Household garbage smashing, winnowing and compressing transportation car

A technology of household garbage and transport vehicles, which is applied in the field of domestic garbage crushing, air separation and compression transport vehicles, which can solve the problems of increasing the burden of environmental improvement, affecting the longitudinal stability of the vehicle, and affecting the surrounding environment, etc., to optimize garbage collection routes, The effect of reducing the gaps of domestic garbage and increasing the amount of garbage loaded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

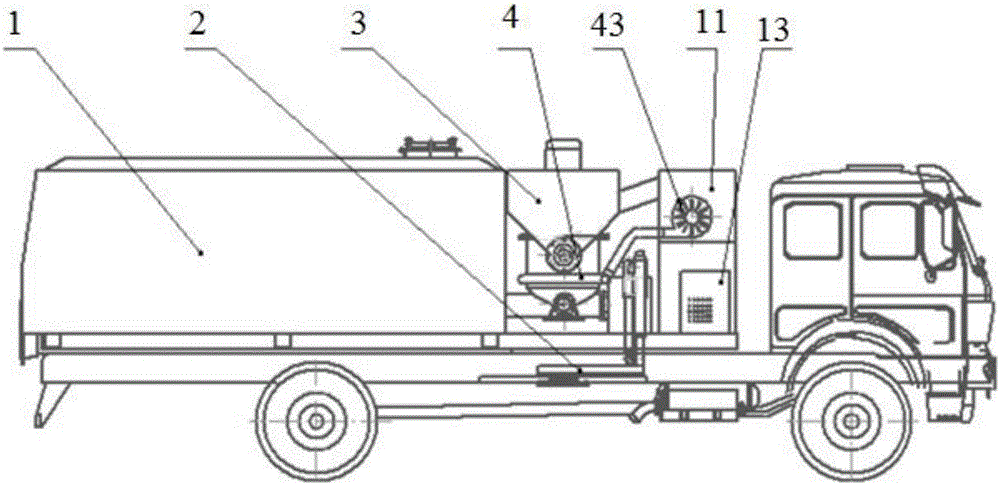

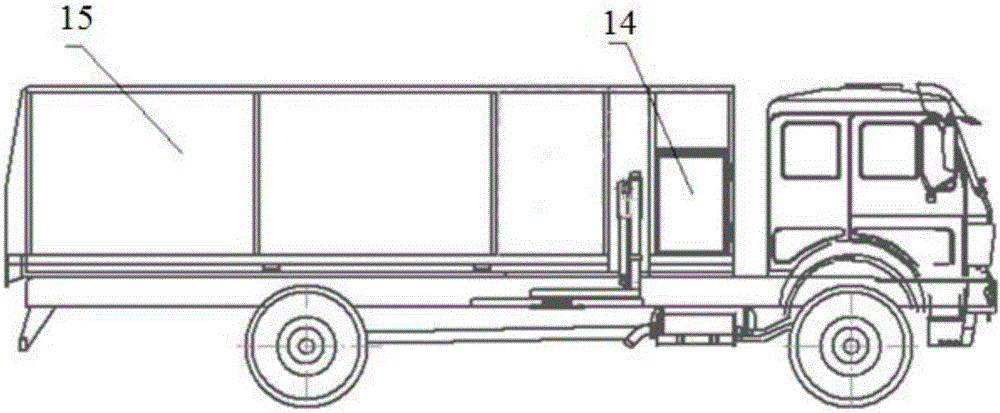

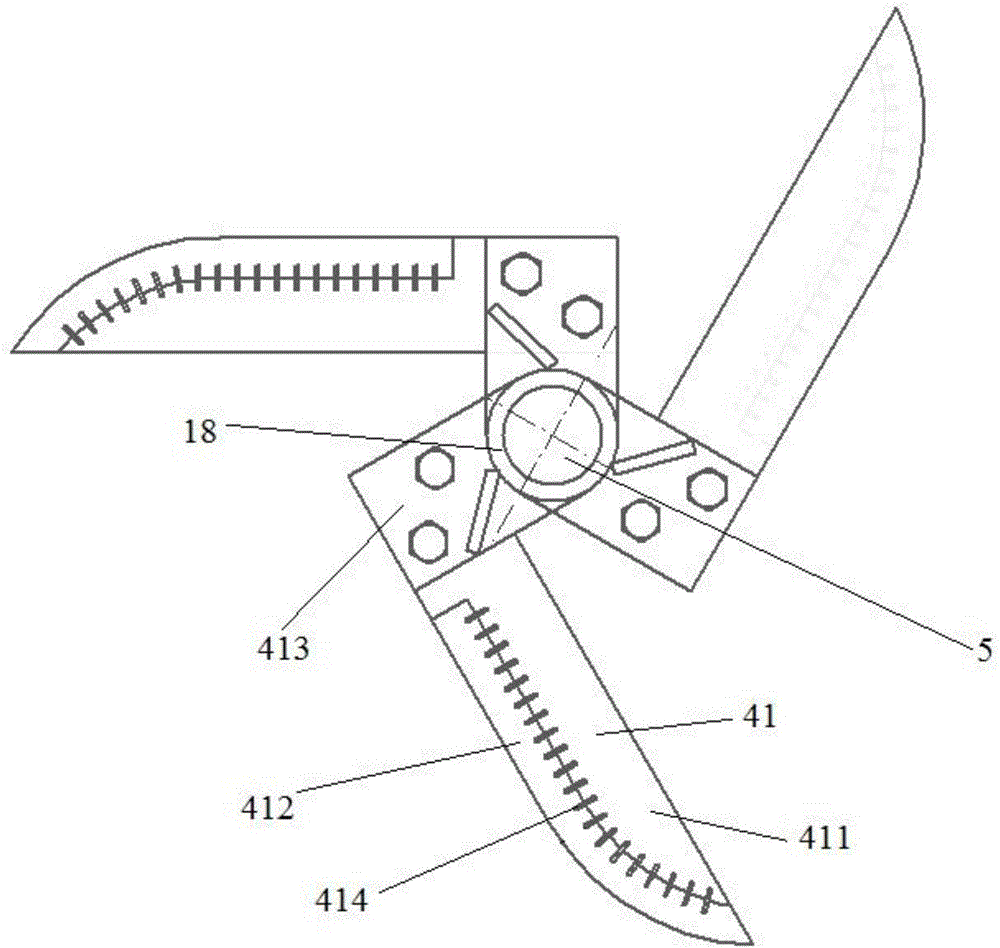

[0037] Such as Figure 1 to Figure 11 Shown, a kind of crushing winnowing compression transportation vehicle of house refuse comprises automobile chassis, is provided with rubbish collection compression tank 1, automatic charging device 2, dustbin 3 and crushing winnowing device 4 on the automobile chassis; Garbage collection compression tank 1 It is arranged at the rear of the car, and the dustbin 3 and the crushing winnowing device 4 are arranged between the head of the car and the tail of the car, and are used to grab the automatic charging device 2 of the roadside dustbin 12 and the side of the chassis of the automobile below the dustbin 3 The sides are connected, and the pulverizing winnowing device 4 for pulve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com