Alloy steel combined frog in wedge-shaped structure

An alloy steel and wedge-shaped technology, applied in the direction of switch, road, track, etc., can solve the problems of low overall stability, driving safety, difficulty in line maintenance, and loose bolts, etc., to facilitate line maintenance, simple structure, and easy Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

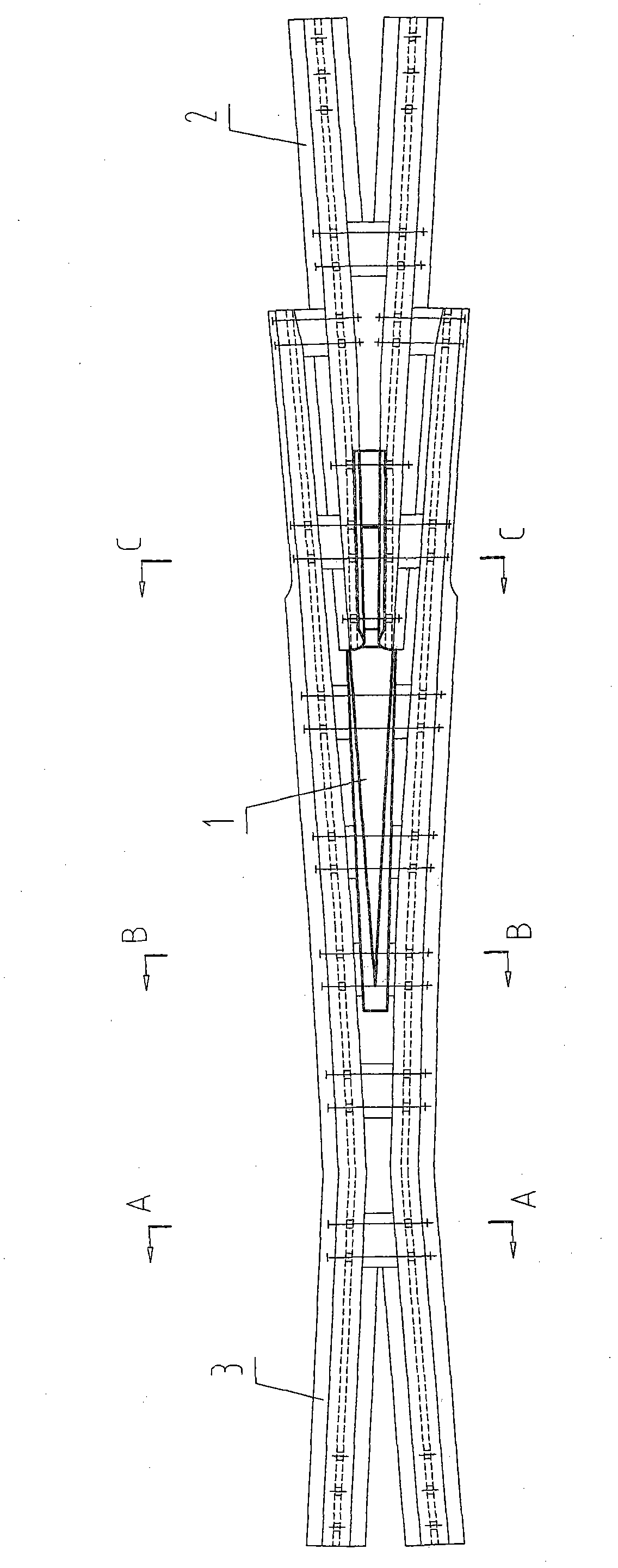

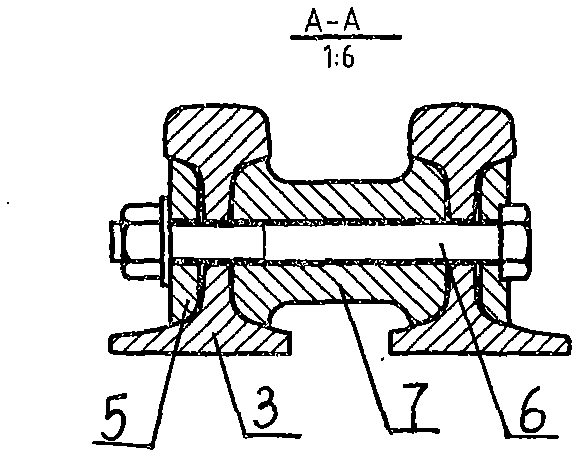

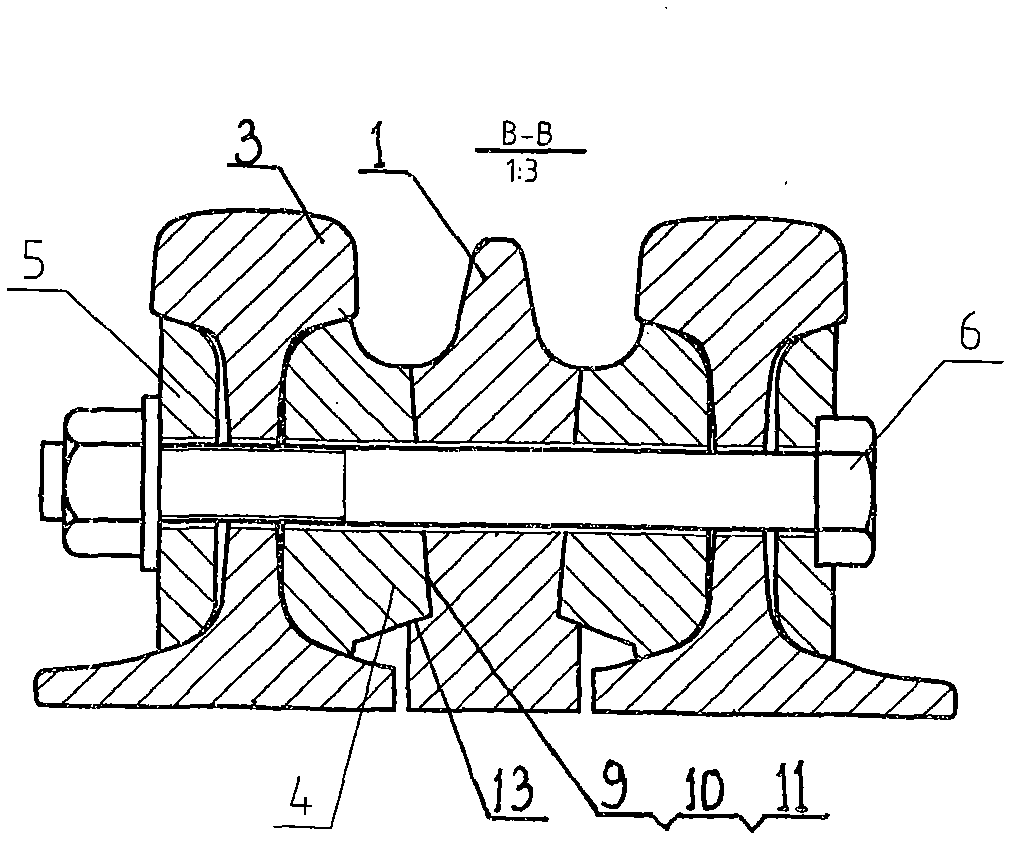

[0020] Attached below figure 1 , 2 , 3, 4, 5, 6, 7, 8 describe an embodiment of the present invention in detail.

[0021] A wedge-shaped alloy steel combined frog has an alloy steel core rail 1, a heel rail 2 and a wing rail 3. Two mutually symmetrical grooves 11 are formed on both side walls of the rail waist 8 of the alloy steel core rail 1, and the sides of the grooves 11 form a slope I9 with the lower end inclined inwardly of the rail waist, and the bottom of the groove 11 Boss 12 is formed to make the cross-sectional shape of rail waist 8 approximately wedge-shaped; the inner end surface of wedge-shaped spacer iron 4 is slope II10 that fits with slope I9, and the lower end surface is plane II13 that fits with boss 12.

[0022] The two wing rails 3 are symmetrically located on both sides of the alloy steel core rail 1, and the two wedge-shaped spacer irons 4 are symmetrically located between the wing rail 3 and the alloy steel core rail 1, and the outer end faces of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com