Strip mining machine for mine

An open-pit and stripping technology, applied in the field of integrated stripping equipment, can solve the problems of low stripping work efficiency, inability to realize continuous operations, and high production costs, so as to expand mine production capacity, improve stripping work efficiency, and production capacity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

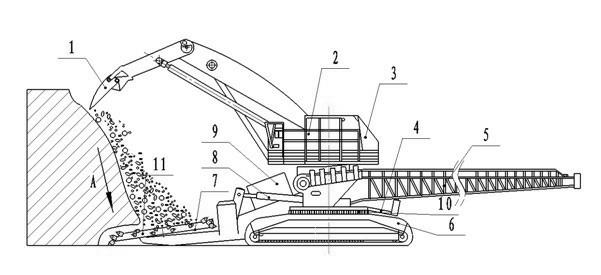

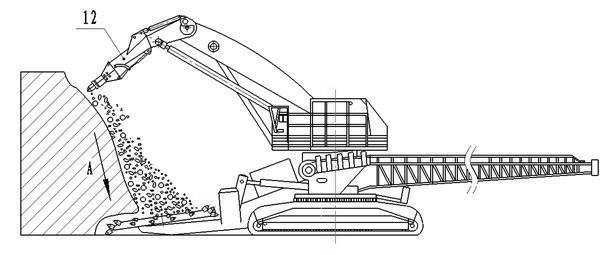

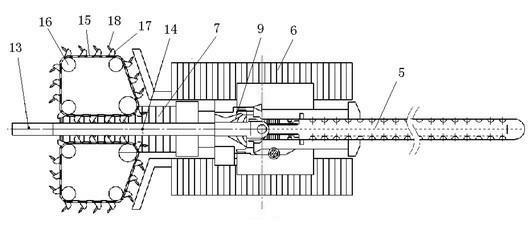

[0023] The present invention consists of a cutting and raking part 11, a scraping part 14, a scraper conveying device 7, a crushing device 9, a tape conveying device 5, a turning and lifting mechanism 4, a walking part 6, a turning part 10, an operating part 2, an electric The control part consists of 3 parts.

[0024] As shown in the figure, the hydraulic negative shovel 1 or hydraulic hammer 12 is hinged on the scraping arm 13 at the front end of the scraping part 14, the rotary part 10 is installed on the upper part of the crawler walking part 6, and the cutting and raking part 11 is installed on the scraper The front end of the transport device 7, the rear end of the scraper transport device 7 extends to the crushing device 9, the scraper adjustment device 8 is installed on the front end of the crushing device 9, the crushing device 9 is connected to the belt transport device 5, and a Slewing and lifting mechanism 4.

[0025] The scraper conveying device 7 and the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com