Patents

Literature

47results about How to "Reduce paper jams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

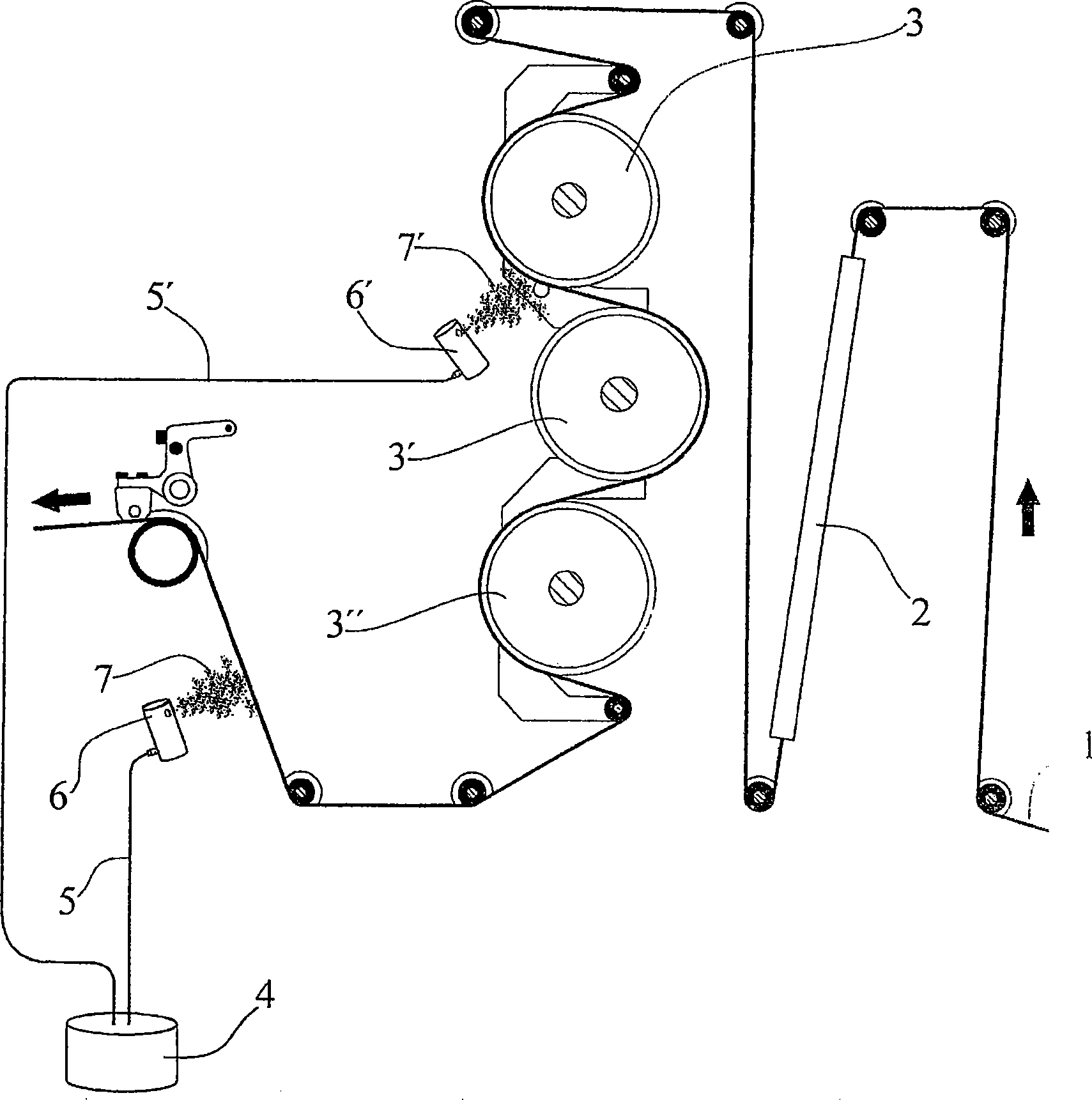

Method and device for conditioning paper

InactiveCN101484319ARealize the operating cycleLow costOther printing apparatusOffice printingLiquid waterLiquid state

Method for conditioning paper, which comprises a first step of cooling and one of applying a liquid to the paper. In the cooling step, the temperature of the paper is reduced, e.g. below ambient temperature or below the dew point of a liquid-saturated gas mass applied in the liquid-application step. The gas may be ambient air and the liquid water. Control means monitor the amount of liquid applied to the paper by means of measuring the relative humidity of the air, the absolute humidity of the paper, the temperature of the device where the liquid is applied and the temperature of the paper. The invention also comprises a device for applying the method and it may be applied to paper emerging from a printer, e.g. a digital printer.

Owner:DIGITAL INTERNET TRANSPORT SYST

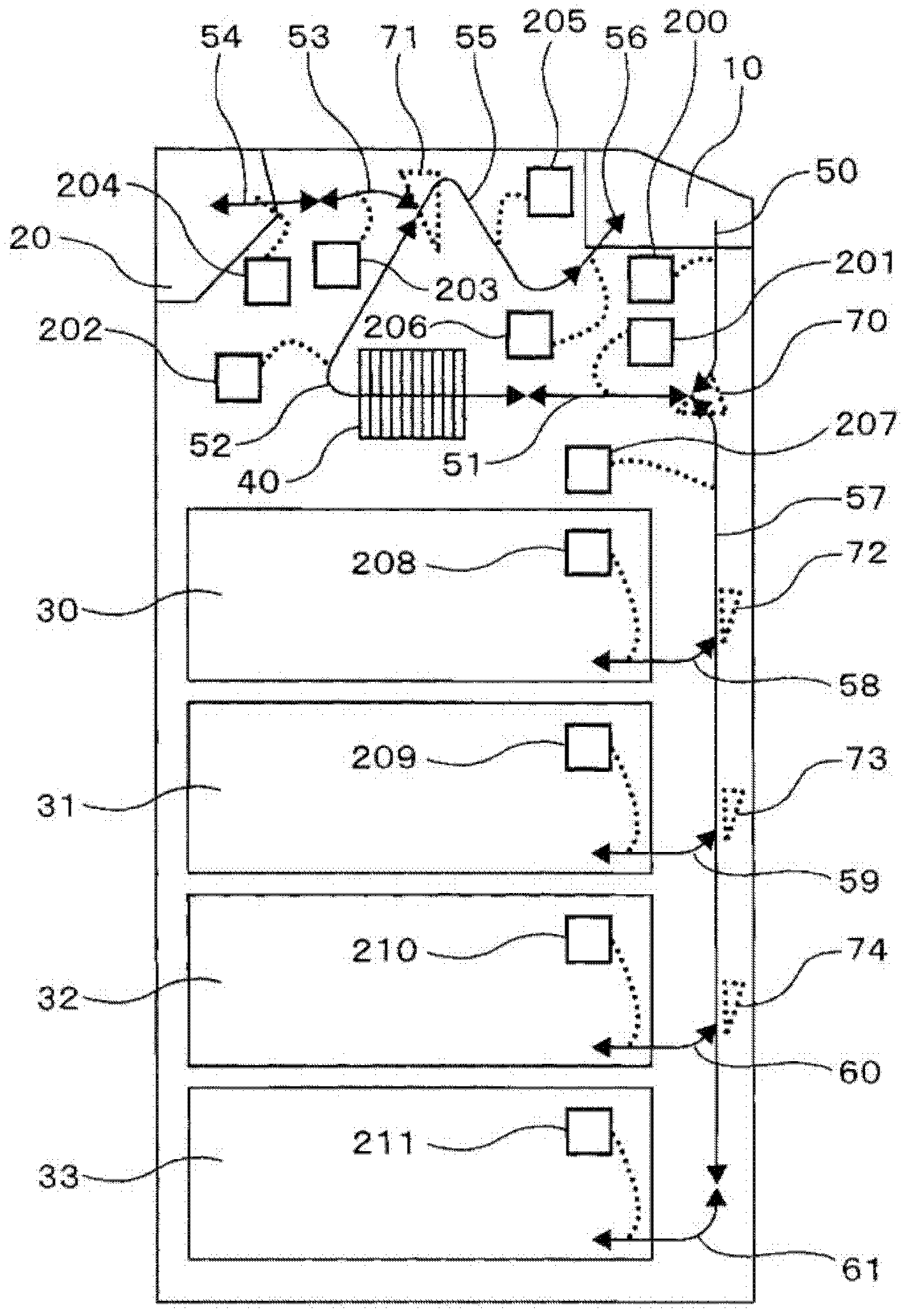

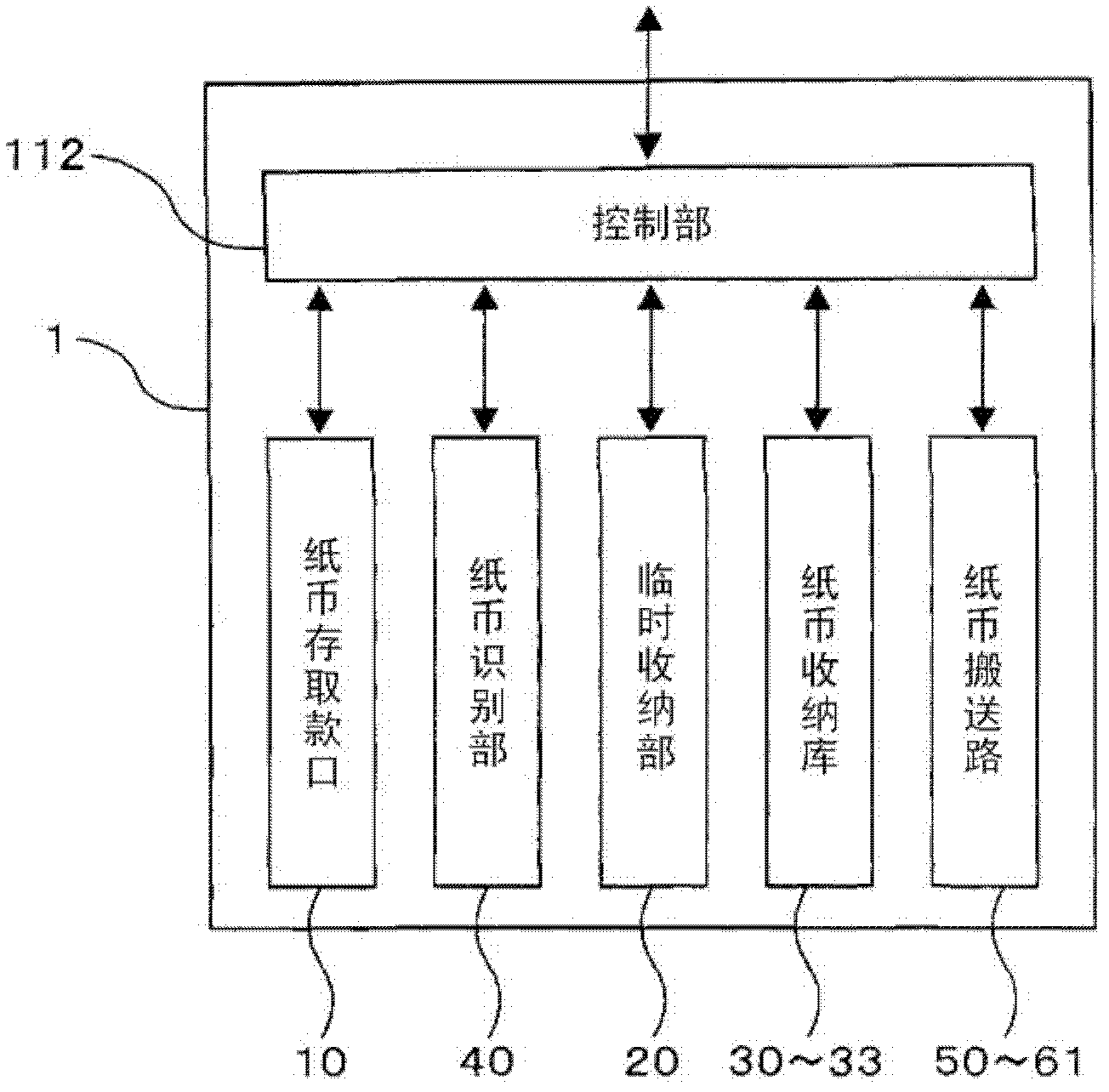

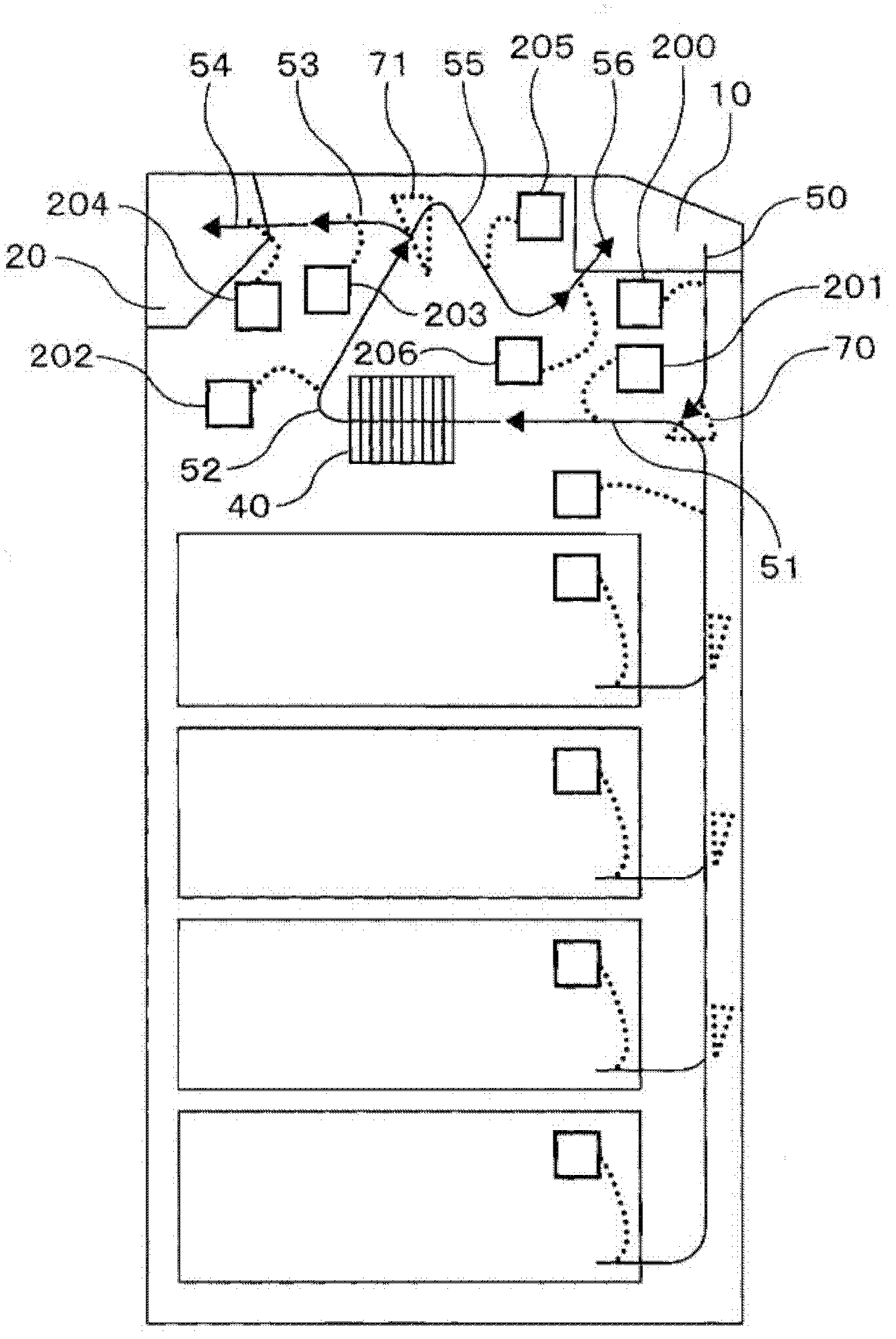

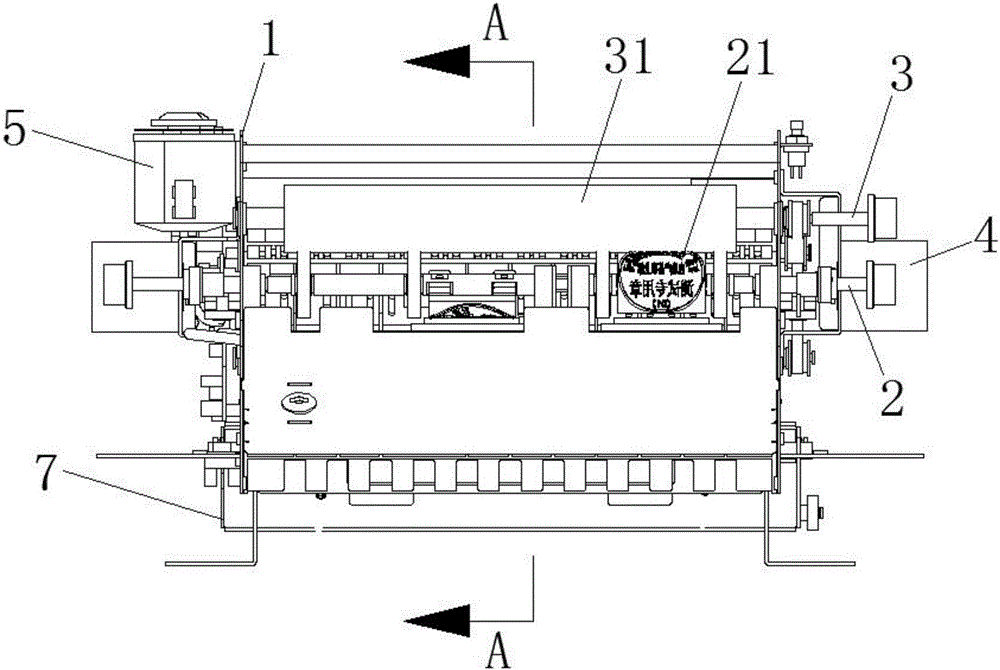

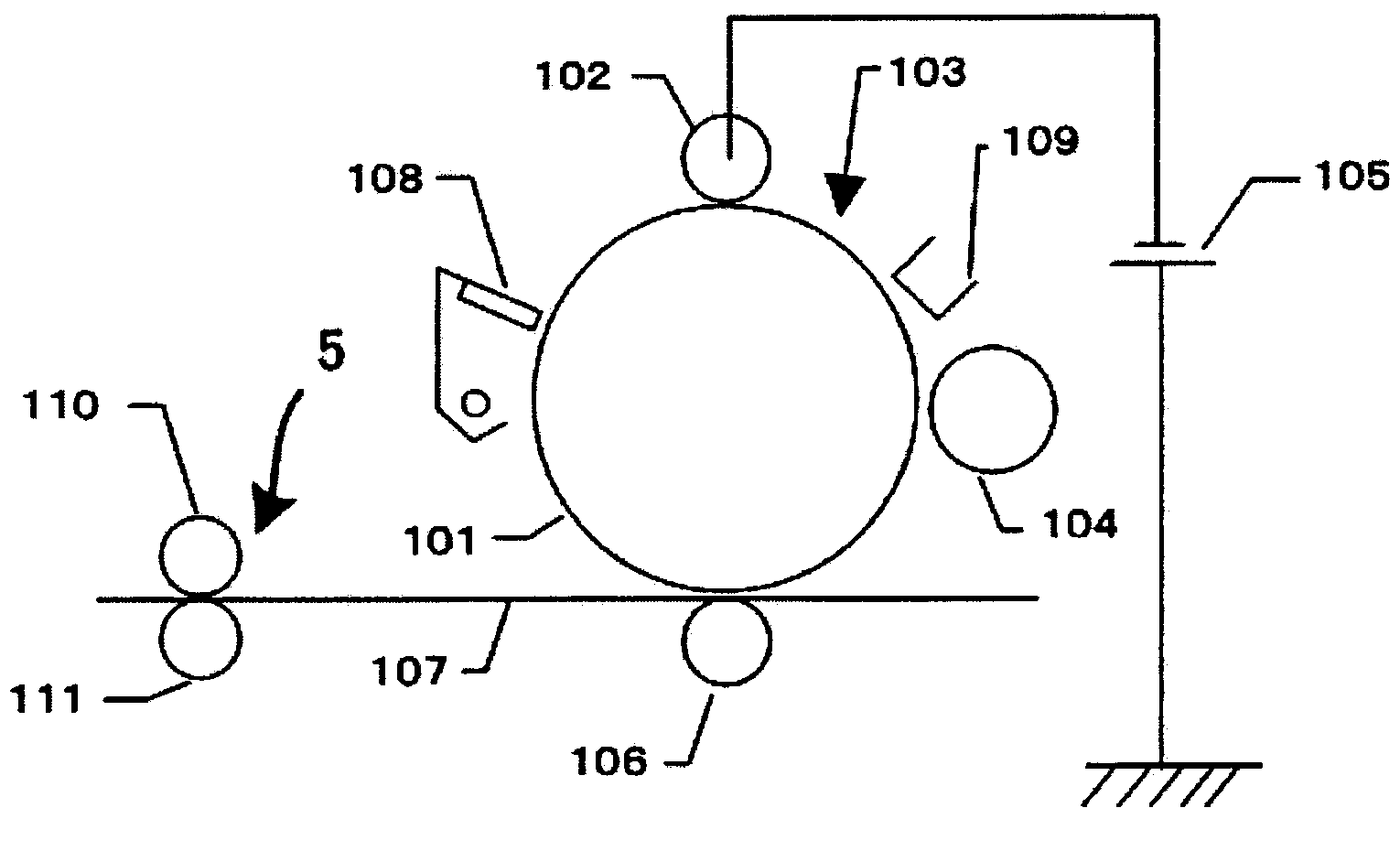

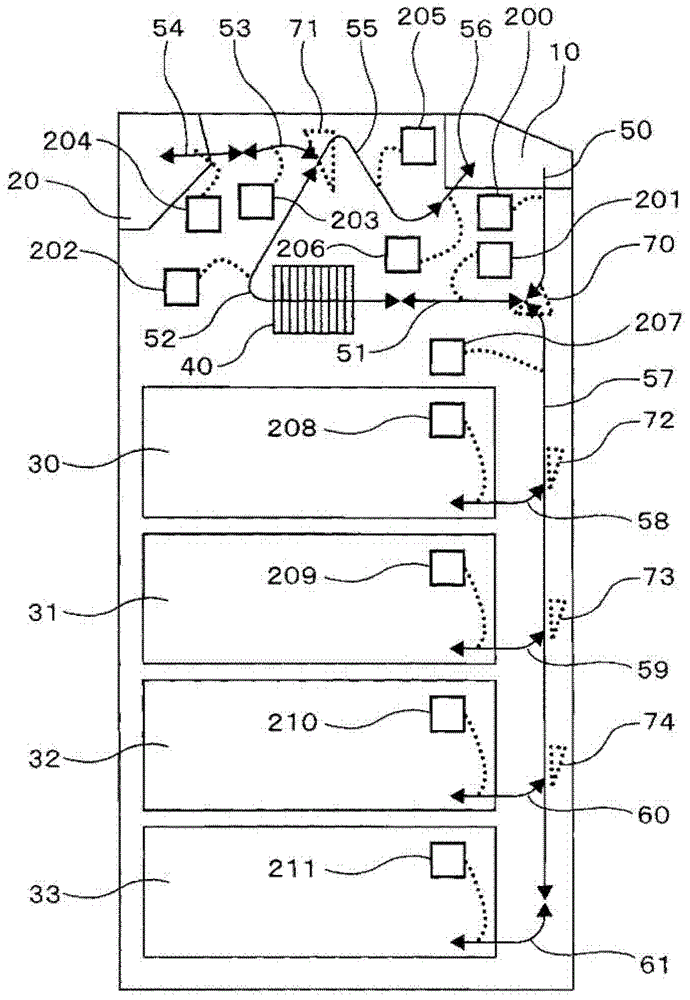

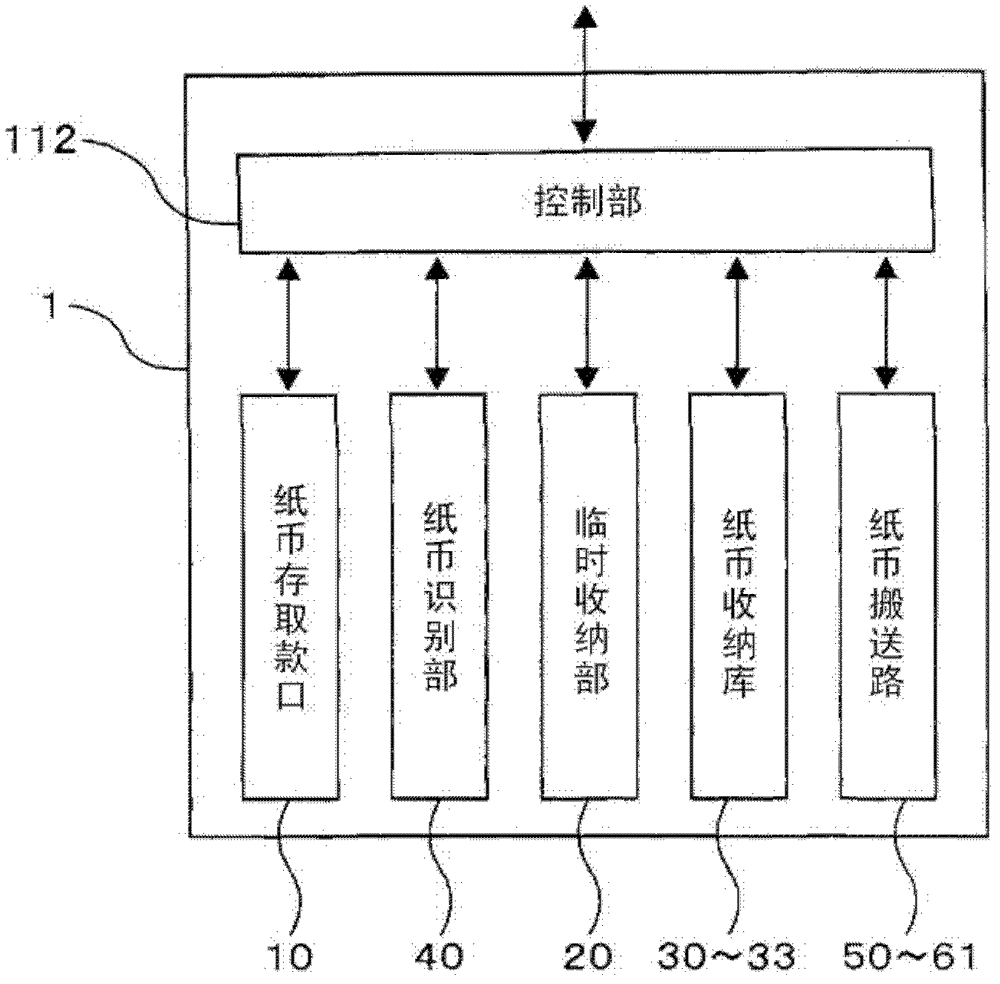

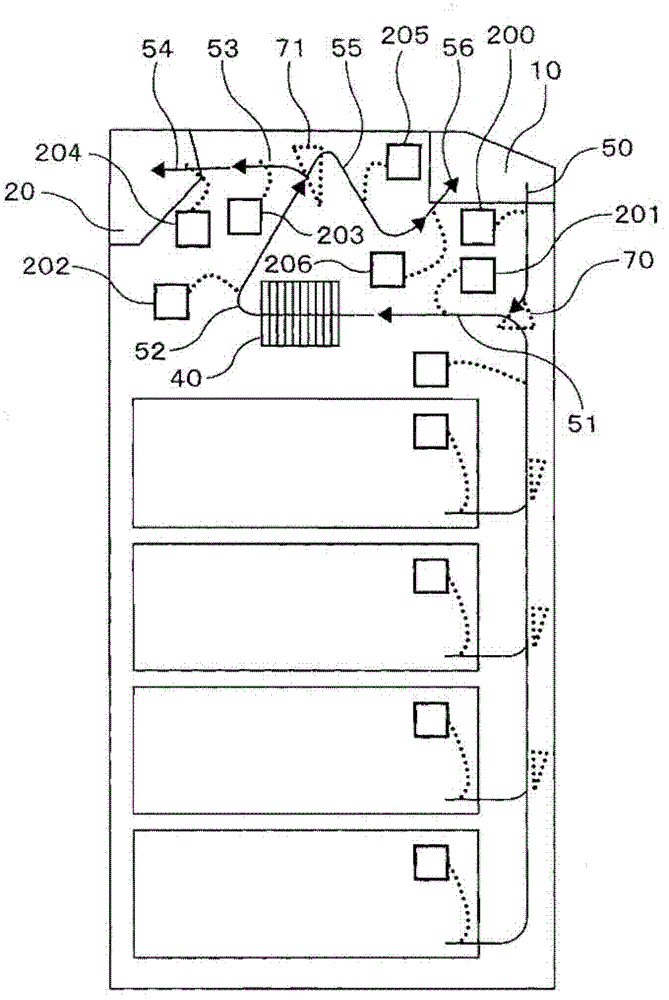

Bill handling device

ActiveCN102622806AReduce stretchReduce paper jamsComplete banking machinesFunction indicatorsEngineeringAcceleration control

The invention provides a bill handling device, which can prevent bill damage and bill jamming, improve convey reliability and realize high-speed conveying of bill. Provided is a bill handling device which comprises: a bill deposit / withdrawal opening (10) where bills to be deposited / withdrawn are collected; a bill discrimination unit (40) for distinguishing bills; a temporary storage part (20) for temporarily collecting and storing bills; bill storage units (30 - 33) for storing and re-separating bills; and bill conveyance paths (50 - 61) for conveying bills to the bill storage units (30 - 33), wherein the bill conveyance paths are each driven by an independent motor, and the bill conveyance speed of the bill conveyance paths is subject to stepwise acceleration control.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

