Automatic feeding and discharging device of type rolling machine

An automatic loading and unloading and letter rolling machine technology, which is applied in the mechanical field, can solve the problems of increasing the letter rolling operation cycle and time waste, and achieve the effect of reducing the operating rhythm, less time consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

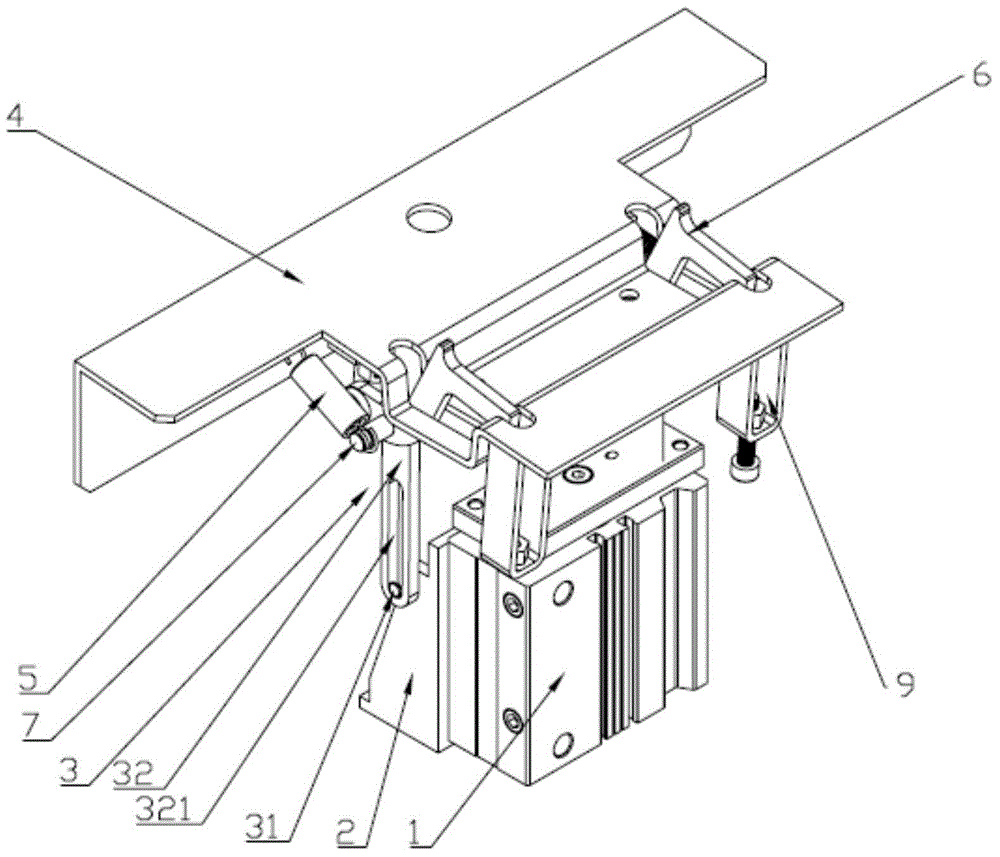

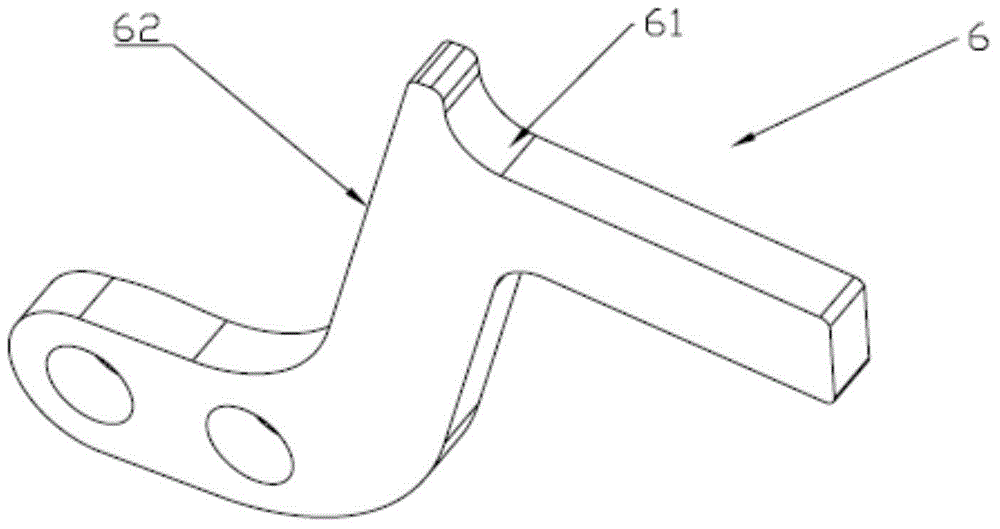

[0023] like Figure 1-Figure 3 As shown, the automatic loading and unloading device of the letter rolling machine includes a driving part 1, a driving part mounting bracket 2, a limit mechanism 3, a feeding mechanism 4, a reset mechanism 5 and a feeding mechanism 6, and the driving part 1 controls the feeding The mechanism 4 and the unloading mechanism 6 reciprocate up and down, the described loading mechanism 4 and the unloading mechanism 6 are rotatably connected, and the described loading mechanism 4 and the driving part mounting bracket 2 are slidably connected through the limit mechanism 3, so The reset mechanism 5 described above controls the blanking mechanism 6 to perform a reset movement;

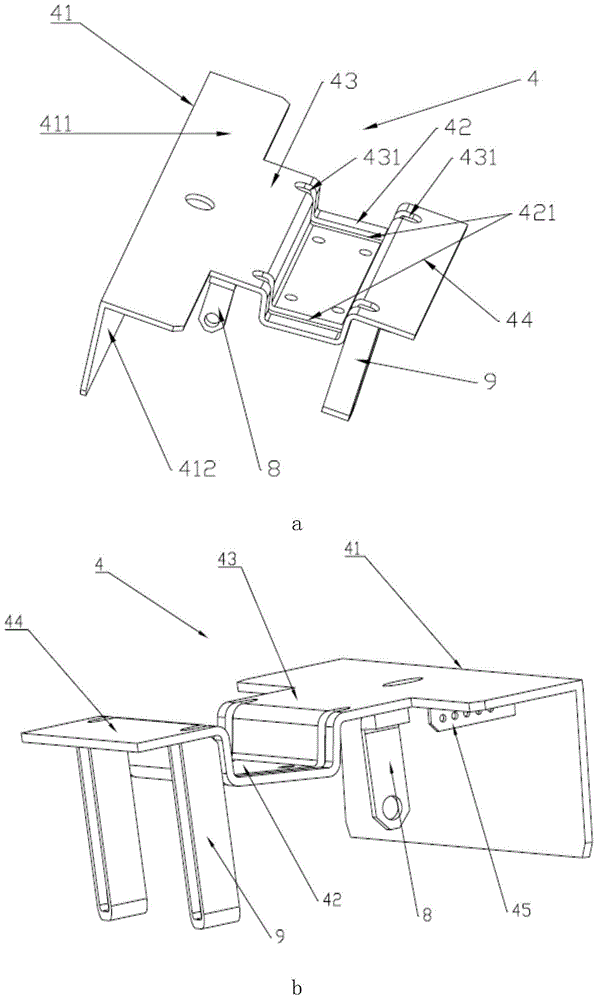

[0024] The feeding mechanism 4 includes an integrally formed bending part 41 and a groove 42, and the two sides of the groove 42 are respectively provided with a first edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com