Forklift special for mounting manual electrical cabinet

A technology for electrical boxes and forklifts, applied in the direction of lifting devices, can solve the problems of low operation performance and stable safety performance, and achieve the effect of improving the safety performance, convenient operation, and stable loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

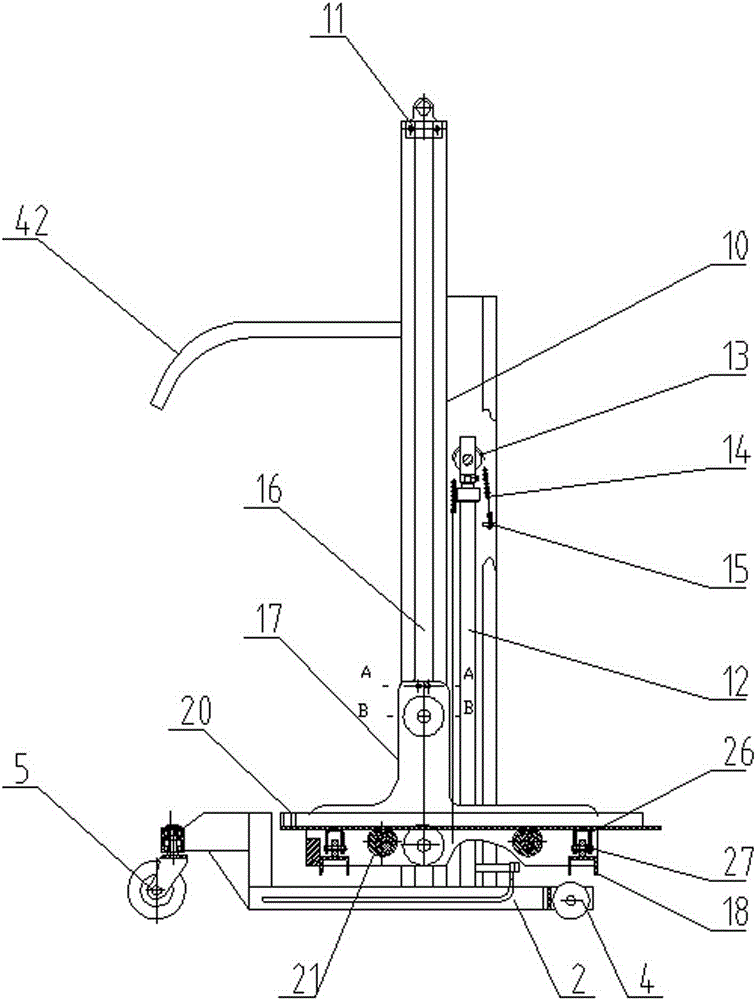

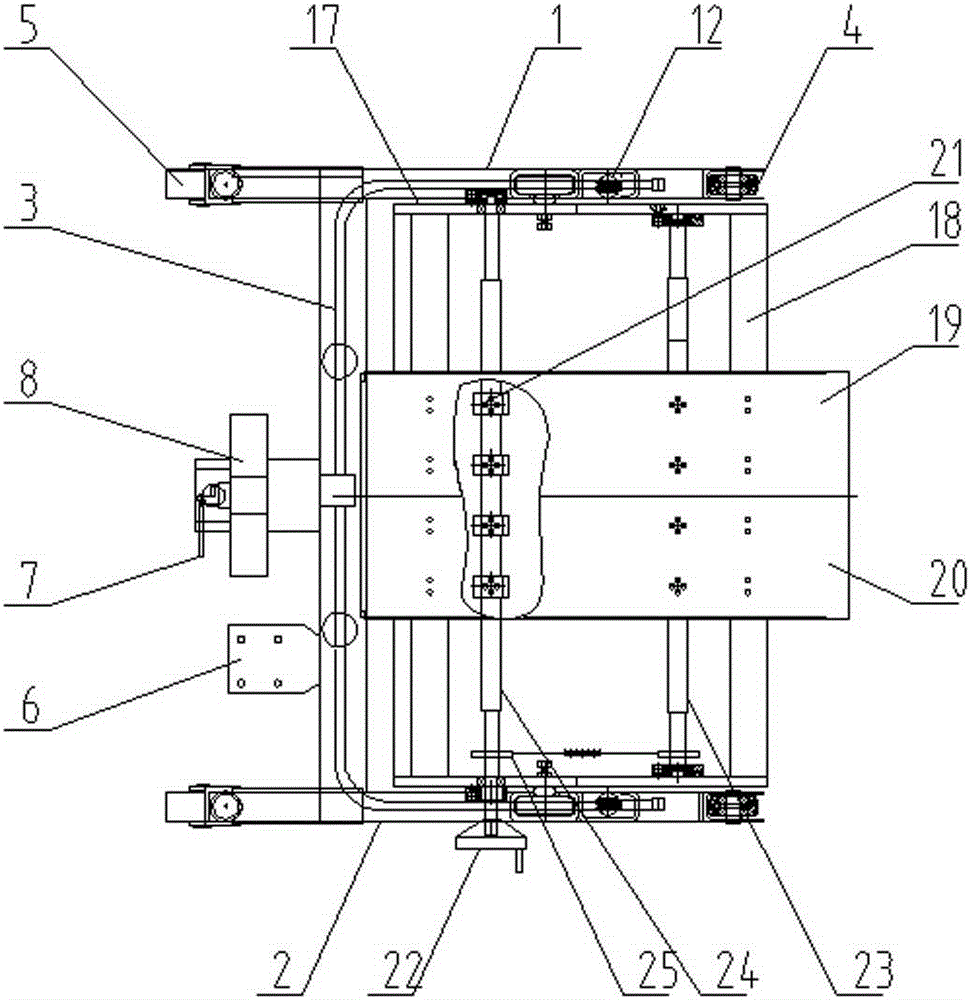

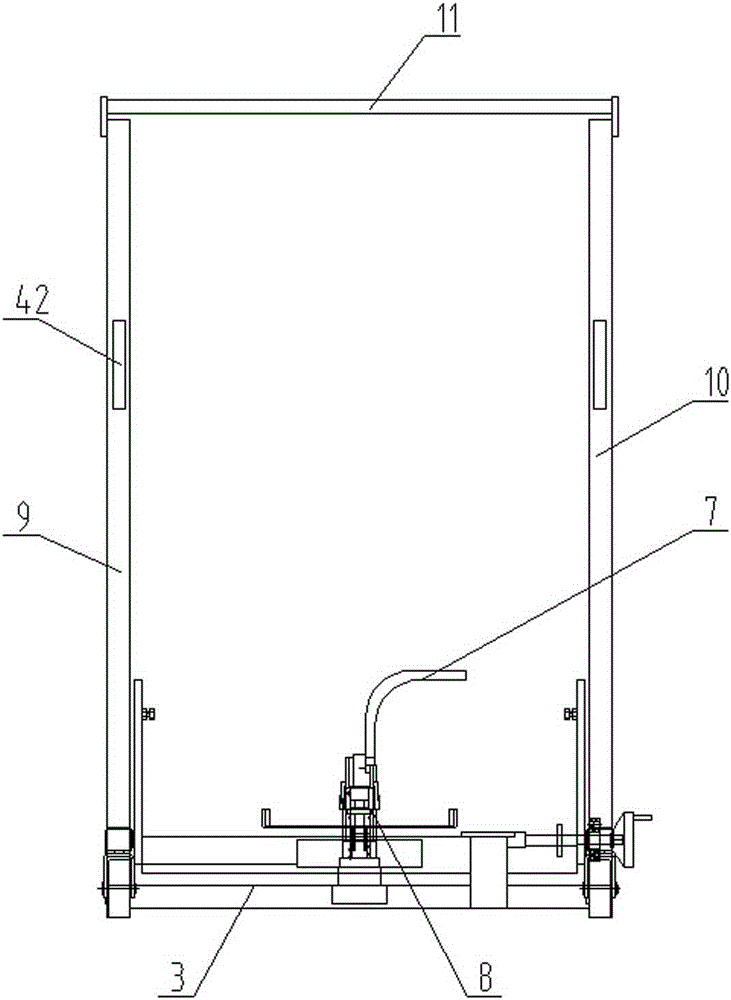

[0025] Figure 1-5 Shown: a special forklift for manual electrical box installation, the left bracket 1 and the right bracket 2 are vertically connected through the middle beam 3, the left bracket 1 and the right bracket 2 are respectively equipped with front wheels 4 and rear wheels 5, and the middle beam 3 Brake 6, oil pump 8 and lifting handle 7 are arranged on the top, left forklift frame 9 and right forklift frame 10 are respectively vertically supported and connected on left support 1 and right support 2, and the rear parts on left support 1 and right support 2 are all connected with Handrail 42, left support 1 and right support 2 are also all vertically provided with oil cylinder 12, and oil cylinder 12 is connected with oil pump 8, and oil pump 8 is controlled by elevating handle 7 and sends oil pressure synchronously to two oil cylinders 12 to complete the sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com