Method for packaging high-furnace cooling wall

A packaging method and cooling stave technology, applied in the field of packaging and transportation of large and medium-sized parts and components of metallurgical equipment, can solve problems such as scrapping, cooling stave damage, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

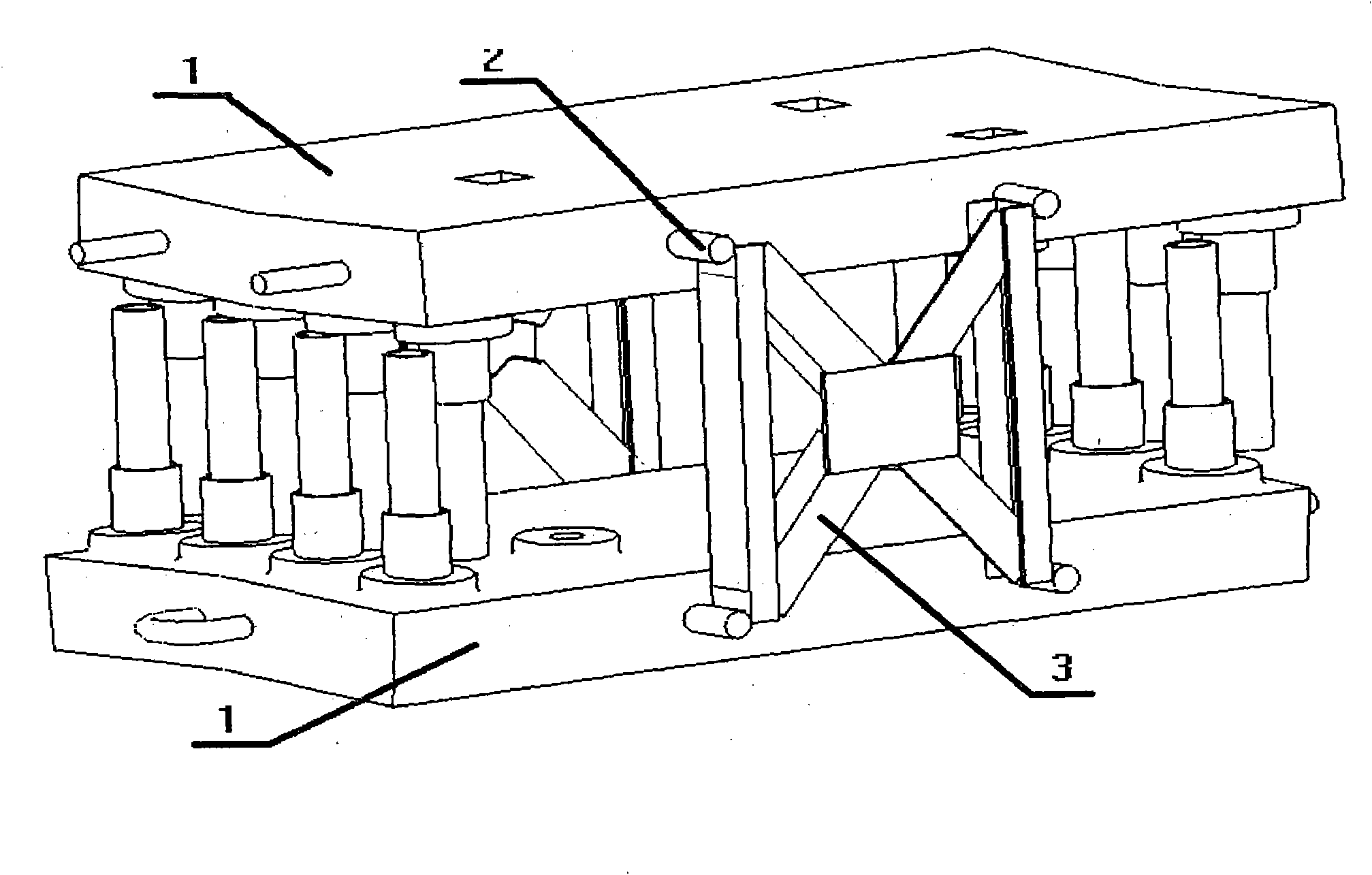

[0014] Such as figure 1 As shown in the perspective view of blast furnace stave packaging structure embodiment 1, the outer walls of two blast furnace staves 1 are stacked back to back so that the inlet and outlet pipes are protected by the two staves. Figure 5 The prefabricated packaging bracket 3 is installed and welded on the packaging cross arm 2 on the stave, so that the two staves form a solid whole with the outer wall convex arc surface inside the inlet and outlet pipes and the inner wall concave arc surface outward. To ensure the safety and reliability of stacking, transportation, loading and unloading; among them, the stave packaging cross arm is made of round steel, according to Figure 4 The cross-arm layout of the blast furnace stave packaging is processed and cast together with the blast furnace stave body to ensure a firm and effective fulcrum for the packaging bracket.

