Installation method of a device capable of releasing internal forces during the installation phase of a steel support

A technology for the installation stage and installation method, which is applied to the processing of pillars and building materials, and the preparation of building components on site, etc. It can solve the problems of being unable to release the internal force of the support installation stage and cannot bear the wind load during the construction stage, so as to achieve support unloading The effect of smooth process, simple structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

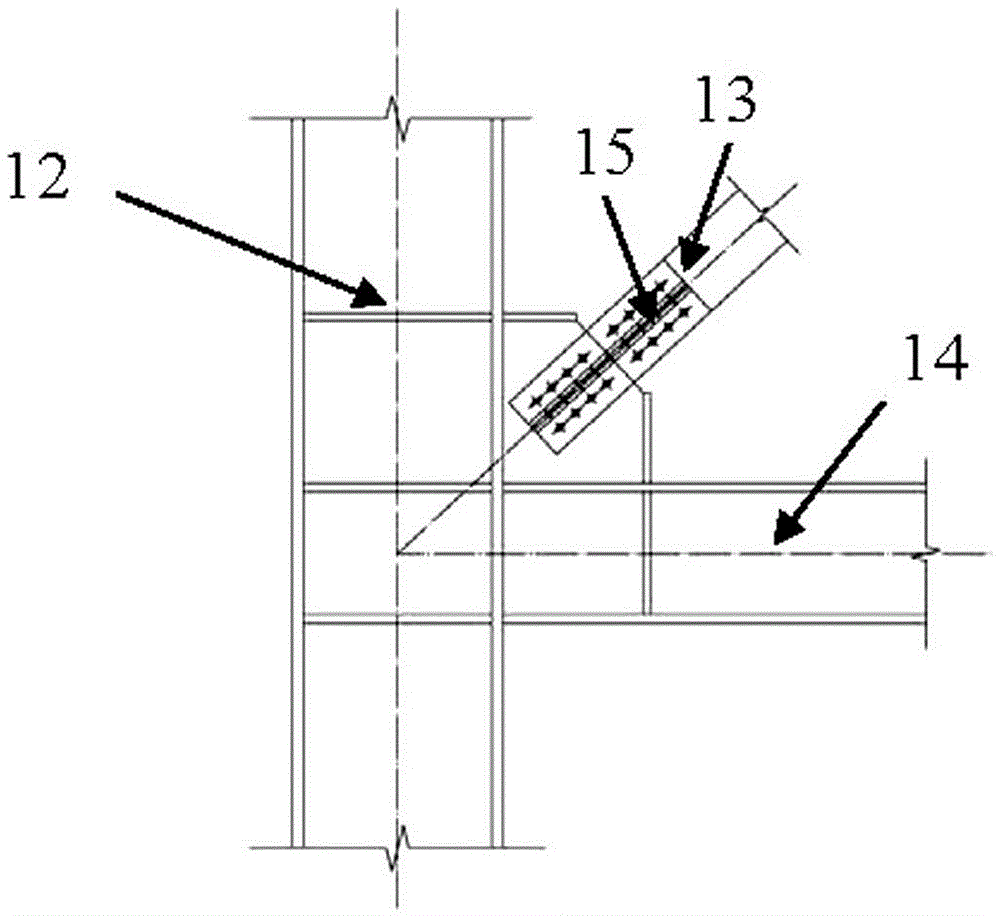

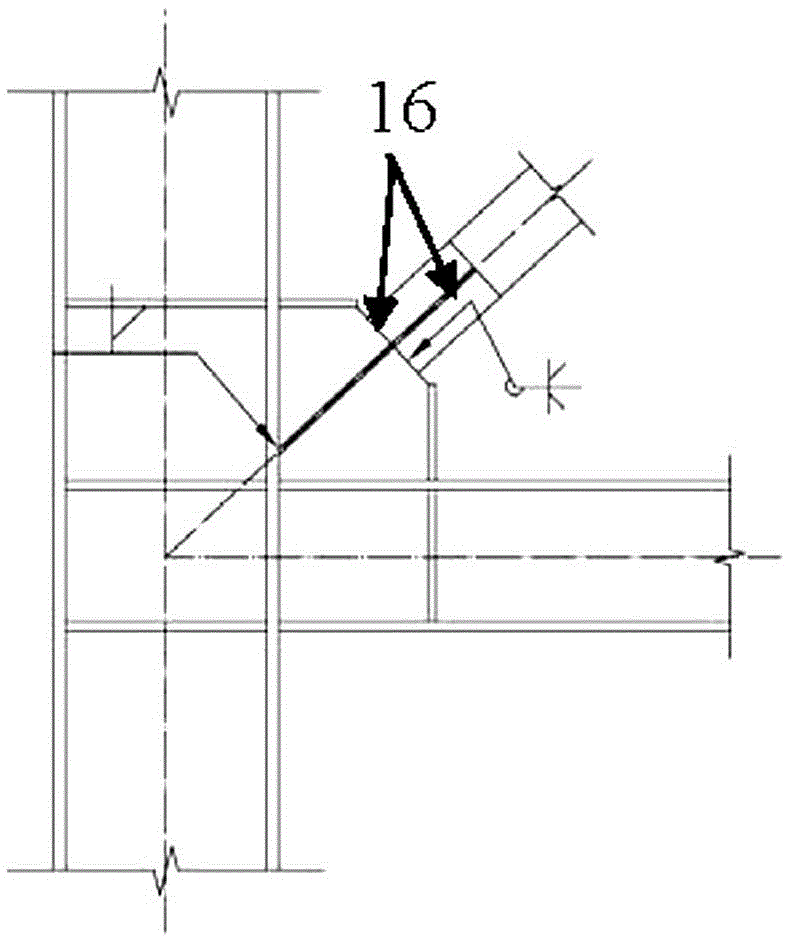

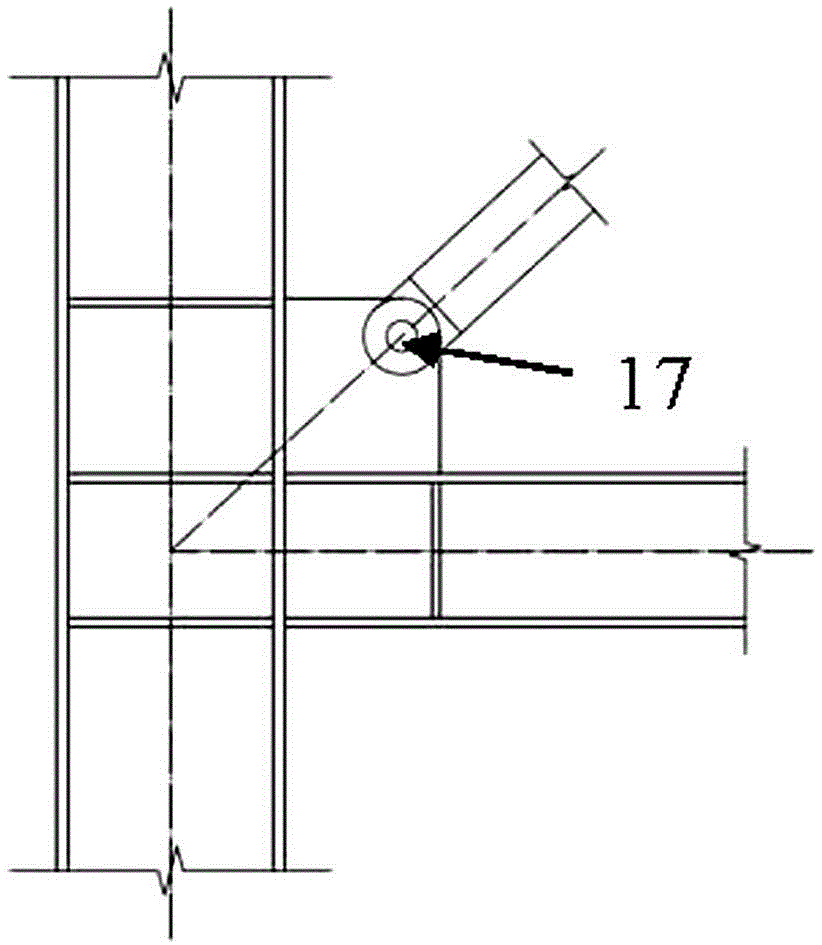

[0039] In order to illustrate the technical solutions of the present invention in detail, specific embodiments are given below in conjunction with the accompanying drawings.

[0040] The core idea of the present invention is that during the support installation process, the support first bears the vertical load and wind load together with the main structure to ensure the safety of the structure during the construction stage. To avoid the internal force of the support, it may bear a large load, which may cause the support to yield prematurely under the wind load or earthquake during the use stage, which will affect the wind and earthquake resistance of the structure.

[0041] Under the guidance of the above-mentioned core idea, it is realized through the following device that can release the internal force of the steel support during the installation stage. The device that can release the internal force of the steel support in the installation stage includes a node connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com