Portal frame type component transportation vehicle and component transportation method

A transporter, gantry-type technology, applied in portable lifting devices, lifting devices, lifting frames, etc., can solve the problems of small footprint, limited flexible operation, inconvenient storage, etc., to reduce production costs and enhance connection. , the effect of avoiding component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

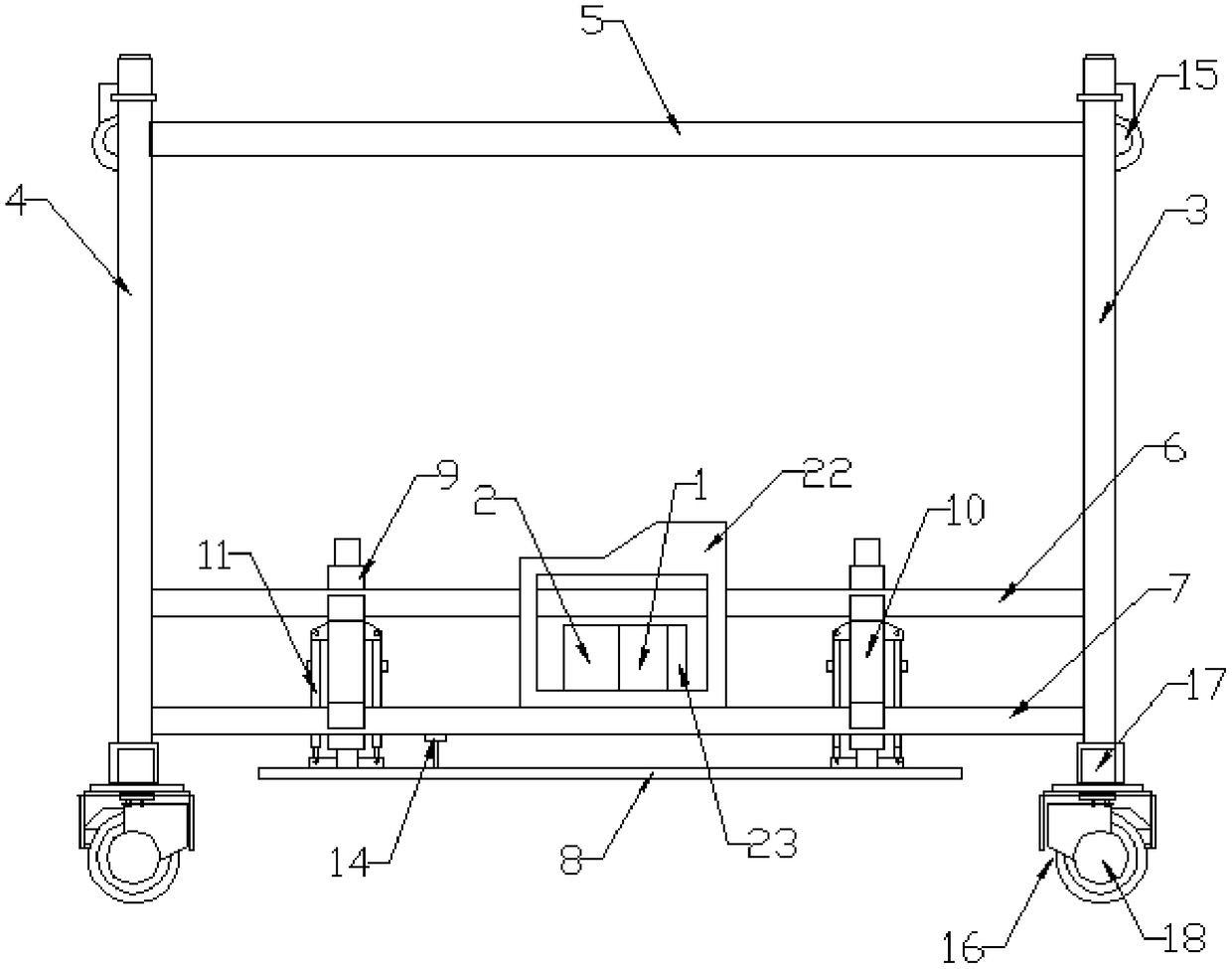

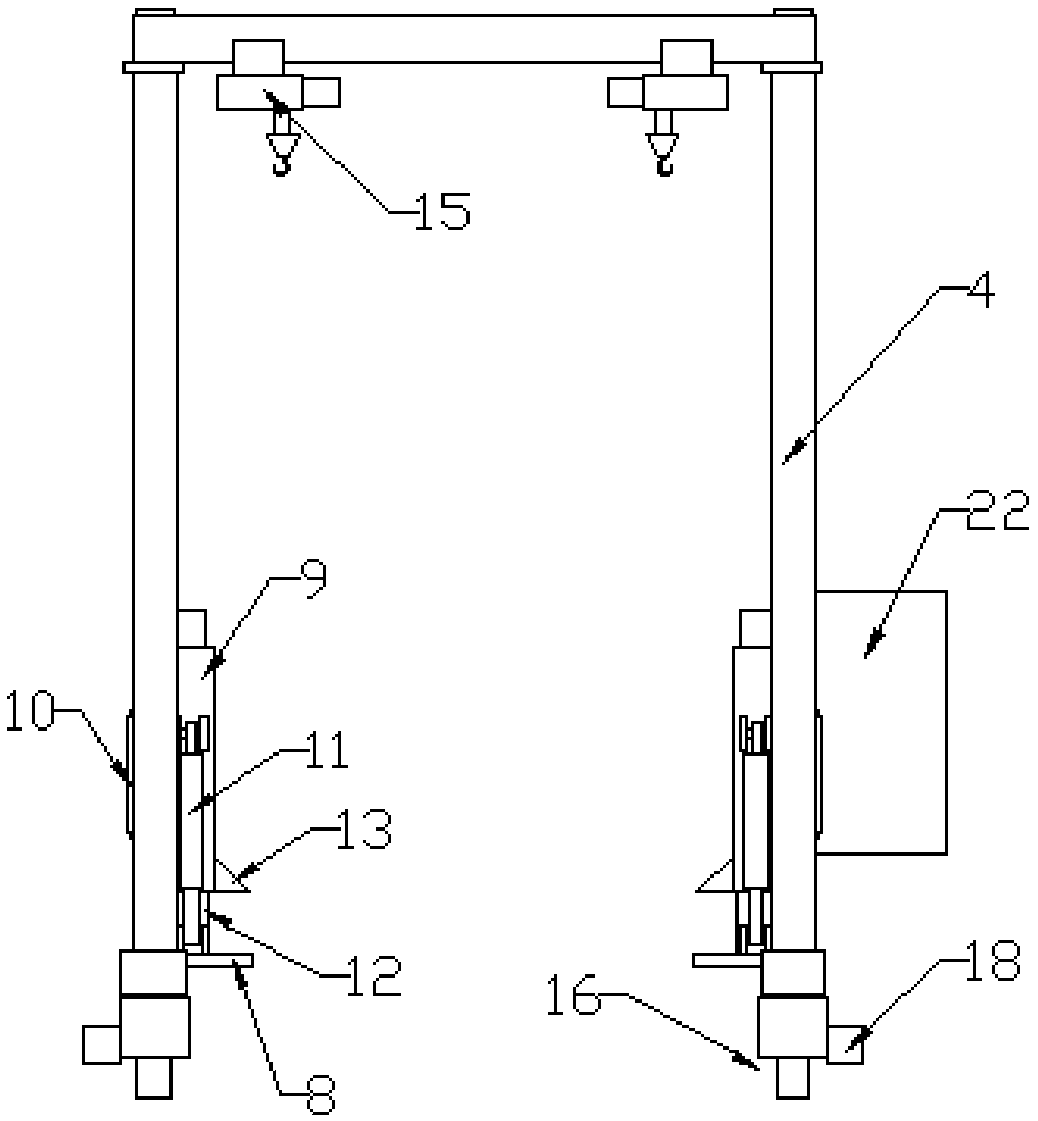

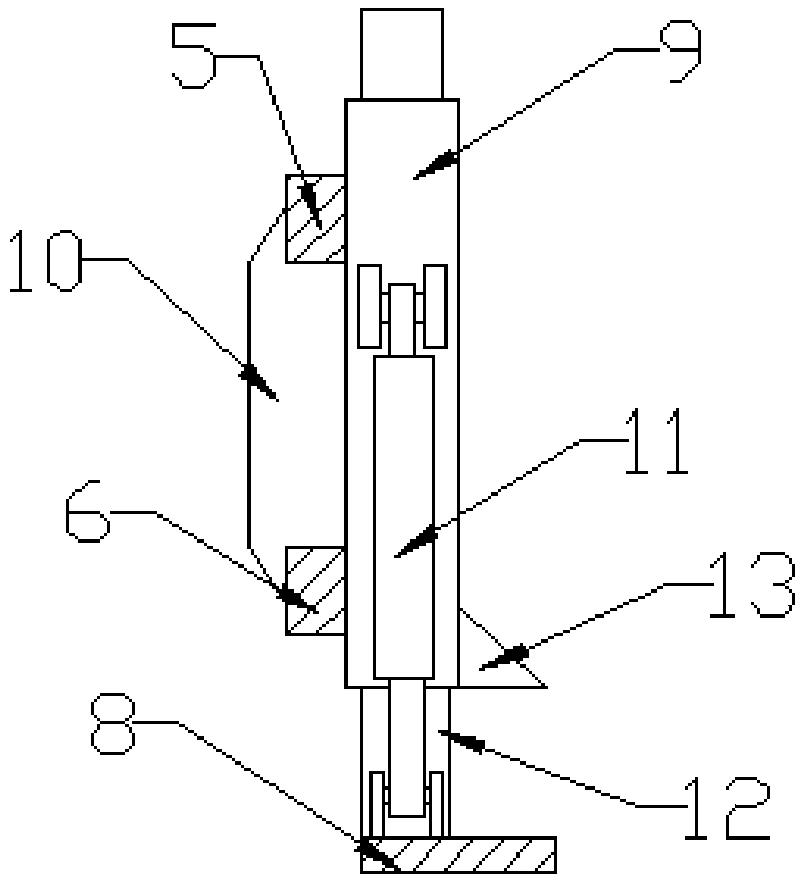

[0034] Such as Figure 1-2 As shown, a gantry-type component transport vehicle includes a transport frame, and the transport frame is provided with a walking steering mechanism, a bracket lifting mechanism, a power mechanism 1 and a hydraulic mechanism 2, the power mechanism 1 is connected with the hydraulic