Embodiment 2

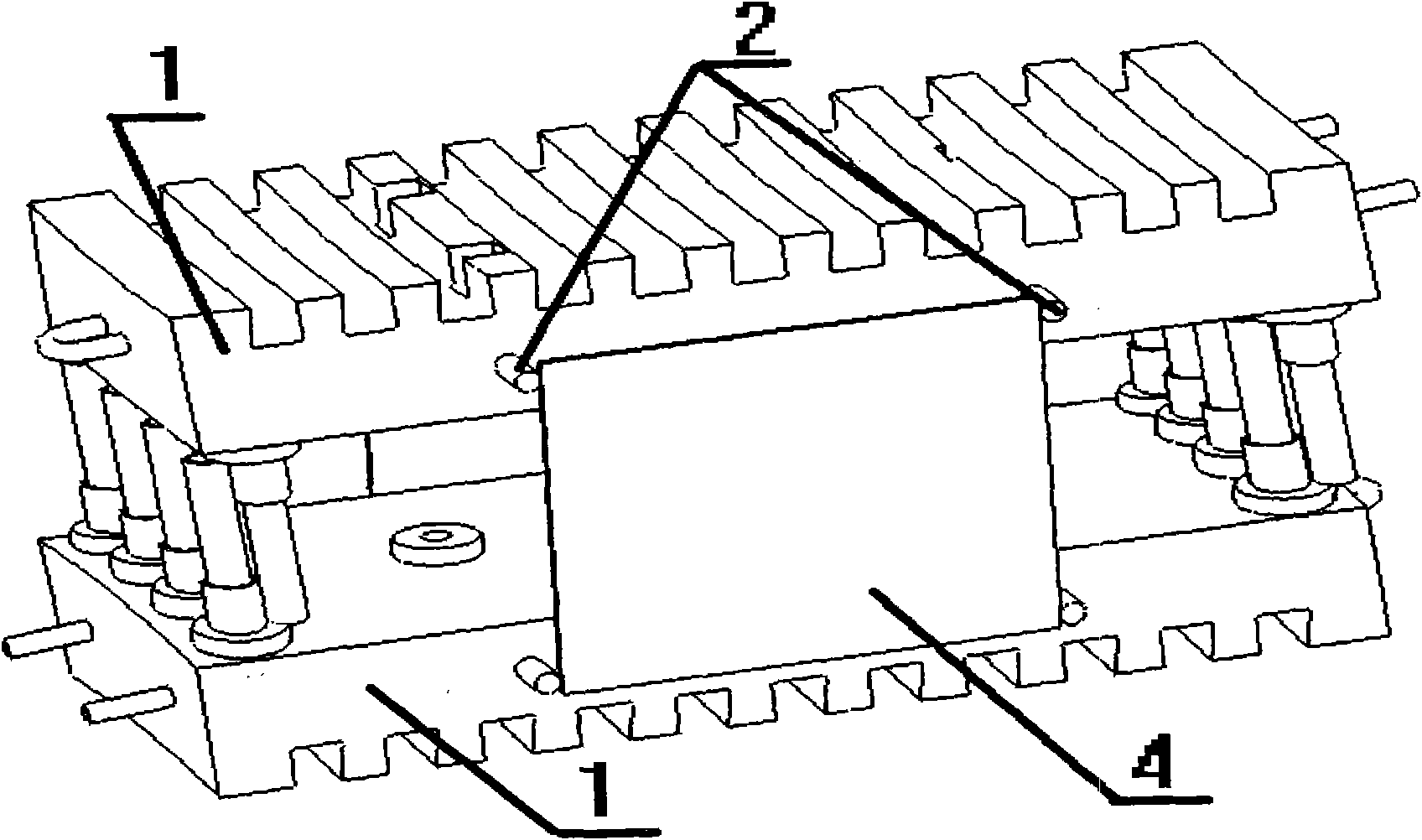

[0016] Such as figure 2 As shown in the perspective view of blast furnace stave packaging structure embodiment 2, the outer walls of two blast furnace staves 1 are stacked back to back so that the inlet and outlet pipes are protected by the two staves. Figure 6 Steel plate packaging bracket diagram The prefabricated packaging bracket 3 is installed and welded on the packaging cross arm 2 on the cooling wall, so that the two cooling walls form a solid whole with the outer wall convex arc surface inside the inlet and outlet pipes and the inner wall concave arc surface outward. To ensure the safety and reliability of stacking, transportation, loading and unloading; among them, the stave packaging cross arm is made of section steel, according to Figure 4 The cross-arm layout of the blast furnace stave packaging requires processing, and it is cast together with the blast furnace stave body to ensure that the packaging bracket has a firm and effective fulcrum.