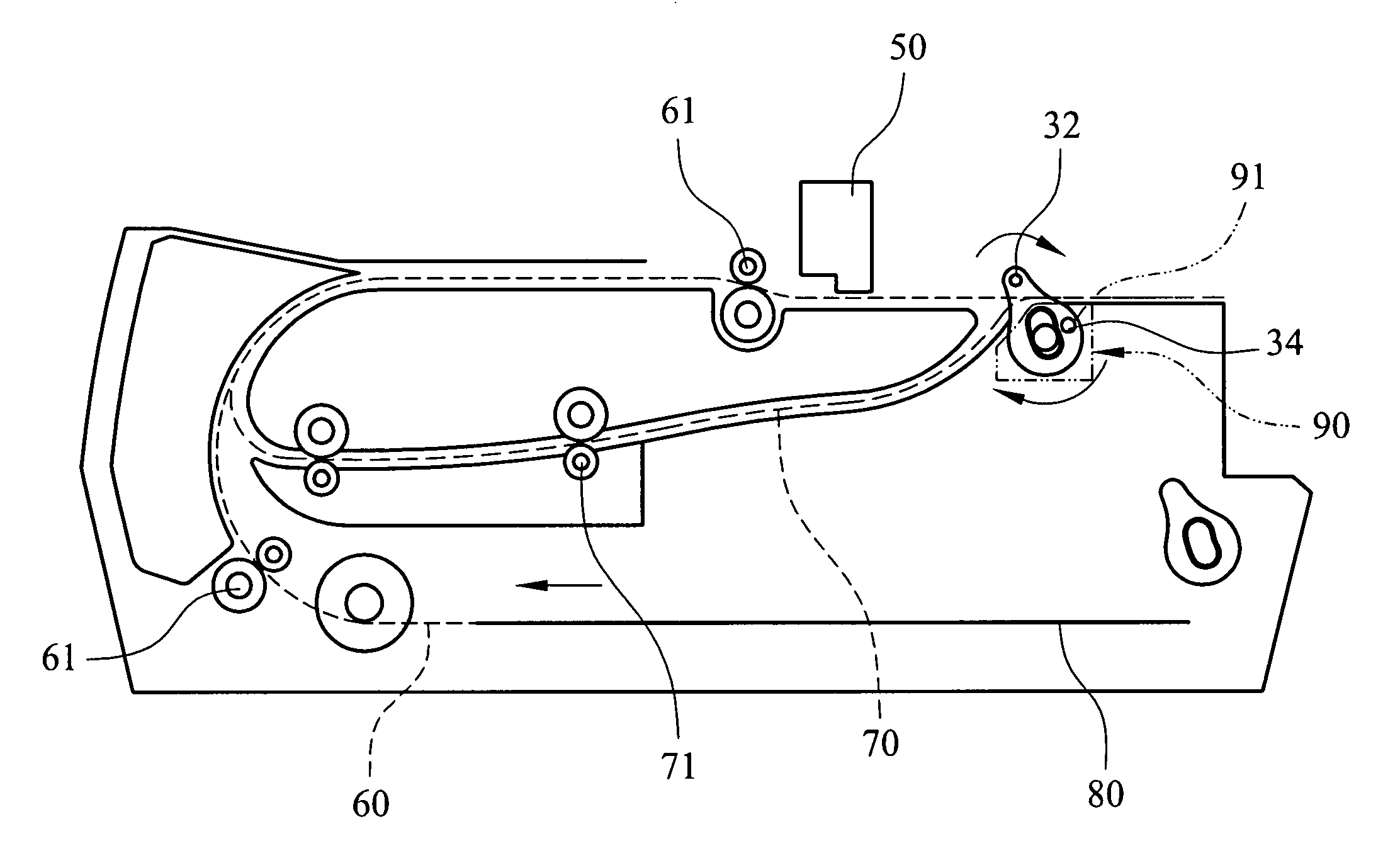

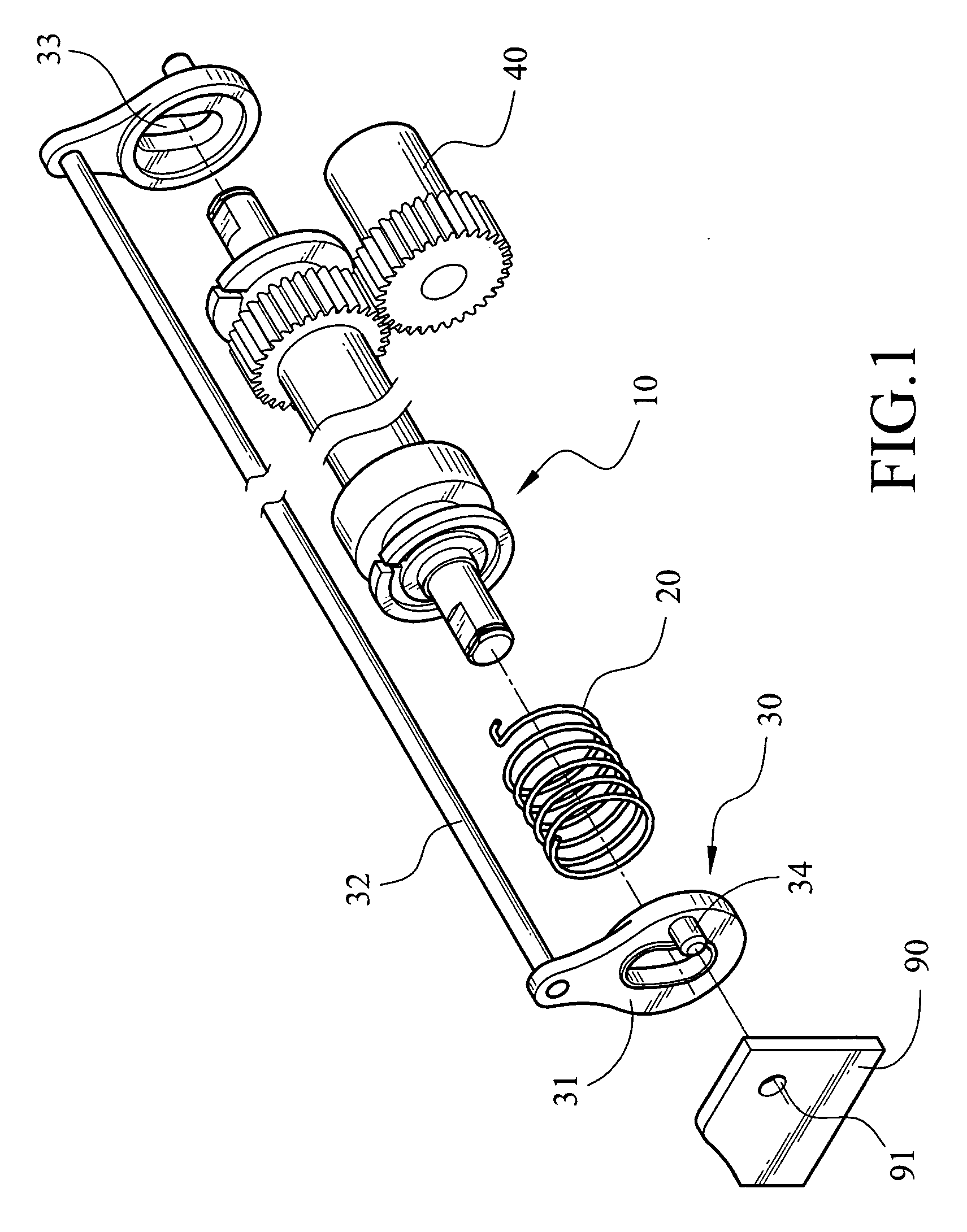

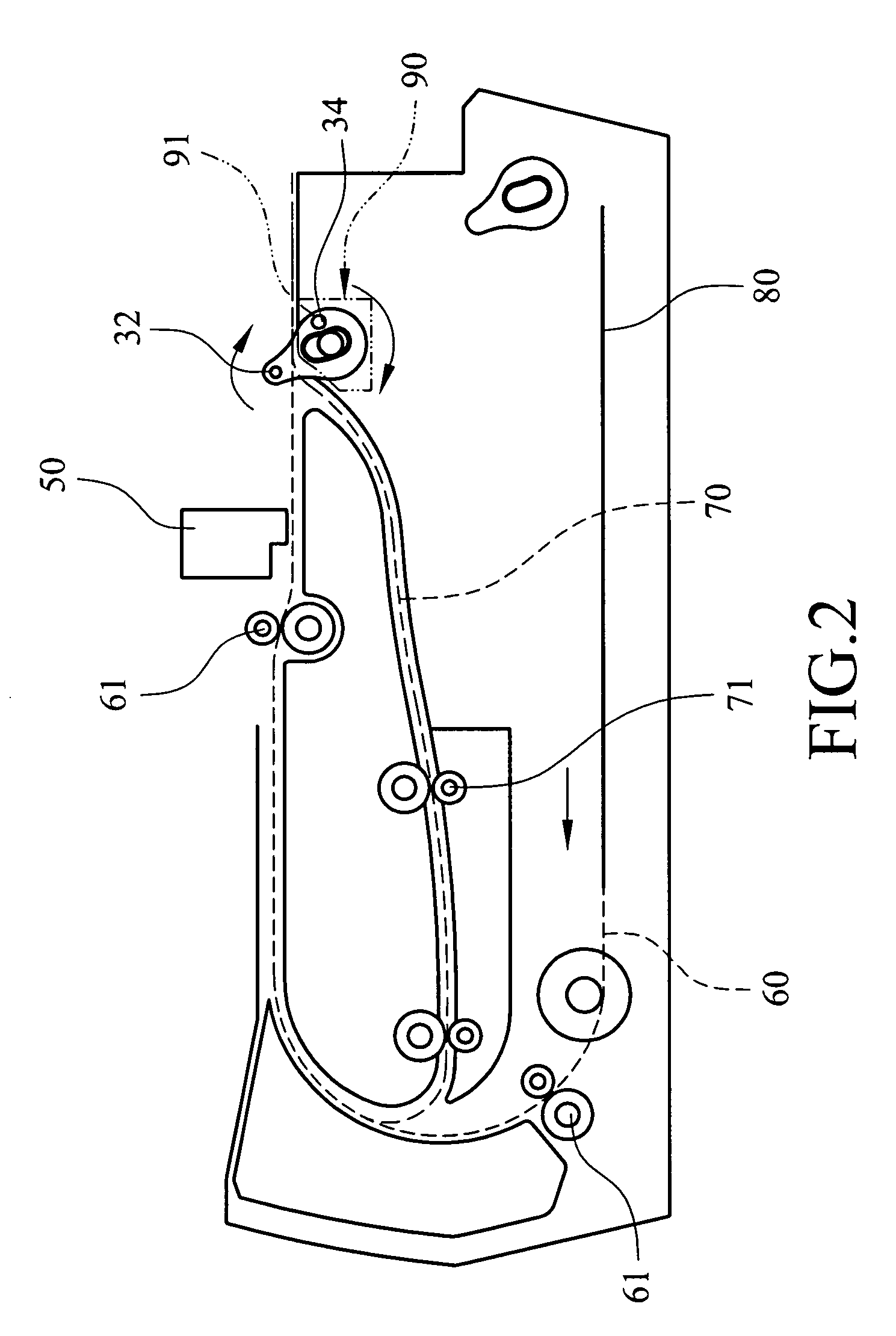

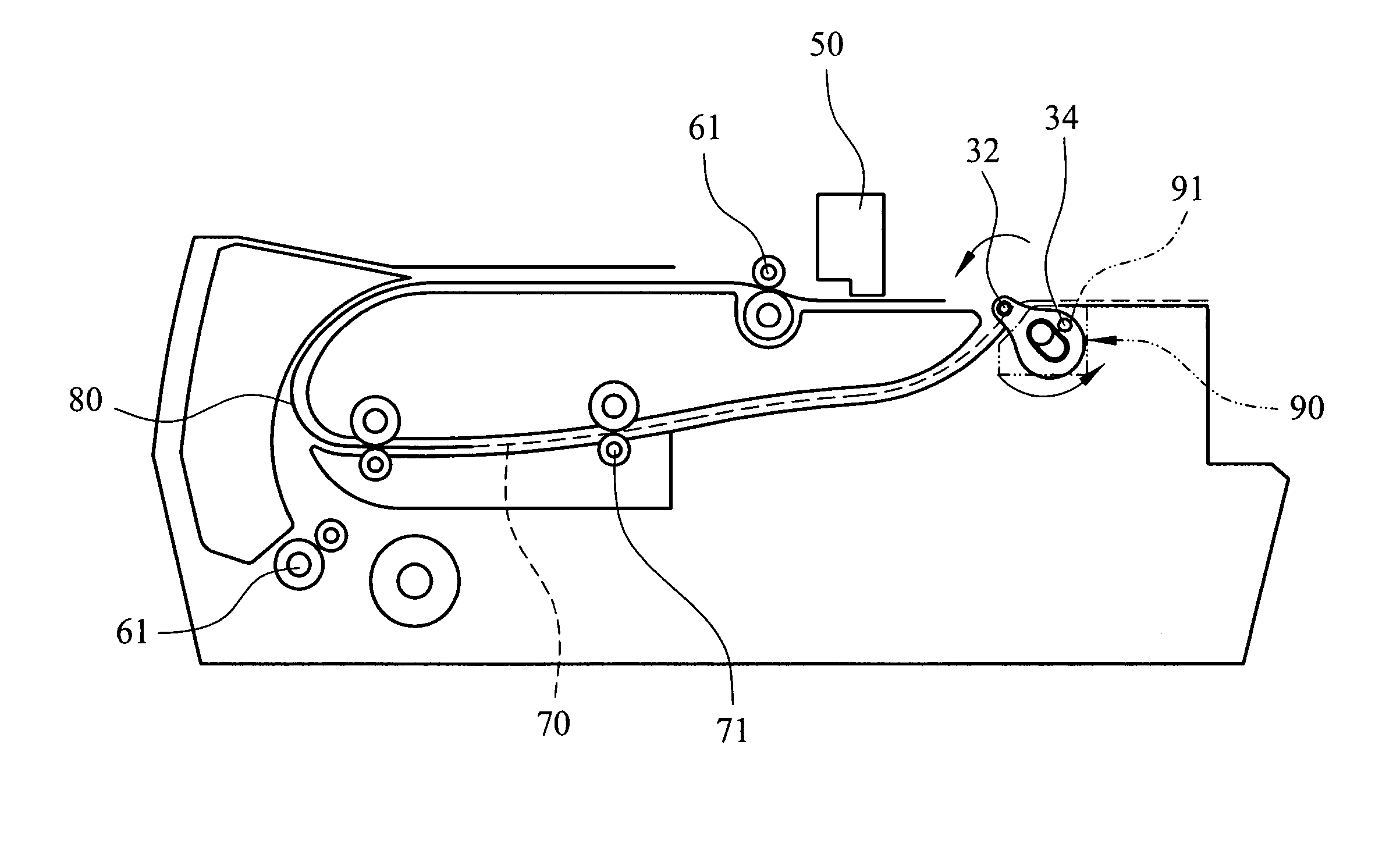

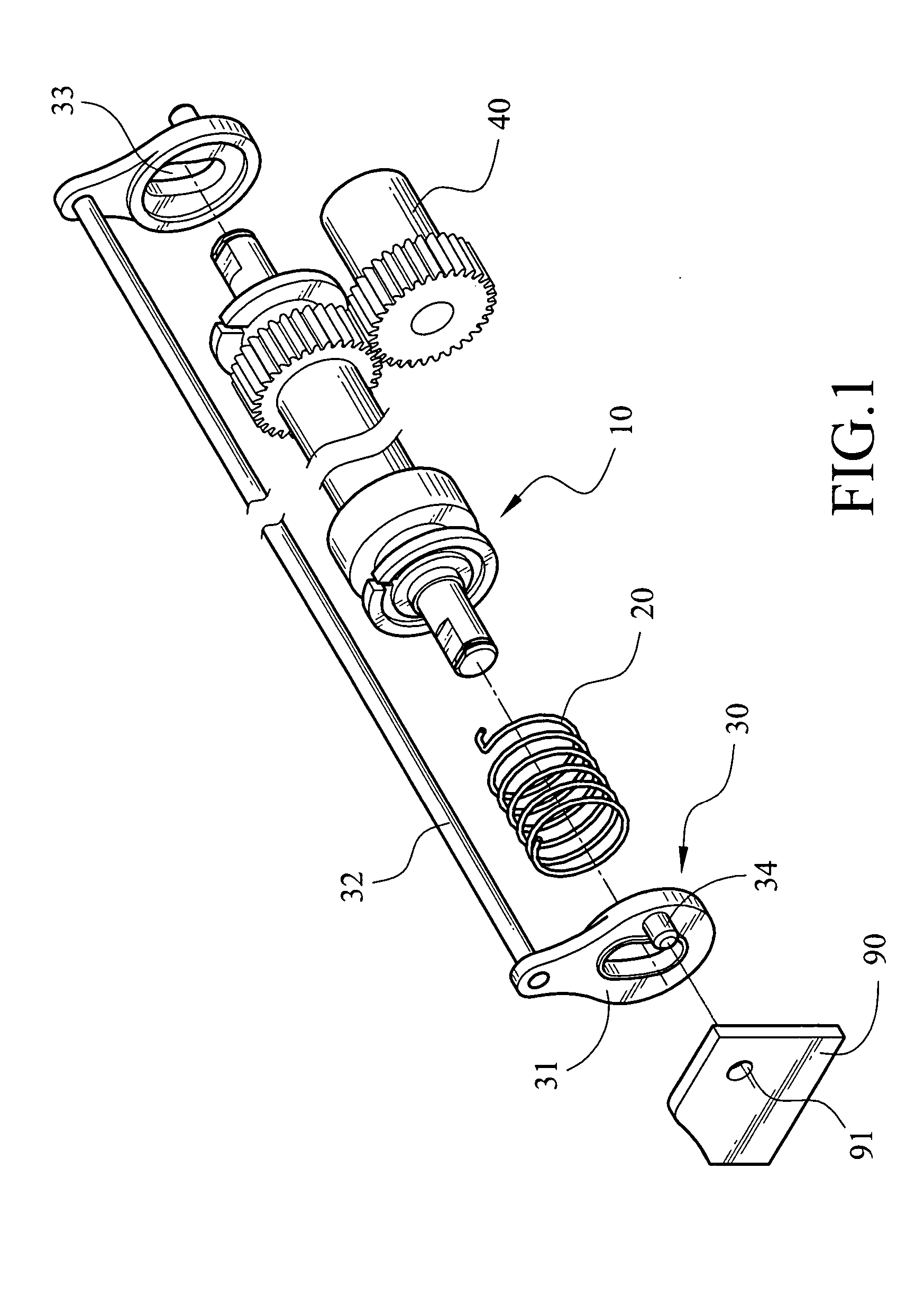

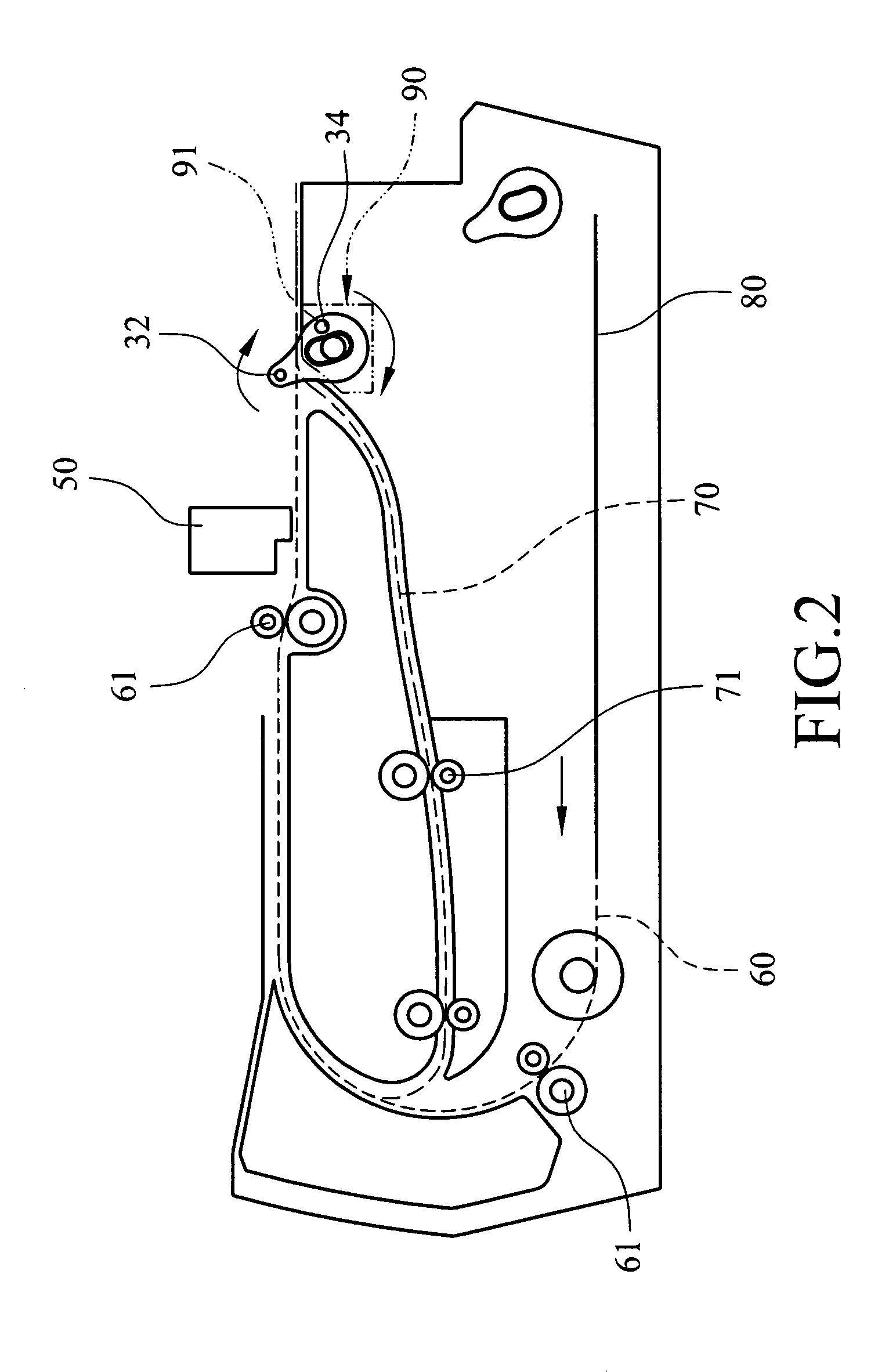

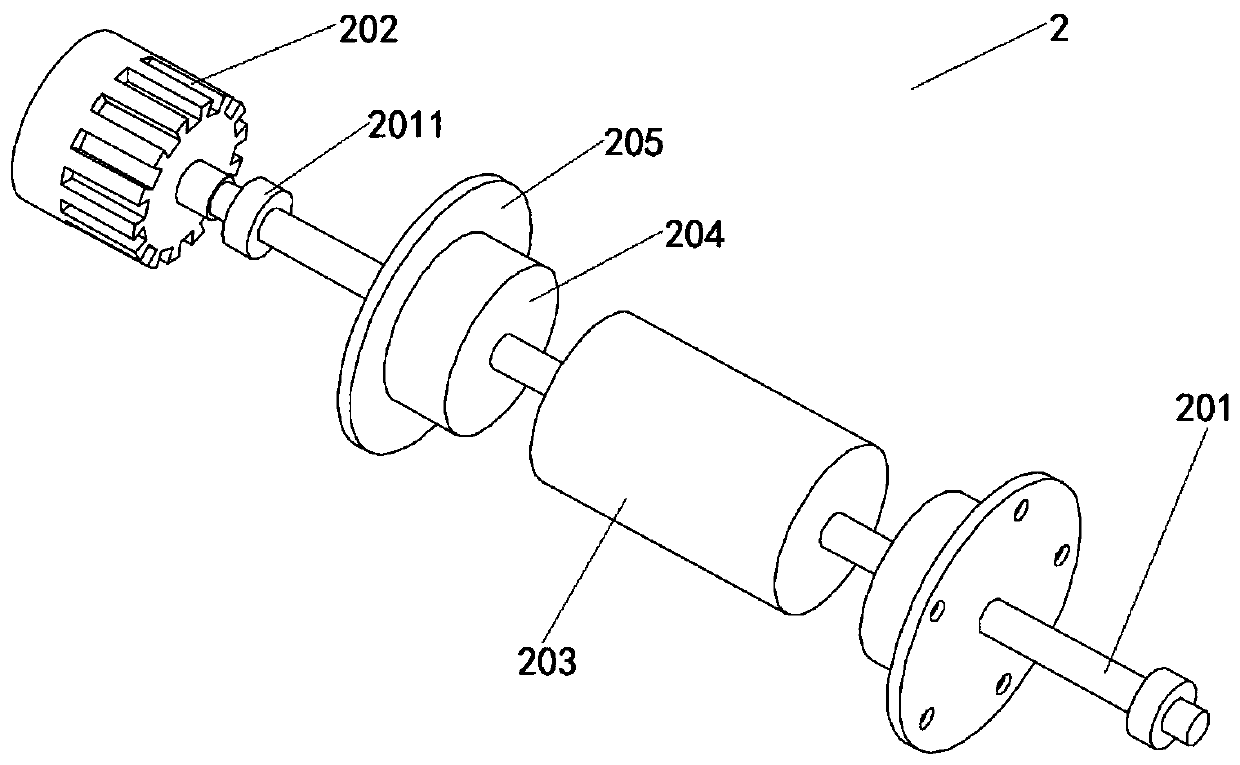

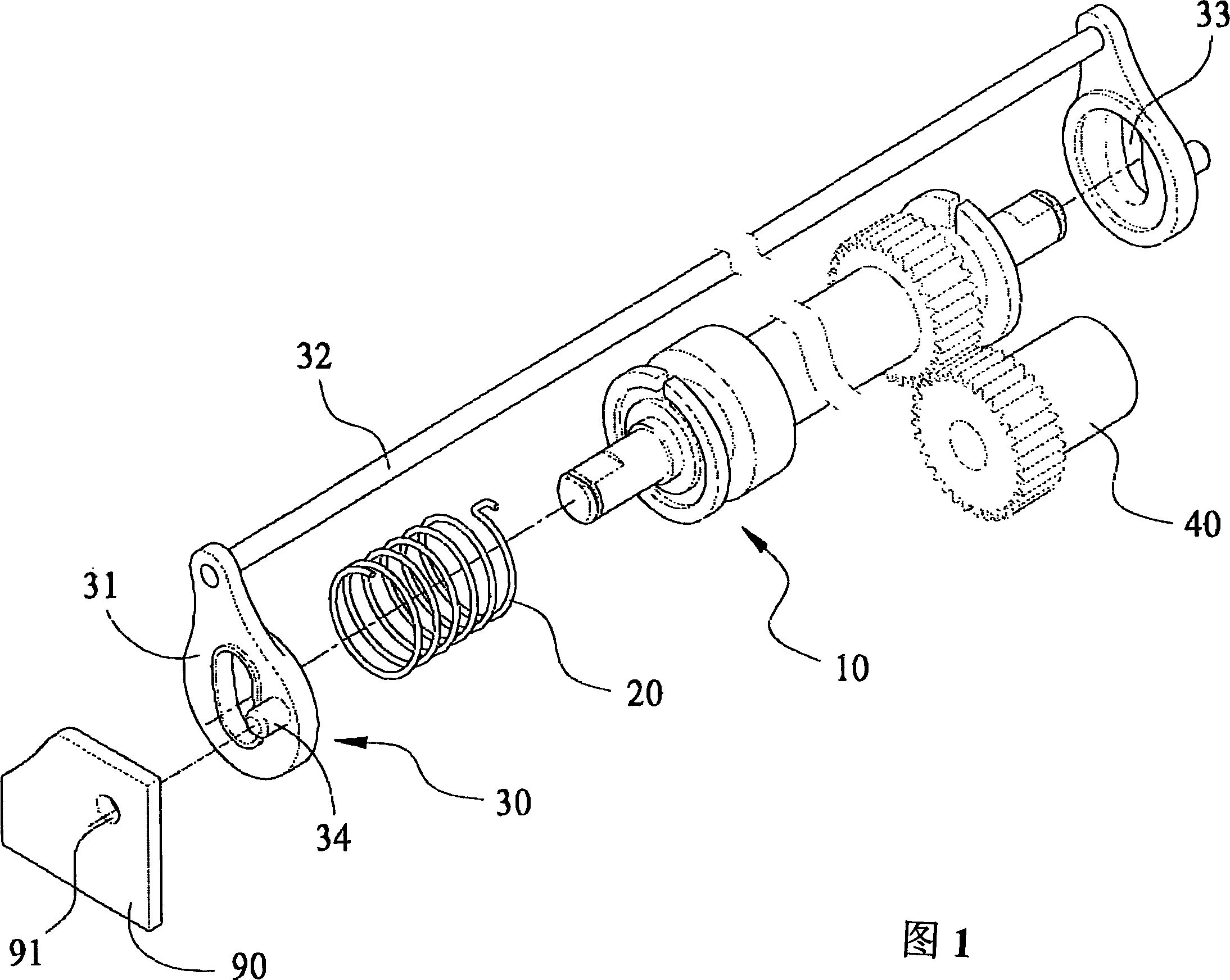

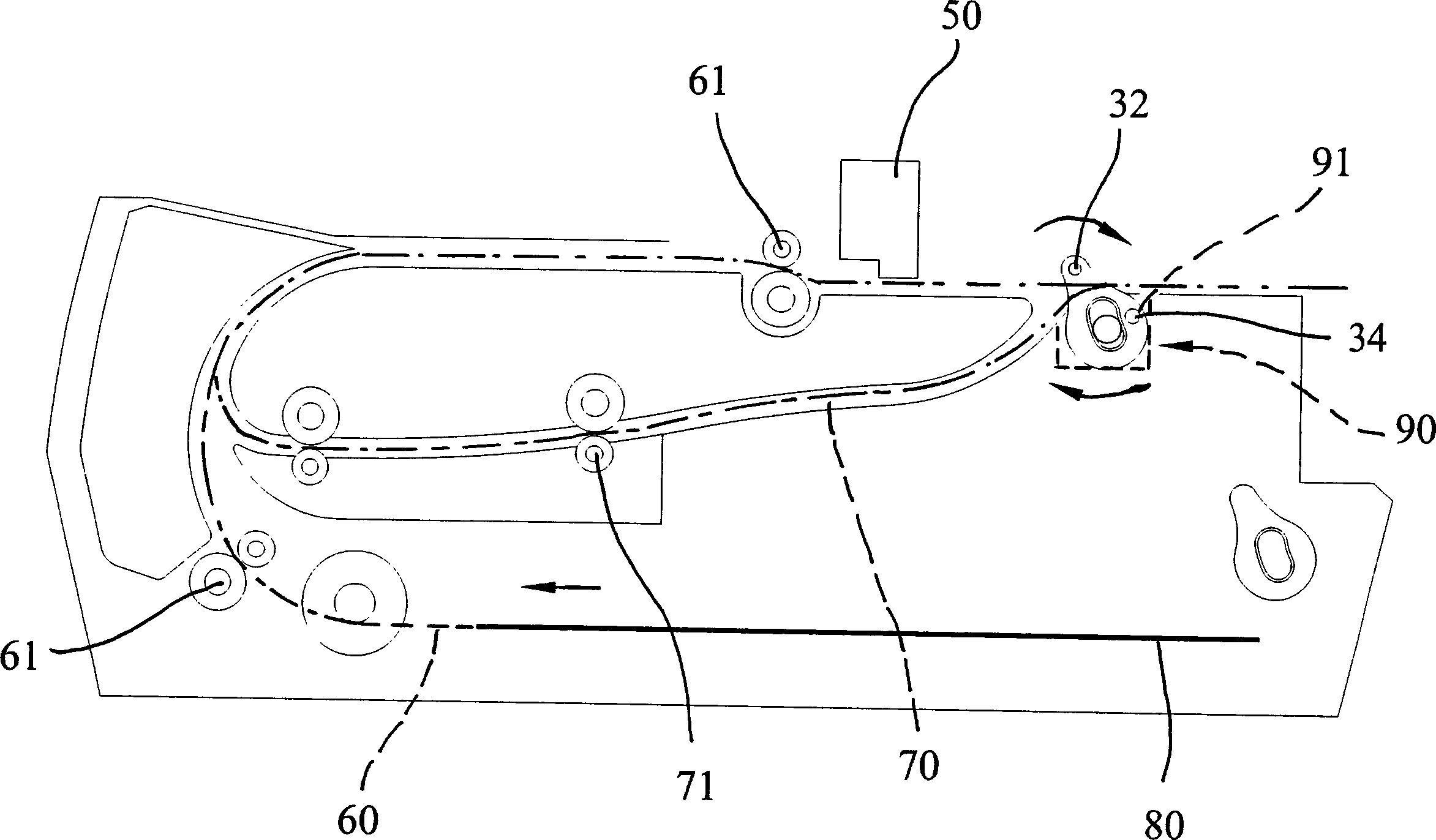

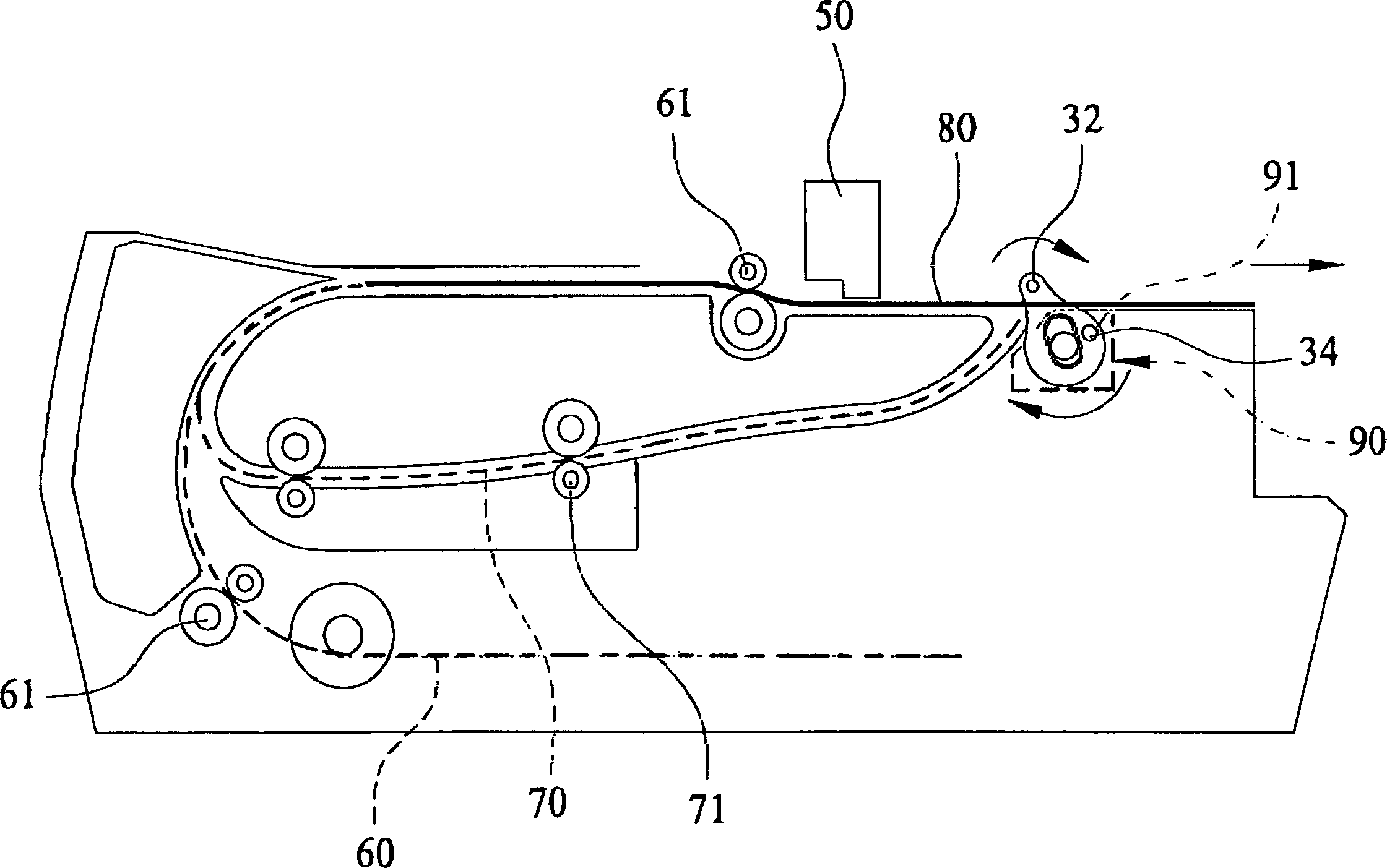

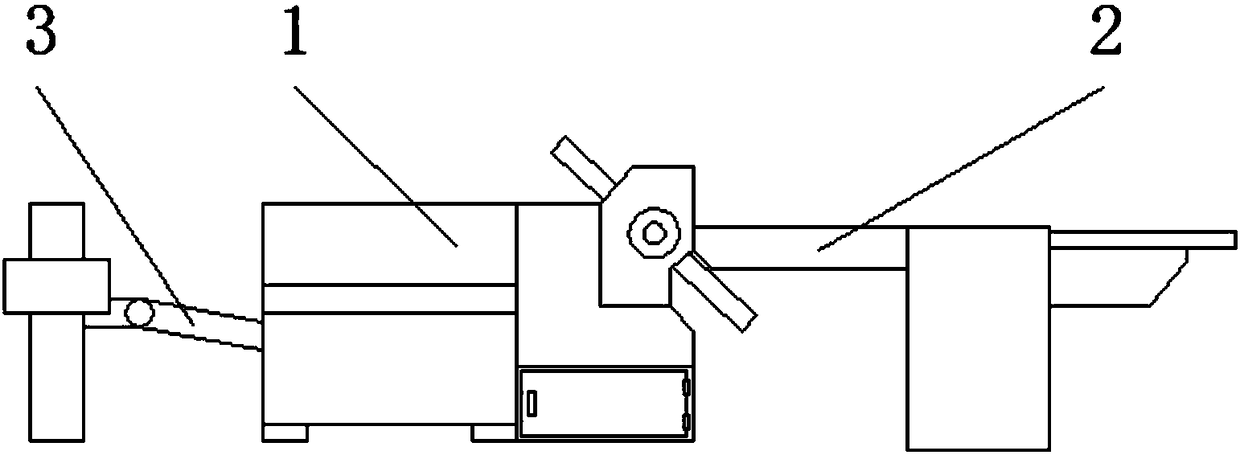

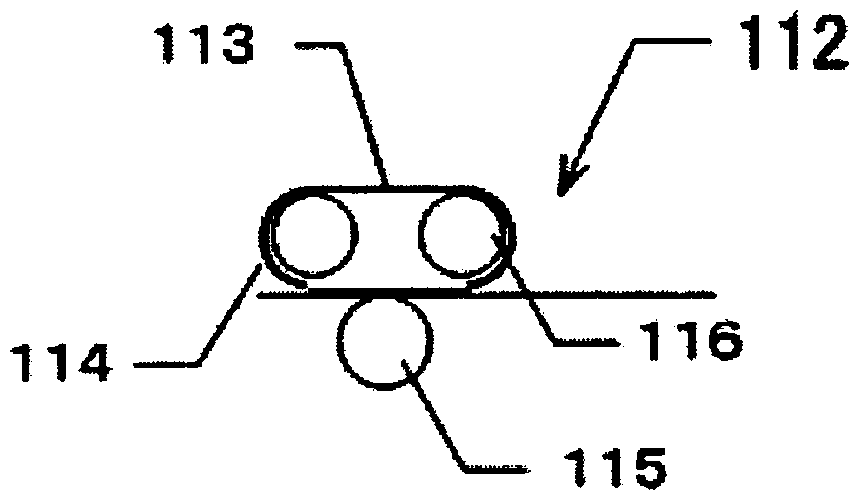

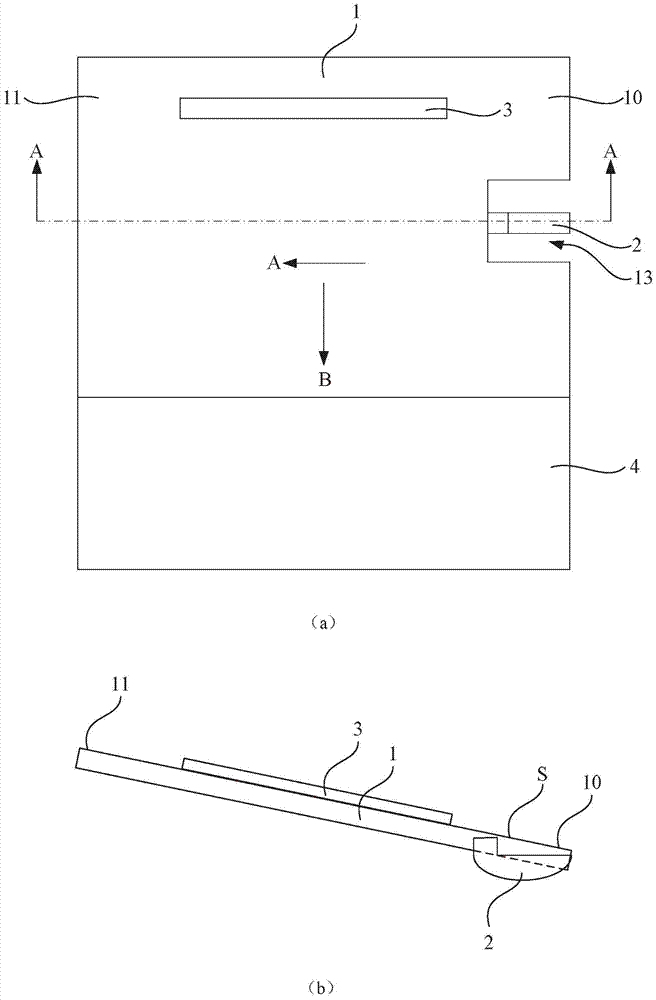

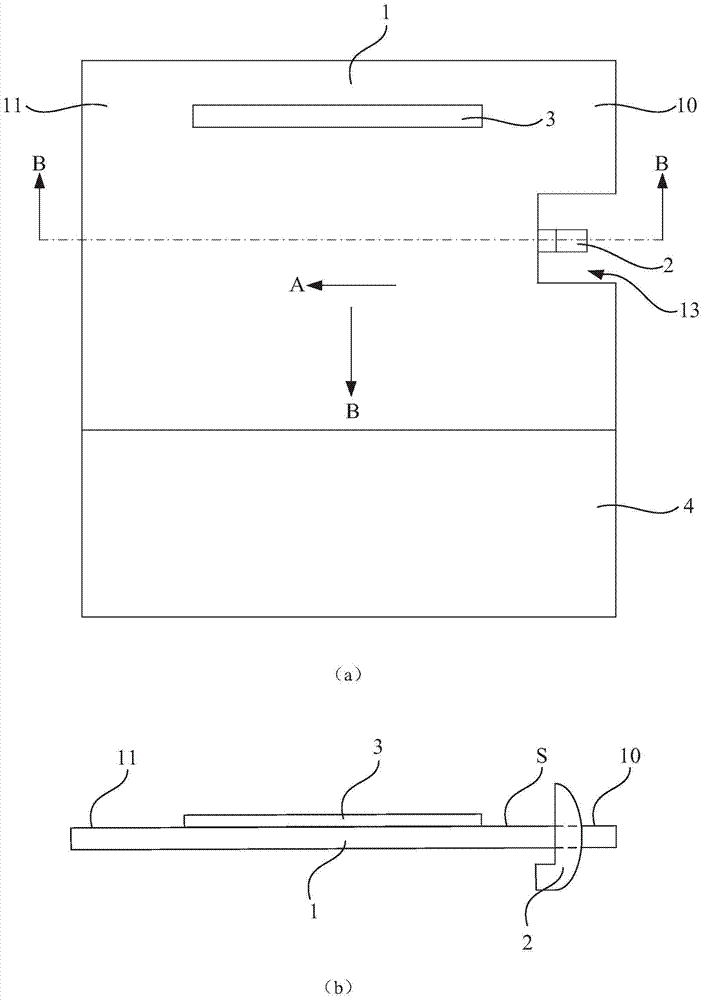

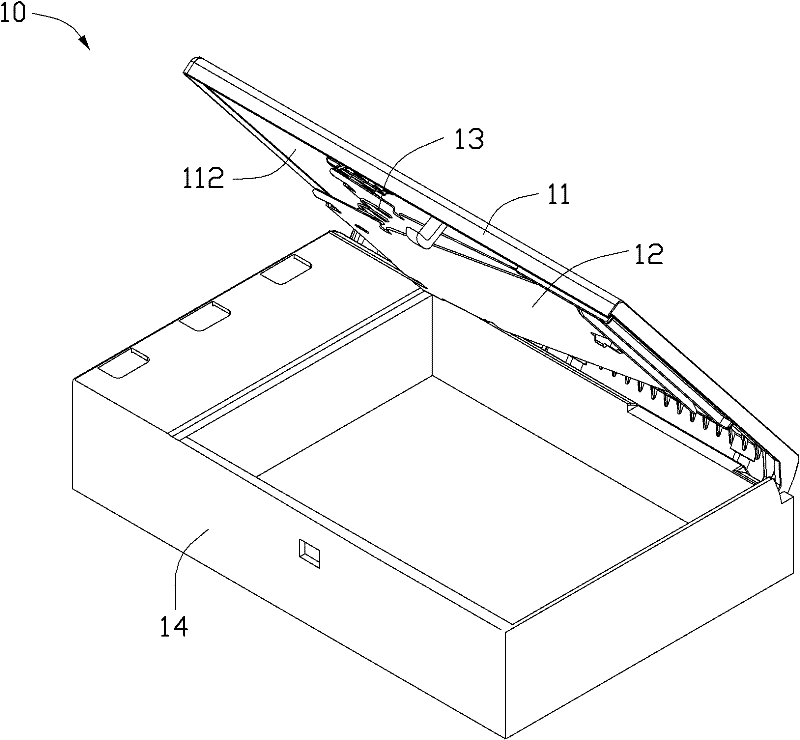

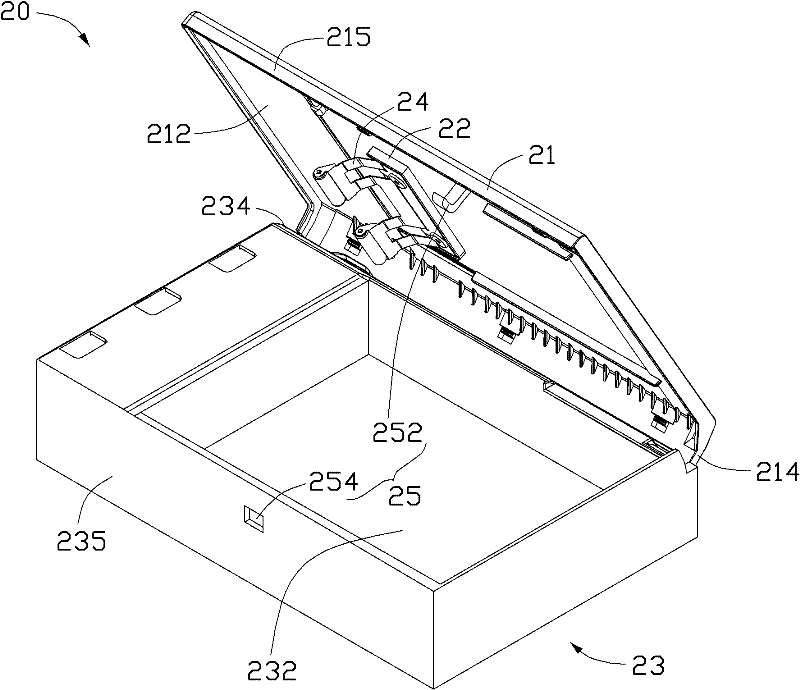

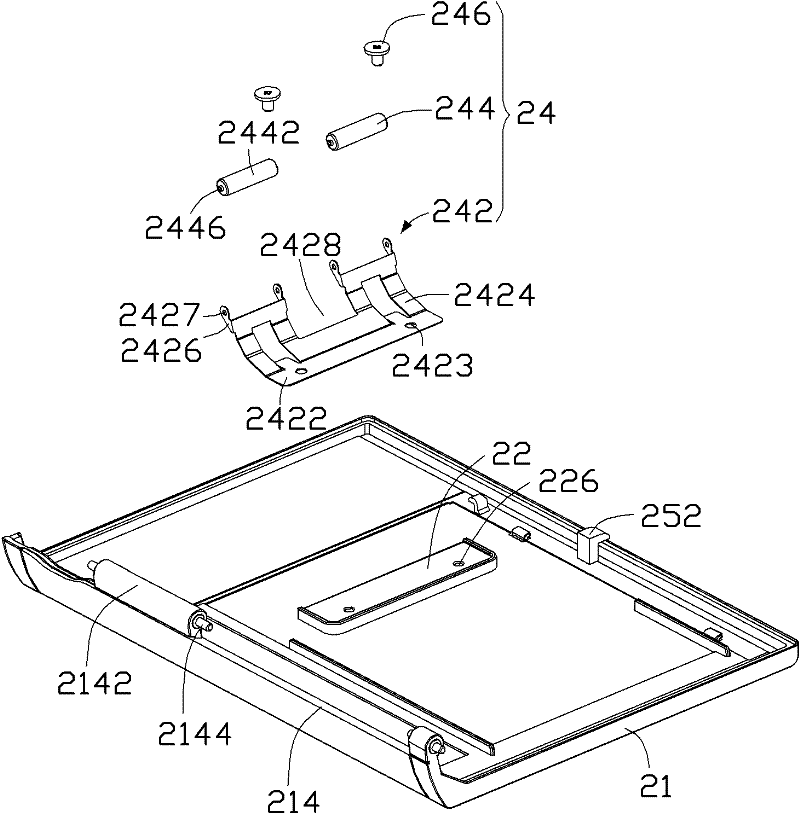

Paper conveying apparatus and method for flipping paper

InactiveUS7823878B2Simple structureLess elementTypewritersElectrographic process apparatusPulp and paper industryMotion transfer

A paper conveying apparatus and method for flipping paper includes a paper feeding roller that can rotate in a positive direction or in a reverse direction, a motion transfer member that has one end coupled