Weights of standard machine loading device

The technology of a loading device and a standard machine, applied in the field of weights, can solve the problems such as the inability of the torque to stabilize, the influence of the accuracy of the indication value, and the influence of the detection efficiency, and achieve the effects of novel structure, accurate weight quality and stable unloading process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

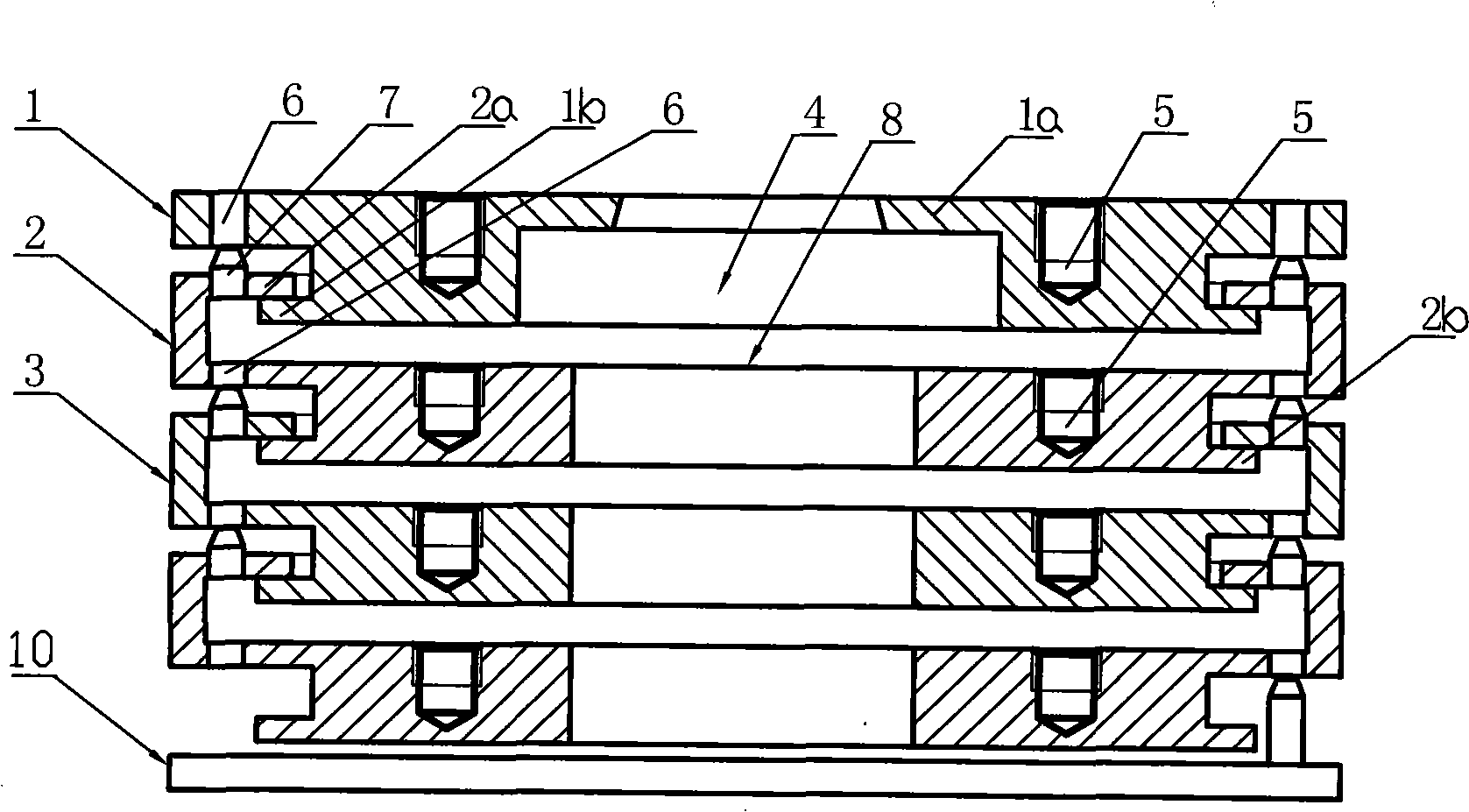

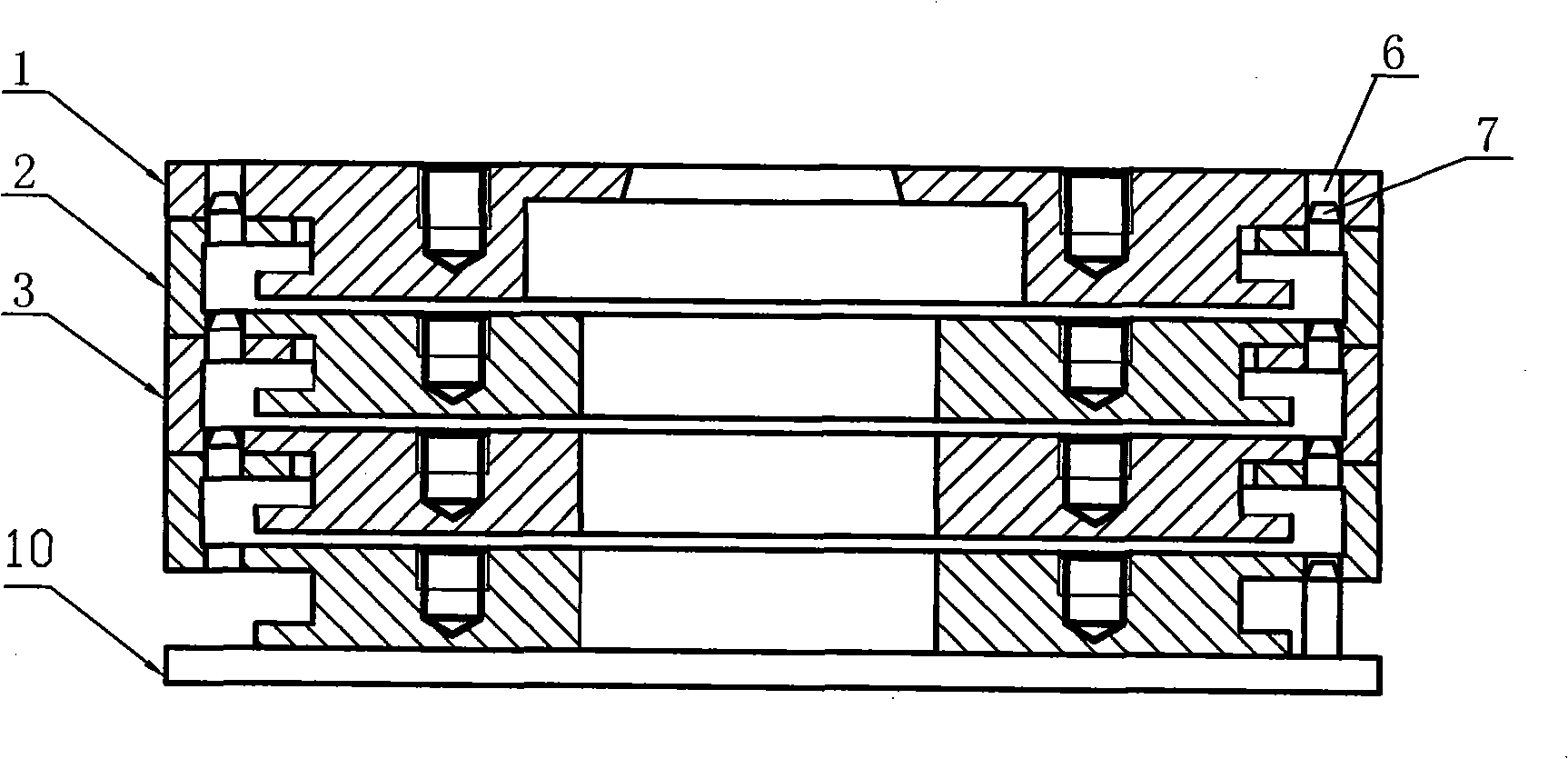

