Scheme for laying container terminal and assemble and unassembled flow

A layout plan and container technology, which is applied to storage devices, loading/unloading, transmission devices with reciprocating piston internal combustion engines, etc., can solve the problems of unfavorable automation, difficult loading and unloading of cranes, and the need for human driving of horizontal transport vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

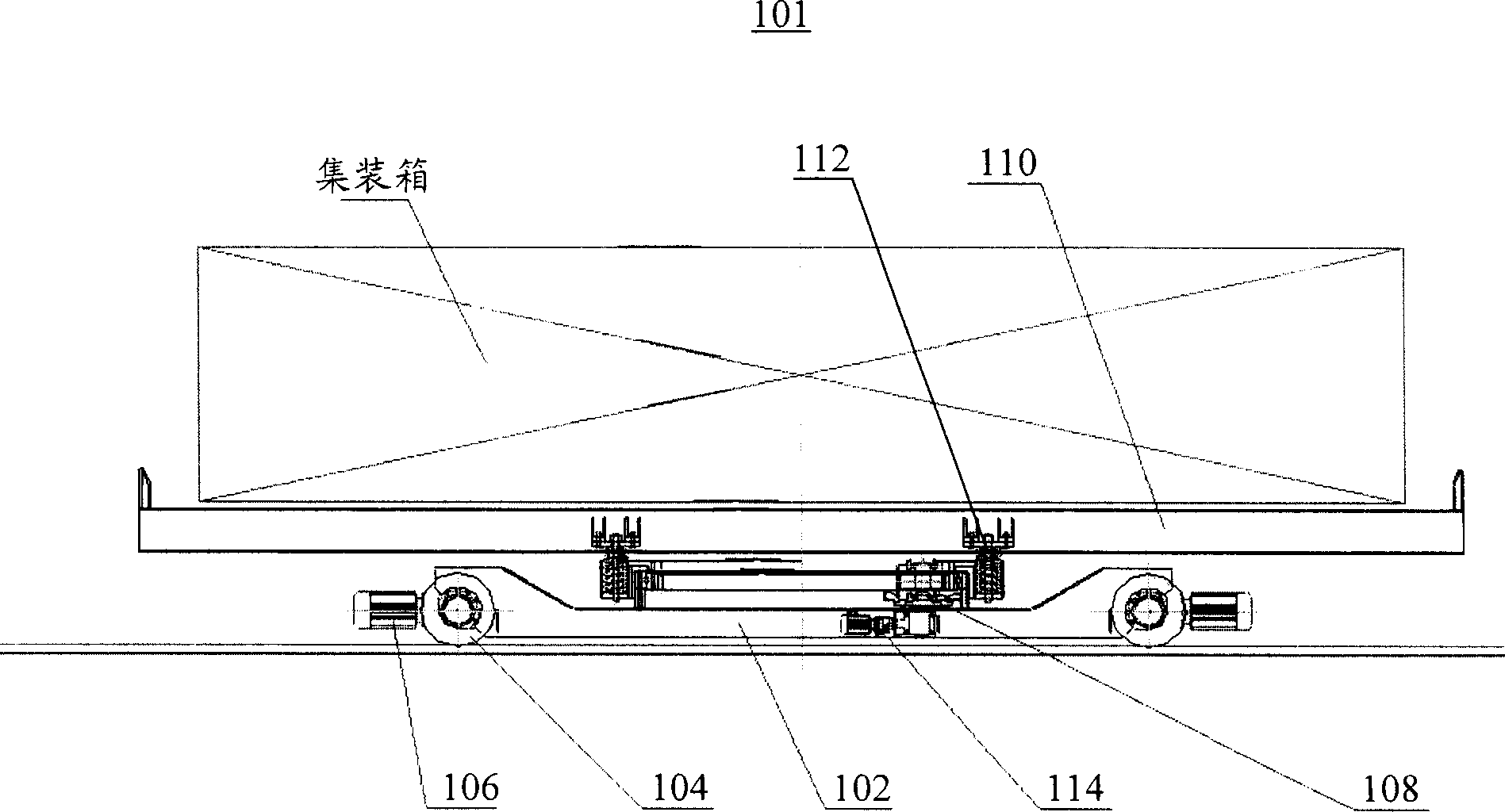

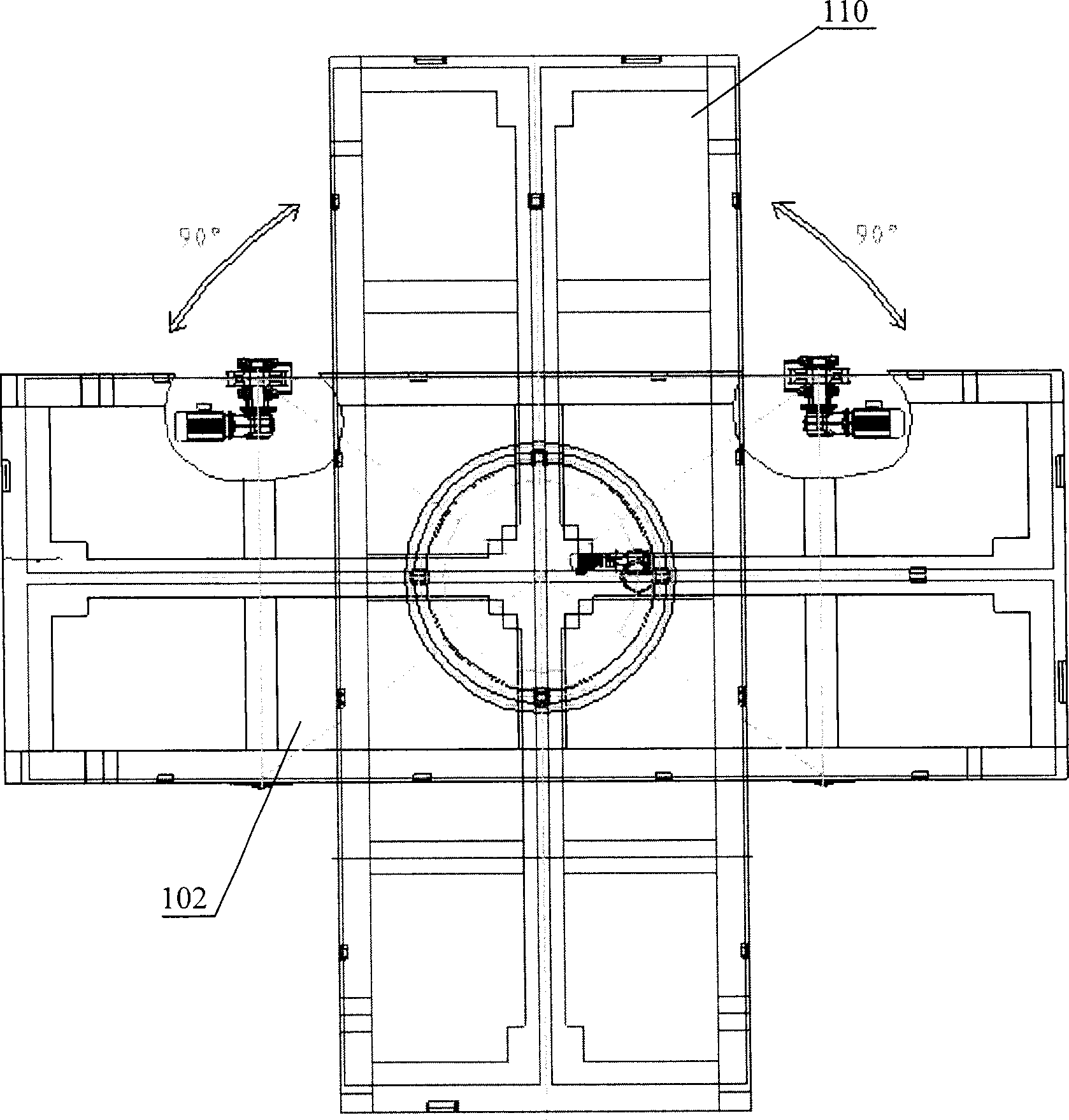