with the paper feeding roller, and a paper depressing element coupled with another end of the motion transfer member to be driven and rotated. The method of flipping paper includes: first, feeding a sheet of paper into a first paper conveying path; next, depressing the paper into a second paper conveying path while the paper is leaving the first paper conveying path; and reentering the paper from the second paper conveying path into the first paper conveying path upside down.

Owner:LITE ON TECH CORP

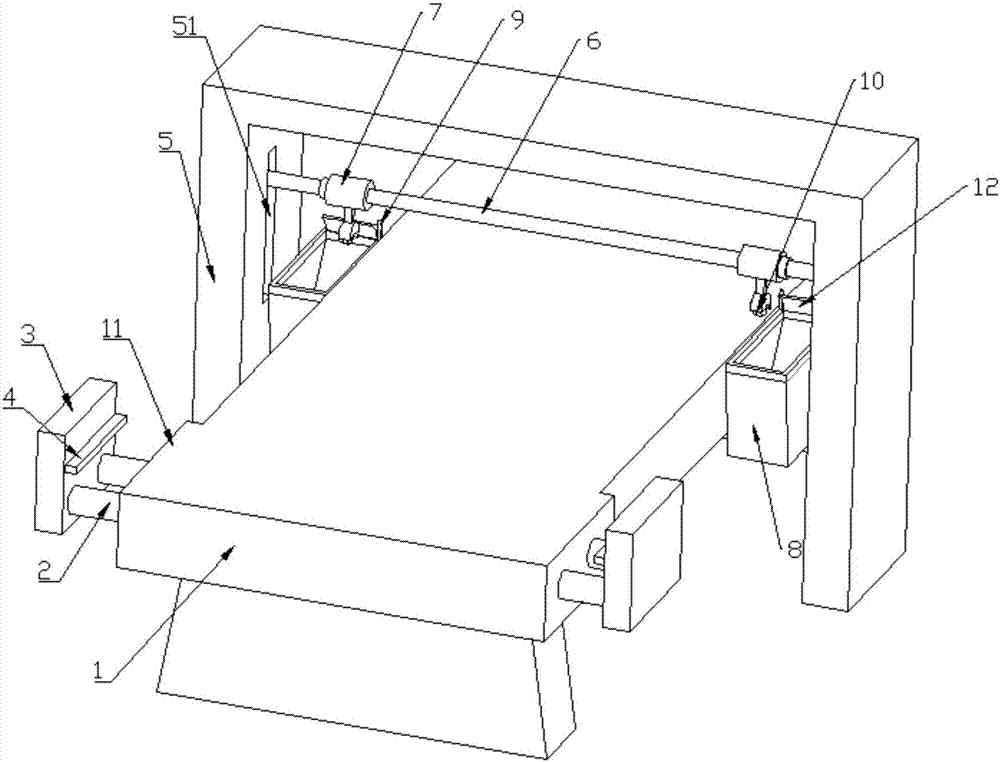

Printed paperboard edge-cutting device

The invention provides a printing cardboard edge cutting device, which includes a cutting edge feeding platform; the two sides of the feeding end of the edge cutting feeding platform respectively protrude outwards to form a whole edge boss, and because of the special The structure makes the waste pass through the recycling bucket more smoothly, and the design of the guide plate and the shielding plate are also designed to reduce the jamming phenomenon that occurs when the recycling bucket is recycling waste.

