Automatic detecting instrument for retaining ring check ring of constant velocity universal joint three-pivot shaft

A constant velocity universal joint and three-pivot technology, which is applied in the testing of instruments, measuring devices, and mechanical components, can solve problems such as mental fatigue, potential safety hazards, and high labor costs, and achieve exquisite instrument structure design and ease of use. Safe and reliable, fast loading and unloading process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

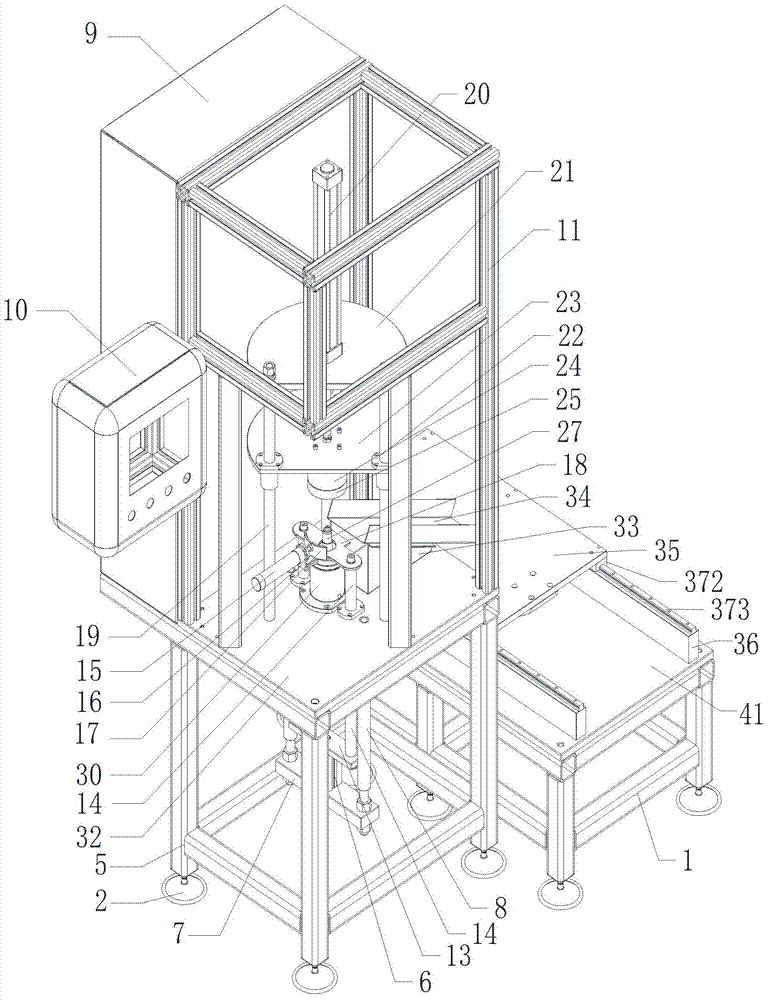

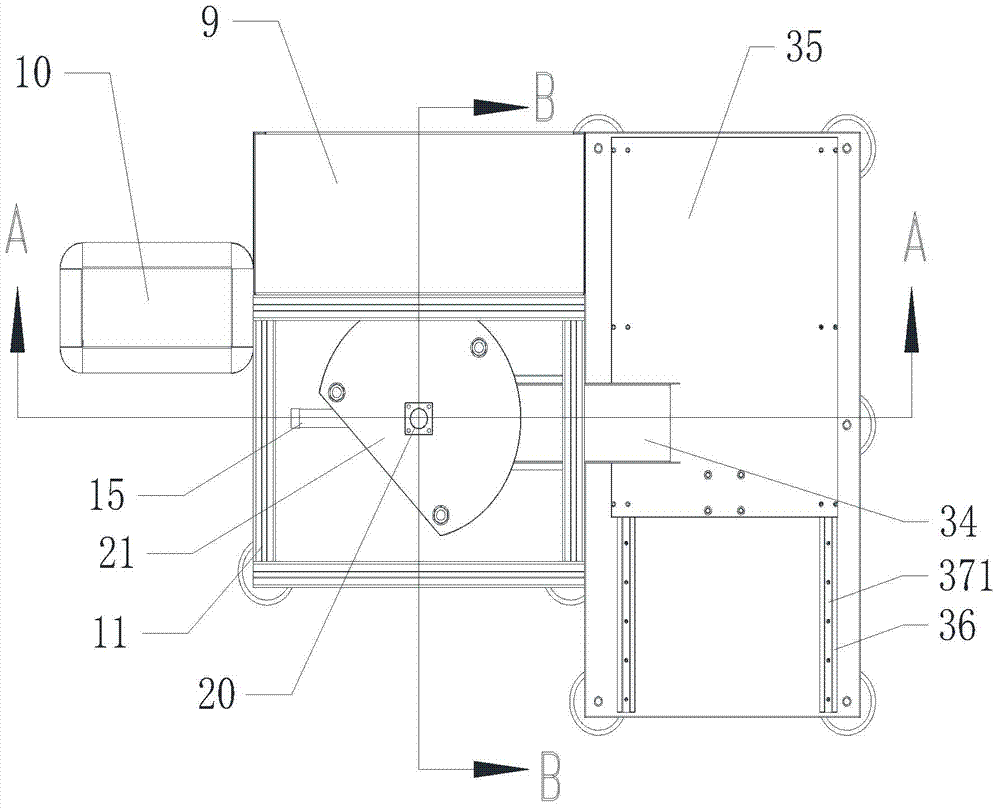

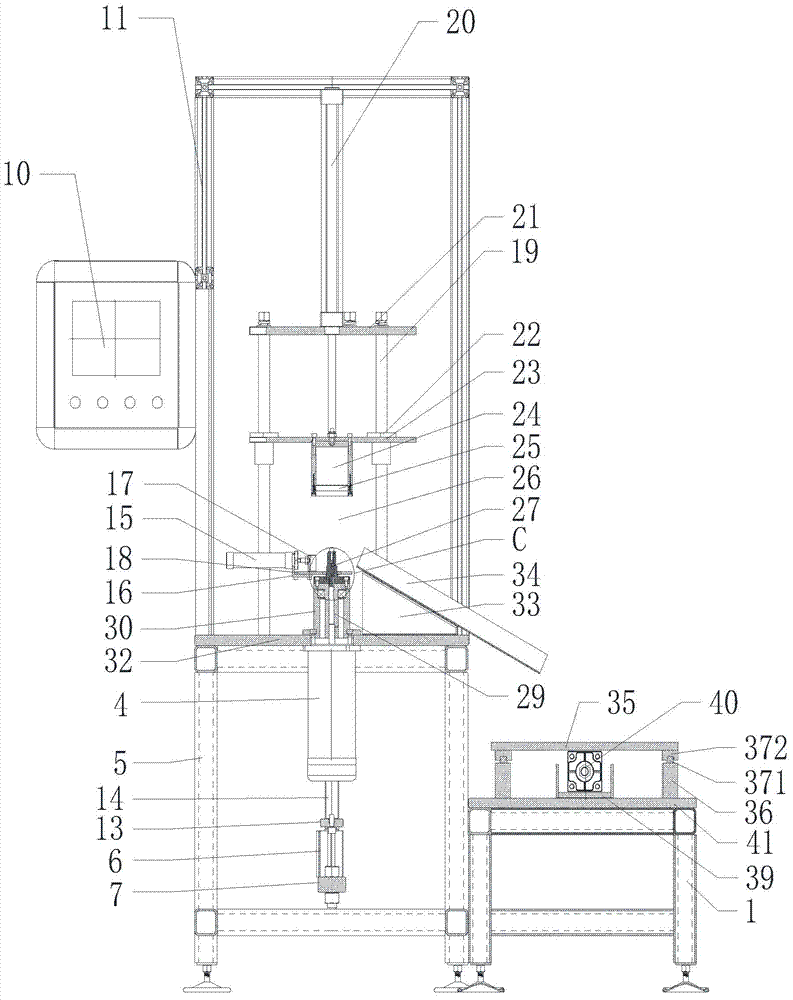

[0037] Such as Figures 1 to 13As shown, the constant velocity universal joint three-pivot buckle ring automatic detector consists of a workbench frame 5, an aluminum alloy frame 11, a sorting basket frame 1, a workbench installation base plate 32, an electrical cabinet 9 and a touch screen Placing box 10 constitutes the frame main body, workbench frame 5, aluminum alloy frame 11, sorting basket frame 1 are all frame structures, aluminum alloy frame 11, electrical cabinet 9 are installed on workbench frame 5 tops together, The electrical cabinet 9 is installed on one side of the aluminum alloy frame 11; the workbench installation base plate 32 is arranged on the top of the workbench frame 5, between the workbench frame 32 and the aluminum alloy frame 11; the touch screen placement box 10 is suspended in the air On the aluminum alloy frame 11, it is a cabinet with a certain volume; the electric control system includes a programmable logic controller (PLC) and a touch screen, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com