Adhesive compound for hot-sealing inserts

A hot-pressing bonding and adhesive technology, which is applied in the direction of adhesives, adhesive heating bonding methods, adhesive types, etc., can solve the problems of loss of three-dimensional configuration, high cost, inability to obtain results, etc., and achieve good separation. The effect of strength, simple manufacture, and simple handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

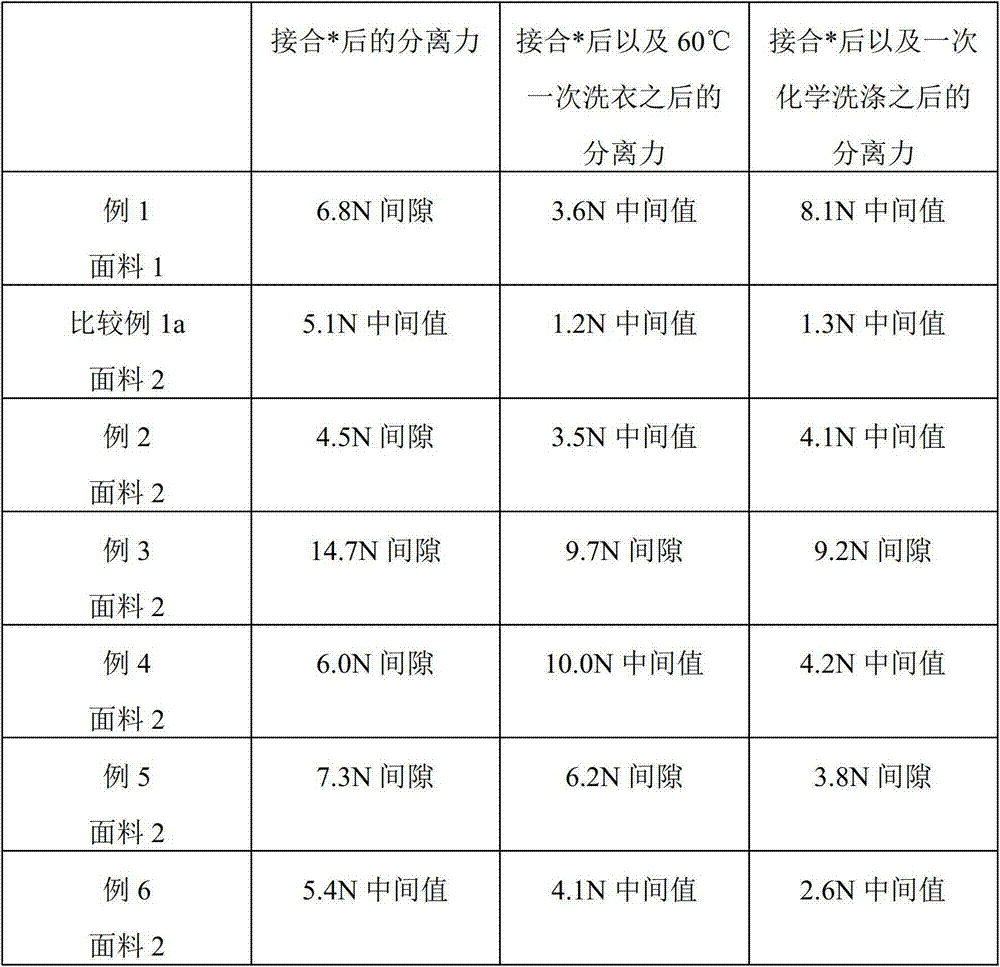

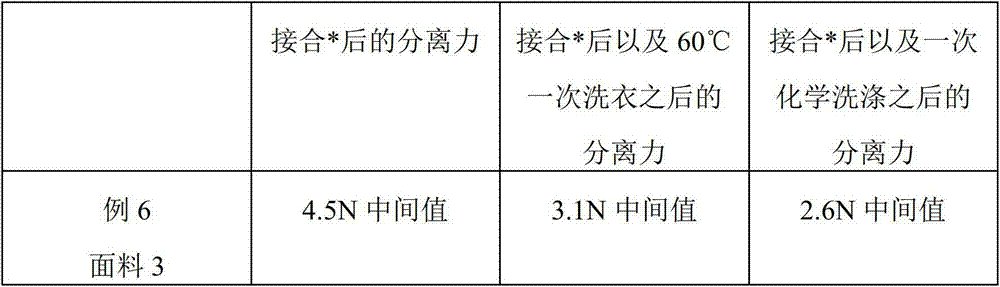

Examples

example 1

[0046] At room temperature, 290 g (56% by weight of the total weight of the undried adhesive including all ingredients) is based on self-crosslinking styrene with a glass transition temperature of Tg = 2°C, a solids content of 60%, and slightly viscous - Aqueous dispersion of polymer of acrylate-copolymer added as viscose to 150 g of water. To this mixture, 1.5 g of melanin based on carbon black and 60 g (11.6% by weight of the total weight of the undried adhesive including all components) of copolyamide (melting temperature range from 90 to 160° C.) were added with stirring. hot melt adhesive. Subsequently, 15 g of a polyacrylate / acrylic acid copolymer were introduced as an aqueous dispersion with a solids content of 33% as thickener. After a stirring time of 30 minutes and a maturation period of 24 hours, the paste was embossed onto the carrier material by means of a squeegee through a perforated template (CP180, hole diameter 0.43 mm) by means of the paste pressing method ...

example 2

[0048] At room temperature, 290 g (56% by weight of the total weight of the undried adhesive including all ingredients) was based on carboxyl-modified A polymer emulsion of acrylic polymer was added as viscose to 150 g of water. To this mixture, 60 g (11.6% by weight of the total weight of the undried adhesive including all components) of hotmelt adhesive based on copolyamide (melting temperature range 90 to 160° C.) are added with stirring. 15 g of a polyacrylate / acrylic acid copolymer were introduced into the mixture as a thickener as an aqueous dispersion with a solids content of 33%. After a stirring time of 30 minutes and a maturation period of 24 hours, the paste was embossed onto the carrier material by means of a squeegee through a perforated template (CP180, hole diameter 0.43 mm) by means of the paste pressing method (rotary screen printing), The carrier material is thermally cured by PS method with 24g / m 2 A man-made fiber nonwoven by weight per unit area consisti...

example 3

[0050] At room temperature, 145 g (accounting for 50% by weight of the total weight of the undried adhesive including all ingredients) based on acrylate (with a glass transition temperature (DSC) of Tg = -43 ° C, a minimum film formation temperature of about 2 A man-made fiber non-woven fabric with a weight per unit area consisting of 65% polyamide fibers and 35% polyester fibers. The printed nonwovens were dried at 130° C. for 90 seconds in an air-circulating oven. The layer of adhesive after drying can reach 20g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com