Owner:中奥文化科技(天津)有限公司

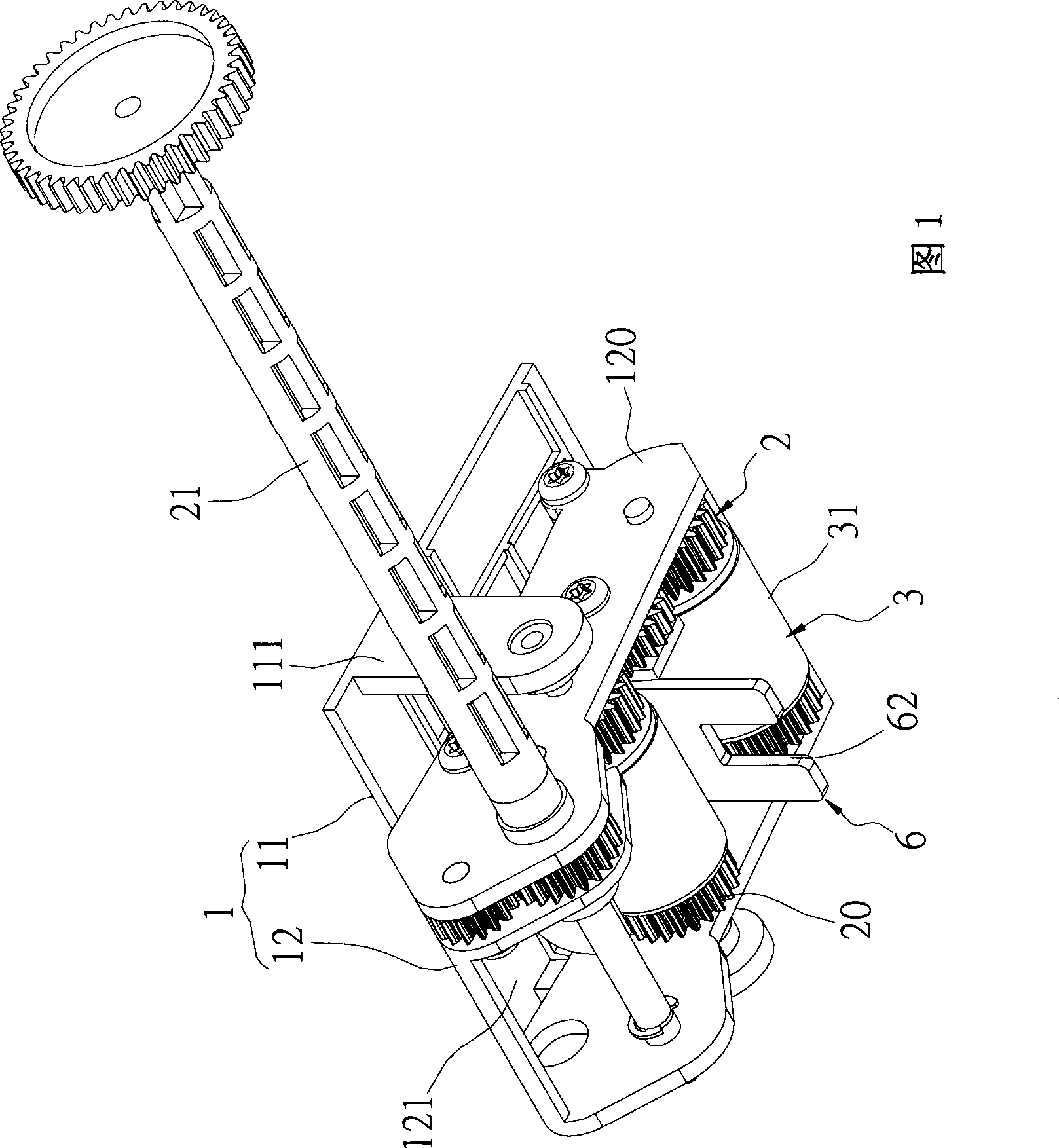

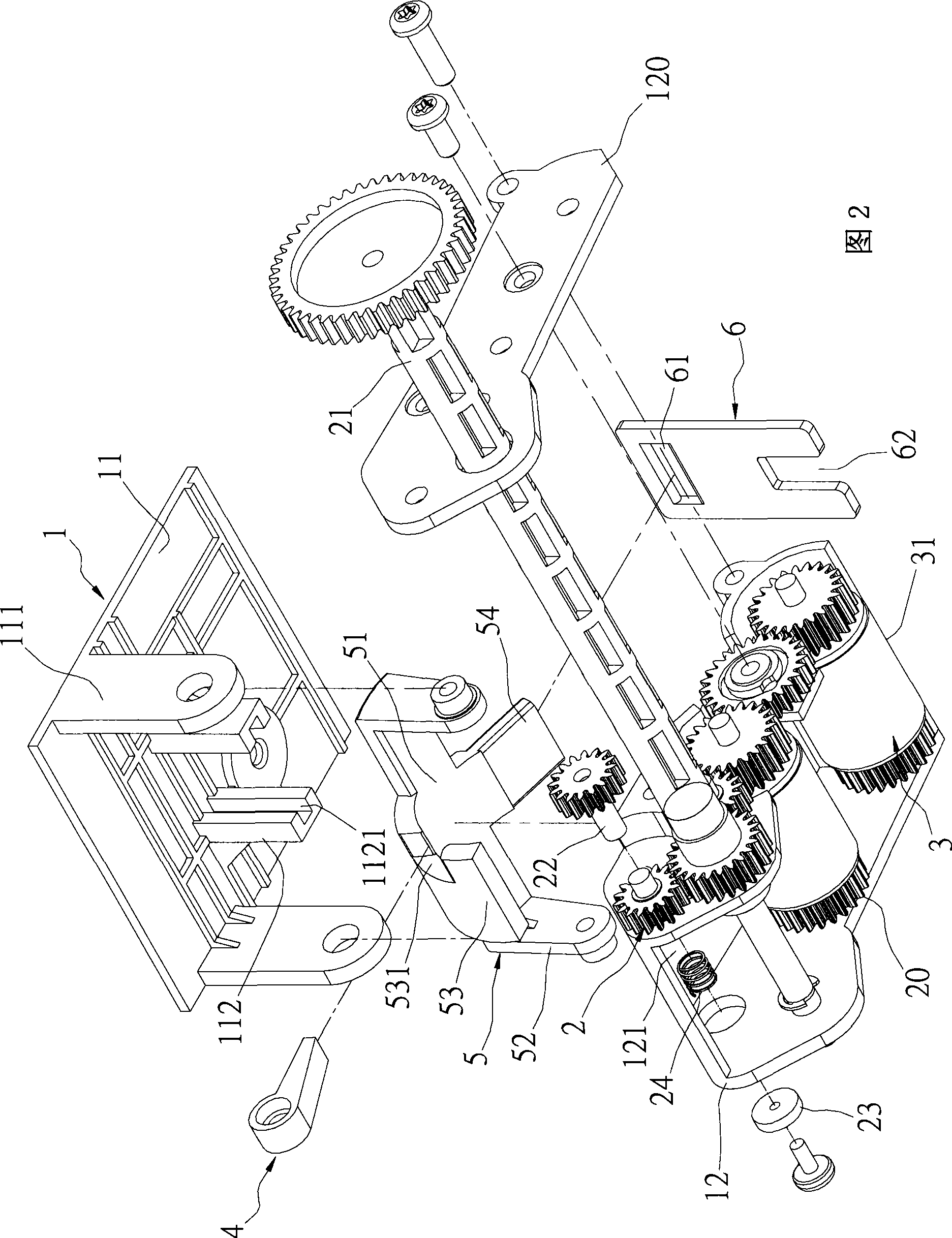

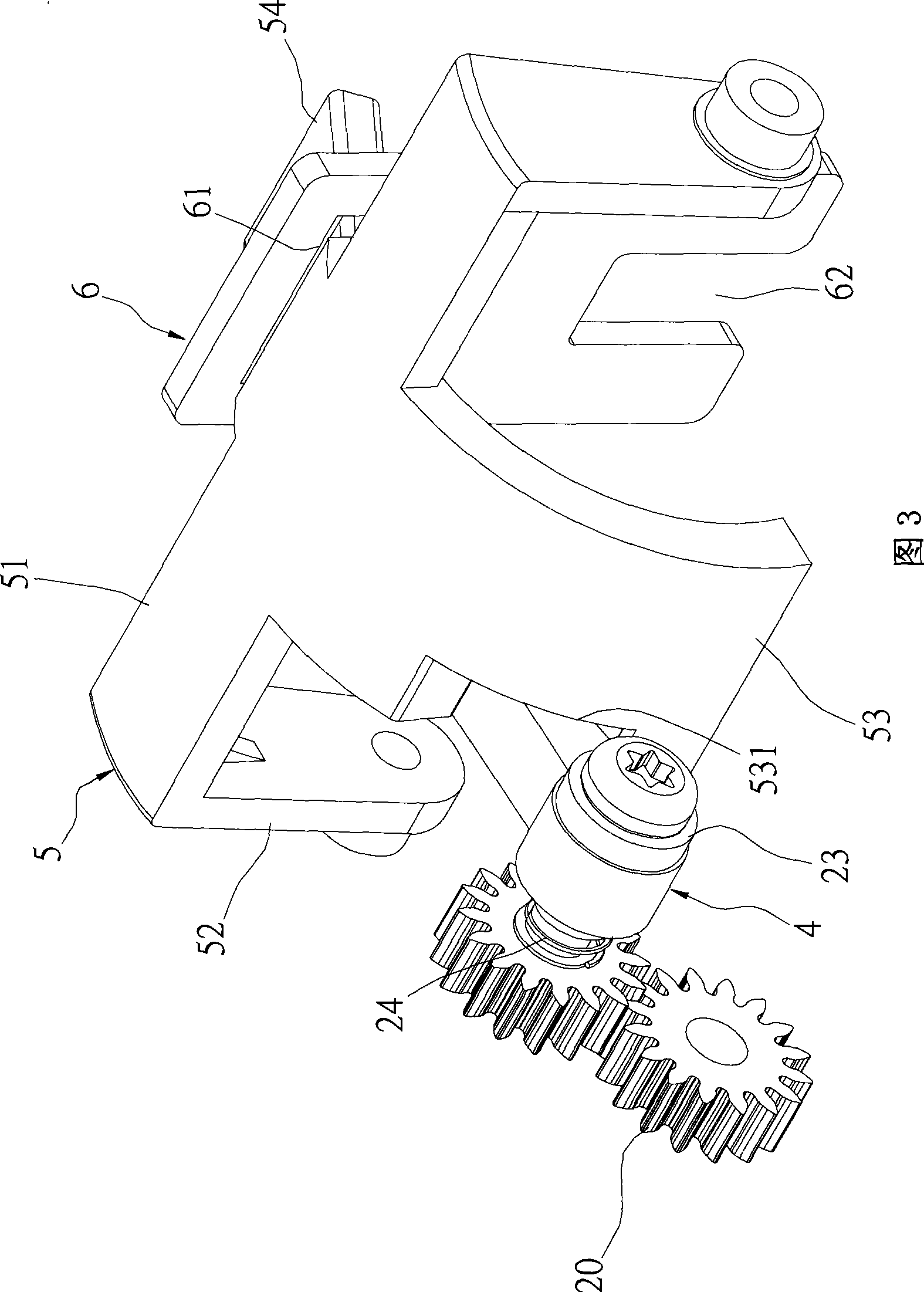

Cam link paper stopping mechanism

The invention discloses a cam linkage-rod paper-blocking mechanism which comprises a casing unit, a transmission gear unit, two paper-charging rollers, a cam, a blocking plate and a revolving element. The casing unit comprises an upper casing and a lower casing. The upper casing is fixedly arranged on a machine body and the lower casing is arranged below the upper casing in a swinging manner. The lower casing is provided with a containing space and the transmission gear unit is arranged on the lower casing. The paper-charging rollers are arranged in the containing space and are connected with the transmission gear unit. One end of the cam is articulated with the transmission gear unit and the blocking plate is arranged on the upper casing in an up-and-down sliding manner and extends out from the lower casing. The revolving element is articulated with the upper casing and one end of the revolving element is connected with the blocking plate while the other end is connected with the cam. Therefore, the transmission distance between the paper-charging roller and the blocking plate can be shortened and then the expected transmission effect can be realized with less transmission components so as to effectively reduce cost.

Owner:CAL COMP ELECTRONICS

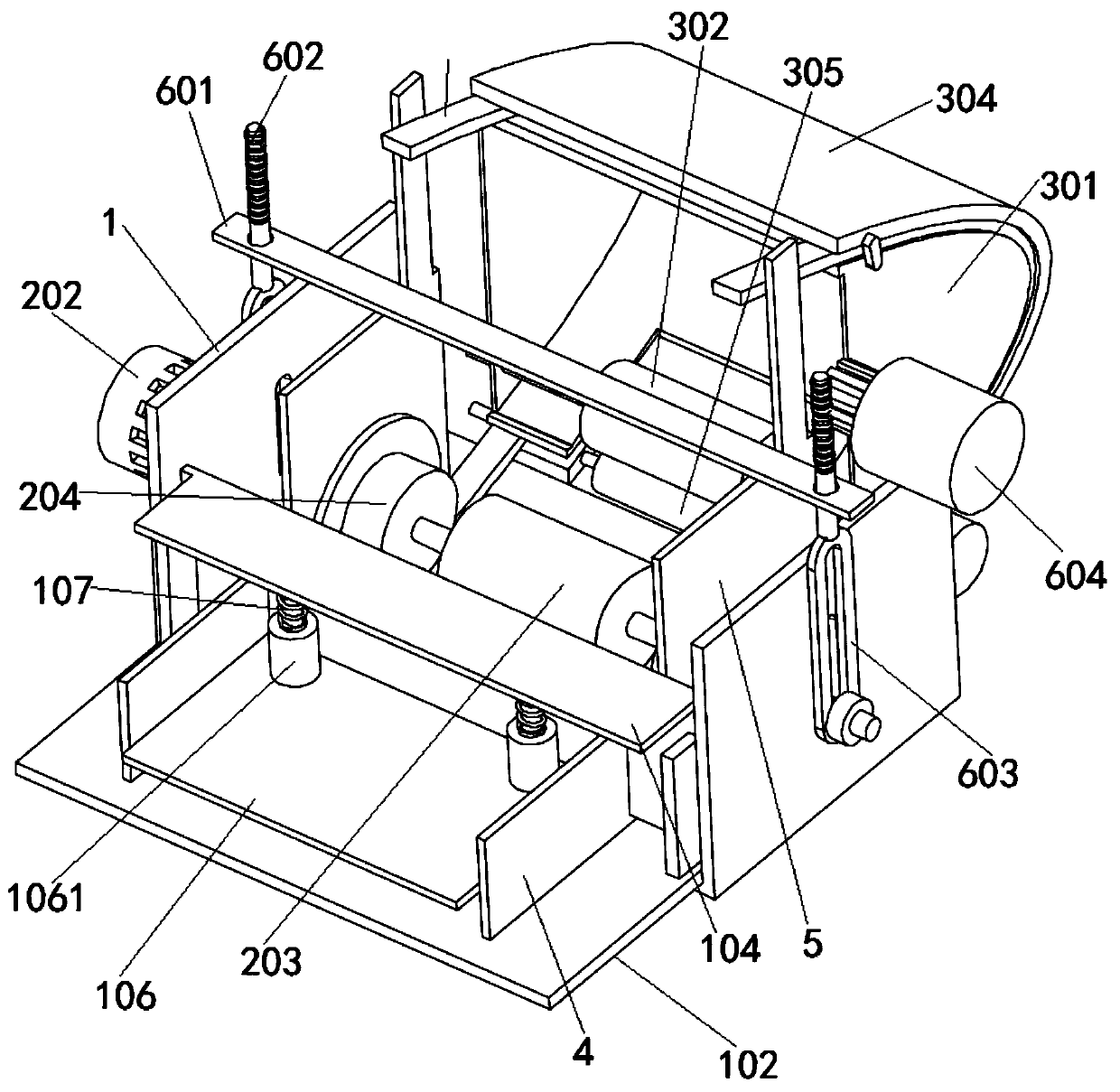

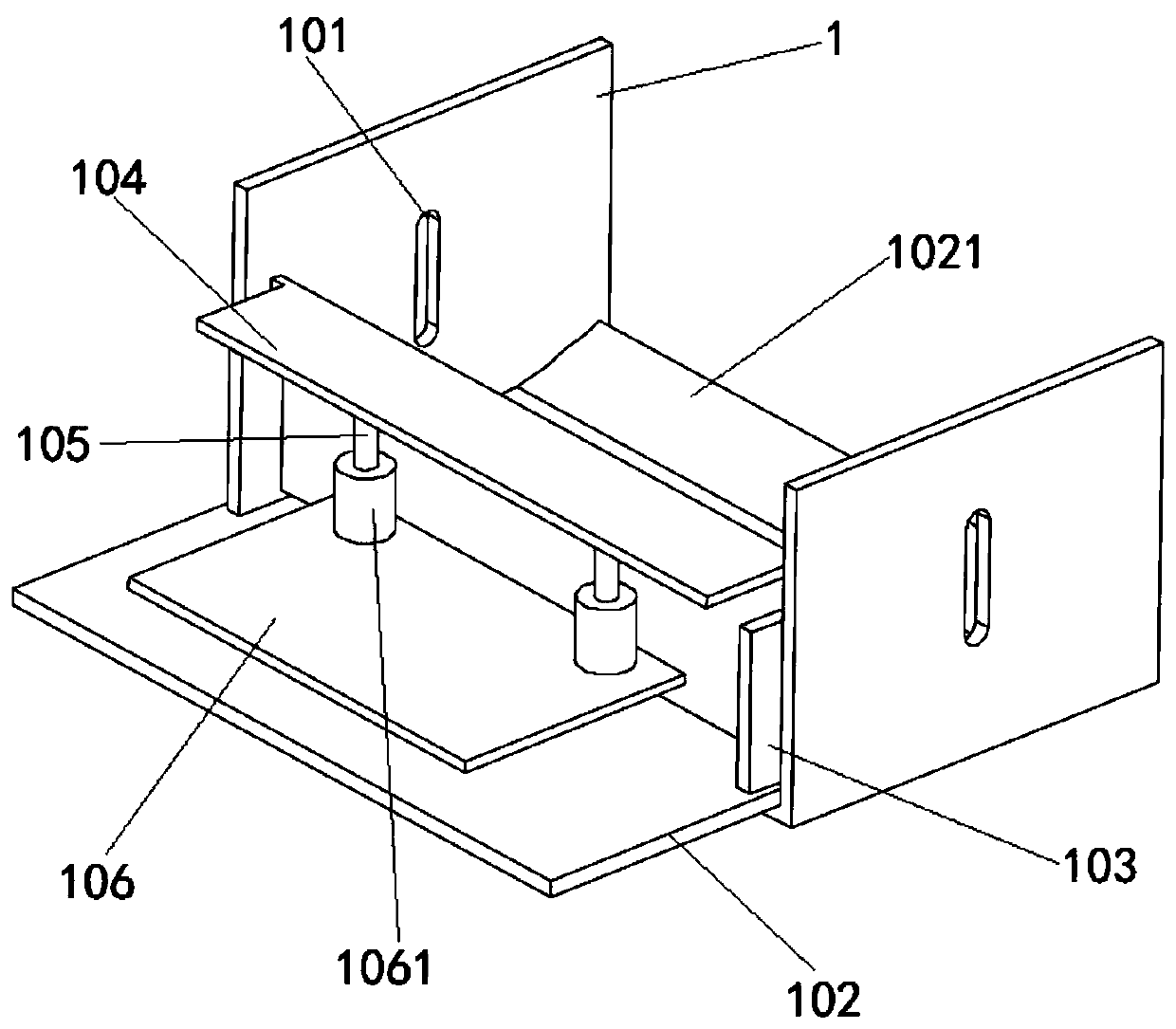

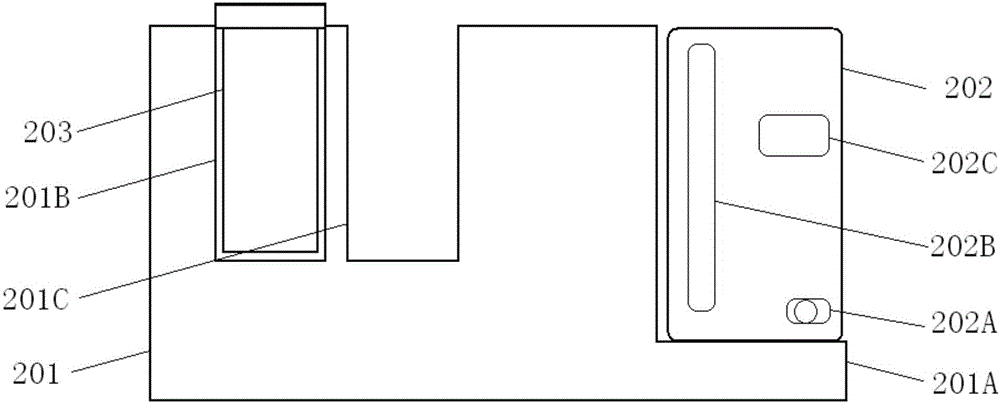

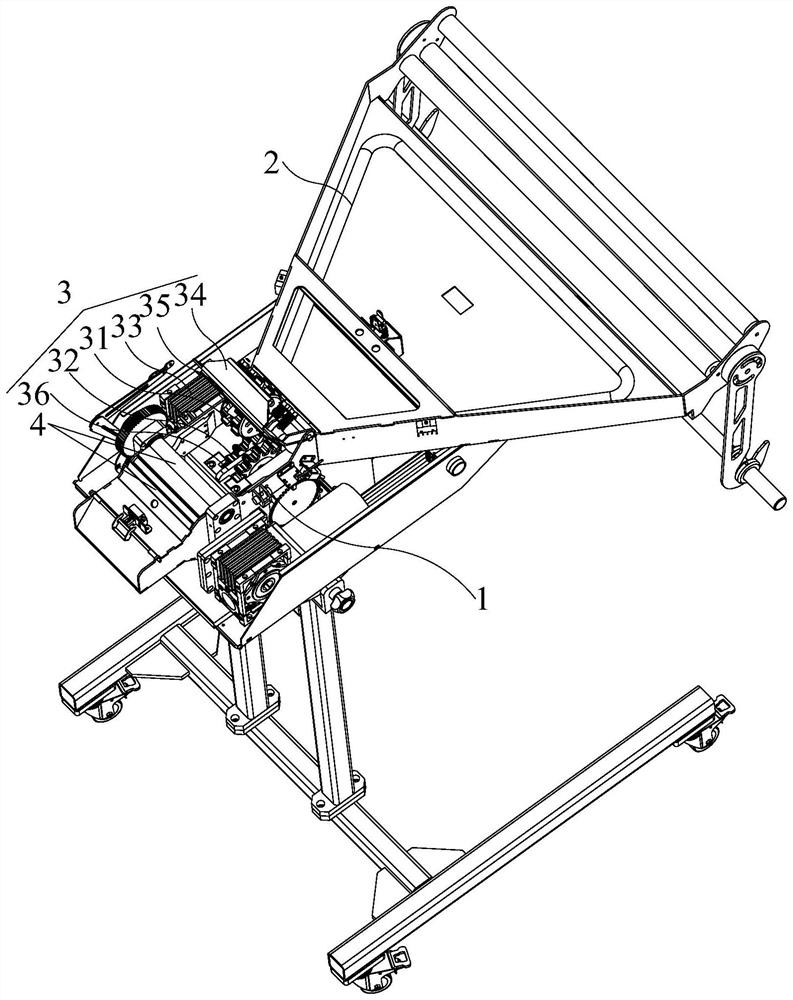

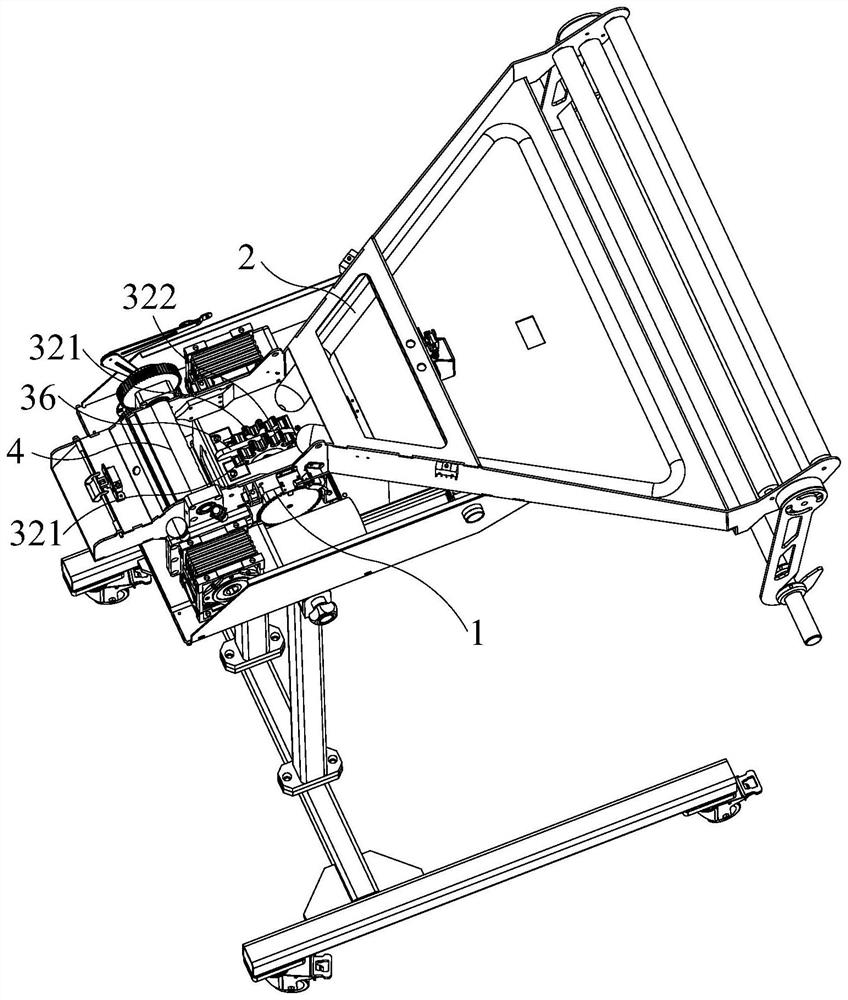

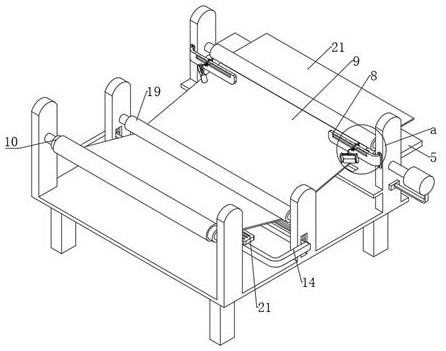

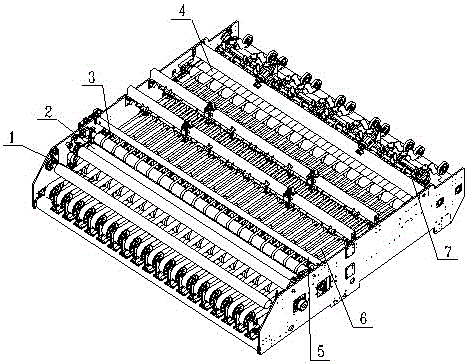

Double rotary knife roll paper splitting machine

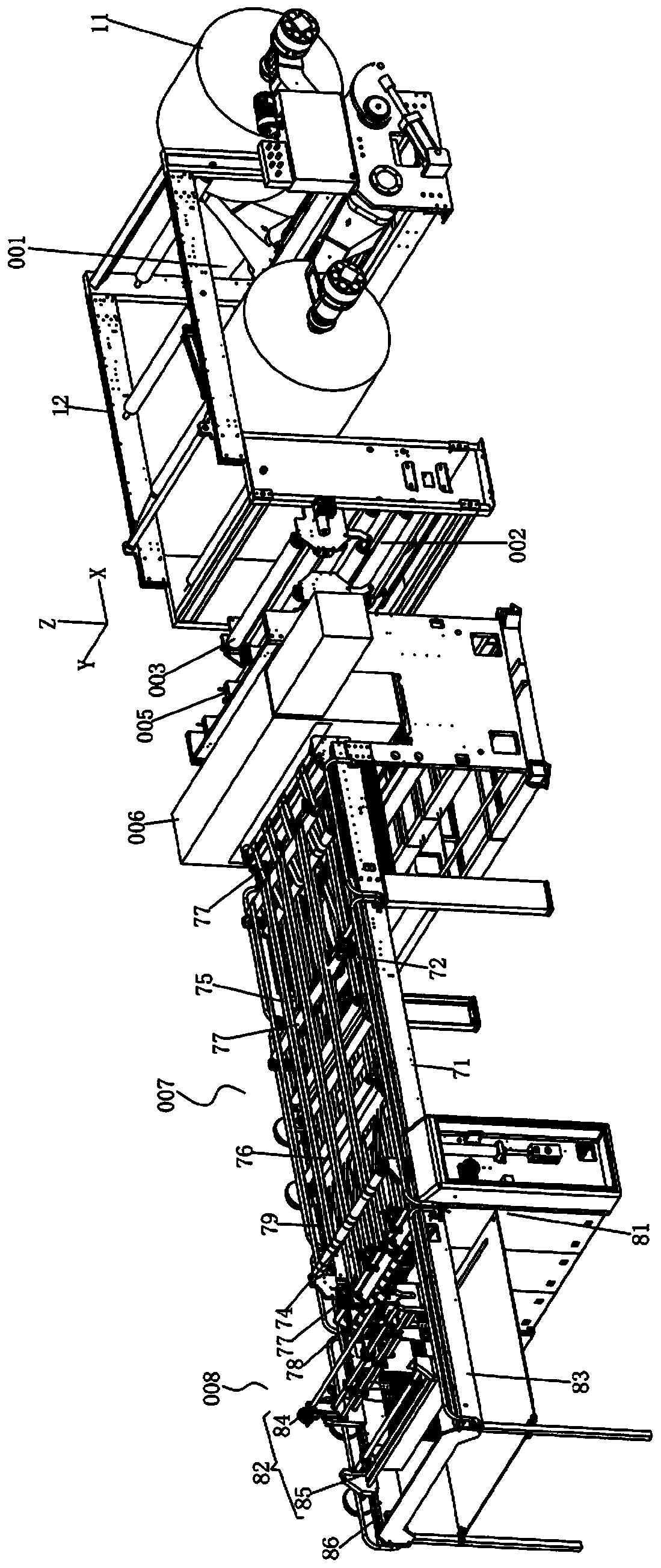

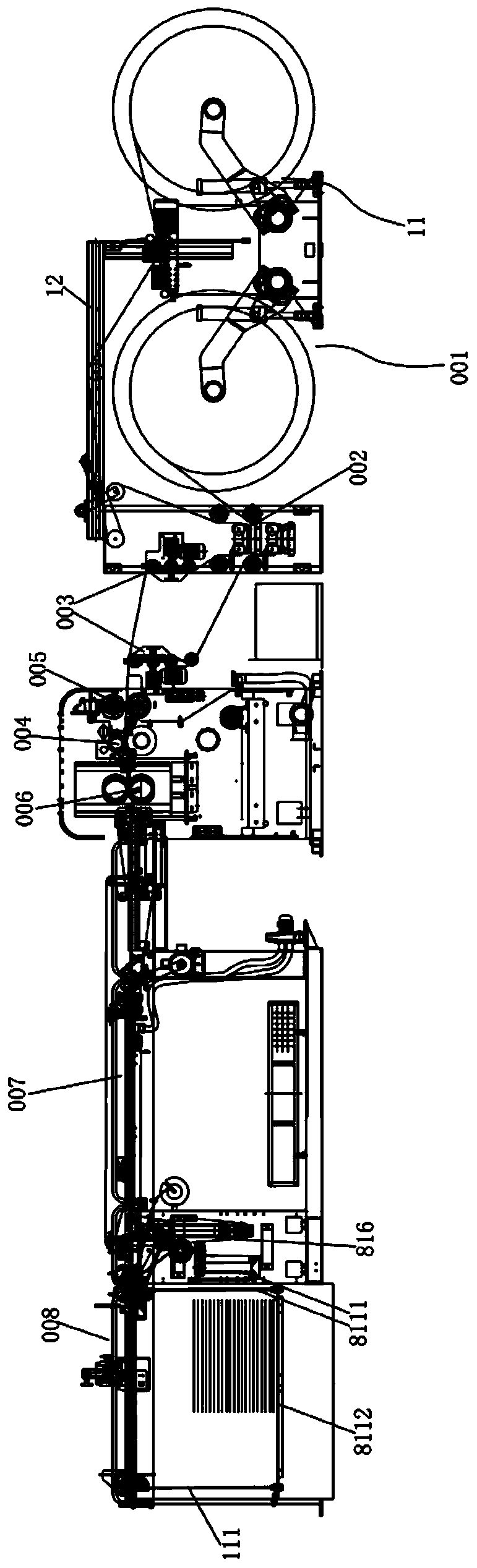

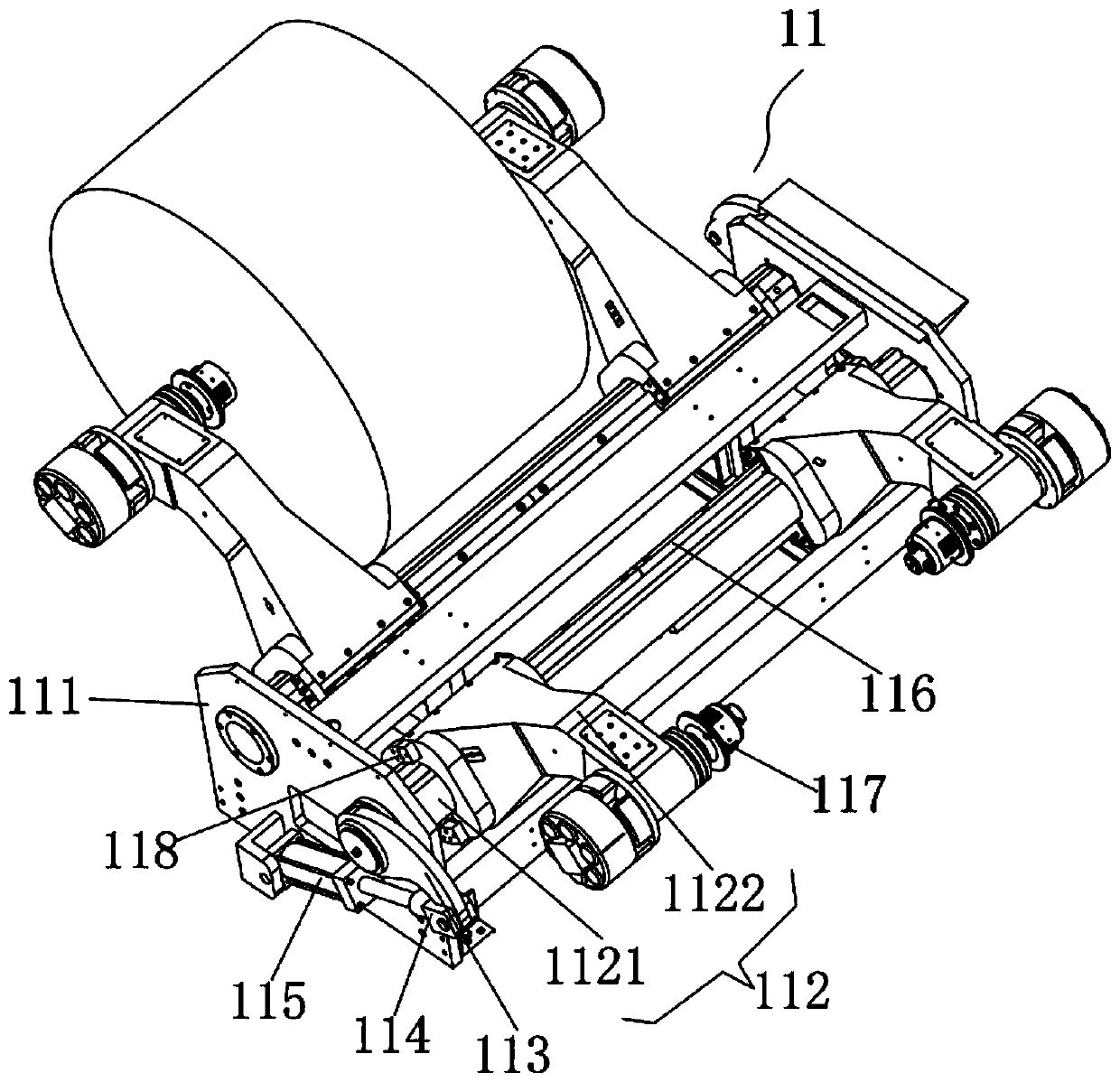

PendingCN110271895AHigh dimensional consistencyLarge size errorPile receiversMetal working apparatusRolling paperTraction system

The invention discloses a double rotary knife roll paper splitting machine which comprises a paper supply system, a traction system, a conveying system and a paper collecting system. The paper supply system is used for being matched with a correcting system and a retroflection system to transfer a plurality of roller paper layers along a transverse direction; the traction system is used for sending laminated roll paper to a traction system of double rotary roller trimmer knife after pulling the roll paper to a stripping system; the conveying system comprises a high speed lower conveying assembly and a laminated paper conveying assembly in butt joint connection through a paper pass assembly and also comprises a high speed upper conveying assembly, a reducing assembly and a paper pressing assembly; the high speed lower conveying assembly and the laminated paper conveying assembly are matched with the high speed upper conveying assembly, and a pile of paper can be overlapped to the previous pile of paper successively and is transferred to the paper collecting system by matching with a conveying speed difference generated by the high speed upper conveying assembly and the laminated paper conveying assembly with reduction of the reducing assembly; and the paper collecting system is used for carrying each pile of paper and stacking the paper.

