Temperature and pressure control method for hydrogenation process and design method and application of temperature and pressure control method

A technology of pressure control and process, applied in the petroleum industry, hydrocarbon oil cracking, hydrocarbon oil treatment, etc., can solve problems such as no better solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

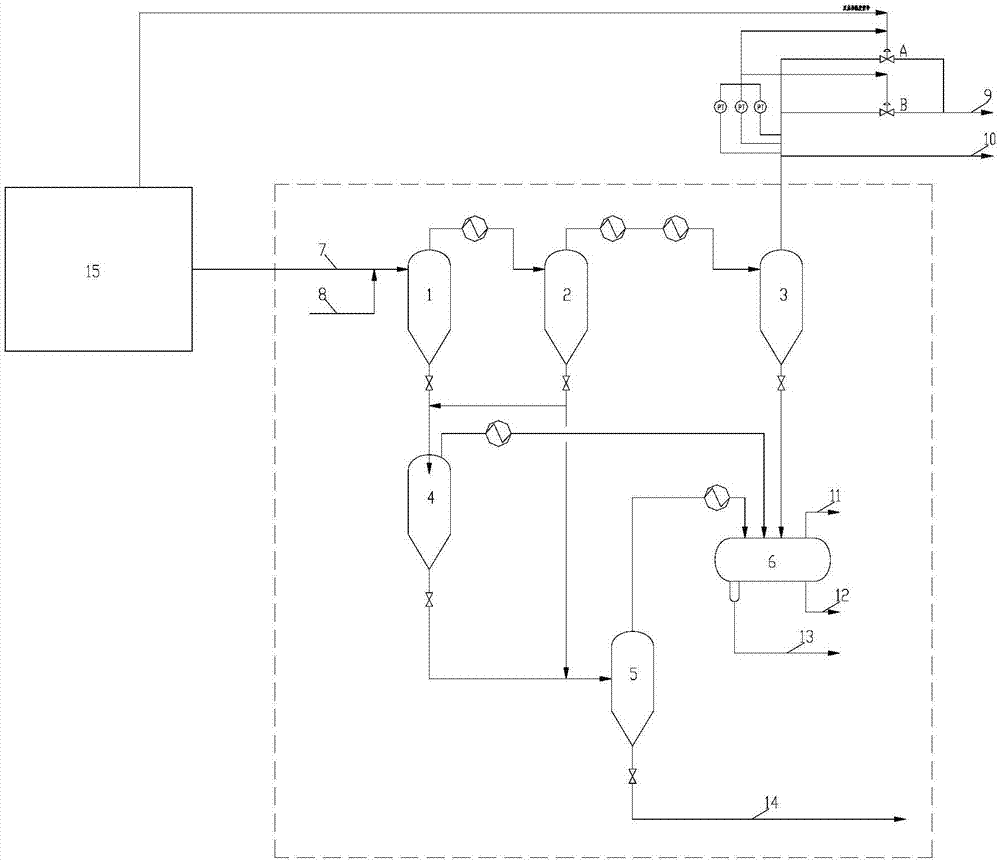

[0024] For further elaborating specific features of the present invention, will combine figure 1 To illustrate, what this example introduces is the depressurization process of the oil-coal slurry bed (with internal circulation structure) hydrogenation process, including such as figure 1 Reactor 15 connected by the connection method shown, hot high fraction 1, warm high fraction 2, cold high fraction 3, hot low fraction 4, temperature low fraction 5, cold low fraction 6, the materials in each stage marked in the figure are respectively Reaction product 7, cold oil 8, pressure relief line 9, cold high fraction gas phase product 10, cold low fraction gas phase product 11, cold low fraction liquid phase product 12, waste water 13, and temperature low fraction oil phase product 14.

[0025] The pressure relief point is set at the outlet of Leng Gaofen 3, which are respectively valve A and valve B, which are set in parallel. The valves are two-position valves, and the pressure relie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com