Embodiment 3

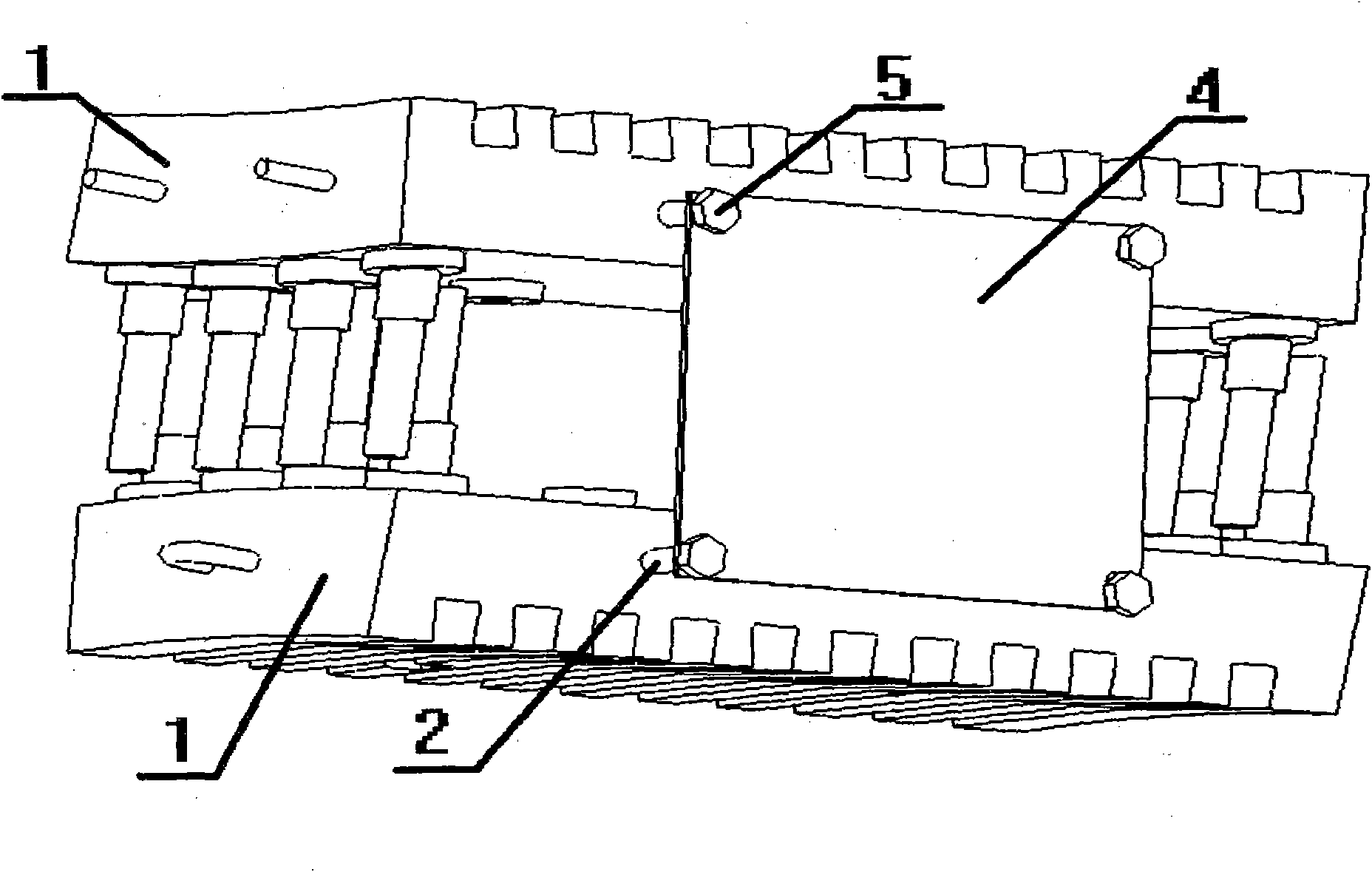

[0018] Such as image 3 As shown in the third perspective view of blast furnace stave packaging structure embodiment, the outer walls of two blast furnace staves 1 are stacked back to back so that the inlet and outlet pipes are protected by the two staves. Steel processed into bolts, press Figure 4 The cross-arm layout drawing of blast furnace stave packaging requires casting together with the blast furnace stave body. press Figure 7 Steel plate packaging bracket diagram (bolt fastening) The prefabricated packaging bracket 3 is installed on the cooling wall packaging cross arm 2, and fastened together with nuts, so that the two pieces of cooling walls form a convex arc surface on the outer wall. The concave arc faces outwards as a solid whole to ensure safe and reliable stacking, transportation, loading and unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com