Owner:DONGGUAN JUNXING MACHINERY TECH

Paper conveying apparatus and method for flipping paper

InactiveUS20060203271A1Simple structureFew elementTypewritersElectrographic process apparatusPositive directionEngineering

A paper conveying apparatus and method for flipping paper includes a paper feeding roller that can rotate in a positive direction or in a reverse direction, a motion transfer member that has one end coupled with the paper feeding roller, and a paper depressing element coupled with another end of the motion transfer member to be driven and rotated. The method of flipping paper includes: first, feeding a sheet of paper into a first paper conveying path; next, depressing the paper into a second paper conveying path while the paper is leaving the first paper conveying path; and reentering the paper from the second paper conveying path into the first paper conveying path upside down.

Owner:LITE ON TECH CORP

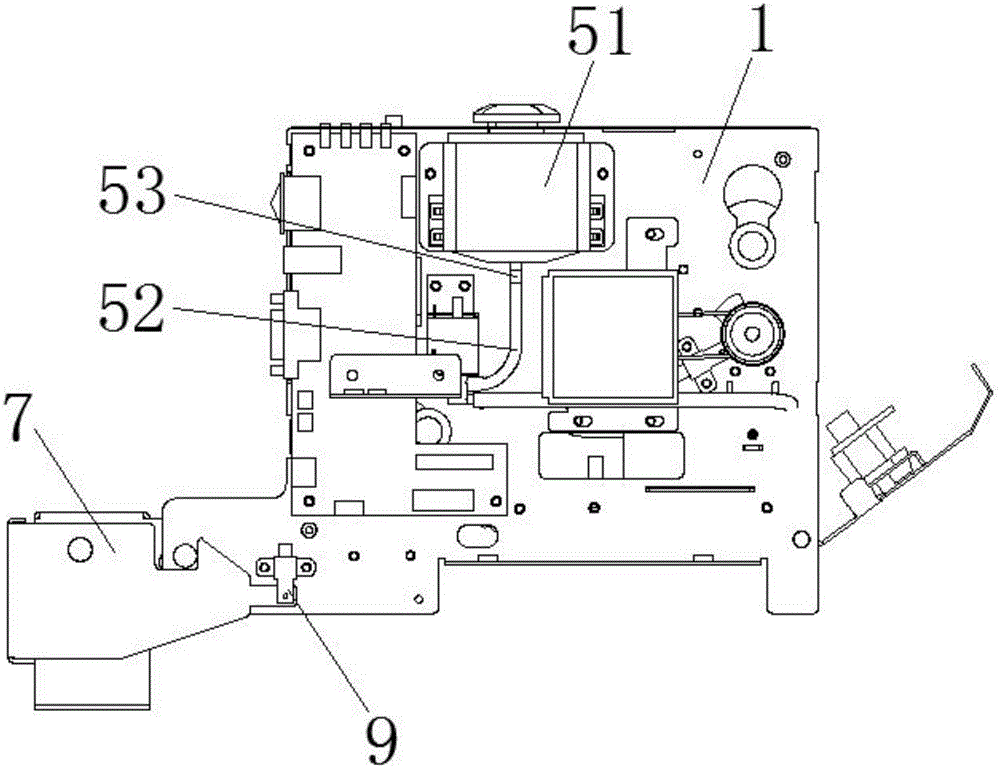

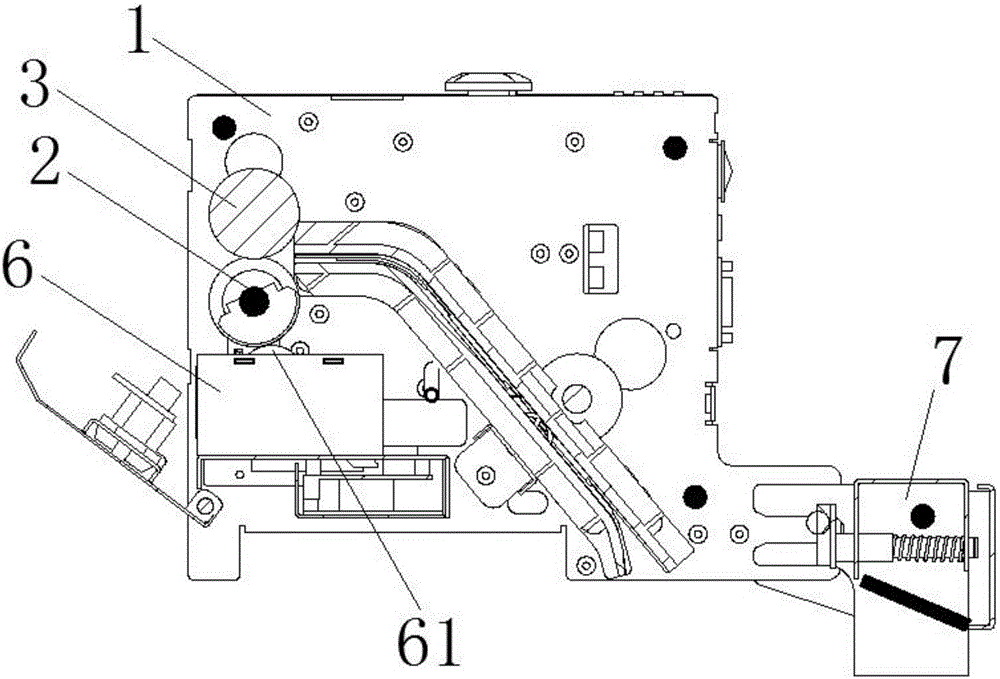

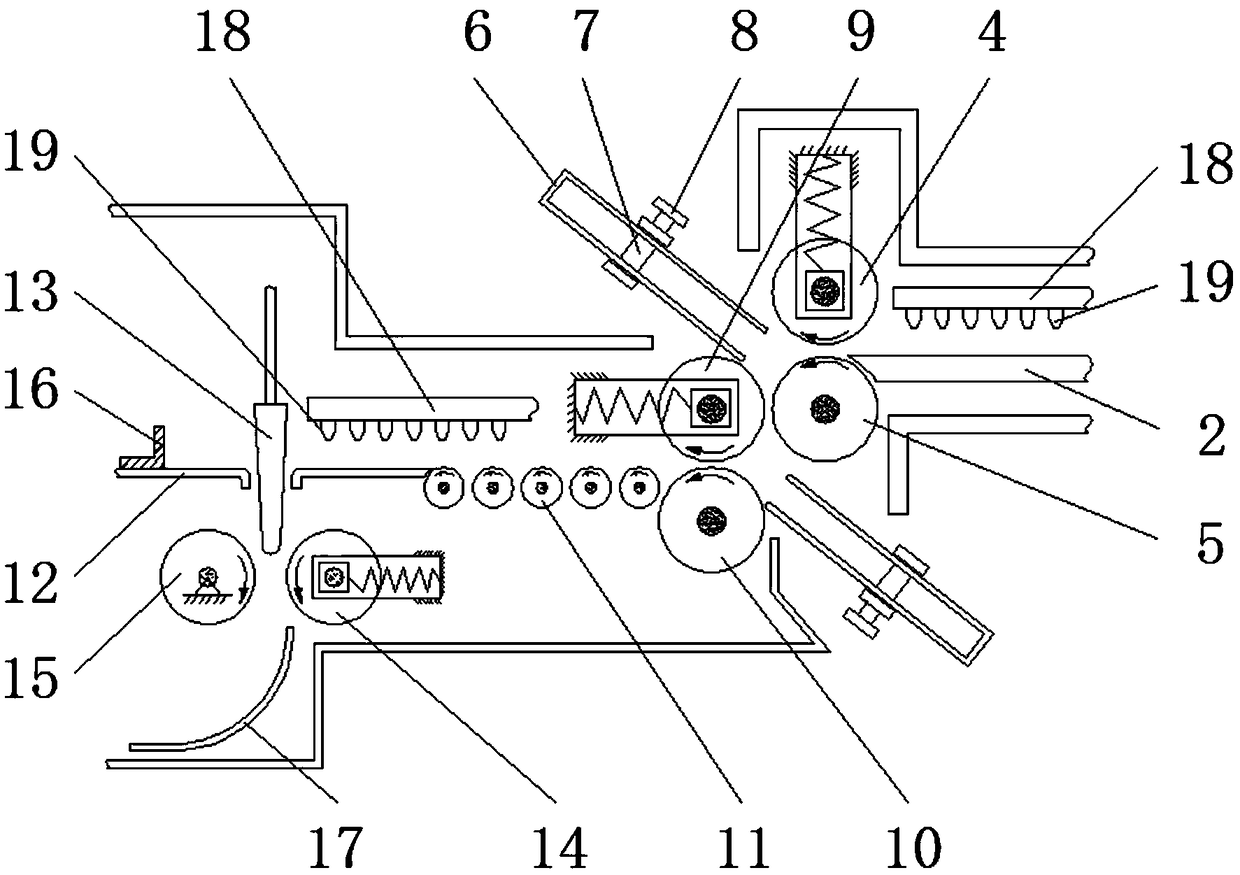

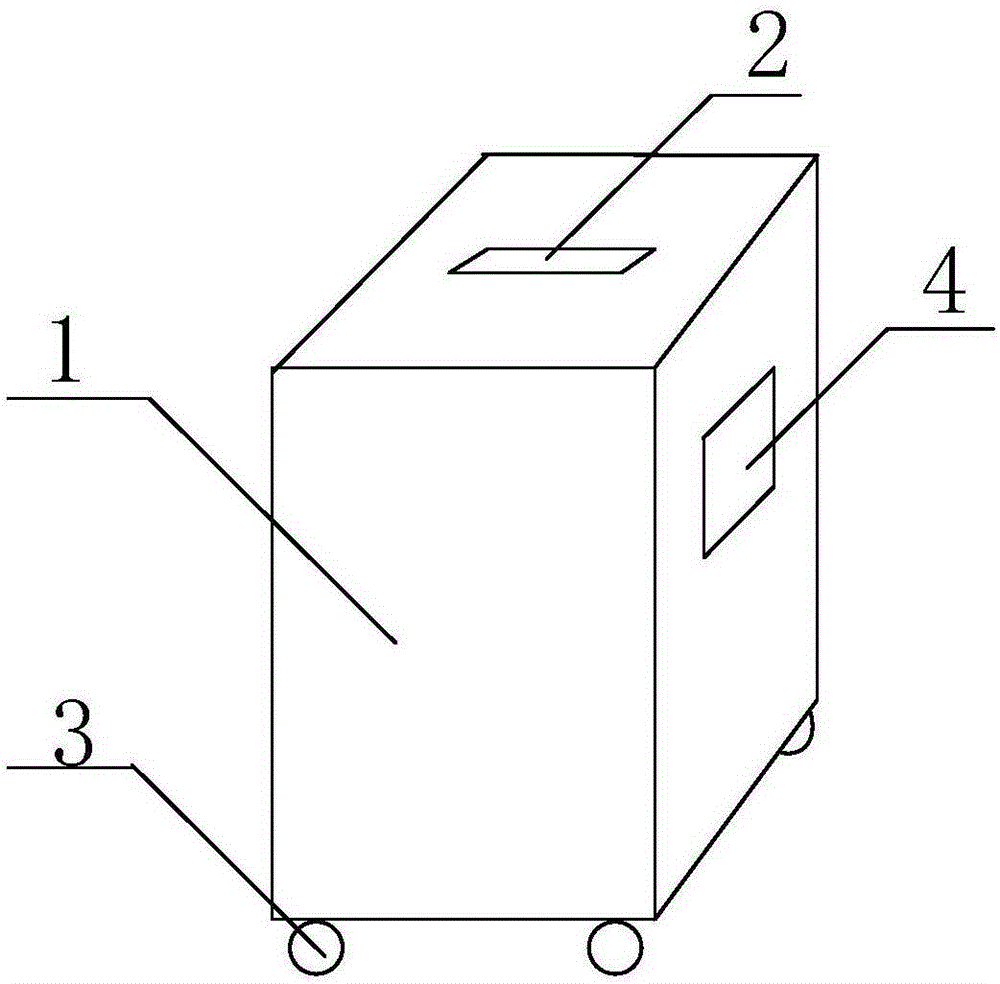

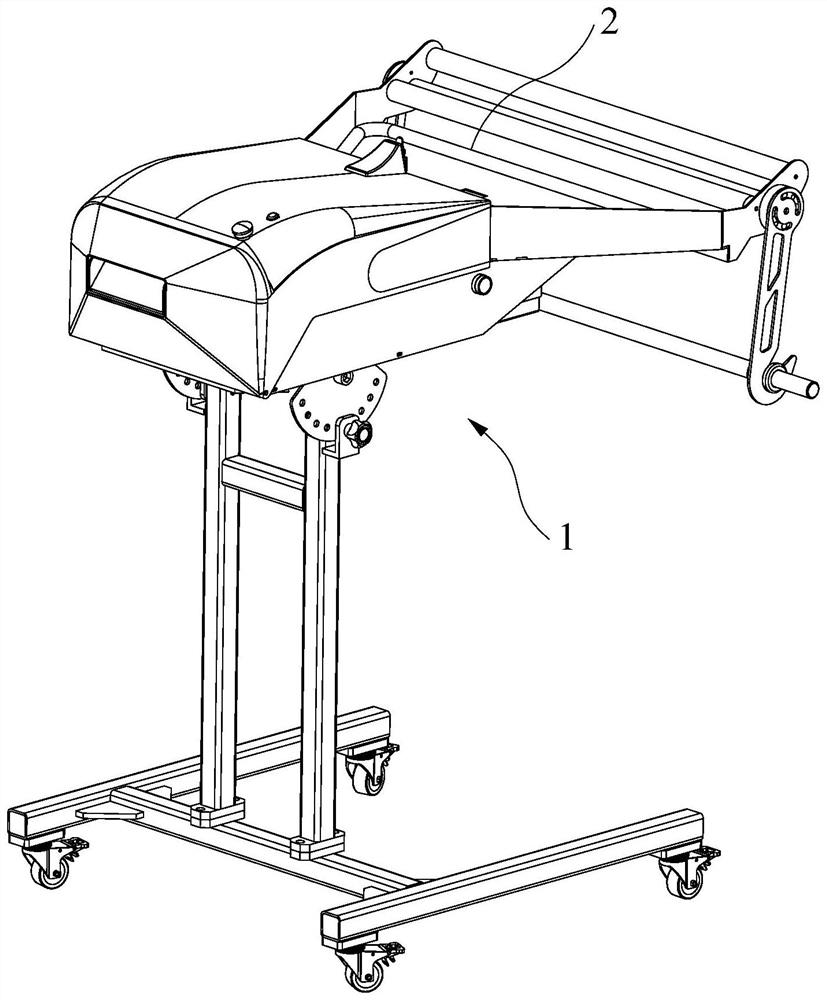

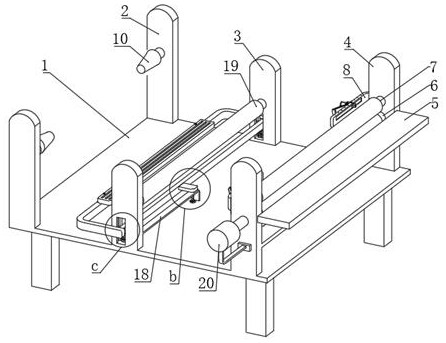

Automatic stamping machine

Disclosed is an automatic stamping machine. The automatic stamping machine comprises a machine frame, a stamp rotating shaft, a rolling rotating shaft, a driving mechanism, an automatic ink adding mechanism, a stamp ink box and a locating locking device. The stamp rotating shaft and the rolling rotating shaft are arranged on the machine frame in parallel in a rotating mode, and the stamp rotating shaft is located below the rolling rotating shaft. At least one rolling stamp is arranged on the stamp rotating shaft, and a rolling printing roller which corresponds to the rolling stamp in position is arranged on the rolling rotating shaft. The driving mechanism is installed on the machine frame and drives the stamp rotating shaft and the rolling rotating shaft to synchronously rotate in the opposite directions. The automatic ink adding mechanism automatically adds ink to the stamp ink box. First rolling wheel printing cotton which makes flexible contact with the rolling stamp is arranged in the stamp ink box. The machine frame and a printer are located and locked through the locating locking device. According to the automatic stamping machine, the relative position between the automatic stamping machine and the printer is accurately guaranteed through the innovative locating locking device, the probability of paper jams is reduced, and the stability and the reliability are improved. The first rolling wheel printing cotton makes flexible contact with the rolling stamp, and the service life is long. The automatic ink adding mechanism can achieve automatic and continuous ink addition.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

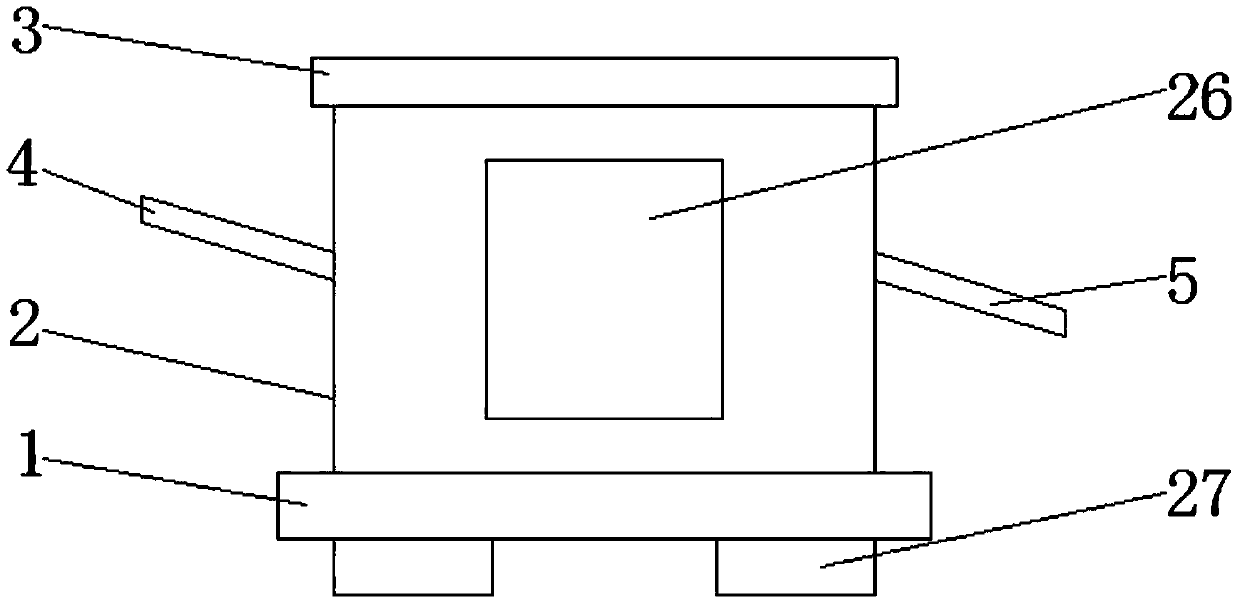

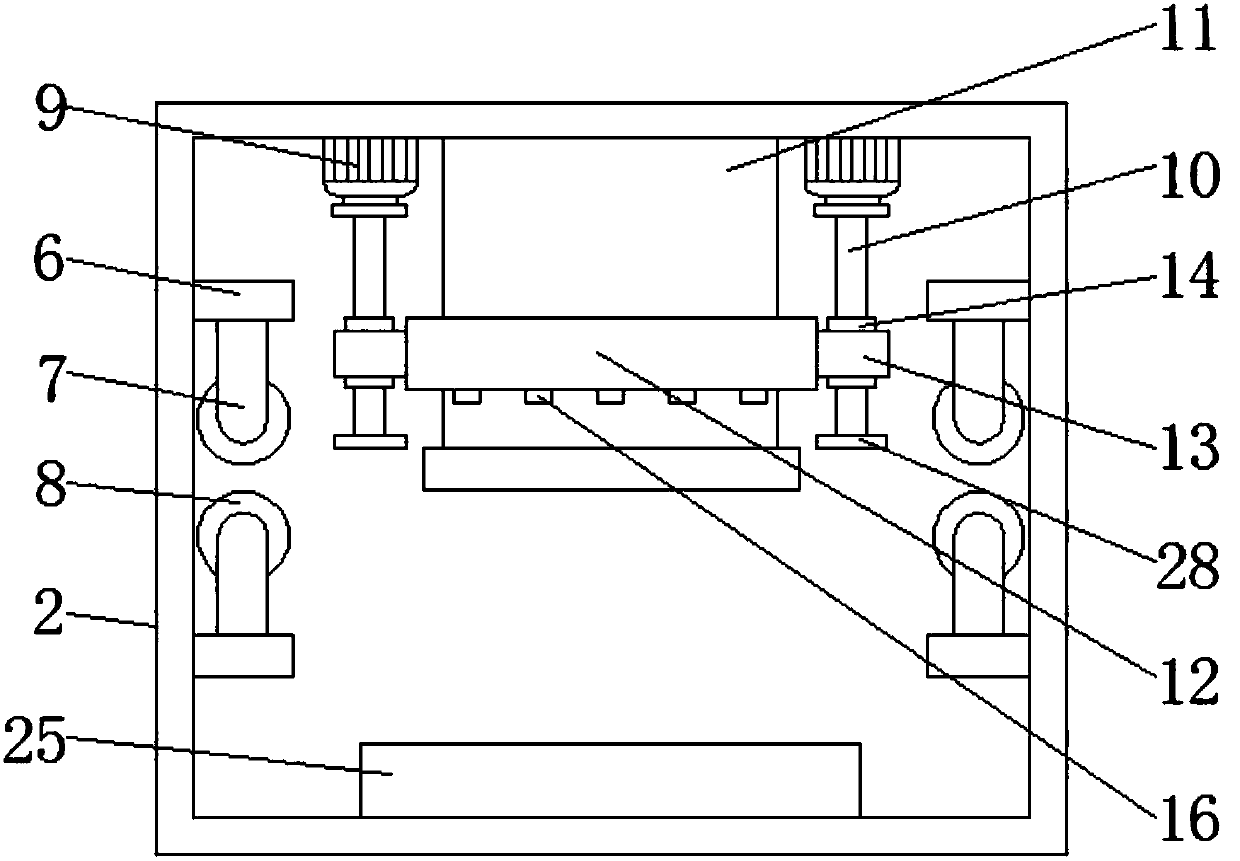

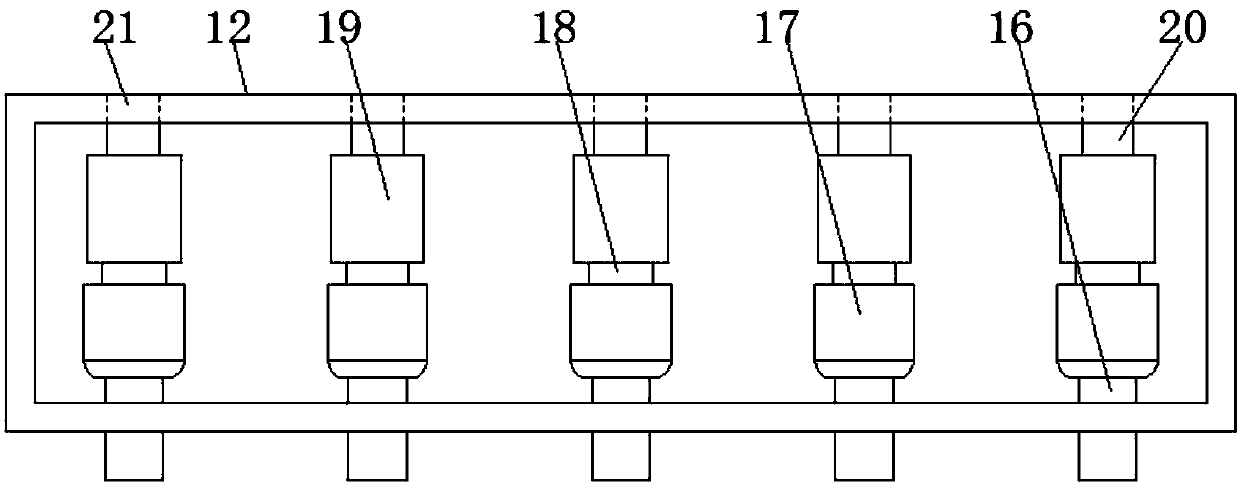

Printing machine with dust removal function

InactiveCN109986881AImprove working environmentImprove the quality of workPrinting press partsCardboardQuality of work

The invention discloses a printing machine with a dust removal function, and relates to the technical field of printing machines. The printing machine with the dust removal function comprises a base;an outer shell is fixedly installed at the top of the base, a top plate is fixedly installed at the top of the outer shell, a paper inlet plate is fixedly installed on one side of the outer shell, a paper outlet plate is fixedly installed at the other end of the outer shell, and pedestals are symmetrically installed on two sides of the inner wall of the outer shell. The invention discloses the printing machine with the dust removal function. A dust removal sleeve, a brush, an air pump and a filter are arranged; when a motor rotates, a fixed block and the dust removal sleeve can move up and down, so the brush can clean dusts on the surface of the printing machine body; meanwhile, the air pump and the filter purify air and the environment in the outer shell, so that dust and impurities in the outer shell are reduced, the working environment of the printing machine is improved, the working quality of the printing machine is improved, and the service life of the printing machine is prolonged.