mechanism 2, and the hydraulic mechanism 2 are respectively connected with the bracket lifting mechanism and the walking steering mechanism.

[0035] The transport frame is welded by Q345B steel plate, including the first gantry 3 and the second gantry 4, the first support rod 5 is welded horizontally on both sides of the upper end between the first gantry 3 and the second gantry 4, and the two sides of the lower end are welded horizontally There is a second strut, the second strut includes an upper second strut 6 and a lower second strut 7, the upper second strut 6 is located above the lower second strut 7, ensuring that the overall structure is always supported by three ...

Embodiment 2

[0044] There are mainly two types of PC component brackets. The first type of PC component bracket has a pull rod 24 that is a channel steel with an opening facing outward, such as Figure 5 As shown, the pull rod 24 of the second PC component bracket is not a channel steel with an opening facing outward, such as Image 6 As shown, the two sides of the upper end of the support frame of the PC component bracket are provided with lifting ears 25 .

[0045] A method for transporting components, using the gantry-type component transport vehicle described in Embodiment 1, comprising the following steps:

[0046] (1) Start the power mechanism 1, manually control the steering hydraulic motor 17 to drive the road wheels 20, and the travel hydraulic motor 18 drives the road wheels 20 to walk, so that the gantry-type component transport vehicle reaches the designated position in the component buffer area, and the PC component bracket Placed between the first gantry 3 and the second gan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com