Container conveyer bogie and transport system

A technology for conveying trolleys and conveying systems, applied in the direction of transporting passenger cars, conveyor objects, trucks, etc., can solve the problems of affecting the speed of loading and unloading, large pollution, difficult lifting by cranes, etc., to achieve efficient loading and unloading, improve horizontal transport speed, and improve efficiency. and technical level effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

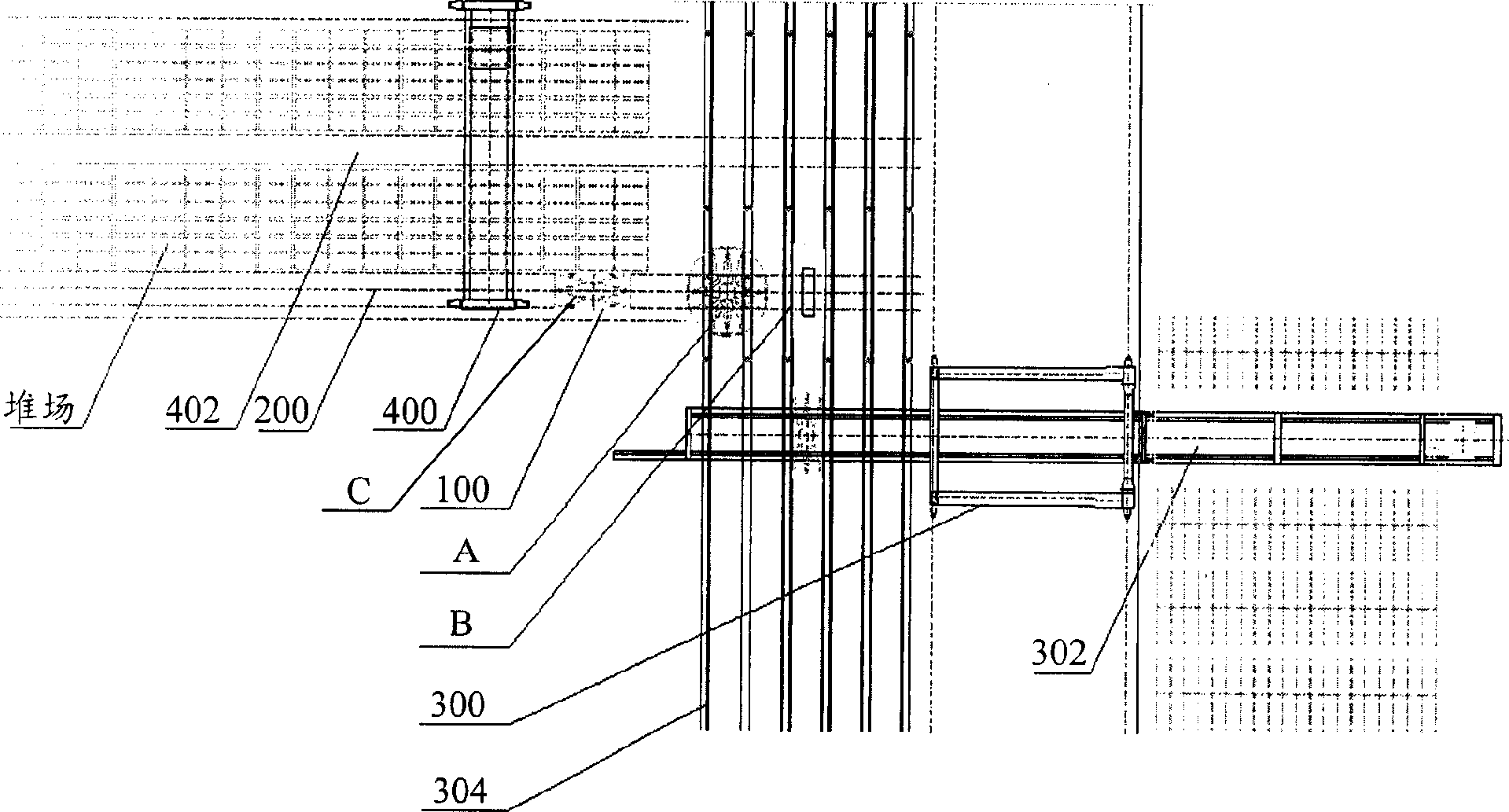

