Casting method for pouring and molding thin-wall investment pattern steel casting

A technology of pouring molding and investment casting, which is applied in the casting field of thin-walled investment steel castings. It can solve the problems of casting shrinkage cavity and casting deformation, and achieve the effect of reducing the production cost of enterprises and improving the qualified rate of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

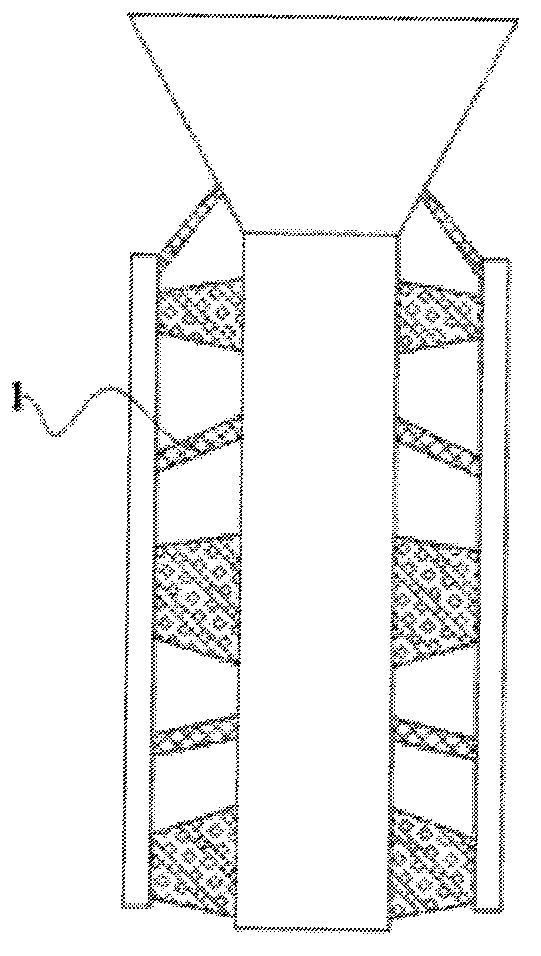

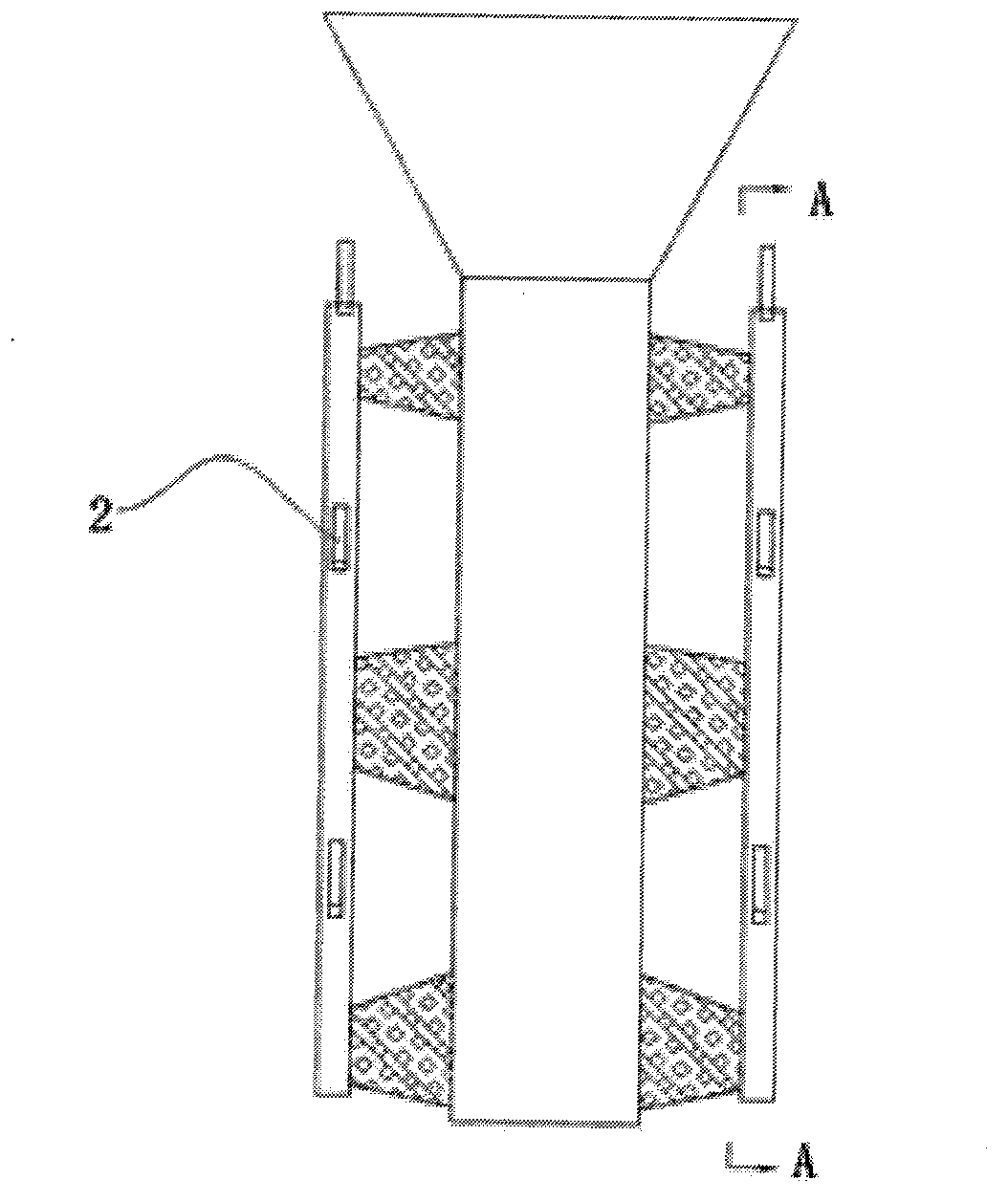

[0030] Such as figure 2 , image 3 , Figure 4 with Figure 5 As shown, the casting method of the thin-walled investment casting steel casting provided by the present embodiment includes the following steps:

[0031] a. First prepare a plurality of straight iron wires with a diameter of 0.5mm and a length of 50mm, and apply a layer of wax with a thickness of 0.1mm on the outer surface of the straight iron wires;

[0032] b. Then insert the straight iron wire in the previous step into the wax mold group 3 after the tree is assembled, and the insertion depth is 4mm;

[0033] c. Then dip the straight iron wire in the previous step with the wax mold group 3 into paint slurry and coat hanging sand;

[0034] d. After forming the mold shell 4 on the surface of the wax mold group 3, first destroy part of the mold shell 4 on the surface of the other end of the straight iron wire, extract the straight iron wire, and then dewax and roast;

[0035] e. When pouring molten steel at th...

Embodiment 2

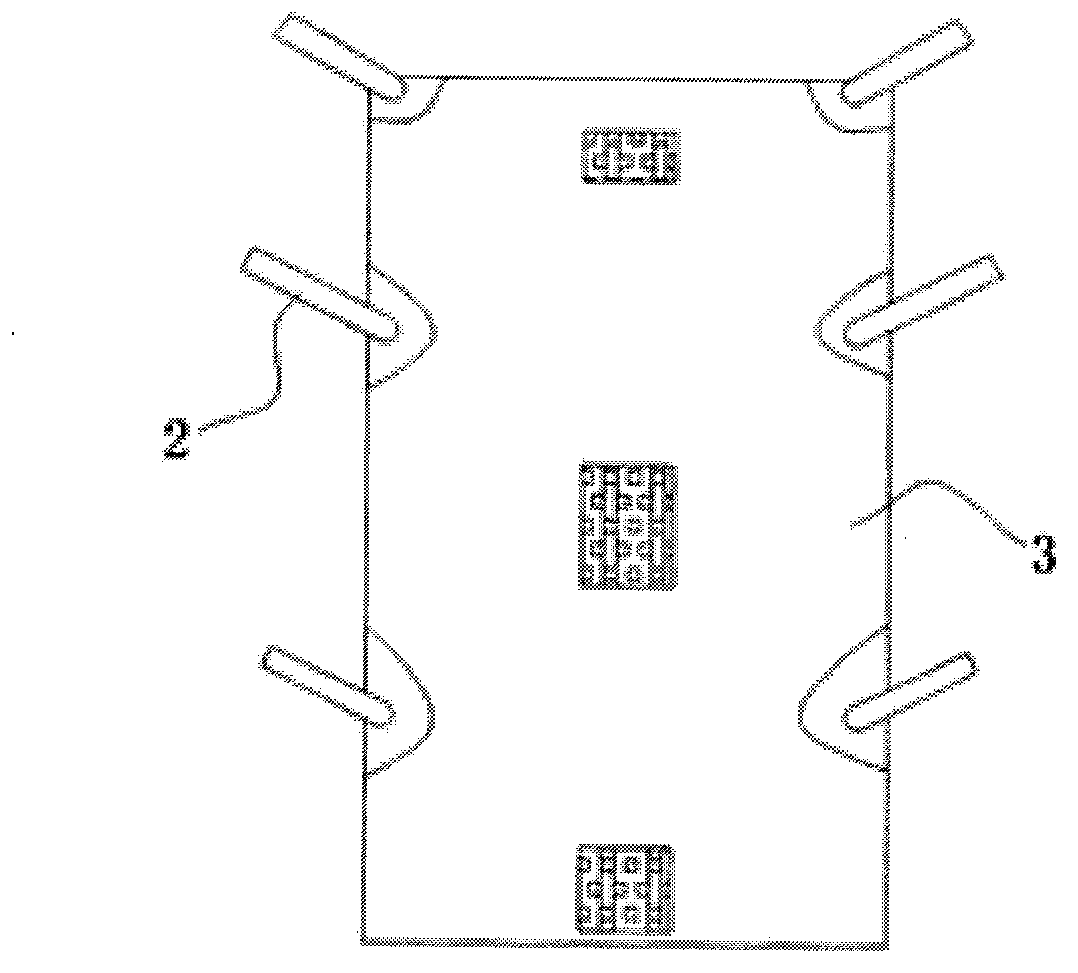

[0037] Such as Image 6 , Figure 7 , Figure 8 with Figure 9 As mentioned above, the thin-walled investment casting casting method provided by this embodiment includes the following steps:

[0038] a. First, prepare multiple hard plastic wires with a diameter of 1mm and a length of 100mm. The bending strength of the above-mentioned hard plastic wires is greater than 15Mpa, and the gasification temperature of burning loss is lower than 800°C;

[0039] b. Then glue one end of the hard plastic line in the previous step to the wax mold group 3 after the tree has been assembled, and the bonding length is 6mm;

[0040] c. Then dip the hard plastic wire in the previous step with the wax mold set 3 and paint the coating slurry and hang sand;

[0041] d. After the mold shell 4 is formed on the surface of the wax mold group 3, dewaxing and roasting are carried out, and the hard plastic line is burned to form a cavity 5 on the mold shell 4;

[0042] e. When pouring the molten stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com