Automatic hanging and unloading system of material basket

A material basket and hanging technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of difficult unloading, unsteady hook or material basket falling off, reducing the automation degree of the production line, etc., to achieve a stable hanging and unloading process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

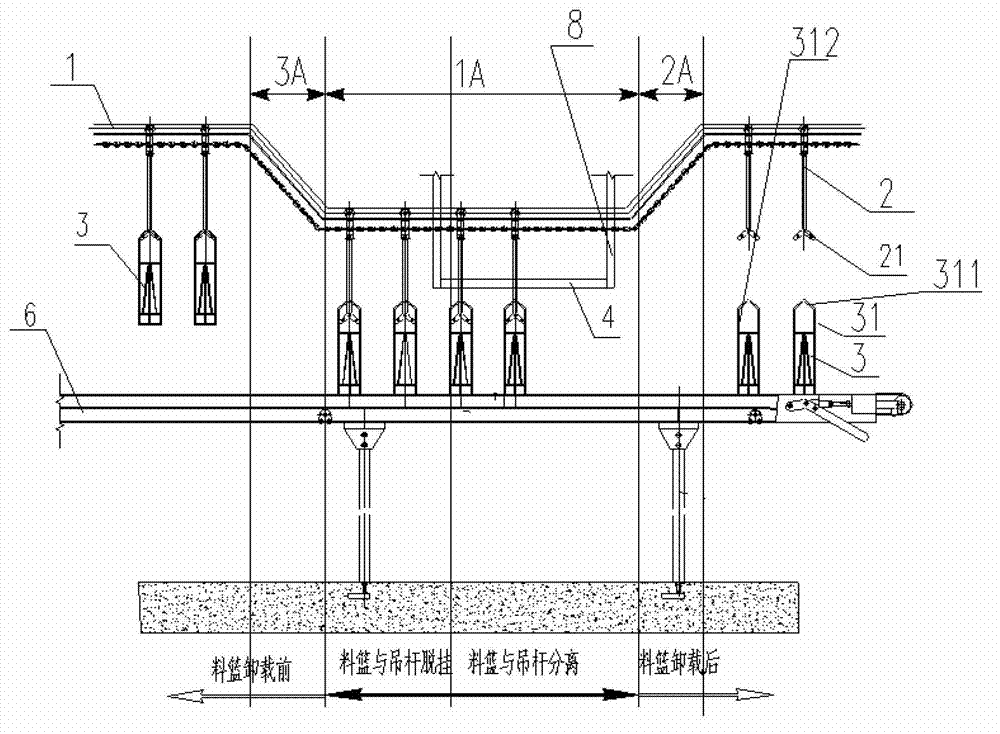

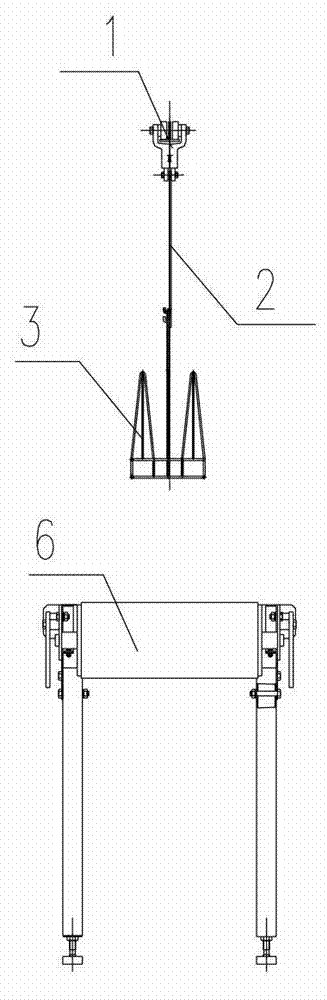

[0034] pass figure 1 Describe this implementation, the automatic unloading system of the material basket includes a suspension conveying line 1, a material basket suspender 2, a material basket 3 and a detachment bar 4, the upper end of the material basket suspender 2 is connected with the suspension conveying line 1, and its lower end passes through The suspension hook 5 and the suspension ring 31 on the material basket 3 realize hoisting, and the material basket suspender 2 can swing at a small angle perpendicular to its conveying direction along the connecting end of its upper part. The hanging conveying line 1 is provided with a material basket detachment conveying area 1A, and the detachment bar 4 is set under the hanging conveying line 1 through a bracket 8, and its position relationship diagram is as follows Figure 6 As shown, and form a horizontal angle with the conveying direction of the hanging conveying line 1 in the basket detachment conveying area 1A, a basket co...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that a downhill conveying area 3A is also provided on the suspension conveying line 1, which is connected to the conveying start end of the material basket detachment conveying area 1A, and the material transported to the downhill conveying area 3A Baskets 3 are driven downwards through the suspension conveyor line 1 . The setting of the downhill conveying area 3A can make the material basket smoothly enter into the material basket unhooking conveying area 1A for unhooking.

[0040] When uninstalling, such as figure 1 , Figure 2-1 to Figure 2-4 As shown, the basket suspender 2 hanging with the basket 3 drops to a certain height along with the suspension conveying line 1, when the basket at the lower end of the basket suspender 2 is detached from the starting end of the conveying area 1A, the basket falls to the bottom of the basket On the conveying device, the suspension hook 5 at the lower end of the materia...

Embodiment 3

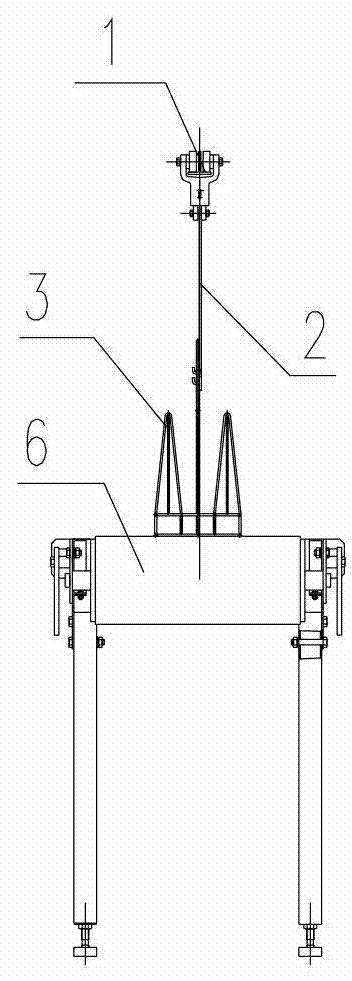

[0042] On the basis of Example 2, such as image 3 As shown, the present invention also sets a material basket hanging conveying area 1B on the hanging conveying line 1, and a hanging stop bar 7 is arranged in the material basket hanging conveying area 1B, and the hanging bar 7 is arranged on the material basket hanging conveying area 1B. Below the suspended conveyor line 1 in zone 1B. The material basket 3 is placed on the material basket conveying device 6 and is located directly below the material basket suspension rod 2; Rod 2 is offset from its vertical plane, such as Figure 4-2 As shown in the structure, the basket suspender 2 at this time is separated from the basket placed on the basket conveying device, and as the suspension conveyor line 1 continues to convey, the basket suspender 2 continues to move along the hanging bar 7 to Front conveying, when the basket boom 2 is conveyed to its end along the suspension bar 7, the hook 5 returns to its vertical surface, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com