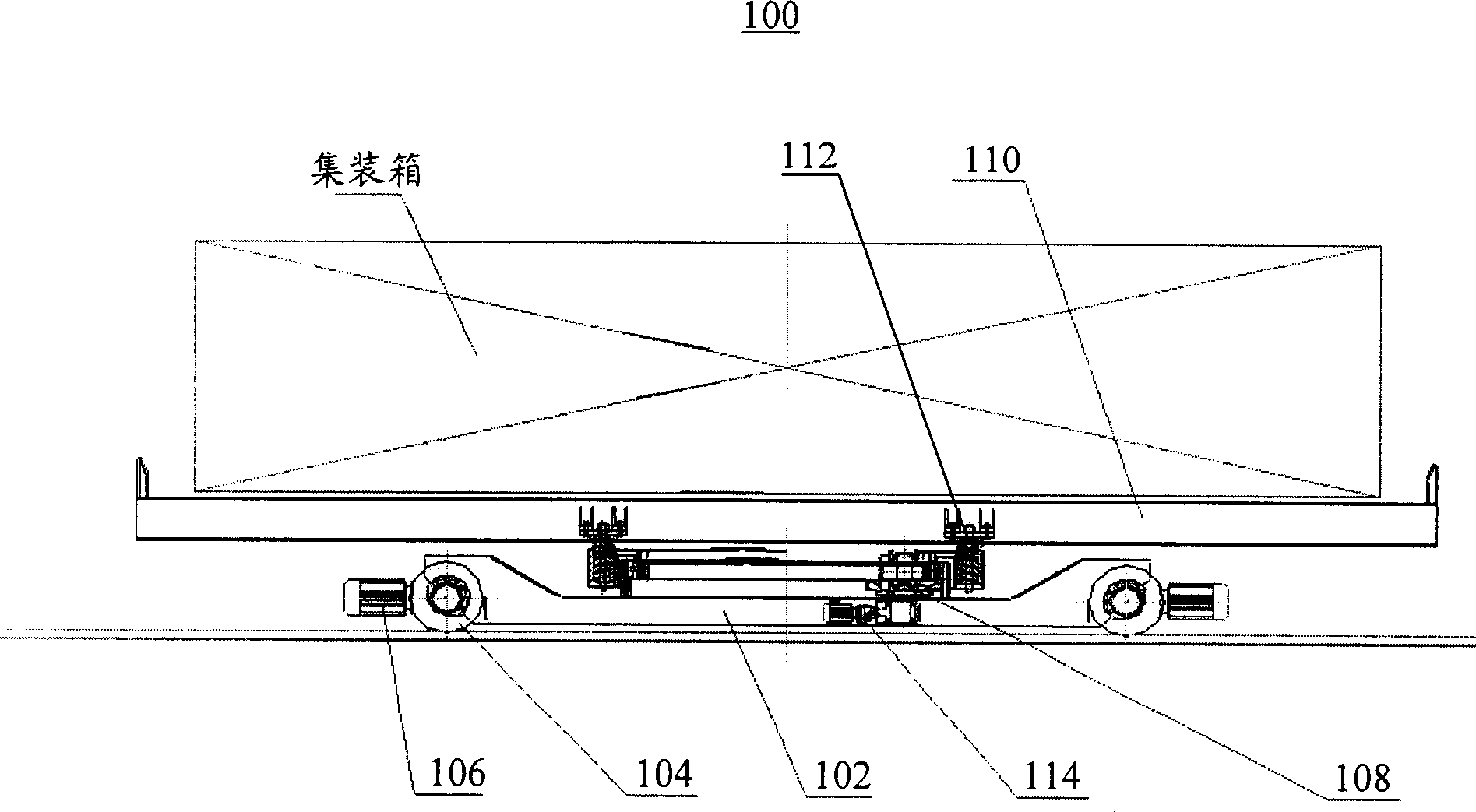

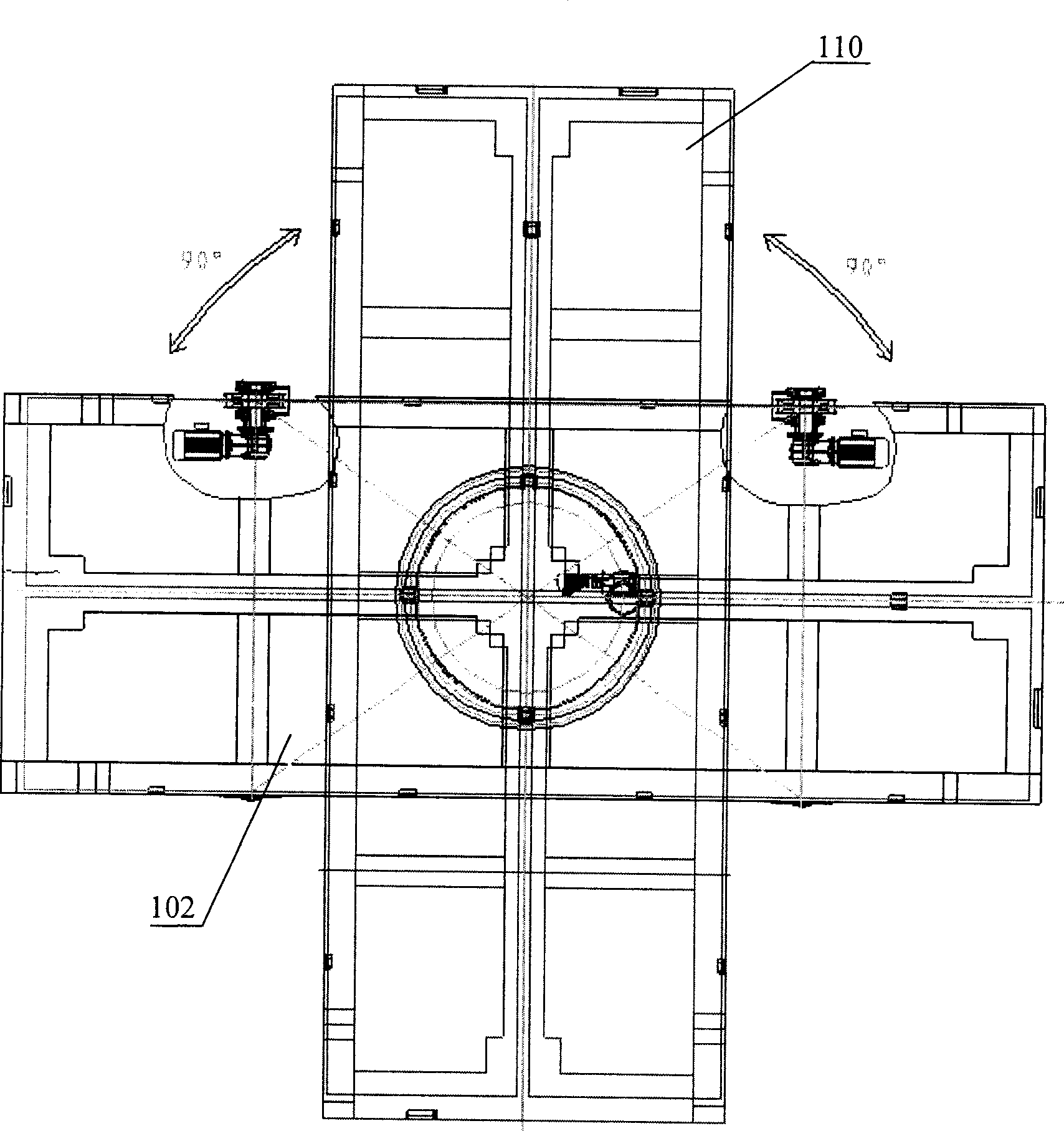

[0046] The main design points of the present invention are: the horizontal transportation of the container is realized by the electric flat car running on the track, the electric flat car can not only move back and forth along the track to transport the container from one place to another, the upper part of the flat car The special slewing platform can also rotate clockwise or counterclockwise with or without boxes, so as to realize the 90-degree conversion of the discharge of containers at the loading and unloading points in front of the wharf and behind the wharf.

[0047] According to the above-mentioned design points of the present invention, the present invention provides a container conveying trolley, a container conveying system, and an overall arrangement scheme of a wharf for automatic and efficient container conveyance.

[0048] Container transport trolley

[0049] According to one aspect of the present invention, a kind of container conveying trolley is provided, wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com