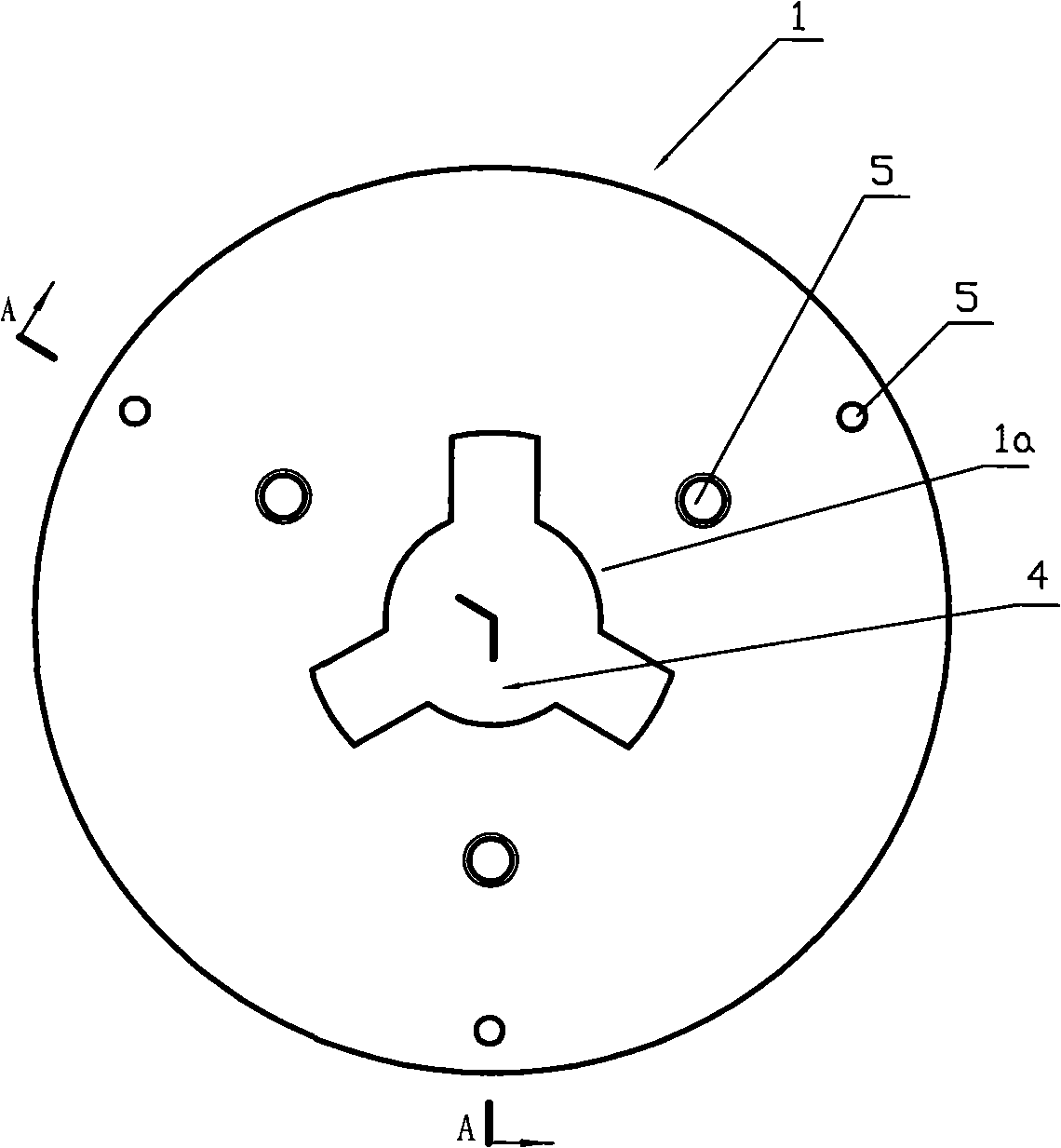

[0017] see Figure 1 to Figure 8 , is a kind of embodiment of weight of the present invention, and weight group comprises a plurality of standard value weights, is usually ten weights for a weight group, (the weight shown in the accompanying drawing only draws four for the sake of simplicity weights). Each weight of the weight group is a stepped cylinder with a through hole in the center of the circle. The upper part of the stepped cylinder is a large diameter section, and the lower part is a small diameter section. The diameters of the large diameter sections of the stepped cylinders of each weight are the same, and the small diameter The segments have the same diameter. At least three outwardly extending flanges are evenly distributed on the bottom circumference of the small diameter section of each weight. In this embodiment, the number of outwardly extending flanges is three, and the three flanges are arranged at intervals to form a socket bottom stop. The upper port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com