Owner:天津市慧翔实业集团有限公司

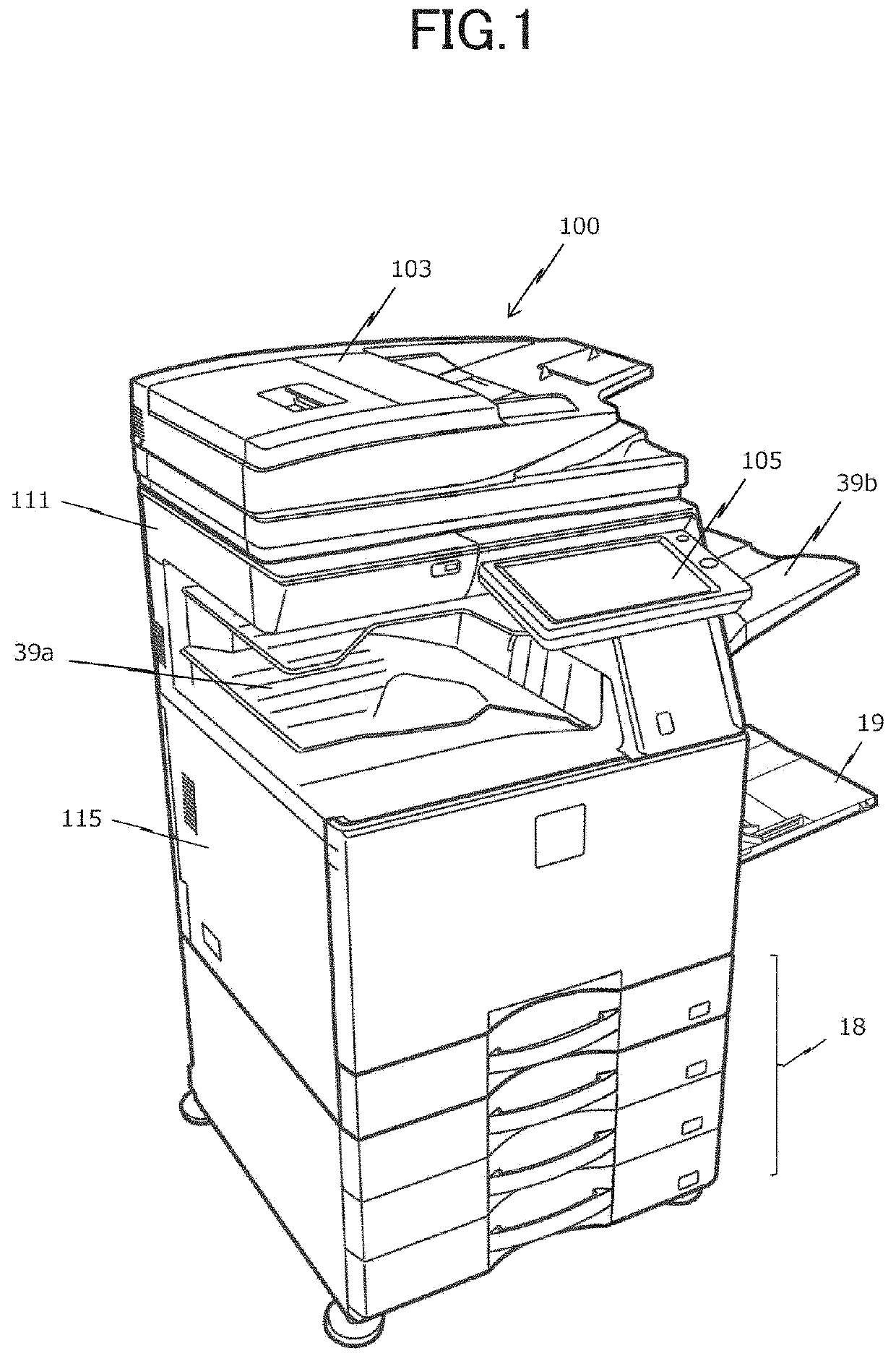

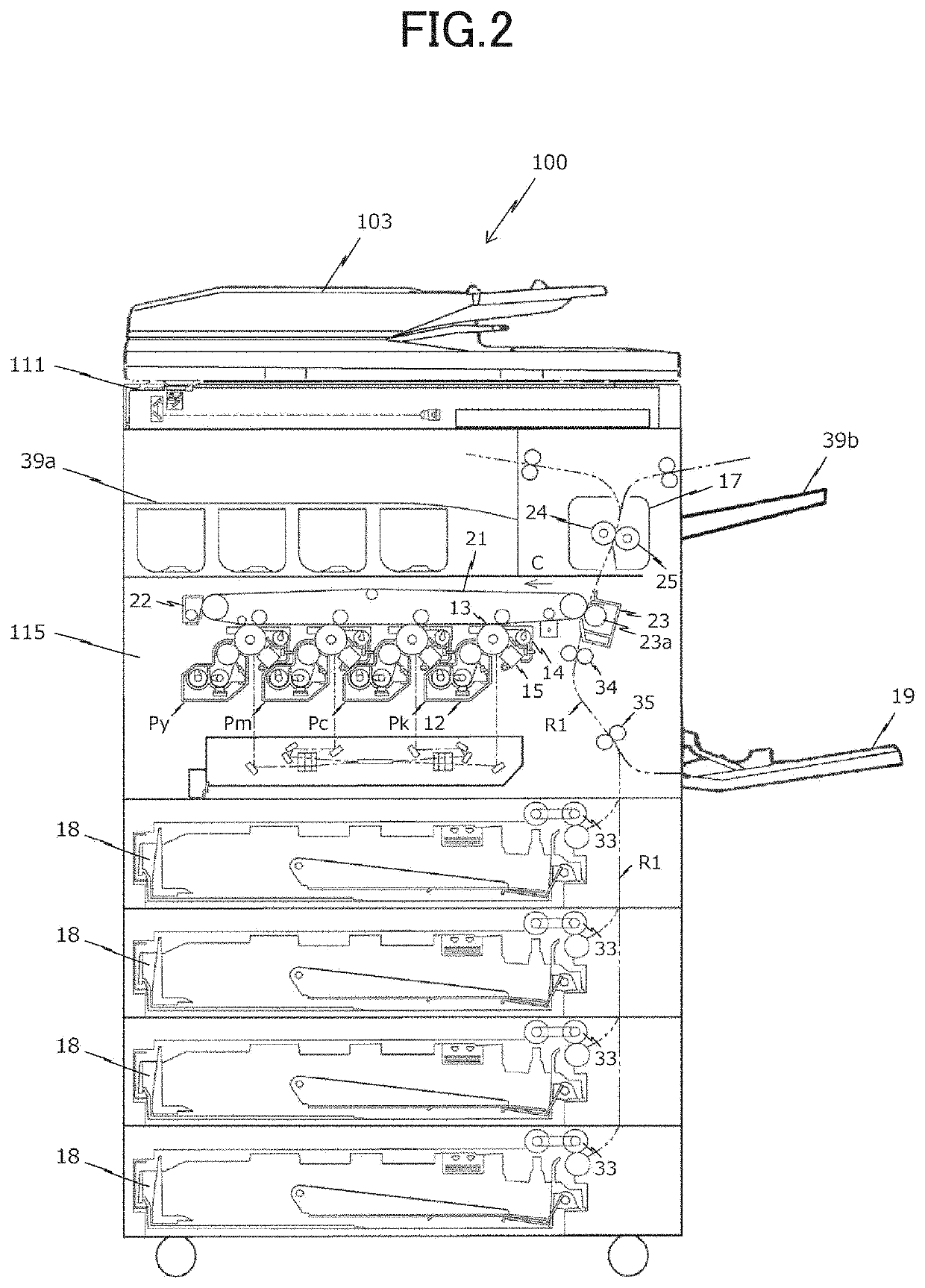

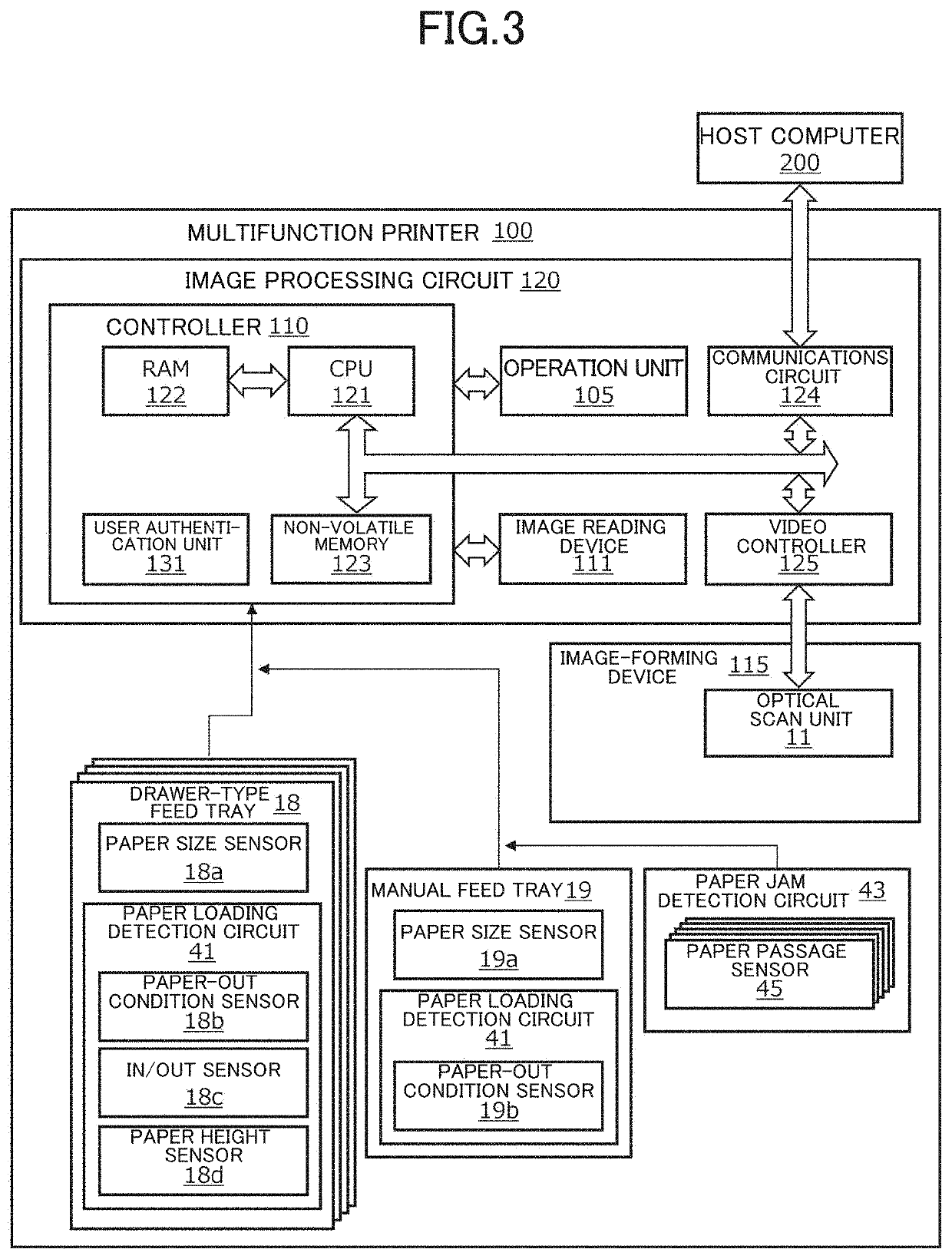

Image forming apparatus and image forming method

ActiveUS20220179350A1Reduce paper jamRealize functionElectrographic process apparatusArticle feedersImage formationProcess engineering

An image forming apparatus includes: a feed tray that contains printing paper therein; a user authentication unit that authenticates a user who is permitted to print; a paper loading detection unit that detects printing paper loaded into the feed tray; a memory device that stores a user authenticated as a paper-supplementing user; a paper feeding mechanism that feeds the printing paper from the feed tray; a paper jam detection unit that detects a paper jam; and a controller that controls a print job. The controller, when a paper jam has occurred, determines whether or not the paper jam is due to the paper-supplementing user having loaded the printing paper in an improper manner. Upon determining that the paper jam is due to the paper-supplementing user having loaded the printing paper in an improper manner, the controller, subsequently when the paper-supplementing user uses, requests that a loading condition be checked.

Owner:SHARP KK

Automatic paper feeding mechanism for copying machine

The invention discloses an automatic paper feeding mechanism for a copying machine and relates to the technical field of copying machines. The automatic paper feeding mechanism for the copying machinecomprises a U-shaped support, a paper feeding assembly, a guiding mechanism, baffles, connecting plates and a moving assembly. Through grooves are formed in opposite inner walls of the U-shaped support correspondingly. A transverse plate is fixedly installed on the inner bottom face of the U-shaped support. A pair of vertical plates are arranged on the surface of the transverse plate. An inverted-L-shaped plate is fixedly installed between the vertical plates. A pair of sliding rods are fixedly installed on the lower surface of a protruding portion of the inverted-L-shaped plate. A paper-pressing plate is slidingly connected to circumferential side faces of the pair of sliding rods. The paper feeding assembly comprises a rotary shaft. One end of the rotary shaft and the output shaft of afirst motor are fixedly installed. A paper feeding wheel is fixedly installed in the middle of the rotary shaft. According to the automatic paper feeding mechanism for the copying machine, through action of the U-shaped support, the paper feeding assembly, the guiding assembly, the baffles, the connecting plates and the moving assembly, the effects that limiting of paper of different width is conveniently conducted, paper is prevented from deviating in the conveying process, clamping of paper is reduced, and the copying quality is improved are achieved.

Owner:安徽扬远信息科技有限公司

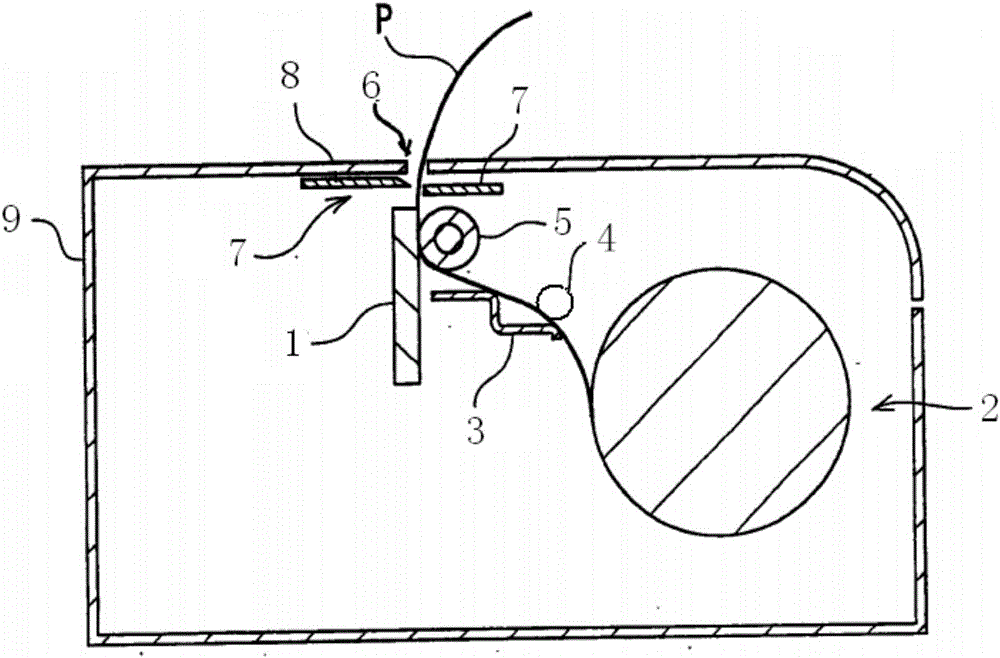

Paper feeding device and its paper turning method

InactiveCN1814531ASimple structureLess componentsRegistering devicesTypewritersPulp and paper industryCounter rotation

The invention relates to a document feeder and the method for turning over paper. It contains document feed roller, which is connected to one end of brake component. Paper pressing component is on the other end of the brake component that could rotate driven by the brake component. The paper turning over method includes the following steps: putting the paper into the first paper feed path, pressing the paper into the second paper feed path while the paper leaving the first paper feed path, the paper would be turned over after coming into the first paper feed path again. The invention is simple structure, and could effectively reduce paper block phenomena.

Owner:LITE ON TECH CORP

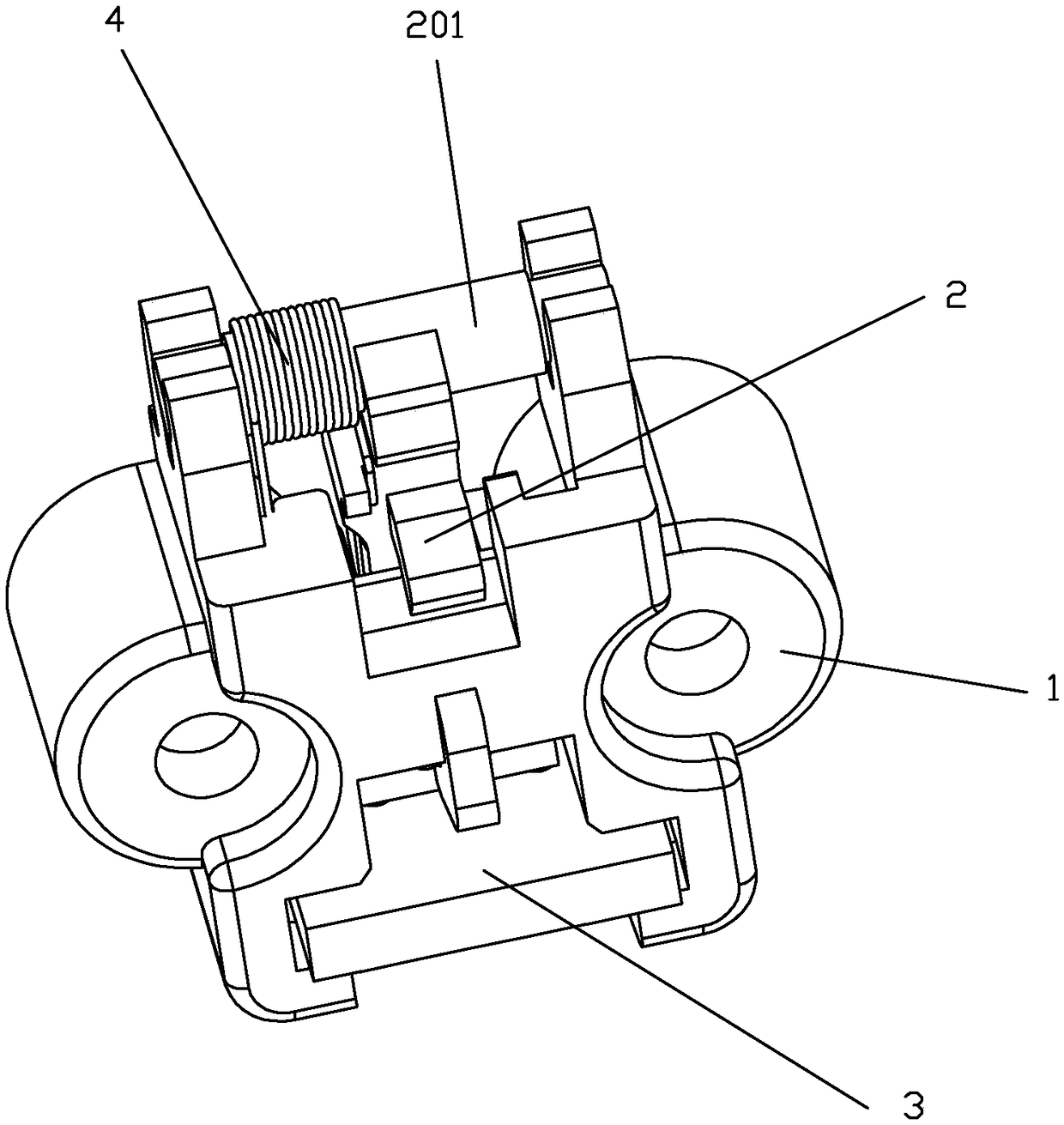

Sensing device determining paper jamming state and printer thereof

ActiveCN107555206AUnaffected by travelReduce paper jamsElectrographic process apparatusArticle feedersLight sensingGrating

The present invention relates to a sensing device, which comprises a housing, a support, a grating module, a first roller, a second roller and a control unit. When the medium contacts the second roller member, the second roller member drives the first roller member to move the supporter relative to the housing according to the thickness of the medium, so as to change the distance between the firstroller member and the grating wheel of the grating module with respect to the location of the shell. And when the media drives the second roller member to rotate, the second roller member drives thefirst roller member to drive the grating wheel to rotate. The control unit determines whether the medium travels at a predetermined speed according to a corresponding light sensing signal generated bythe grating module when the grating wheel rotates, thereby reminding the user of the progress of the medium.

Owner:AVISION

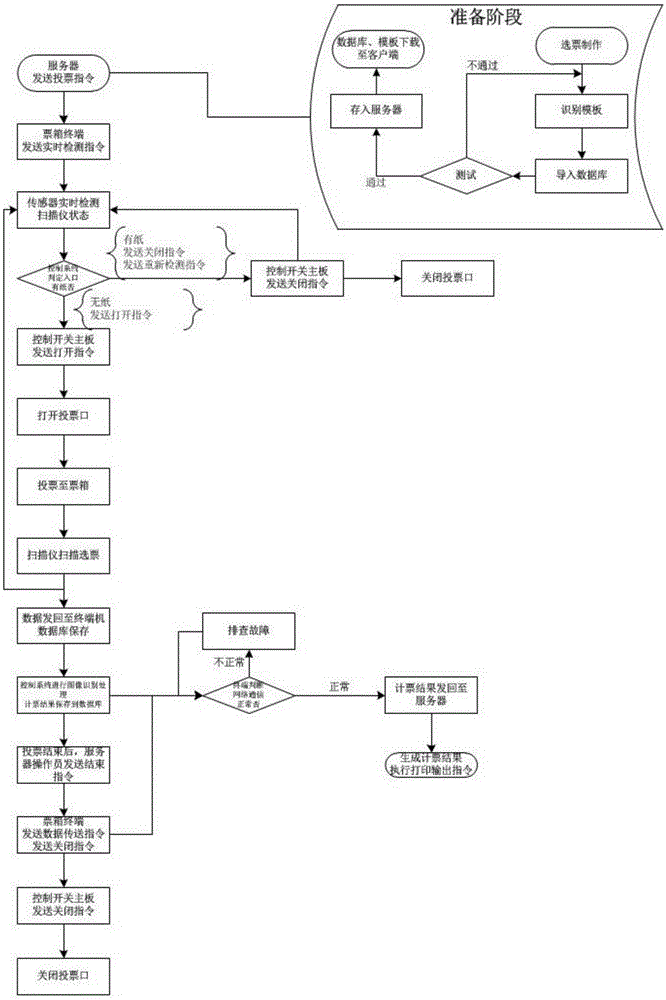

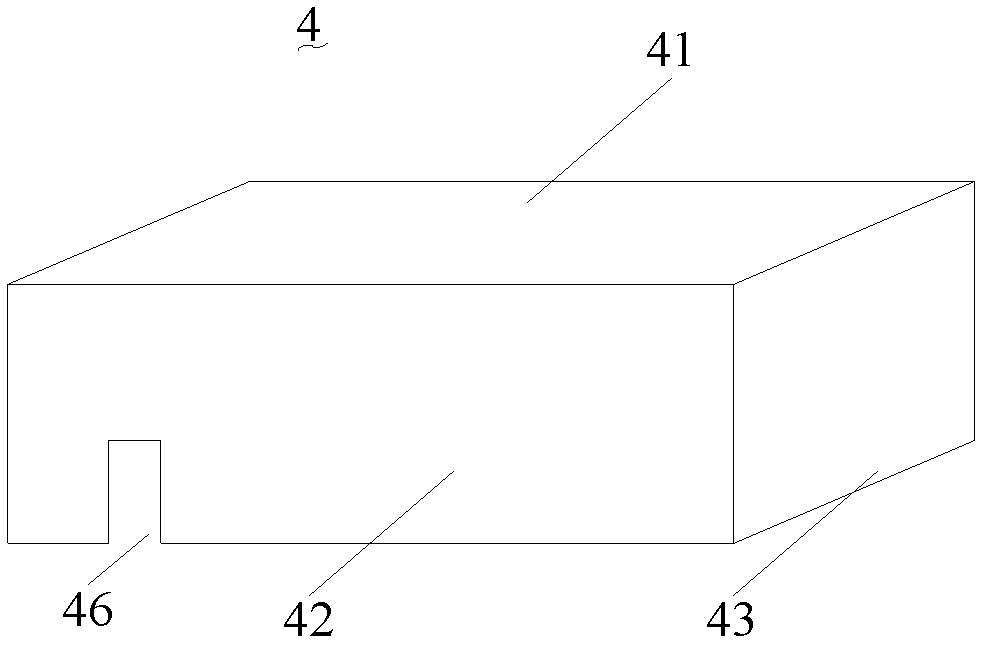

Vote counting system and method thereof

The invention discloses a vote counting system and a method thereof. The vote counting system comprises an electronic vote box, the electronic vote box comprises a box body, the top surface of the box body is provided with an opening-and-closing-controllable voting mouth, the bottom in the box body is provided with a central processor and a vote cabinet for storing votes, and the vote cabinet is connected with the voting mouth through a voting channel; the voting channel is provided with a high speed scanner, the high speed scanner scans volts entering the voting channel from the voting mouth and transmits the scanned voting image to the center processor in order to carry out image processing, and the central processor stores data obtained after the vote image processing; the paper inlet of the high speed scanner is also provided with a paper detection sensor used for detecting whether a vote exists at the paper inlet of the high speed scanner or not; the central processor is connected with a server; and the server is connected with output equipment, and the server counts the received data obtained after the vote image processing, and sends a counted result to the output equipment in order to output a final voting result.

Owner:浪潮数字(山东)科技有限公司

Double-sided printer

PendingCN109932879ASimple structureImprove printing efficiencyElectrographic process apparatusPulp and paper industry

Owner:杭州旭鹏智能箱柜有限公司

Mixed folding machine

PendingCN108382917AWon't liftThose who don't know foldFolding thin materialsArticle deliveryPulp and paper industryPaper sheet

The invention discloses a mixed folding machine which comprises a folding device, a first horizontal folding roll, fences, a folding knife and air pipes. A paper feed device is arranged on the right side of the folding device, and a paper collection device is fixed to the left side of the folding device. A second horizontal folding roll is arranged below the first horizontal folding roll. First baffles are mounted on the fences. Transfer rollers are mounted on the left side of a fourth horizontal folding roll. A first vertical folding roll and a second vertical folding roll are mounted below the folding knife. The air pipes are arranged on the right side of the folding knife and the right side of the first horizontal folding roll, and air nozzles are fixed to the lower end face of each airpipe. According to the mixed folding machine, the air pipes cooperate with the air nozzles, paper in the transfer process bears pressure of air blown out from the upper air nozzles, the paper is attached to a transfer device, and it is guaranteed that the paper cannot upwarp or be folded in the transfer process; and the two movable baffles are arranged, and adaptability of the device to differentfolding requirements is increased.

Owner:宜春市同茂印务有限公司

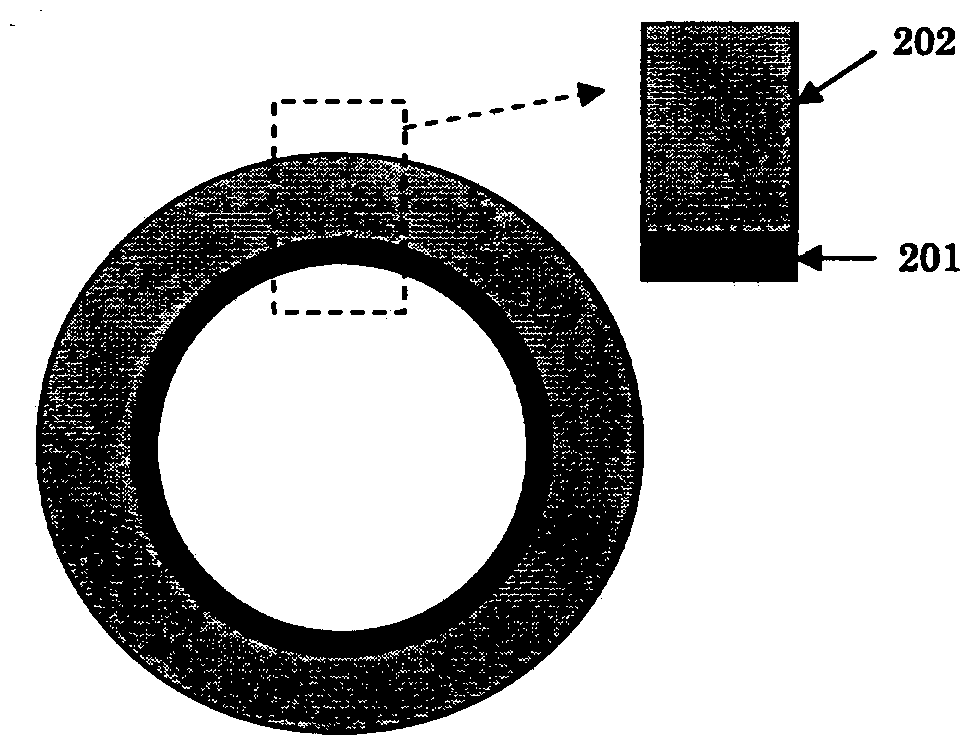

Fixing member, fixing device, and image forming apparatus

InactiveCN103415815AImprove wear resistanceIncreased durabilityElectrographic process apparatusEngineeringOxygen

To provide a fixing member, which contains a base, and a polyorganosiloxane layer provided on the base, where the polyoranosiloxane layer contains polyoranosiloxane including a silicon atom bonded to three or four oxygen atoms, and wherein the fixing member is designed to be used in a process for heating a toner image on a recording medium to fix the toner image onto the recording medium.

