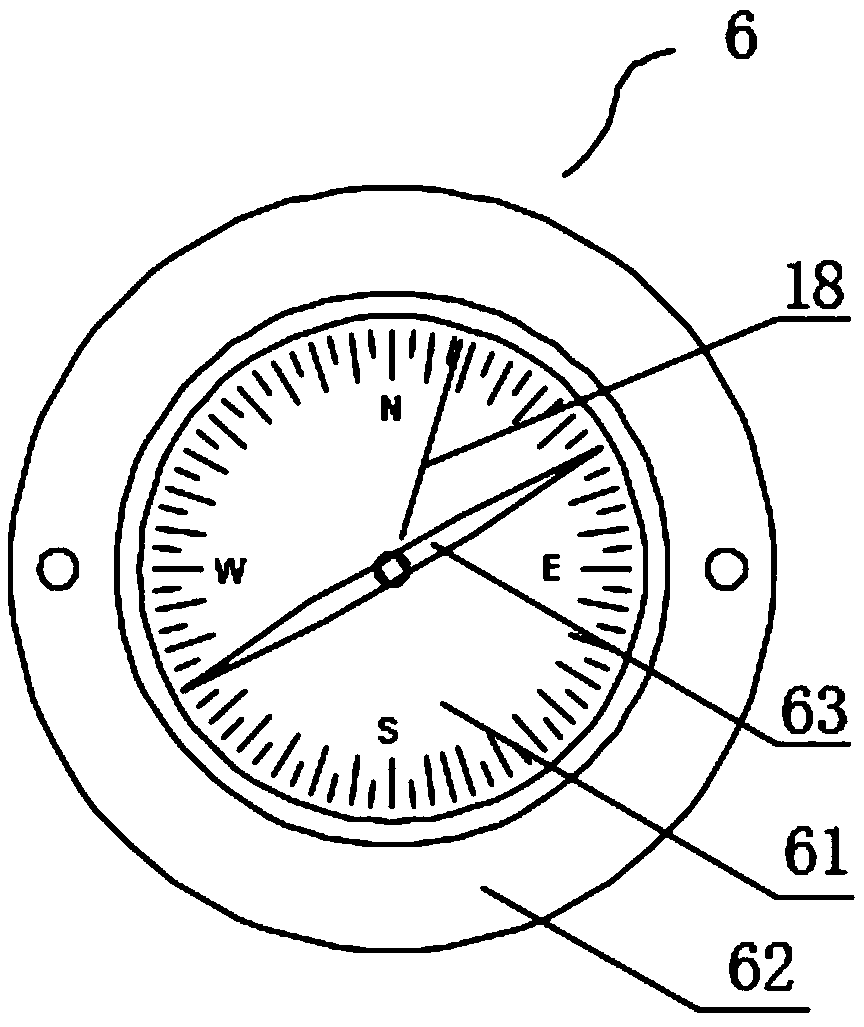

[0019] like figure 1 and figure 2 As shown, a borehole orientation device for hydraulic fracturing ground stress testing provided by the present invention includes a top seat 1 and an outer casing 3, the upper end of the top seat 1 is connected with the lower end of the packer 17 through threads, and the top The lower end of the seat 1 is threadedly connected to the upper end of the outer sleeve 3, and an inner support 4 and a pressure switch 8 are connected to the lower end of the top seat 1. The inner support 4 and the pressure switch 8 are all located inside the outer sleeve 3, and there is also a A battery pack 9, an ultraviolet lamp 10 and a geological compass 6 encapsulated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com