Multi-purpose mechanical hand clamp

A manipulator and multi-purpose technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of limited scope of application, easy rebound and shaking of the clamp arm, shaking of objects, etc., and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

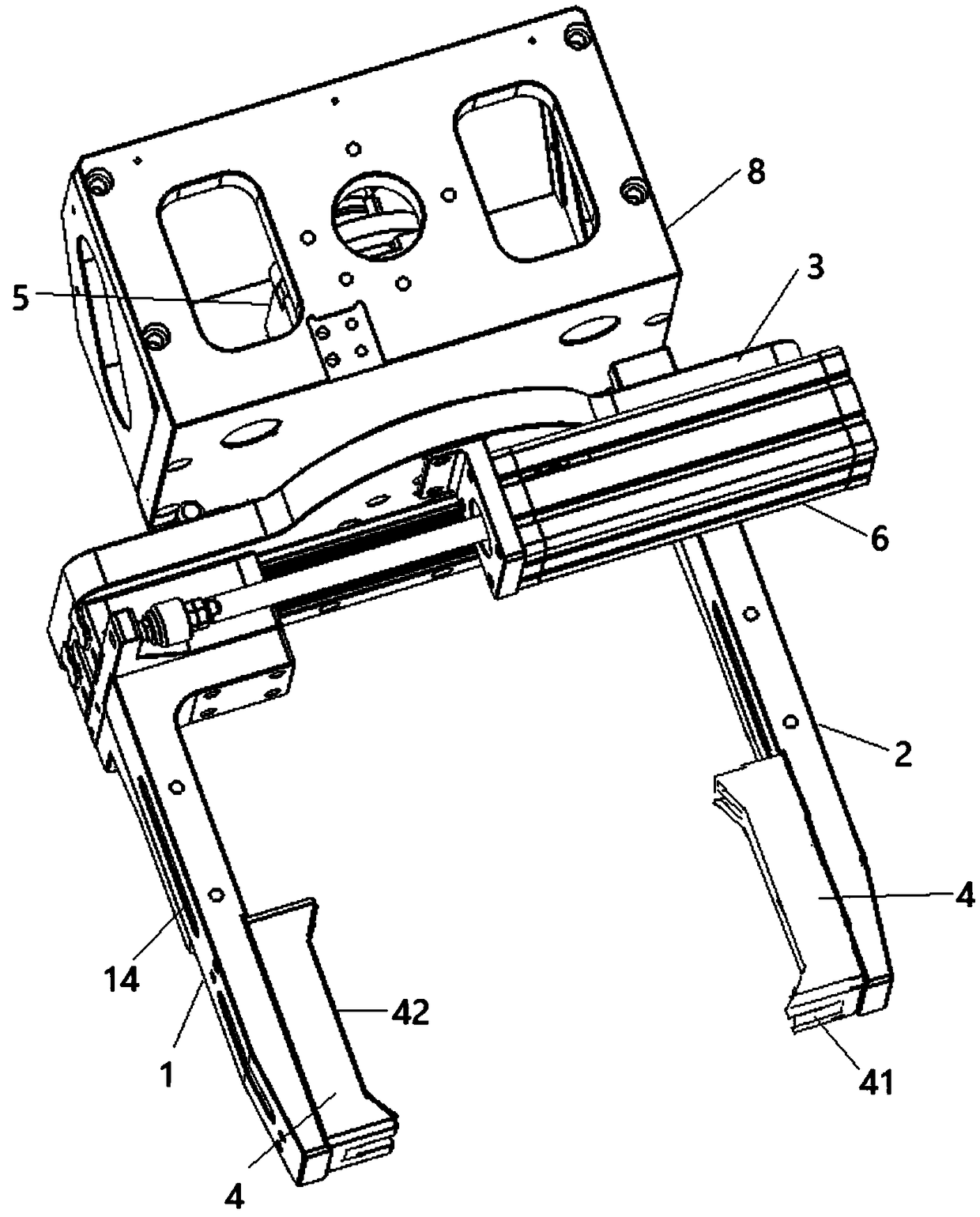

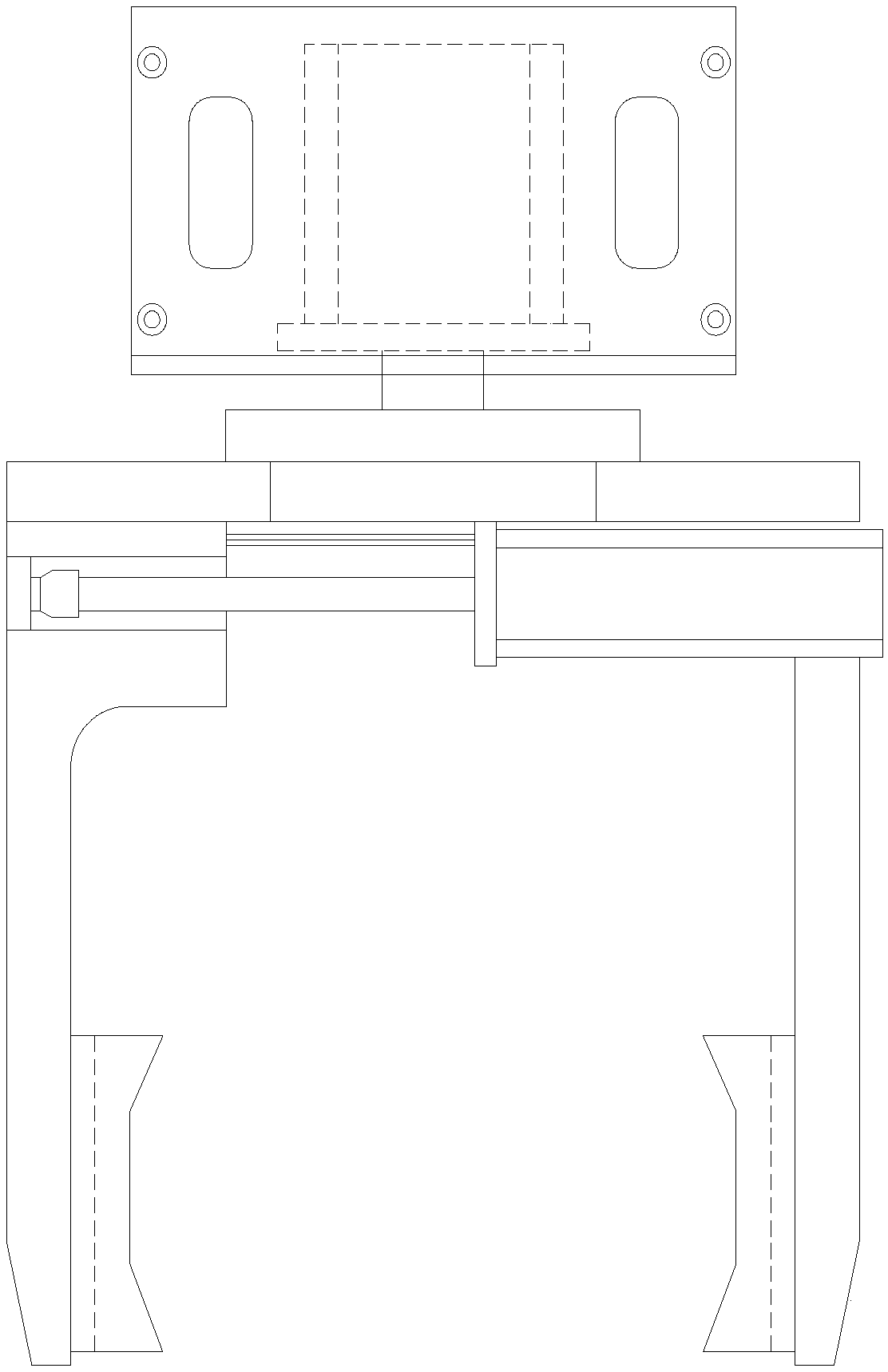

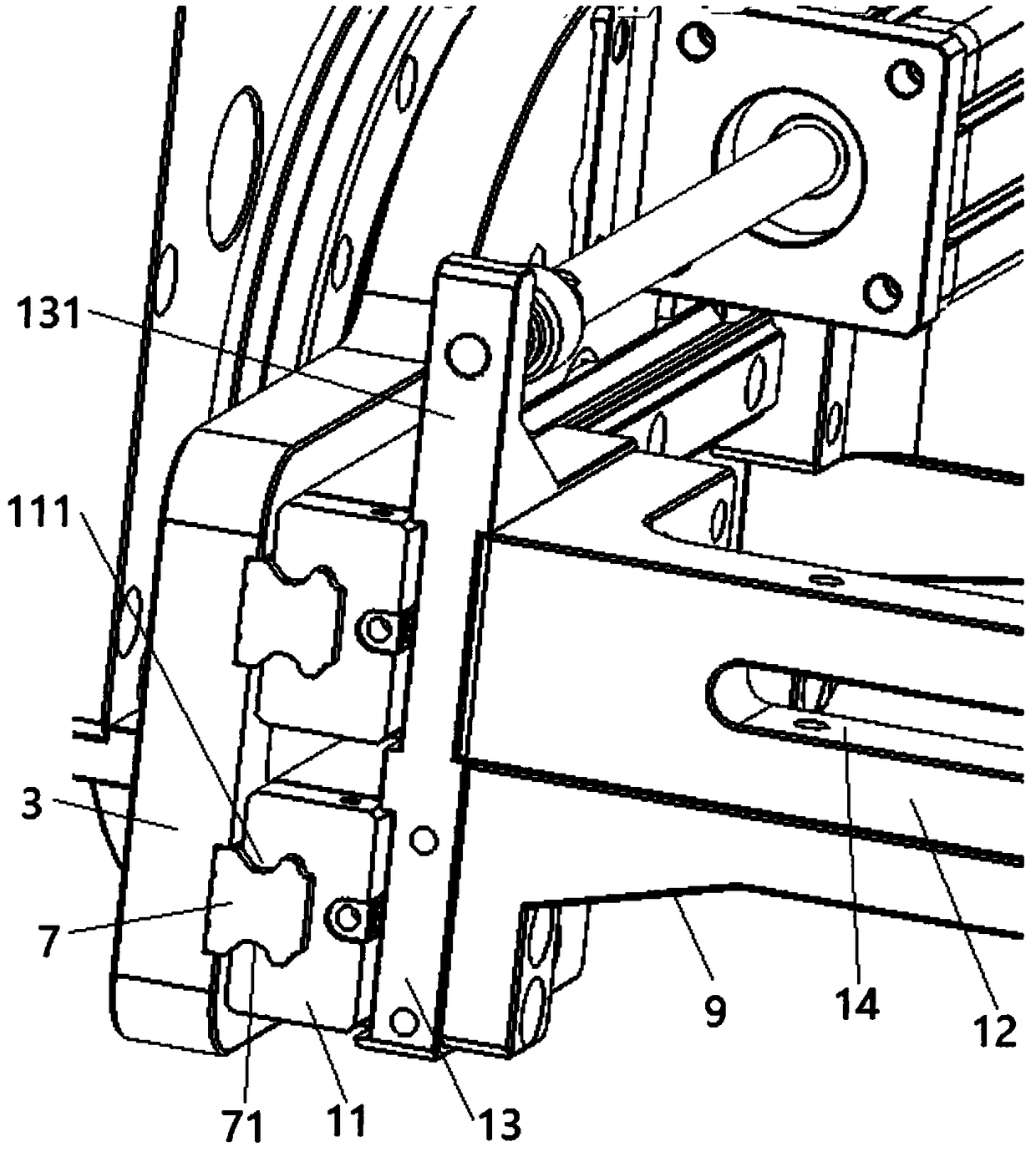

[0020] Such as Figure 1 to Figure 3 As shown, a multi-purpose manipulator clamp includes a left clamp arm 1, a right clamp arm 2 and a cross arm 3 vertically connecting the left clamp arm 1 and the right clamp arm 2, and the right clamp arm 2 and the cross arm 3 are fixedly connected , the left clamping arm 1 is slidably connected with the cross arm 3, and the inner sides of the left clamping arm 1 and the right clamping arm 2 are respectively provided with two opposite clamping blocks 4, and the two clamping blocks 4 are respectively provided with a card slot 41, and the card slot 41 The clamping block 4 runs through the direction parallel to the left clamping arm 1 and the right clamping arm 2, and the opening ends of the two clamping grooves 41 are oppositely arranged, and the clamping grooves 41 can be used to fork objects with ribs on both sides; this embodiment also Including the second drive cylinder 5, the second drive cylinder 5 is connected to the side of the cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com