Owner:RICOH KK

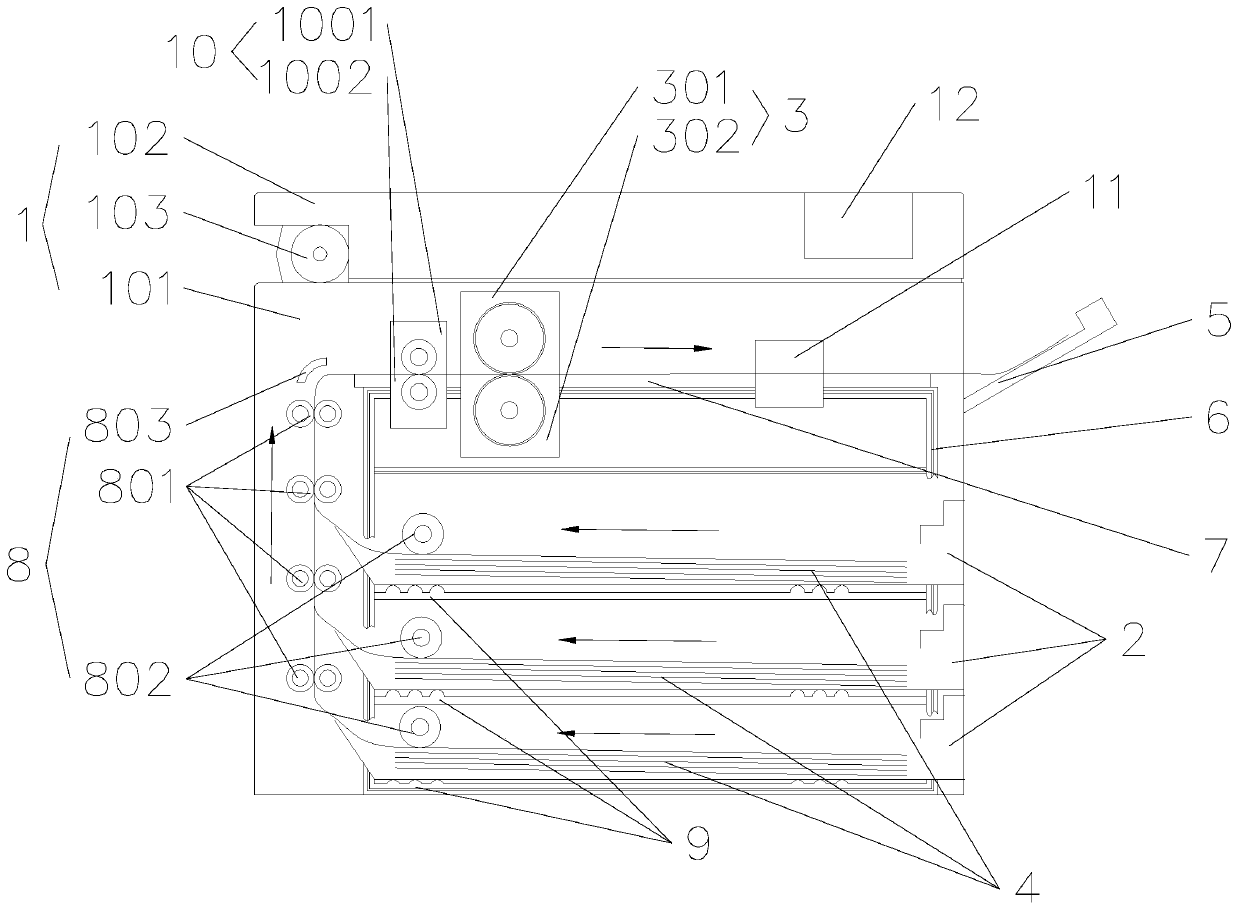

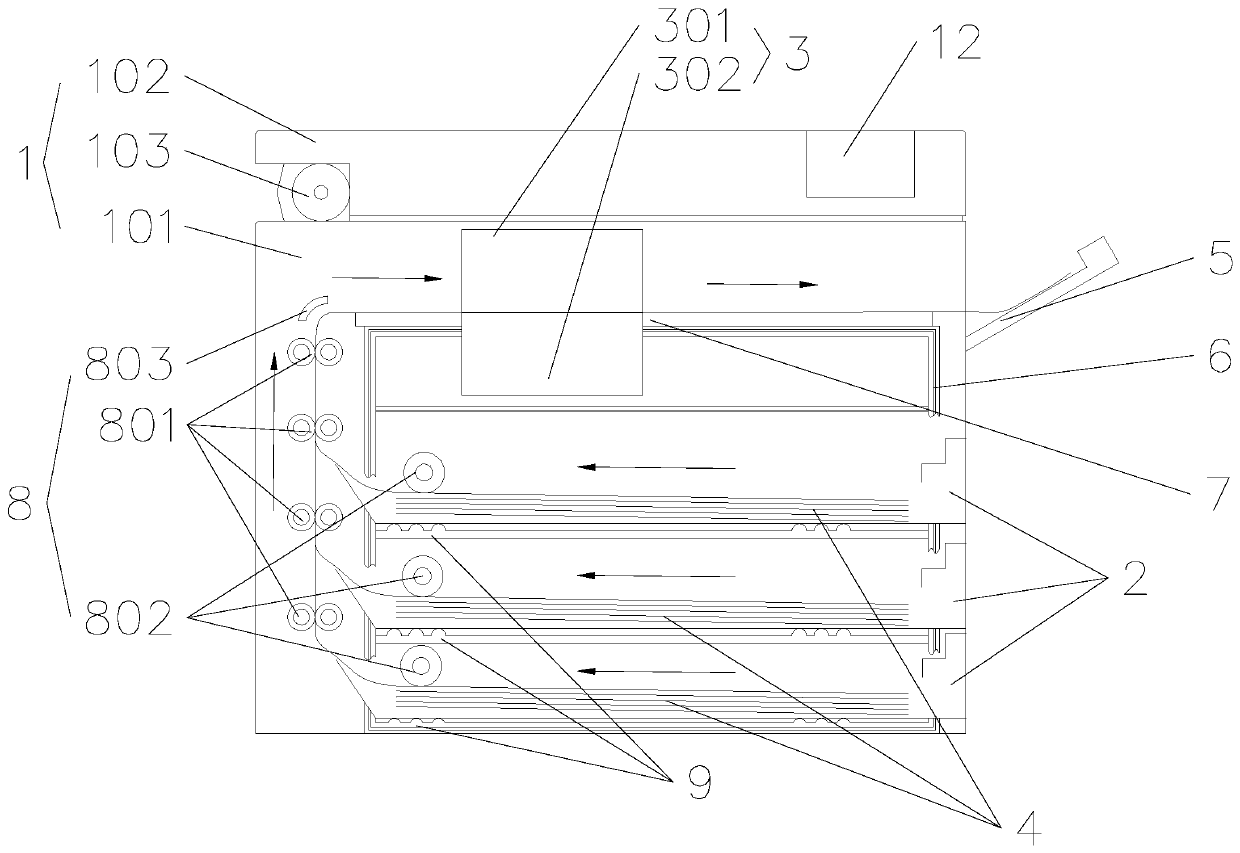

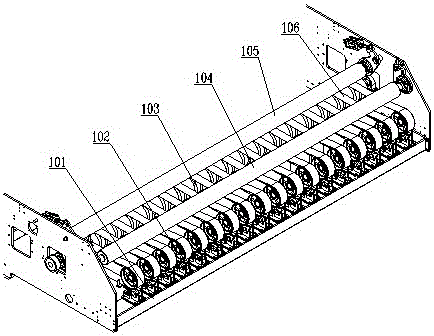

Electronic ballot box capable of preventing ballot tickets from accumulation and working method of electronic ballot box

ActiveCN105184946AWith double sheet processing functionSolve the double sheet problemVoting apparatusImaging processingPulp and paper industry

The invention discloses an electronic ballot box capable of preventing ballot tickets from accumulation and a working method of the electronic ballot box. The electronic ballot box comprises a box body, wherein a ballot ticket putting-in hole, which can be controlled to open and close, is formed in the top surface of the box body; a central processing unit and a ballot cabinet for storing the ballot tickets are arranged at the bottom in the box body; the ballot cabinet is connected with the ballot ticket putting-in hole through a ballot ticket putting-in channel; the ballot ticket putting-in channel is provided with a high-speed scanner; the high-speed scanner is used for scanning the ballot tickets entering the ballot ticket putting-in channel from the ballot ticket putting-in hole, and transmitting scanned ballot ticket images to a central processing unit so as to be subjected to image processing, and data obtained by the image processing is stored into the central processing unit; a paper putting-in hole of the high-speed scanner is further provided with a paper sheet detection sensor; if the ballot ticket exists at the paper putting-in hole of the high-speed scanner, information detected by the paper sheet detection sensor is transmitted to the central processing unit, and the ballot ticket putting-in hole is controlled by the central processing unit to close; otherwise, the ballot ticket putting-in hole is controlled by the central processing unit to open.

Owner:浪潮数字(山东)科技有限公司

Thermo-sensitive type train ticket printer

ActiveCN106393989AImprove removal efficiencyImprove efficiencyPrintingEngineeringPulp and paper industry

The invention discloses a thermo-sensitive type train ticket printer which adopts an external mounting type paper supply box design, wherein the external mounting type paper supply box is provided with a transparent observation window or a paper storage capacity count-down unit; the external mounting type paper supply box adopts a one-step insertion-extraction mounting way, and is used once inserted; a pressure roller structure suitable for the hardness of a ticket base material is adopted, so that a paper blocking condition due to the fact that train tickets have difficulty in passing through a paper feeding gap or a paper outlet because of deformation of the train ticket base material can be sufficiently reduced; and a printer head structure which is dismounted in a one-step insertion-extraction mode can be arranged on the outer part of a machine enclosure, so that the printer head can be taken out to check, clean and replace without opening the machine enclosure; and a pre-heating design is arranged for replacing a new printer head, so that removal efficiency for related faults of the printer is greatly improved.

Owner:浙江网新电气技术有限公司

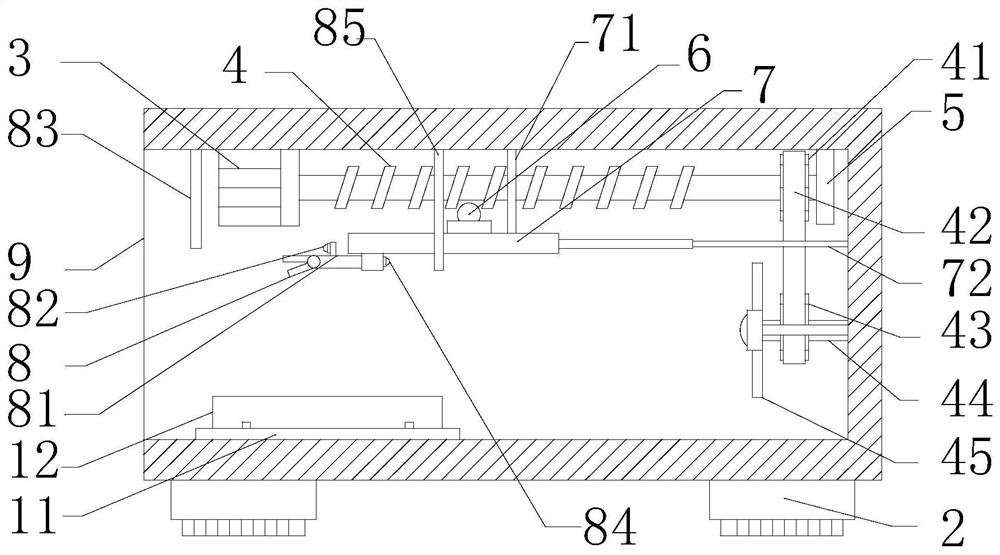

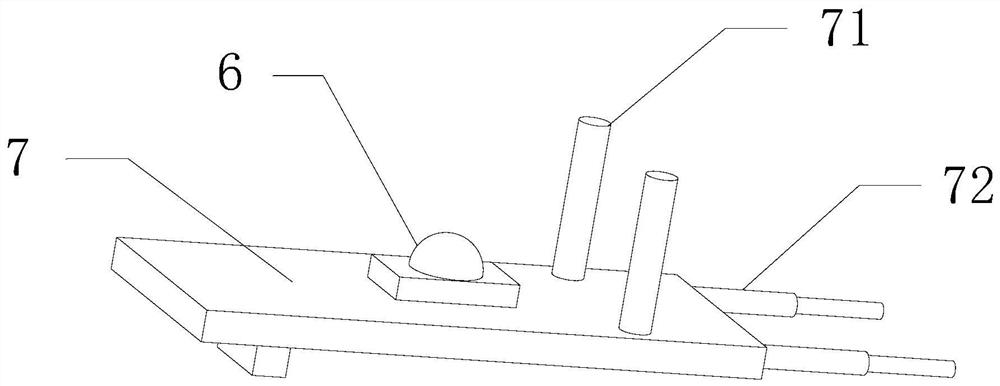

Buffer paper pad machine with paper jam detection function

PendingCN114229581AAvoid damageReduce gapContainers to prevent mechanical damageArticle deliveryIndustrial engineeringPaper cut

The invention discloses a buffer paper pad machine with a paper jam detection function. The buffer paper pad machine comprises a paper guide mechanism, a paper pressing mechanism and a paper cutting mechanism which are sequentially arranged on a rack. The paper pressing mechanism comprises an upper pressing wheel and a lower pressing wheel which are meshed with each other up and down; the buffer paper pad machine further comprises at least one paper jam detection mechanism which is installed on the machine frame and arranged close to the output side of the paper pressing mechanism, and the paper jam detection mechanism is provided with a microswitch. Whether the buffer paper pad machine is jammed or not can be detected through the jammed paper detection mechanism, so that people are reminded and the buffer paper pad machine is controlled to stop in time when the jammed paper occurs.

Owner:XIAMEN AMESON NEW MATERIAL INC

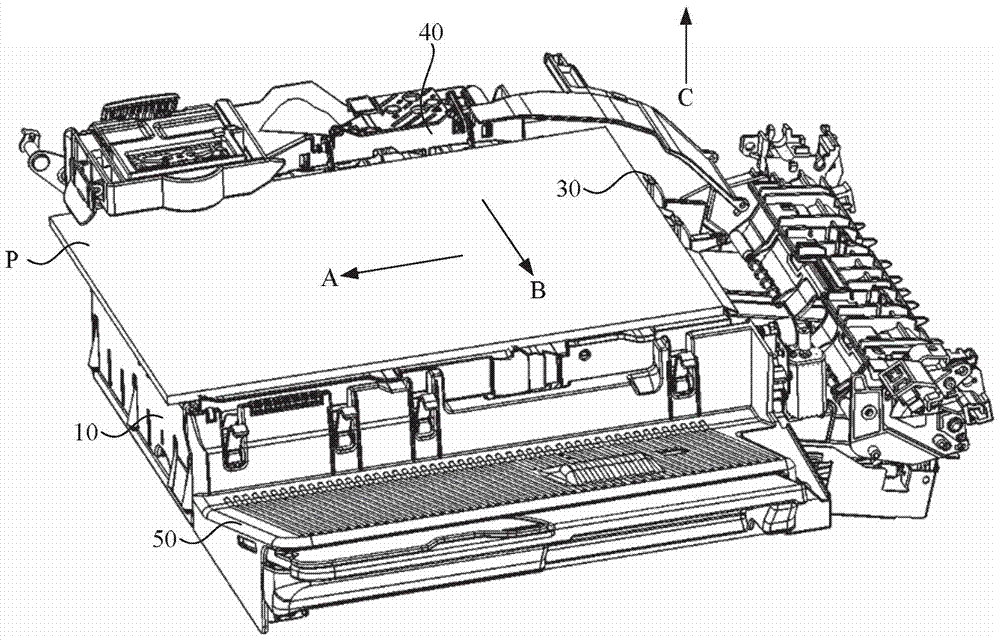

Banknote processing device

ActiveCN102622806BReduce stretchReduce paper jamsComplete banking machinesFunction indicatorsEngineeringAcceleration control

Provided is a bill handling device which comprises: a bill deposit / withdrawal opening (10) where bills to be deposited / withdrawn are collected; a bill discrimination unit (40) for distinguishing bills; a temporary storage part (20) for temporarily collecting and storing bills; bill storage units (30 - 33) for storing and re-separating bills; and bill conveyance paths (50 - 61) for conveying bills to the bill storage units (30 - 33), wherein the bill conveyance paths are each driven by an independent motor, and the bill conveyance speed of the bill conveyance paths is subject to stepwise acceleration control.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

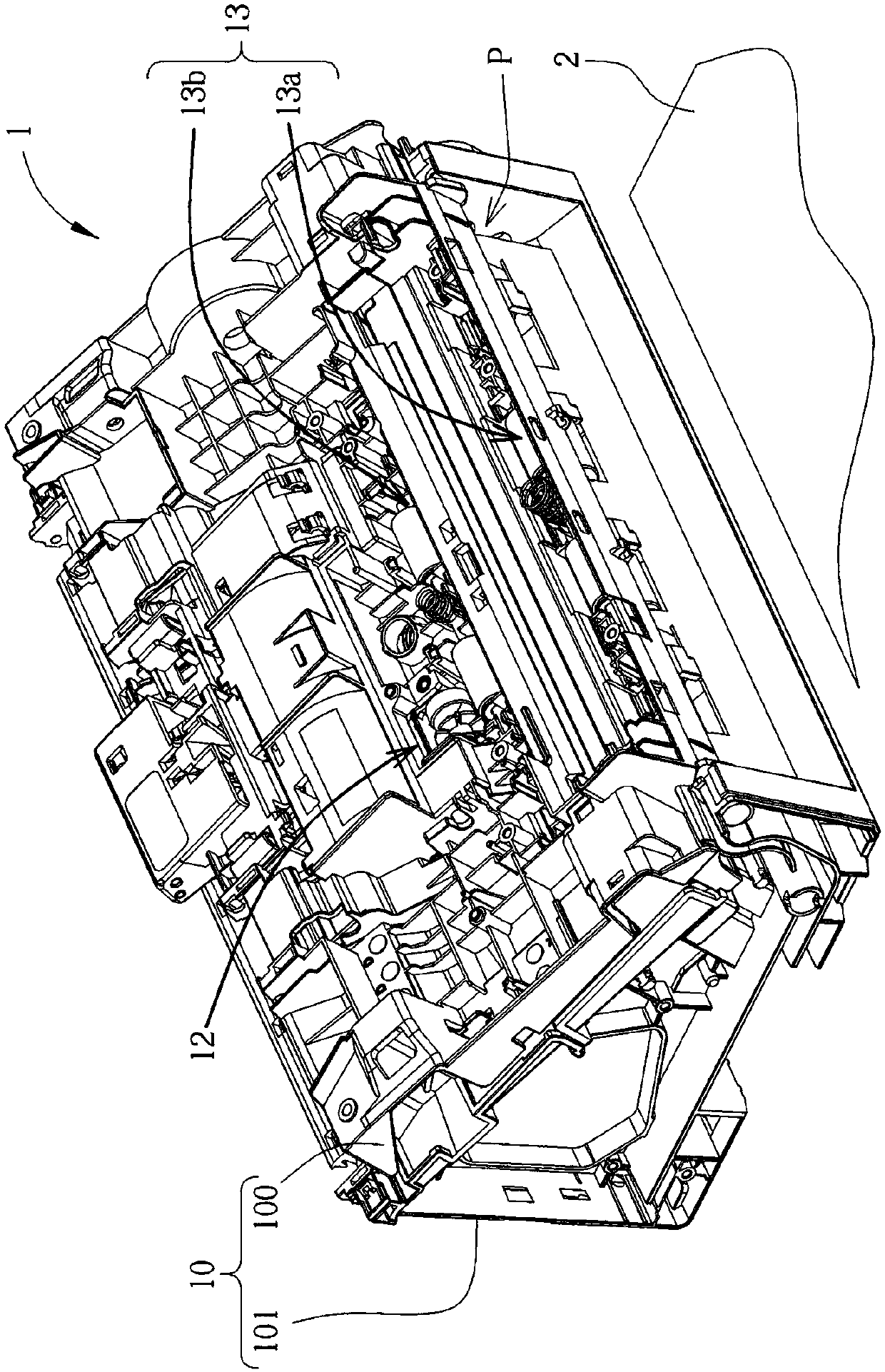

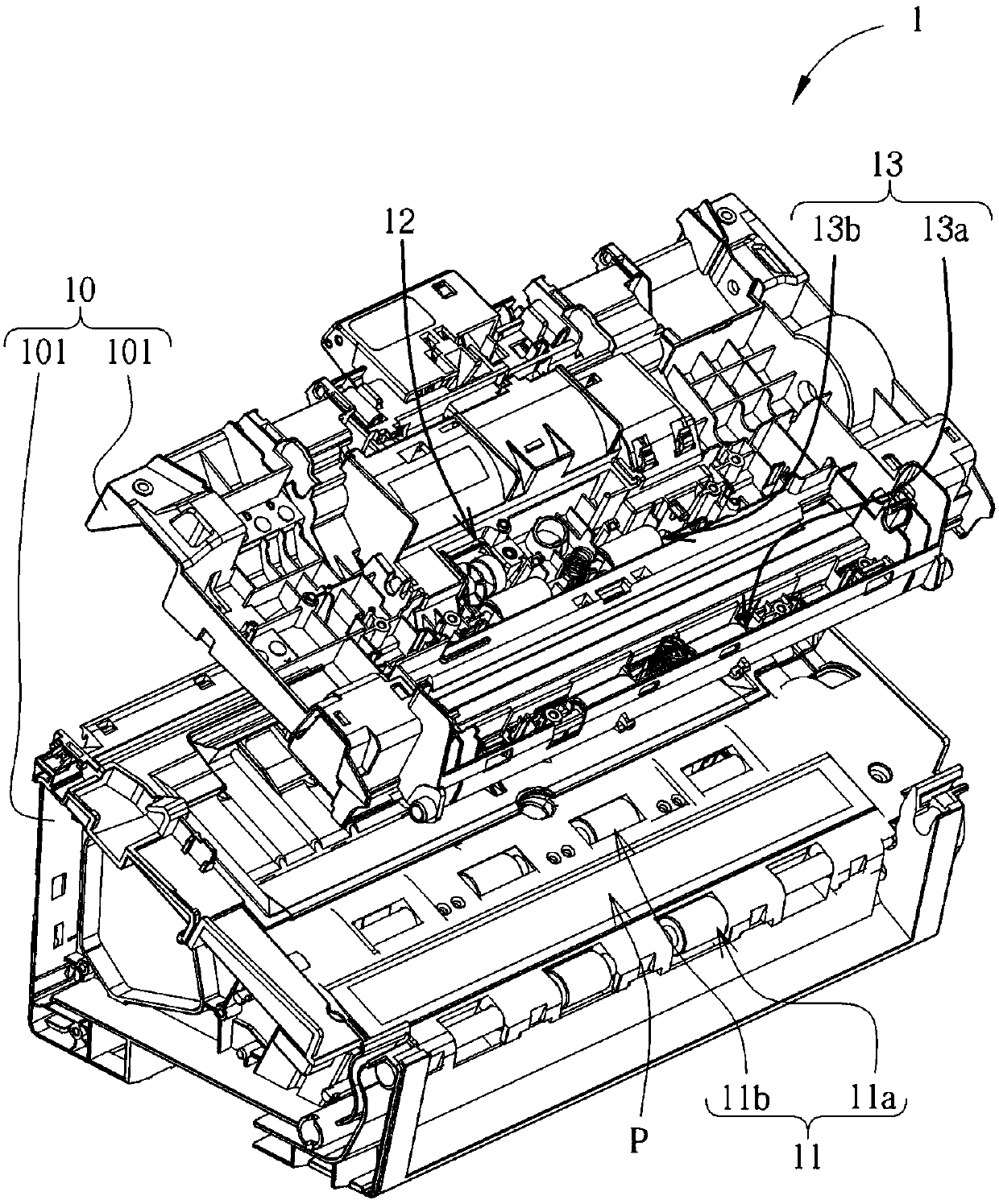

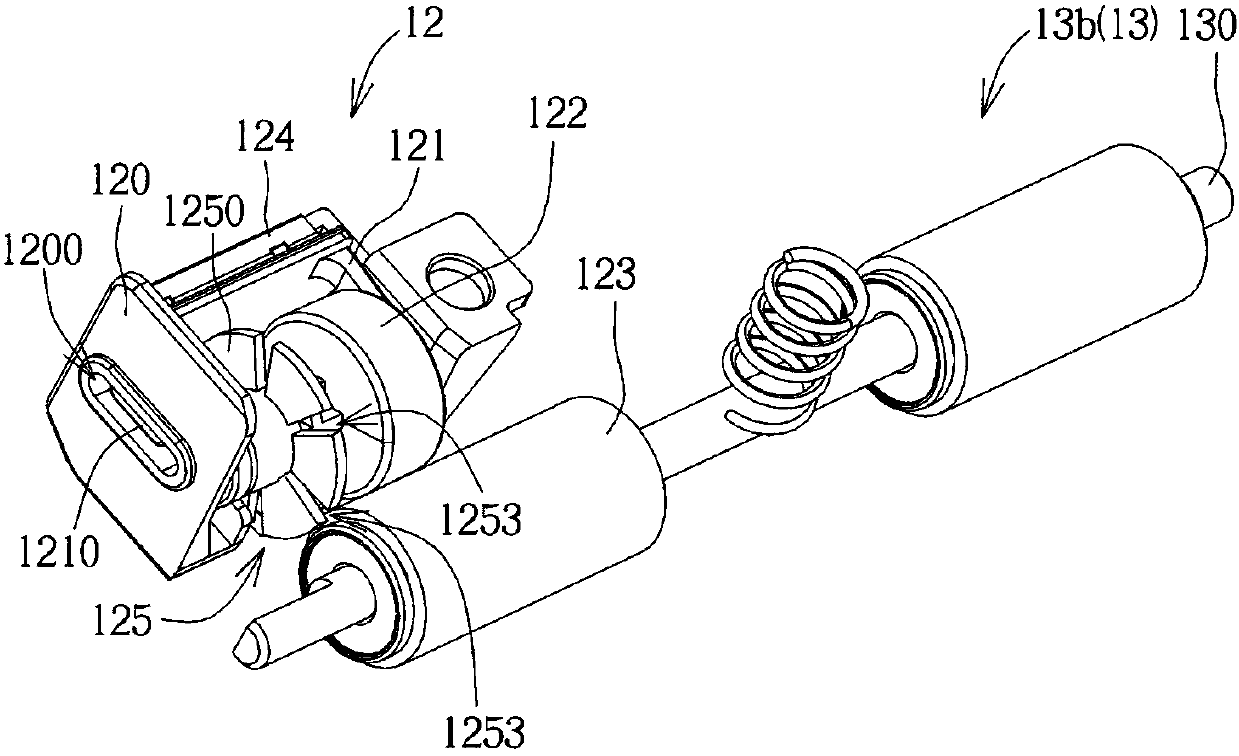

Image forming device and its paper discharge mechanism

ActiveCN105398867BReduce paper jamsIncrease production capacityArticle deliveryAfter treatmentEngineering

An image forming device and its paper discharge mechanism, the paper discharge mechanism includes: a tray for carrying paper discharged from a paper outlet along a discharge direction, the tray is located at an initial inclined position in a paper discharge state, and in a post-processing state The tray is located at a horizontal position; an adjustment part, linked with the tray, is used to adjust the tray to the horizontal position and the initial inclined position; the storage part is arranged at the upstream end of the tray along the discharge direction; a holding part, in the post-processing state, the holding part protrudes from the receiving part to the carrying surface of the tray, so that the upstream end of the paper on the tray along the discharge direction abuts against the holding part; In the paper discharge state, the holding part is located in the storage part; the interlocking part makes the holding part be located in the storage part before the tray is adjusted to the initial inclined position by the adjustment part. The invention solves the problem that the paper discharge mechanism of the existing image forming device cannot solve paper jams and low productivity at the same time.