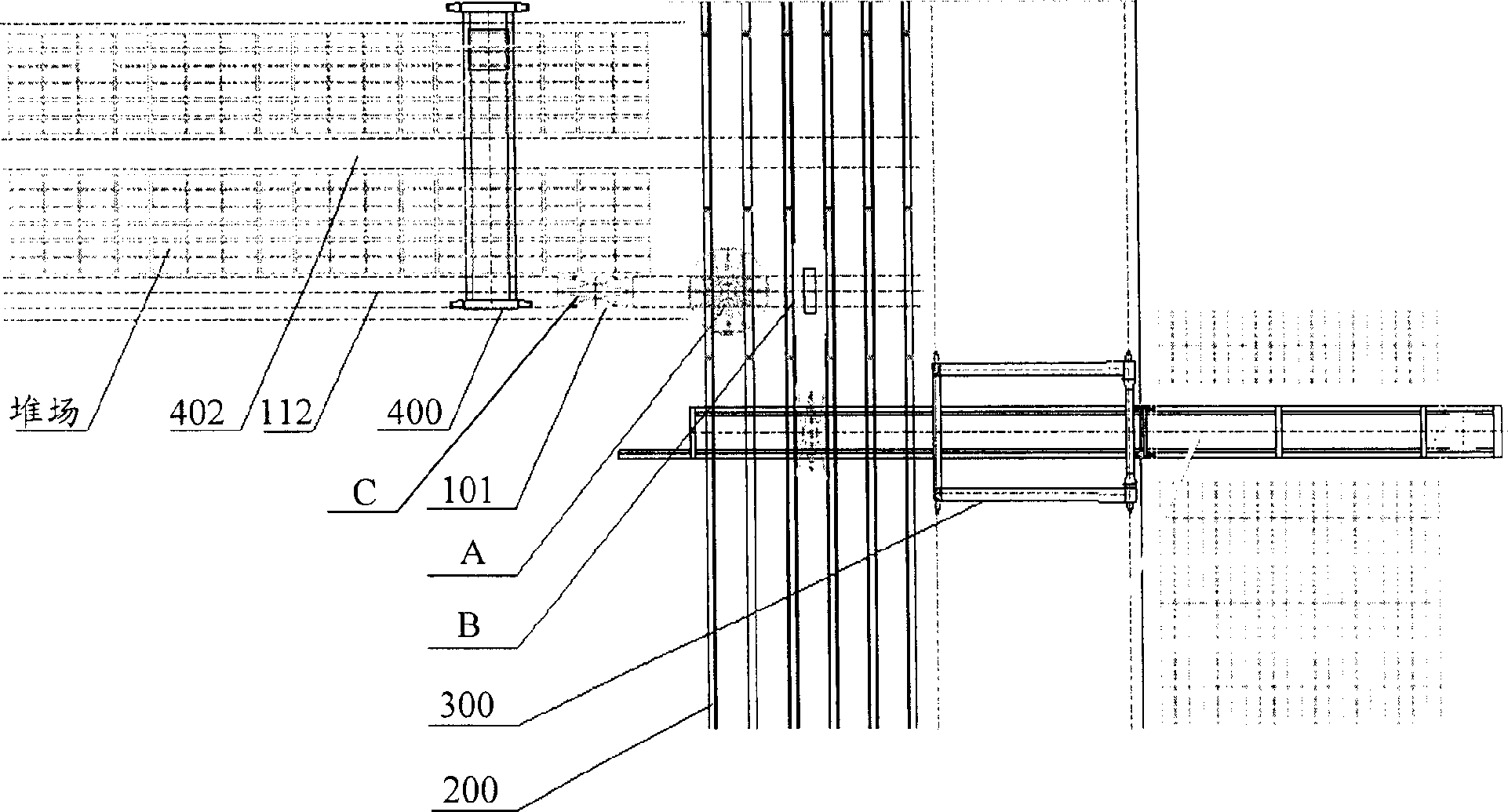

[0084] The main design points of the present invention are: arranging a low bridge system and a transfer trolley system between the quay crane and the yard crane, and realizing the leveling of the container through the electric flatbed trolley (low bridge bridge trolley and transfer trolley) running on the track. For transportation, the electric flatbed car can reciprocate and move horizontally along the track to transport the container from one place to another, and the rotary platform on the upper part of the transfer trolley can also rotate clockwise or counterclockwise with or without a box , so as to realize the 90-degree conversion of the discharge of the container on the ship and the container in the yard.

[0085] According to the above-mentioned design points of the present invention, the present invention provides a low bridge system, a transfer trolley system, and a container terminal layout scheme based on the above-mentioned system, so as to realize automatic and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com