Mobile hydraulic pressure adjusting board

A regulating plate, mobile technology, applied in the direction of fluid pressure actuation device, transportation and packaging, loading/unloading, etc., can solve the problems of logistics enterprises increasing equipment investment cost and cargo platform damage, and achieves safe loading and unloading, convenient for mobile use , The effect of convenient moving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

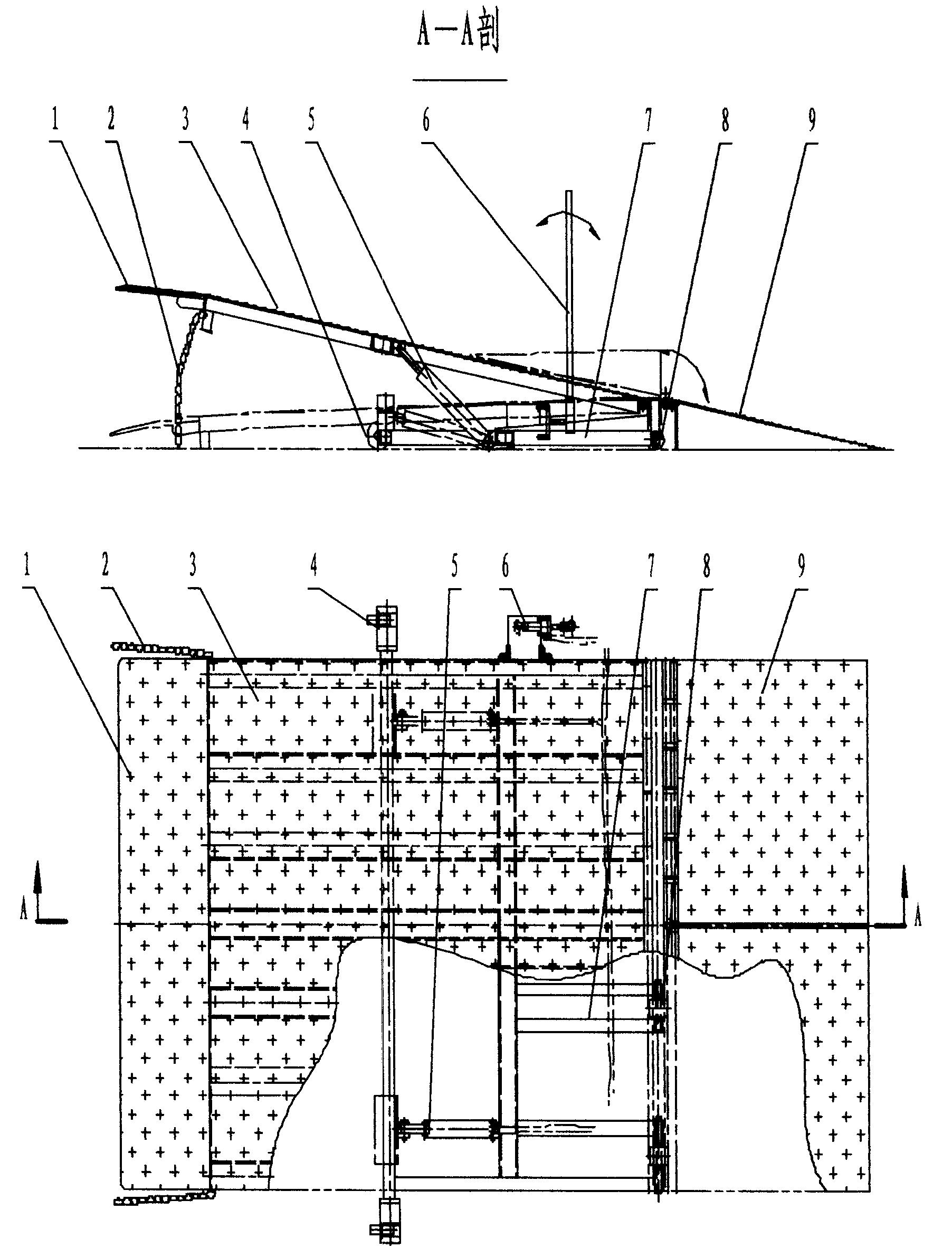

[0015] exist figure 1 In (general assembly drawing), butt plate (1), table top (3), slope (9) are connected on the underframe by tubular hinge, and manual oil pump (6) utilizes bolt to be fixed on the underframe. The safety chain (2) is fixed on the front end of the table, which is convenient to be connected with the loading and unloading truck, so as to ensure that the adjusting plate is integrated with the truck during loading and unloading. The oil cylinder (5) is installed on the table top and the hinge ear of the underframe, and the table top is lifted and lowered by the expansion and contraction of the oil cylinder (5). The oil cylinder (5) is communicated with the manual oil pump (6) through a high-pressure steel wire hose, and the power hydraulic oil enters and exits the oil cylinder through the high-pressure steel wire hose.

