A miniaturized thermal battery integrated assembly device

A technology for assembling device and thermal battery, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problem of rarely reported thermal battery assembly technology, and achieves shortened assembly time, reduced material and processing costs, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

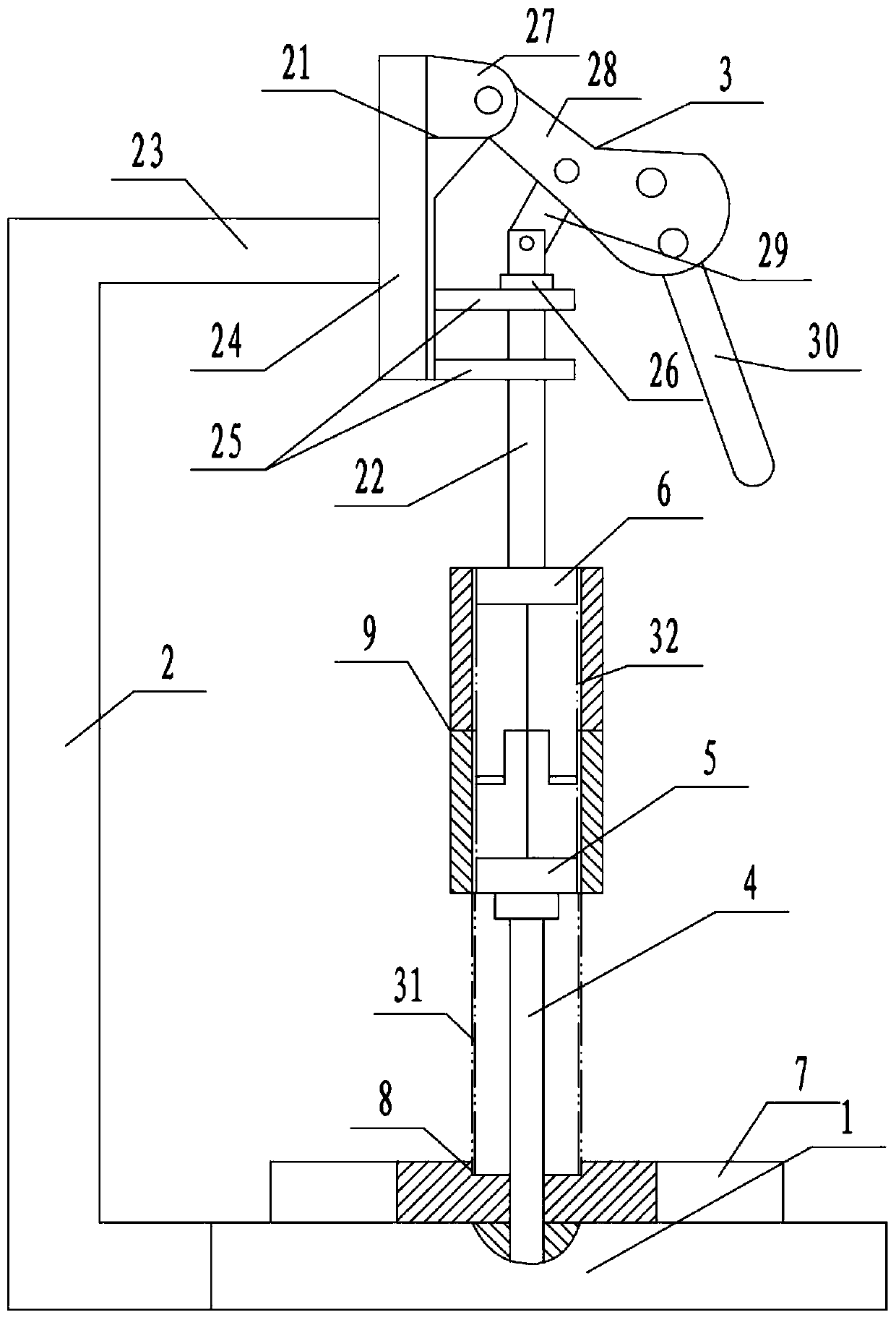

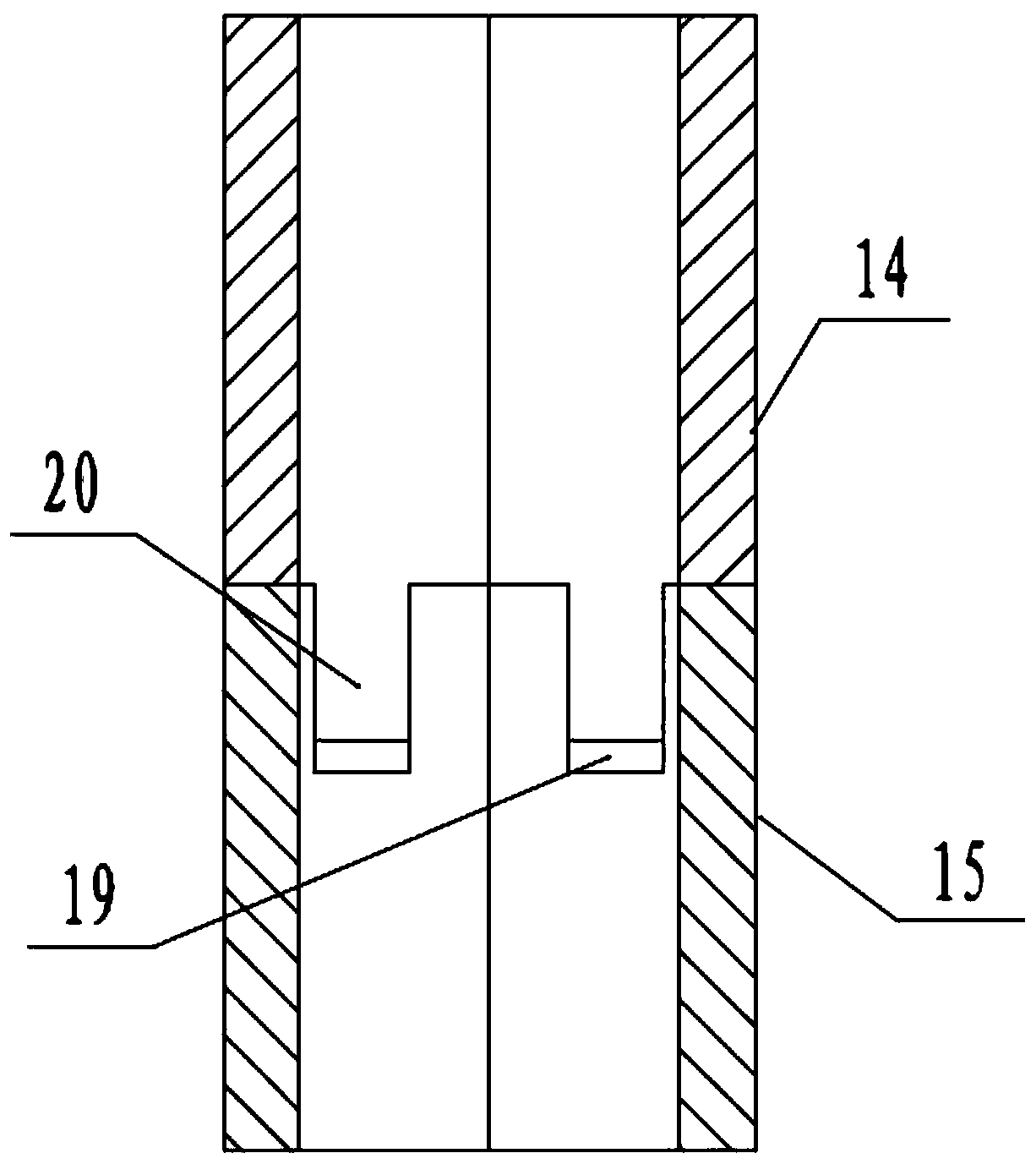

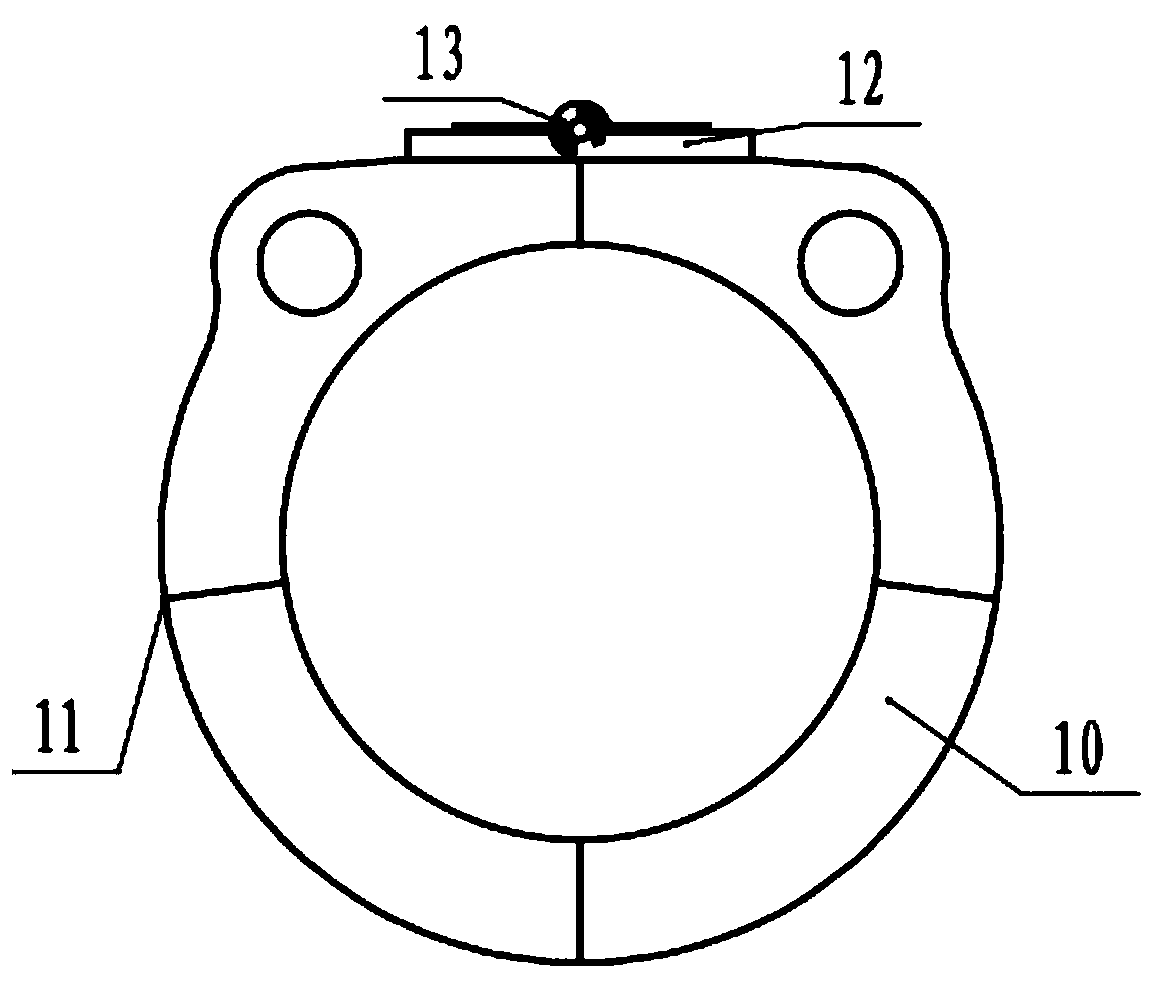

[0024] Embodiment 1: as Figure 1-6 As shown, a miniaturized thermal battery integrated assembly device includes a base 1 and a horizontal U-shaped bracket 2, the lower end of the bracket 2 is fixedly connected to the base 1, the upper end is connected to a clamping device 3, and the base 1 is fixedly connected to a screw rod 4. The upper end of the screw rod 4 is fixedly connected with the lower pressing plate 5, the clamping device 3 is connected with the upper pressing plate 6, the upper end of the screw rod 4 is connected with the hand wheel 7, and the upper end of the hand wheel 7 is provided with a placement groove 8 for vertically placing the battery case. Sleeve the battery case 31 on the screw rod, place the battery stack in the center between the upper and lower platens, and lock it through the clamping device. After wrapping the battery stack 32, turn the hand wheel to push the battery case up to be sleeved on the battery stack. .

[0025] Preferably, the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com