Shoal sea area rescue operational ship with pile driving and pulling device and ship body fixing method

A technology for working boats and piles, which is applied in the directions of boat parts, anchoring arrangements, and boat construction, can solve problems such as limited carrying capacity, unfixable, unsafe, etc., to reduce power consumption and driving resistance, shorten operation time, The effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

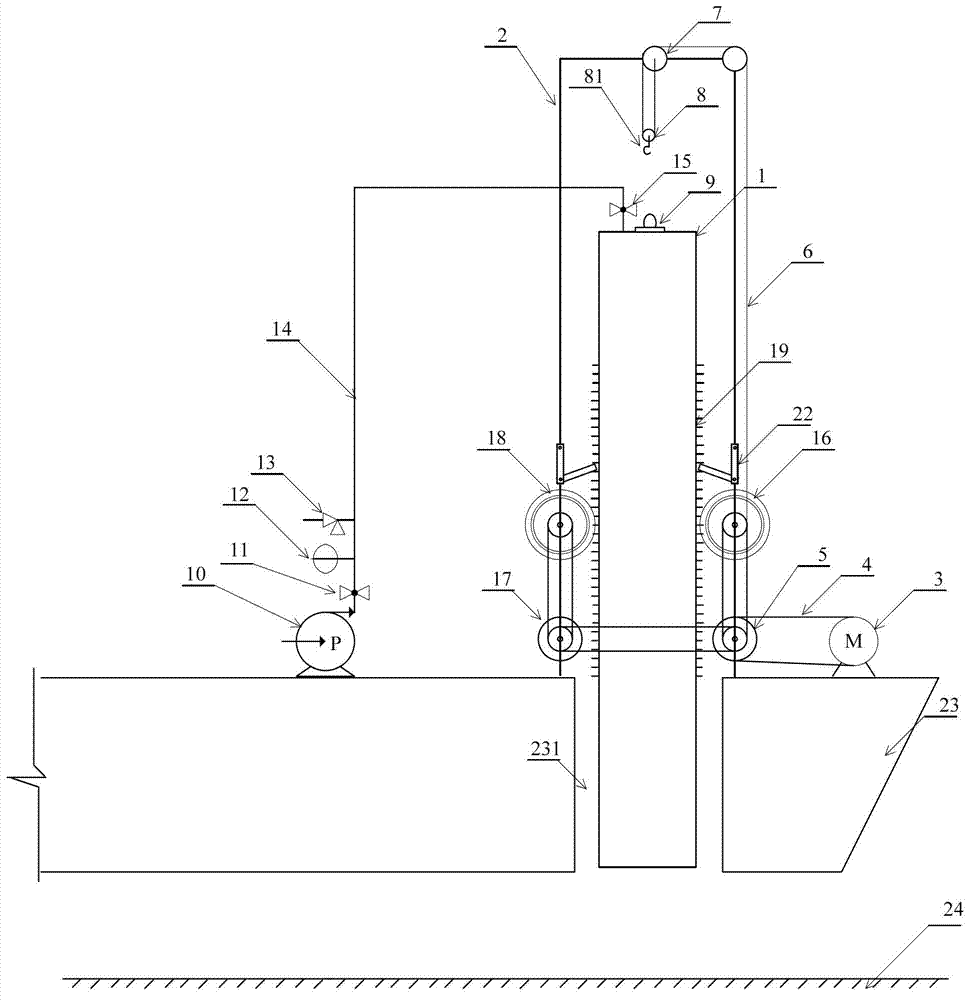

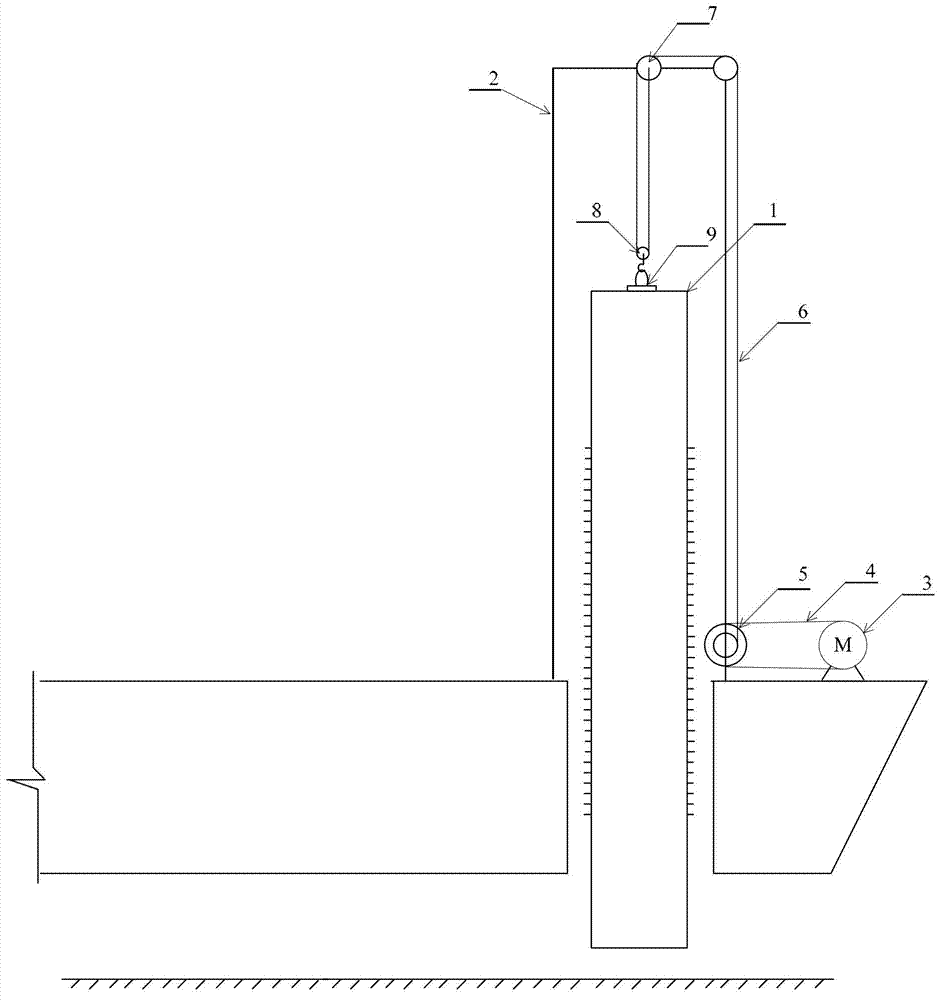

[0060] Attached below figure 1 to attach Figure 8 The specific structure of the present invention will be described in more detail.

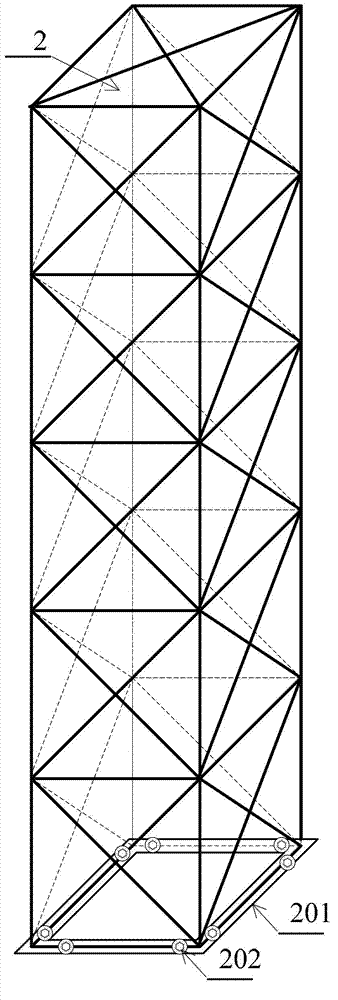

[0061] An emergency operation ship in a shallow sea area provided with a pile insertion and extraction device, which has an operation ship, and a through hole 231 for the insertion and removal of the pile body 1 is opened on the deck of the hull 23 of the operation ship, and the hull at the upper edge of the through hole 231 There is a hollow hoisting truss 2 fixedly connected to the deck, and a vertical pile body 1 is hoisted inside the hoisting truss 2. The top of the pile body 1 is hooked with the hoisting system, and a toothed rack 19 is arranged on the longitudinal symmetrical side of the outer surface of the pile body. What the bar 19 engages is the lifting mechanism that drives the pile body 1 to move longitudinally back and forth and causes the pile body 1 to be inserted into or pulled out of the seabed 24 . see figure 1 .

[0062] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com