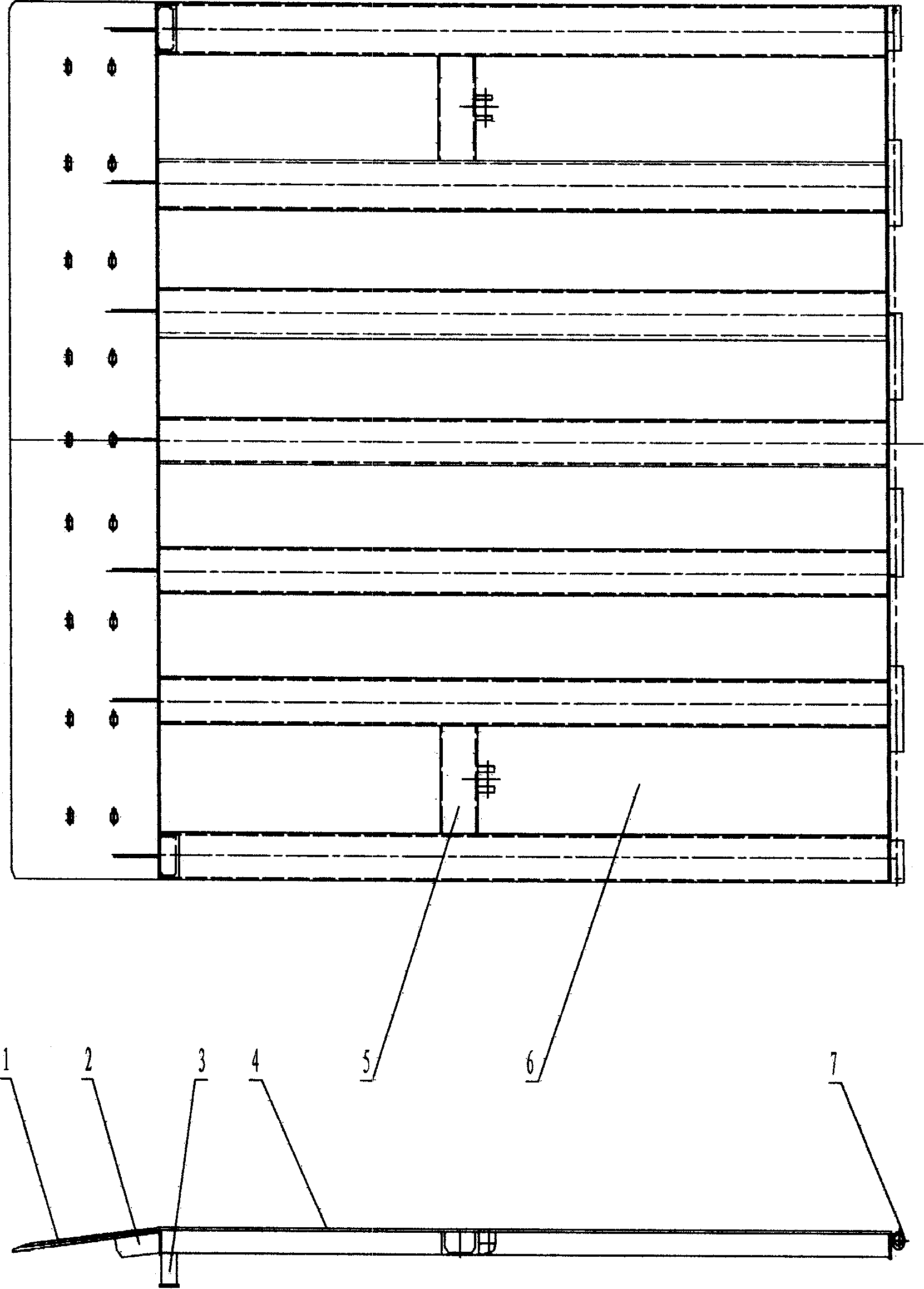

[0016] exist figure 2 Among them, the strapping plate (1), stiffener plate (2), and the lowest support (3) are welded to the left end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com