Floatable track type special underwater operation robot suitable for extremely soft geology

An underwater operation and crawler-type technology, which is applied to tracked vehicles, motor vehicles, amphibious vehicles, etc., can solve the problems of underwater shooting difficulties, increase the input of manpower and material resources, and damage the ore-collecting head, so as to shorten the operation time and task cycle , Improve the reliability of the device and reduce the effect of grounding specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

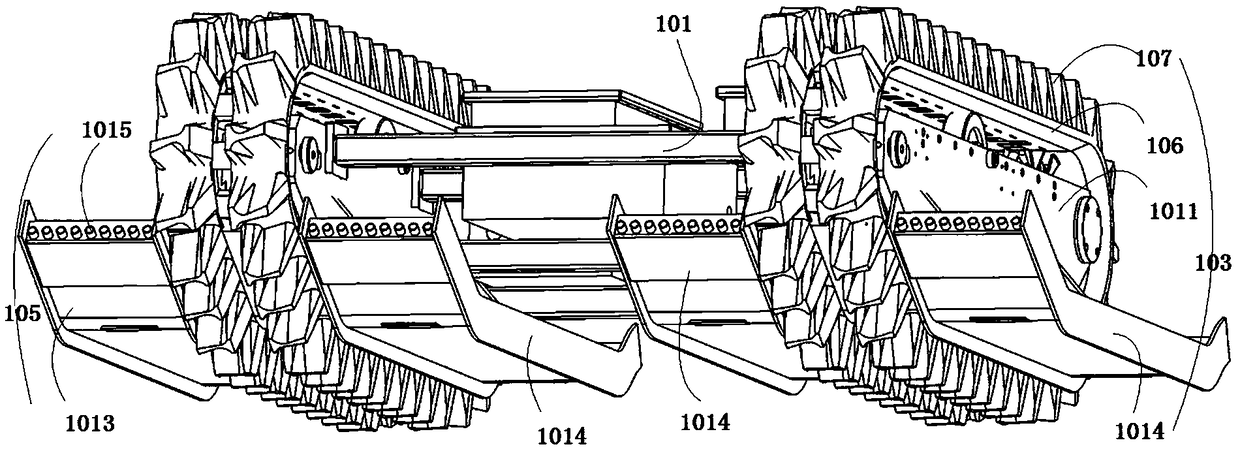

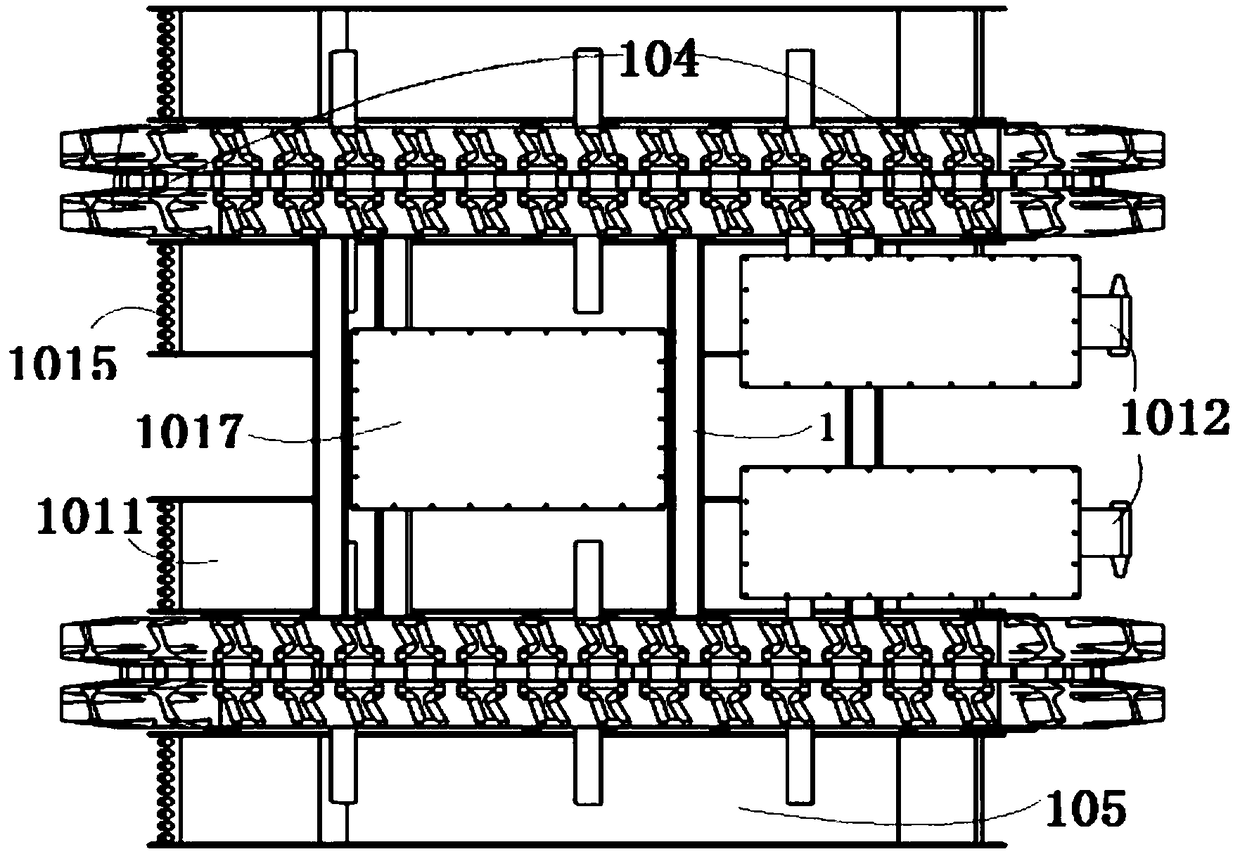

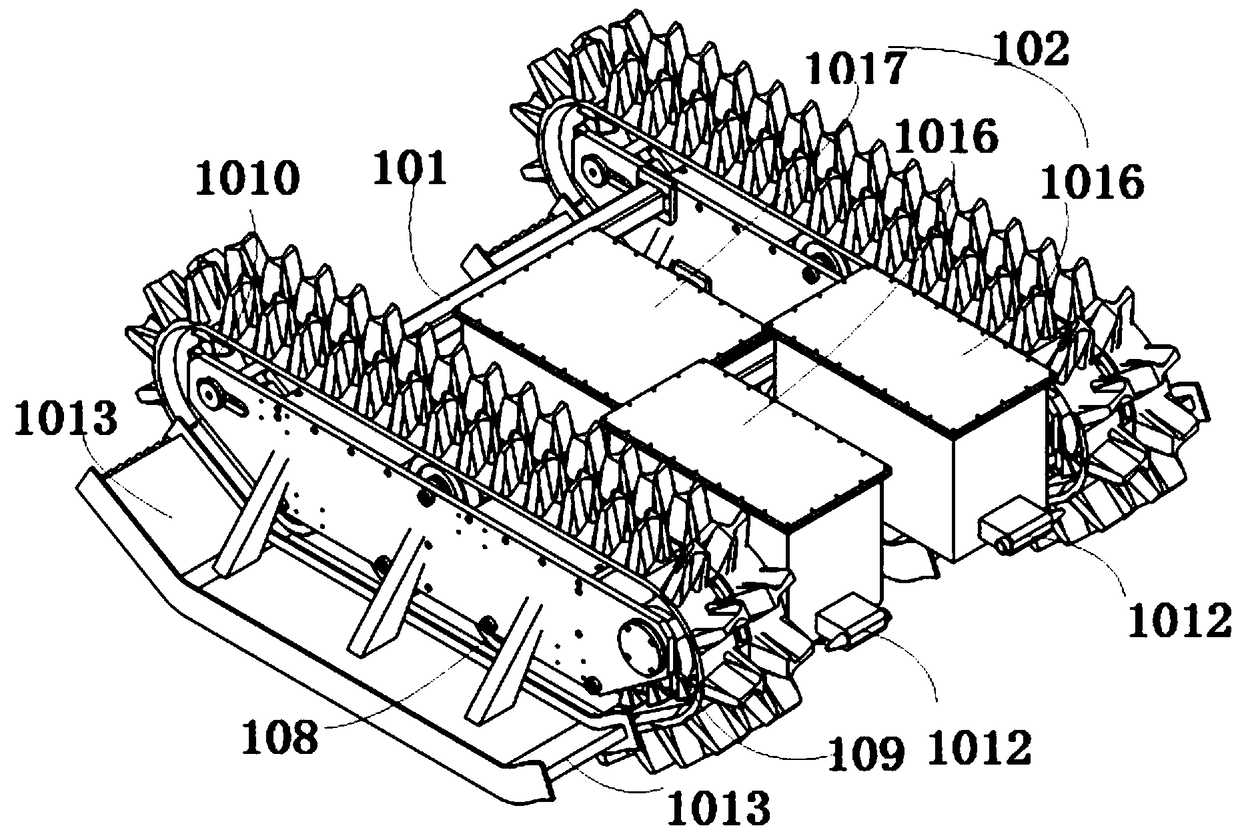

[0067] In this example, see Figure 1-3 , the crawler track adapted to the extremely thin and soft underwater ground environment is used to travel on the seabed and other rare and soft geological conditions. The track is a sled track, including the following parts: rubber track 106, spur 107, roller 108, driving gear 109, guide wheel assembly 1010, track walking structure side panel 1011, track water jet device 1012 and other structures.

[0068] The rubber track 106 is composed of track shoes, track pins and the like. The track pins connect the track shoes to form a track link. There are holes at both ends of the track shoes, which mesh with the driving wheel, and there are inducing teeth in the middle, which are used to regulate the track and prevent the track from falling off when the device turns or rolls, which improves the stability of the device.

[0069] The thorns 107 are fixed on the bottom of the rubber crawler, and their length is longer than that of ordinary tho...

Embodiment 2

[0097] The difference between the walking mechanism in this embodiment and the first embodiment is that the caterpillar belts on the left and right sides of the robot are divided into front and rear units respectively.

[0098] This embodiment has the same design idea and structure as the first embodiment, and can realize all the functions of the first embodiment. On this basis, the present embodiment also has additional designs, which are specifically described as follows:

[0099] see Figure 7 , 10 , 12. The center of the robot chassis is in the shape of a bell mouth with a large bottom and a small top. The collection box 2 is in a ring structure. There is a columnar space in the ring structure. The upper end of the columnar space is a water inlet, and the lower end is a water outlet. A propeller 8 is set at the center, and the propeller can drive water into the columnar space; a slightly raised baffle 1018 is fixed below the columnar space, and under the blocking effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com