An automatic stamping machine

An automatic stamping machine and automatic oiling technology, which is applied in stamping, printing, etc., can solve the problems of cost increase, cumbersome oiling operation, and paper jams, so as to improve stability and reliability, reduce the probability of paper jams, and avoid mechanical The effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

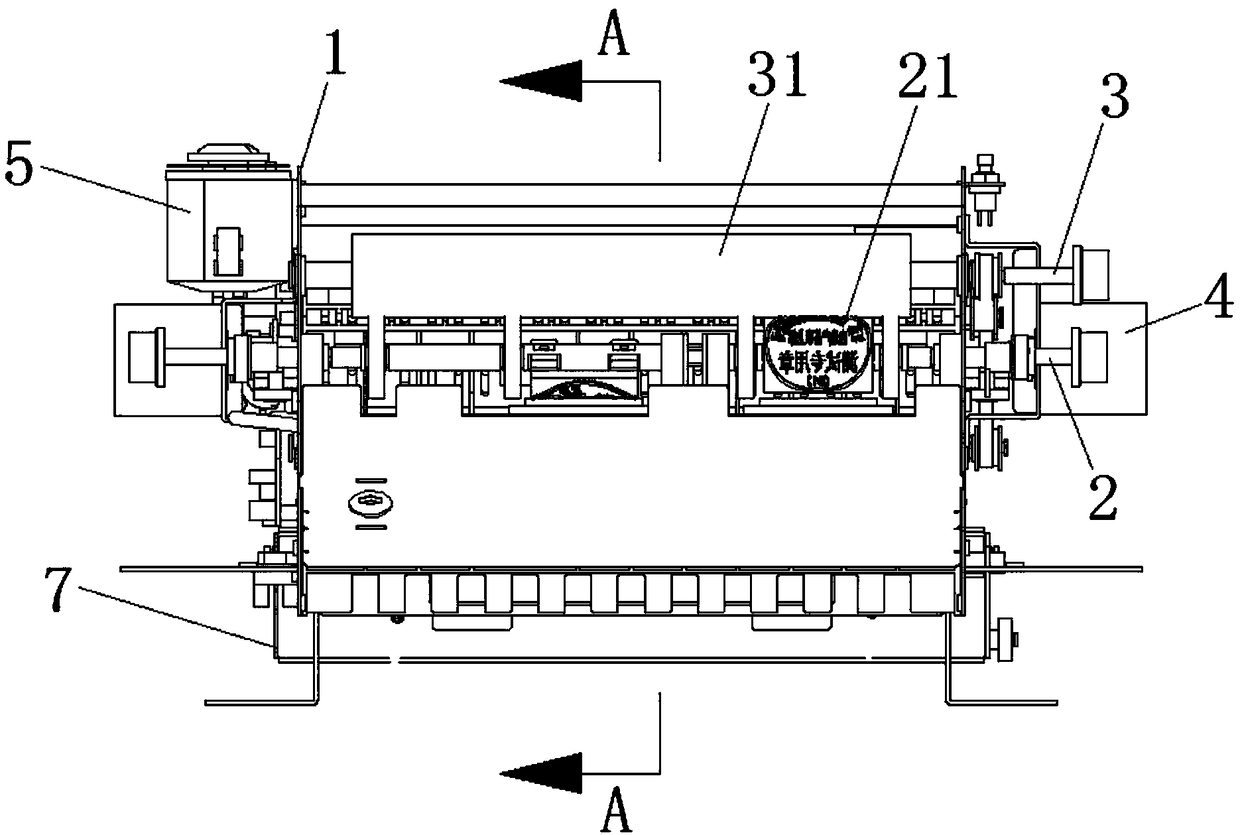

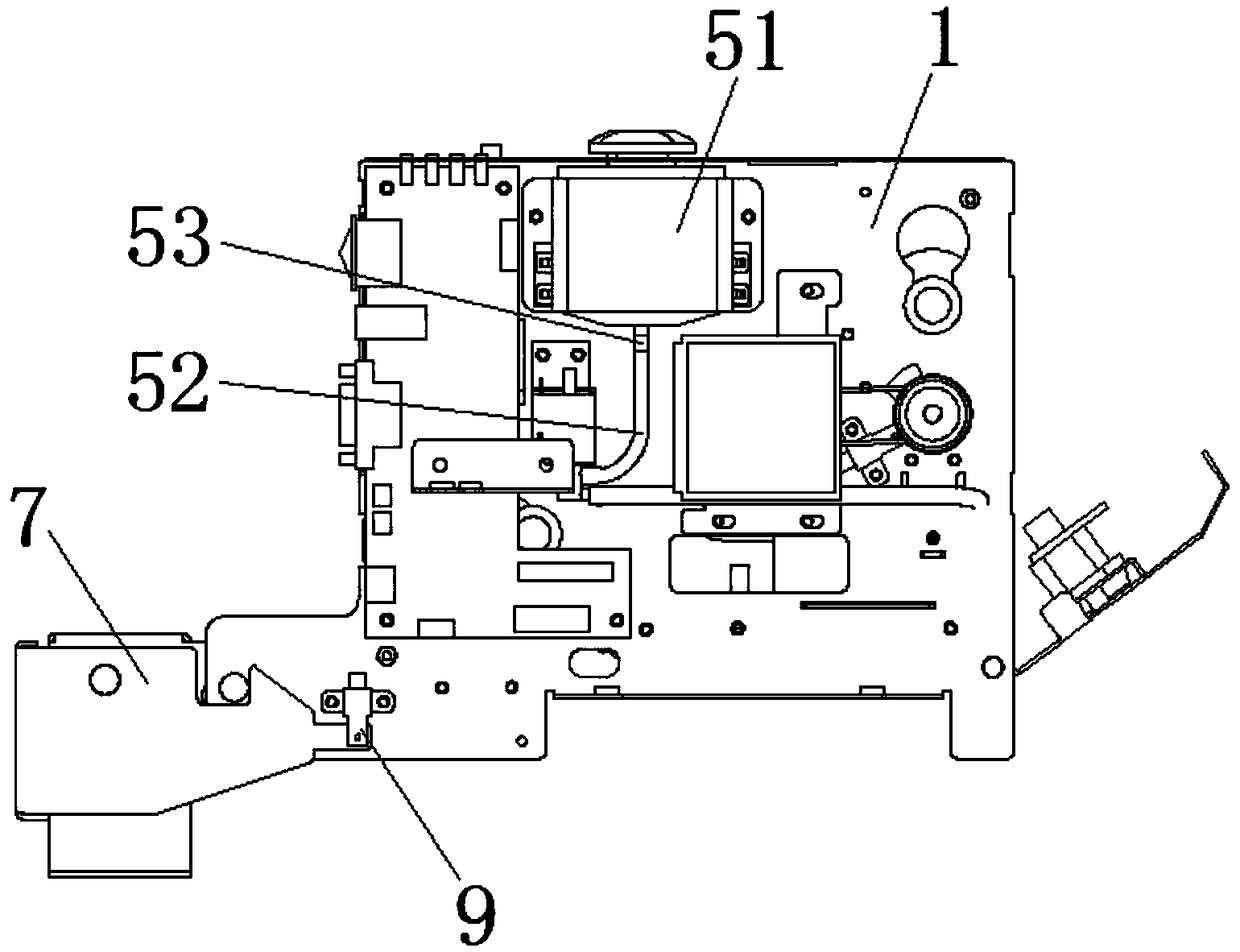

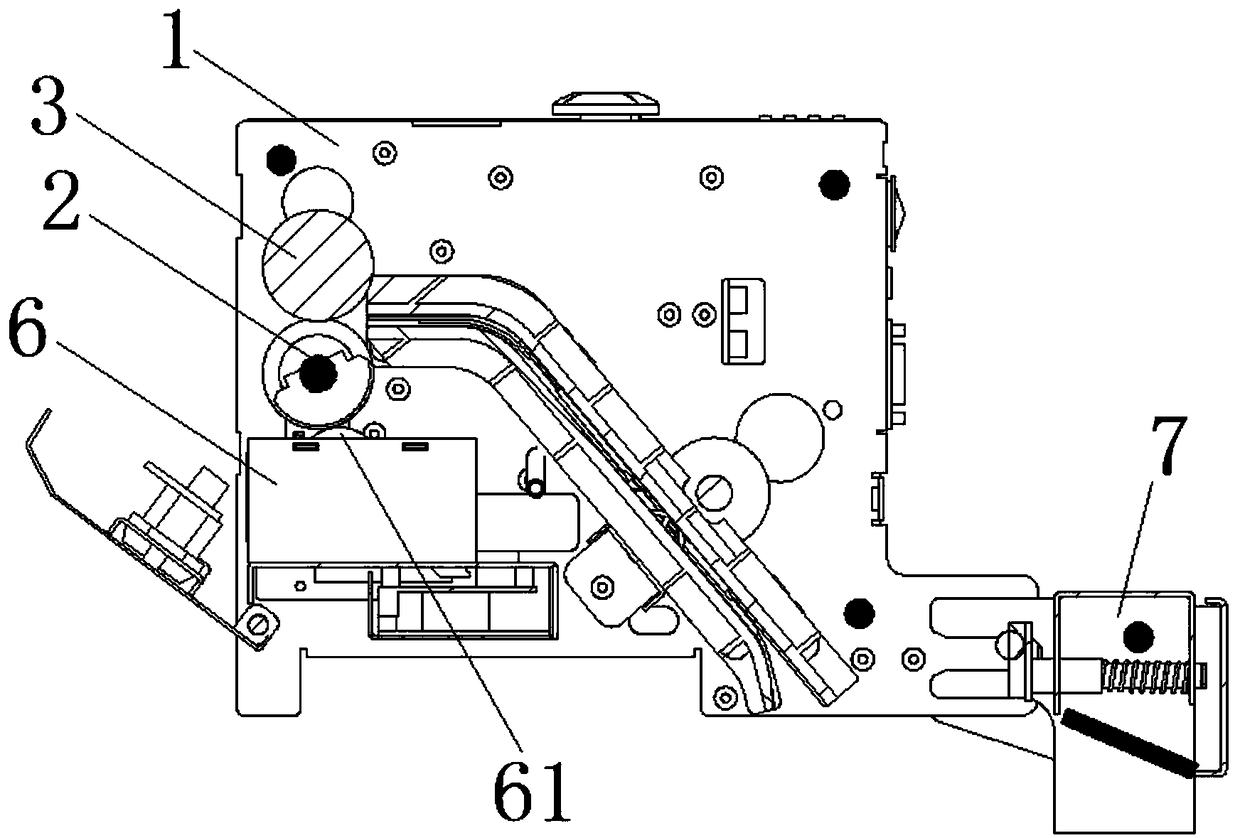

[0046] See Figure 1 to Figure 5 , the automatic stamping machine of the present embodiment comprises a frame 1, a seal rotating shaft 2, a rolling rotating shaft 3, a driving mechanism 4, an automatic oiling mechanism 5, an ink cartridge 6, a positioning locking device 7, a first groove sensor 8 and a first Two slot sensors9.

[0047] The seal rotating shaft 2 and the rolling rotating shaft 3 are arranged on the frame 1 in parallel rotation, and the seal rotating shaft 2 is located below the rolling rotating shaft 3 . Seal rotating shaft 2 is installed on the frame 1 by elastic bearing seat. At least one scrolling stamp 21 is provided on the stamp rotating shaft 2 , and a rolling printing roller 31 corresponding to the position of the scrolling stamp 21 is provided on the scrolling rotating shaft 3 .

[0048] The driving mechanism 4 is installed on the frame 1, and drives the seal rotating shaft 2 and the rolling rotating shaft 3 to rotate in opposite directions synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com