Owner:KONICA MINOLTA TECH DEV WUXI

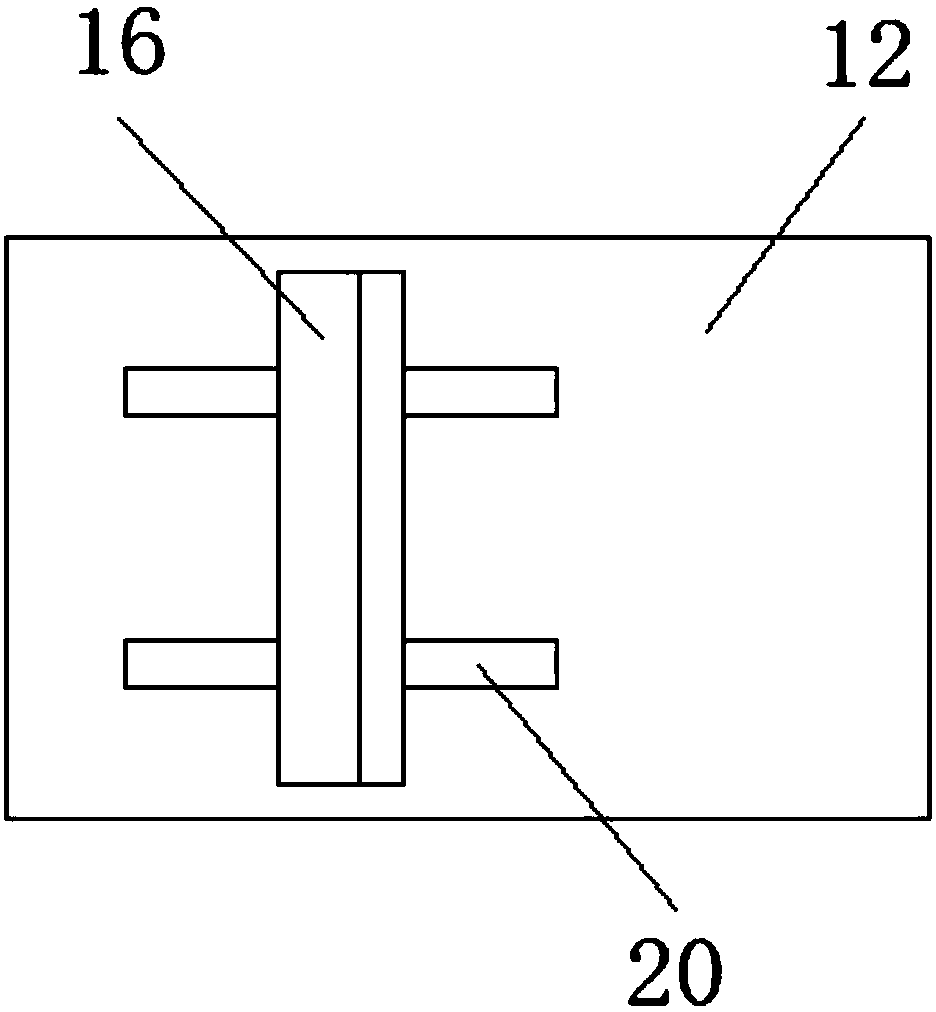

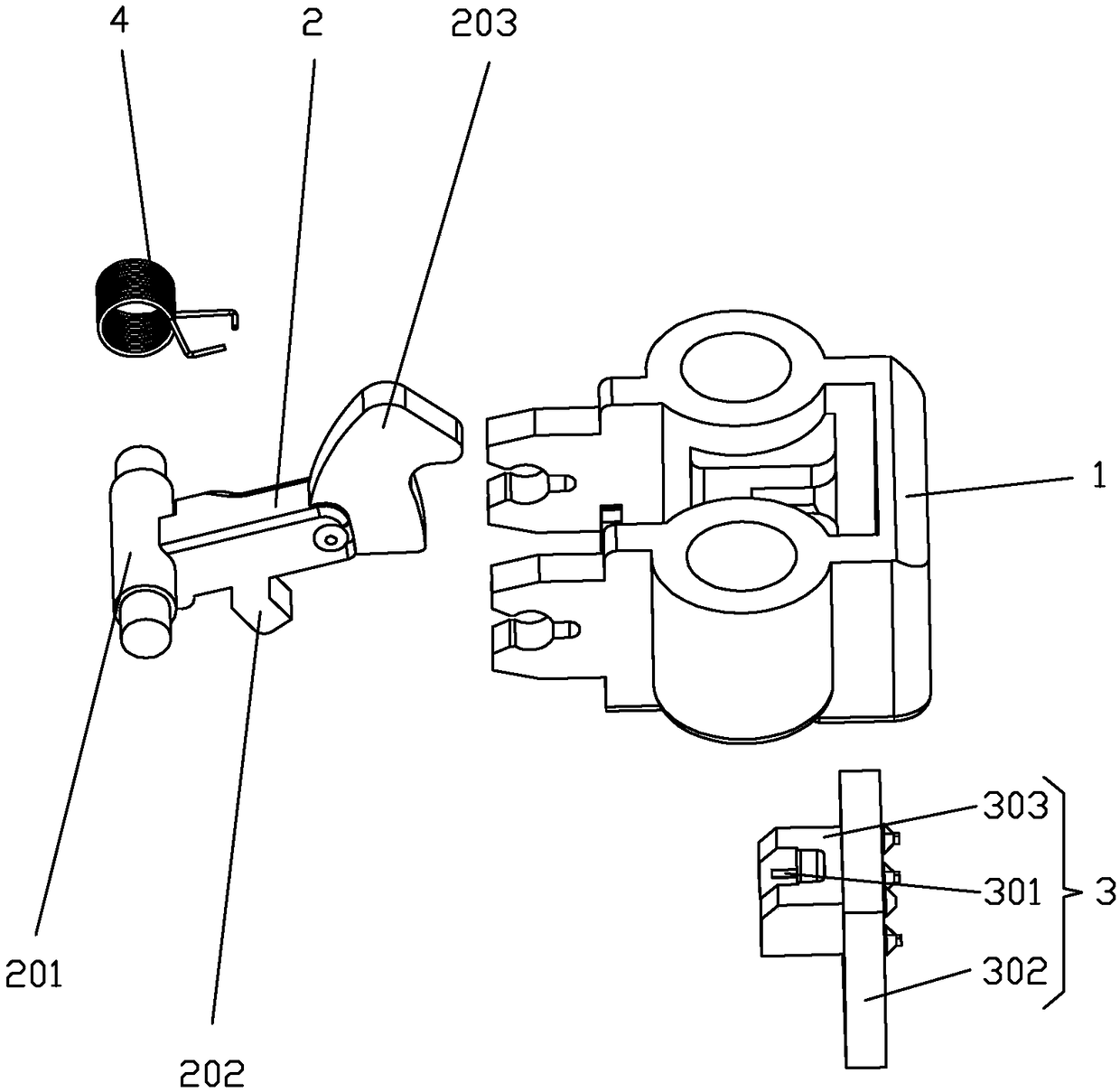

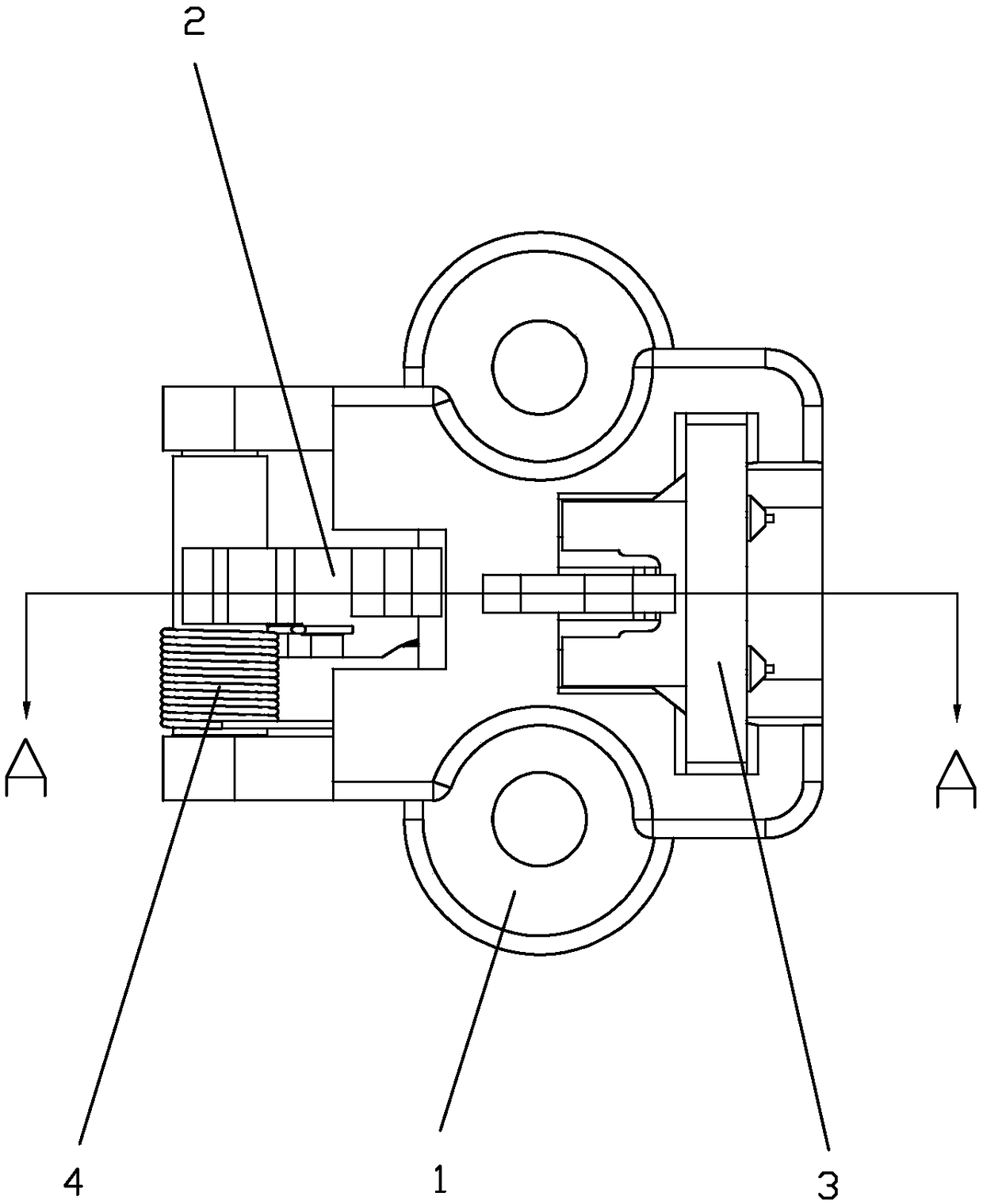

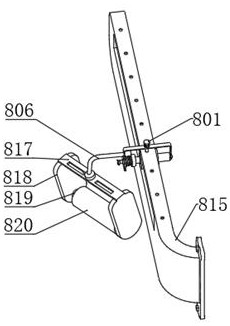

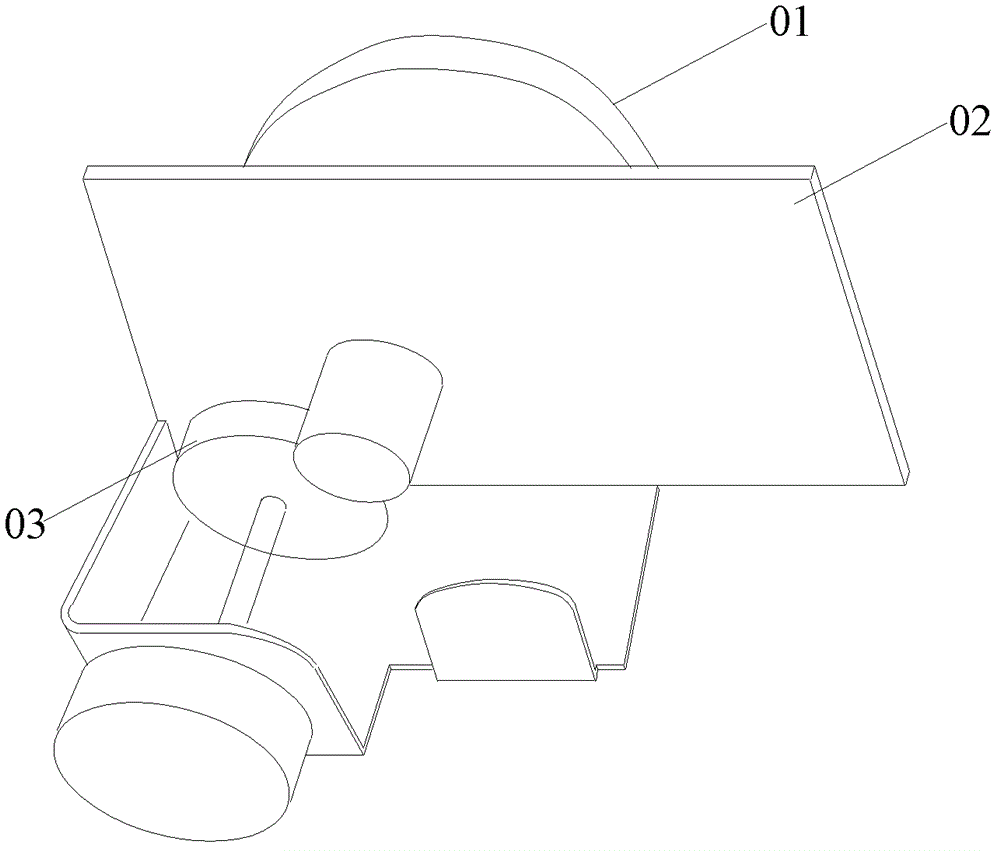

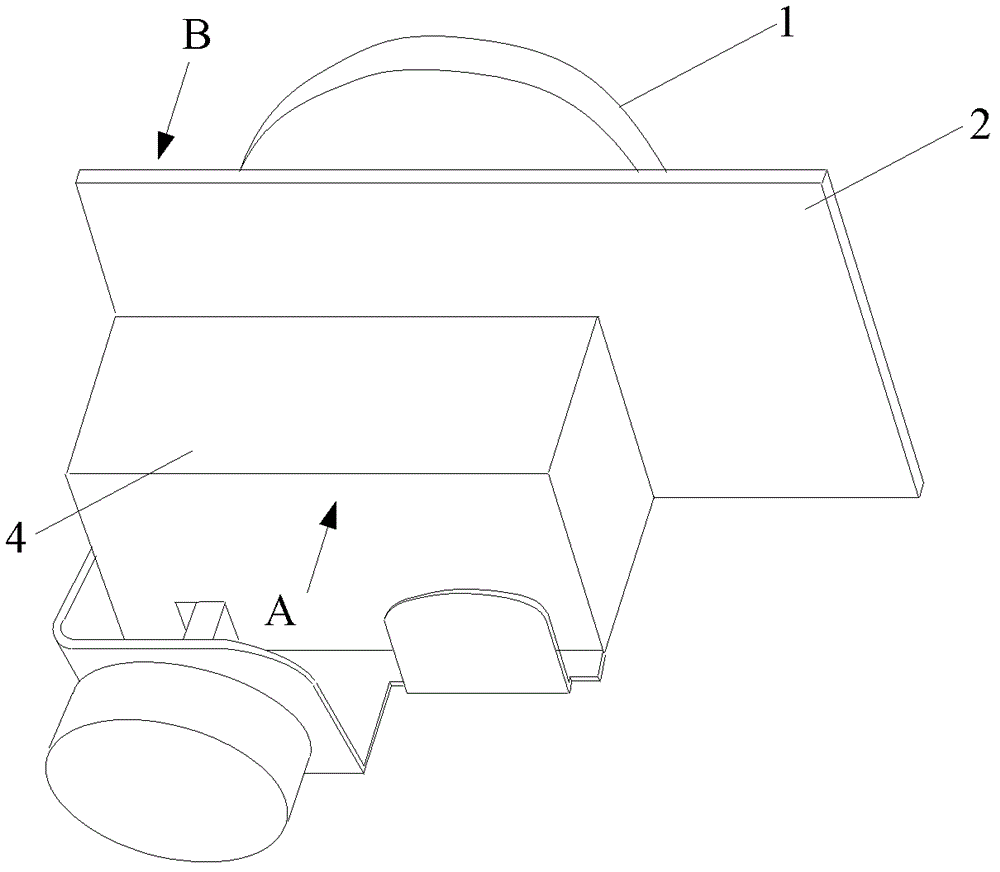

A paper feed sensor for a miniature printer

ActiveCN106197489BReduce paper feed resistanceAvoid mechanical wearOther printing apparatusConverting sensor output opticallyLight sensingDark color

The invention discloses a paper feeding sensor of a miniprinter. The sensor comprises an installation frame connected to a printer engine, a touch arm, and a support provided with a photoelectric sensor, wherein a rotary shaft perpendicular to the touch arm is arranged at one end of the touch arm, the touch arm is hinged to one end of the installation frame through the rotary shaft, the rotary shaft is sleeved with a torsion spring, one of the two positioning ends of the torsion spring is clamped to the touch arm, and the other positioning end of the torsion spring is clamped to the installation frame; the support is installed on the installation frame and provided with a light sensing channel, a limiting block is arranged on the lower side of the touch arm, a limiting surface is arranged at the lower end of the installation frame, the limiting block is matched with the limiting surface to enable the lower side face of the touch arm to be as high as the upper edge of the light sensing channel, and a sensing part protruding out of the installation frame is arranged on the upper side face of the touch arm. The photoelectric sensor is combined with a mechanical blocking structure, reaction speed is high, required printing paper pressure is small, paper feeding is smoother, paper jamming is reduced, and the paper feeding sensor is suitable for printing paper in dark color.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

Conveying structure for plastic packaging paper printing

PendingCN114455373AReasonable heatingAvoid creasesRotary pressesWebs handlingPlastic packagingEngineering

The invention provides a conveying structure for plastic packaging paper printing, and relates to the technical field of conveying structures.The conveying structure comprises a connecting base, a screw is mounted at one end of a screw mounting frame, one end of an abutting block is fixedly connected with a warming plate mounting frame, and a warming plate is fixedly mounted on the upper surface of the warming plate mounting frame; the heating plate is located below the paper body, the upper surface, close to the driving roller, of the paper body is provided with an edge warping prevention assembly, the edge warping prevention assembly comprises a connecting wheel and a pin rod, the lower surface of the connecting wheel is in rolling connection with the upper surface of the edge of the paper body, and the lower end of the pin rod abuts against the bottom wall of the abutting hole. Through the arrangement of the warming plate, the paper body is moderately heated in an auxiliary mode so that the paper body can be soft, the edge of the paper body is pressed in a rolling mode through the connecting wheel on the edge warping prevention assembly so that the paper body can be smooth as much as possible, warping edges are prevented from being pressed into creases by the driving roller, the next printing work is better guaranteed, and the paper clamping situation of the printing machine is reduced.

Owner:重庆归正包装技术有限公司

Packaging box material plate automatic positioning device and punching and waste discharging production line

InactiveCN113459586AAvoid wrinklesAvoid contaminationBox making operationsPaper-makingProduction linePunching

The invention discloses a packaging box material plate automatic positioning device and a punching and waste discharging production line. The packaging box material plate automatic positioning device comprises a material conveying assembly, an abutting assembly, a transverse positioning assembly and a longitudinal positioning assembly. The abutting assembly is movably arranged relative to the conveying assembly and used for abutting against the upper surface of a paperboard in the packaging box material plate. The transverse positioning assembly transversely positions the paperboard in the packaging box material plate in the direction perpendicular to the material conveying direction, and the longitudinal positioning assembly longitudinally positions the paperboard in the packaging box material plate in the material conveying direction. According to the packaging box material plate and the punching and waste discharging production line, when the packaging box material plate is automatically positioned, the packaging box material plate is prevented from being stained with residual glue on surface paper, the defects existing in the prior art are overcome, and the packaging box material plate and the punching and waste discharging production line have the advantages of being reliable and accurate in positioning and simple in structure.

Owner:佛山常晟智能科技有限公司

An automatic stamping machine

Disclosed is an automatic stamping machine. The automatic stamping machine comprises a machine frame, a stamp rotating shaft, a rolling rotating shaft, a driving mechanism, an automatic ink adding mechanism, a stamp ink box and a locating locking device. The stamp rotating shaft and the rolling rotating shaft are arranged on the machine frame in parallel in a rotating mode, and the stamp rotating shaft is located below the rolling rotating shaft. At least one rolling stamp is arranged on the stamp rotating shaft, and a rolling printing roller which corresponds to the rolling stamp in position is arranged on the rolling rotating shaft. The driving mechanism is installed on the machine frame and drives the stamp rotating shaft and the rolling rotating shaft to synchronously rotate in the opposite directions. The automatic ink adding mechanism automatically adds ink to the stamp ink box. First rolling wheel printing cotton which makes flexible contact with the rolling stamp is arranged in the stamp ink box. The machine frame and a printer are located and locked through the locating locking device. According to the automatic stamping machine, the relative position between the automatic stamping machine and the printer is accurately guaranteed through the innovative locating locking device, the probability of paper jams is reduced, and the stability and the reliability are improved. The first rolling wheel printing cotton makes flexible contact with the rolling stamp, and the service life is long. The automatic ink adding mechanism can achieve automatic and continuous ink addition.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

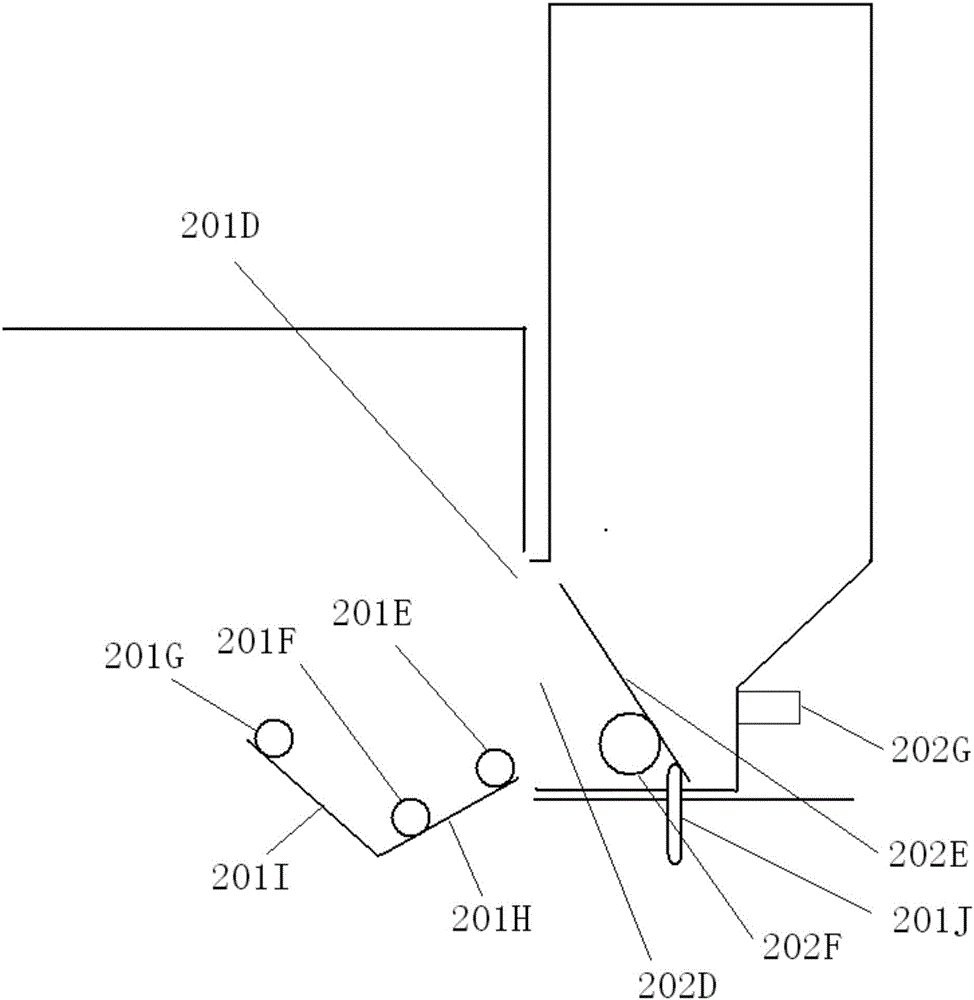

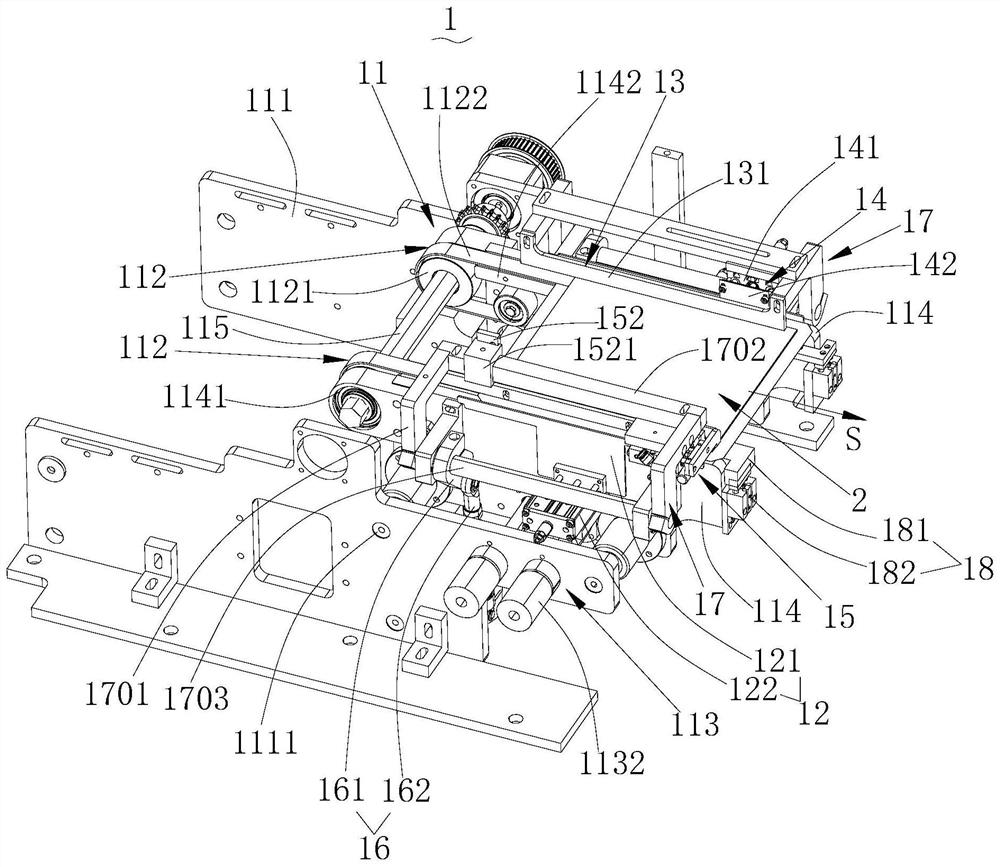

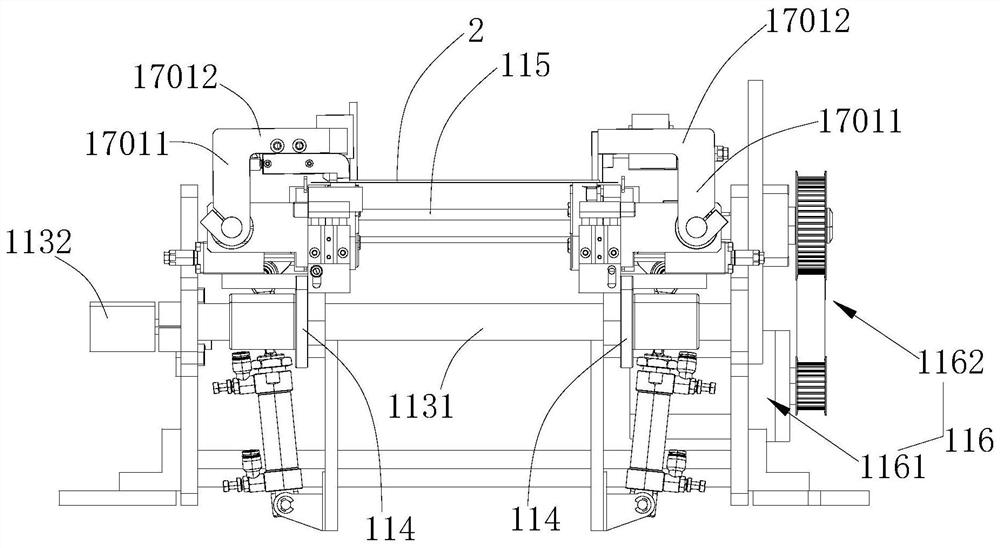

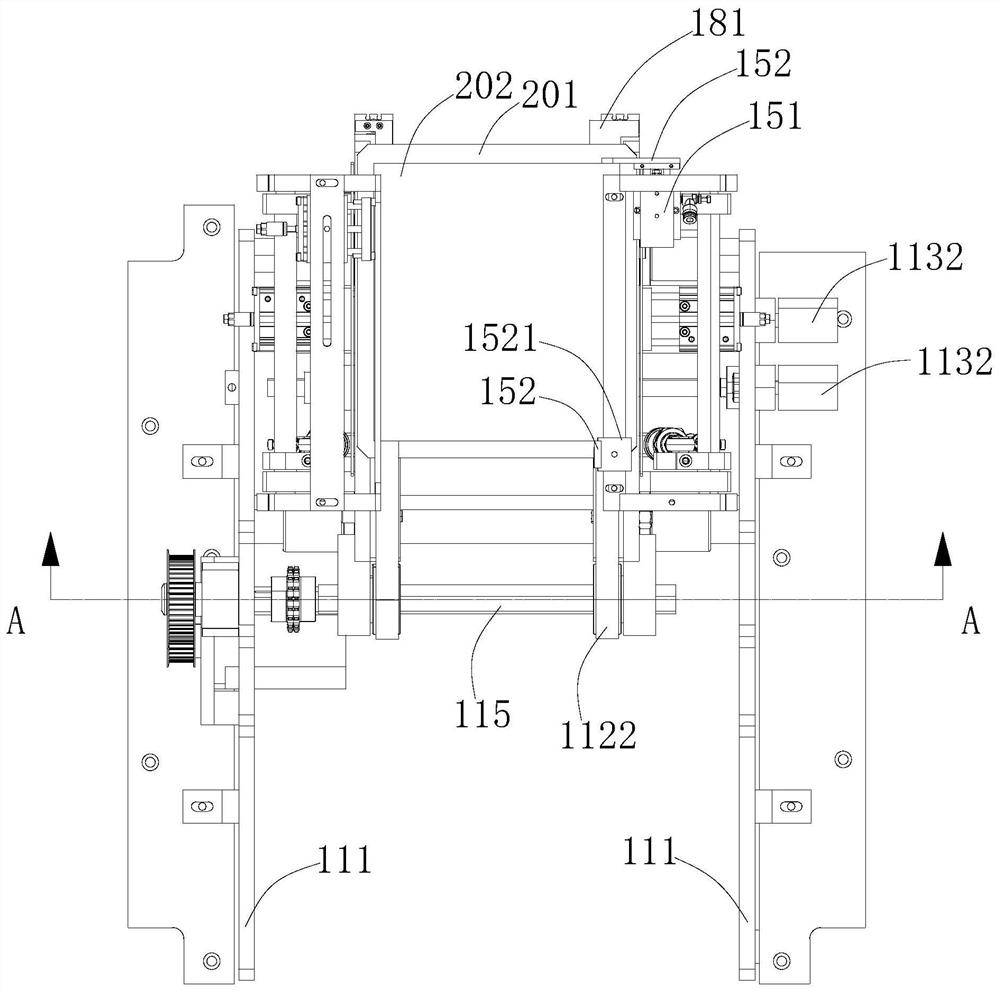

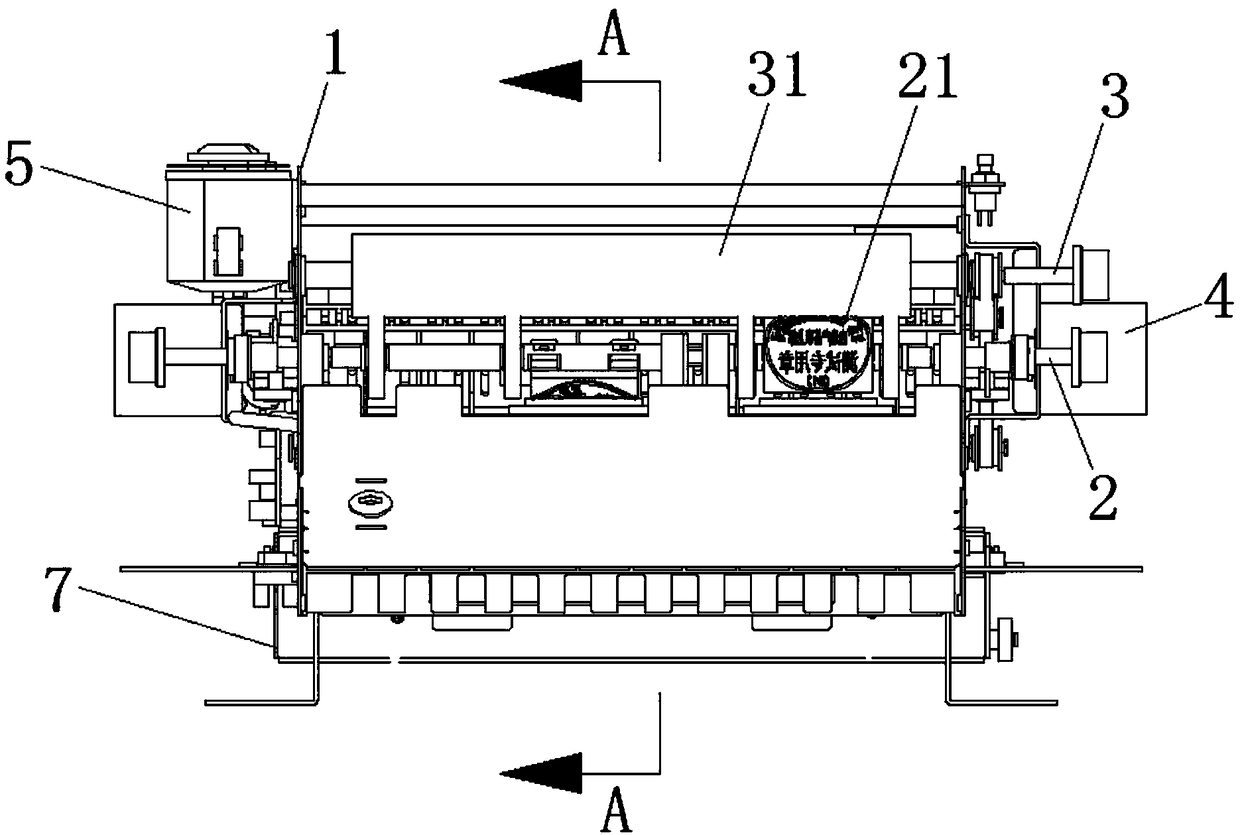

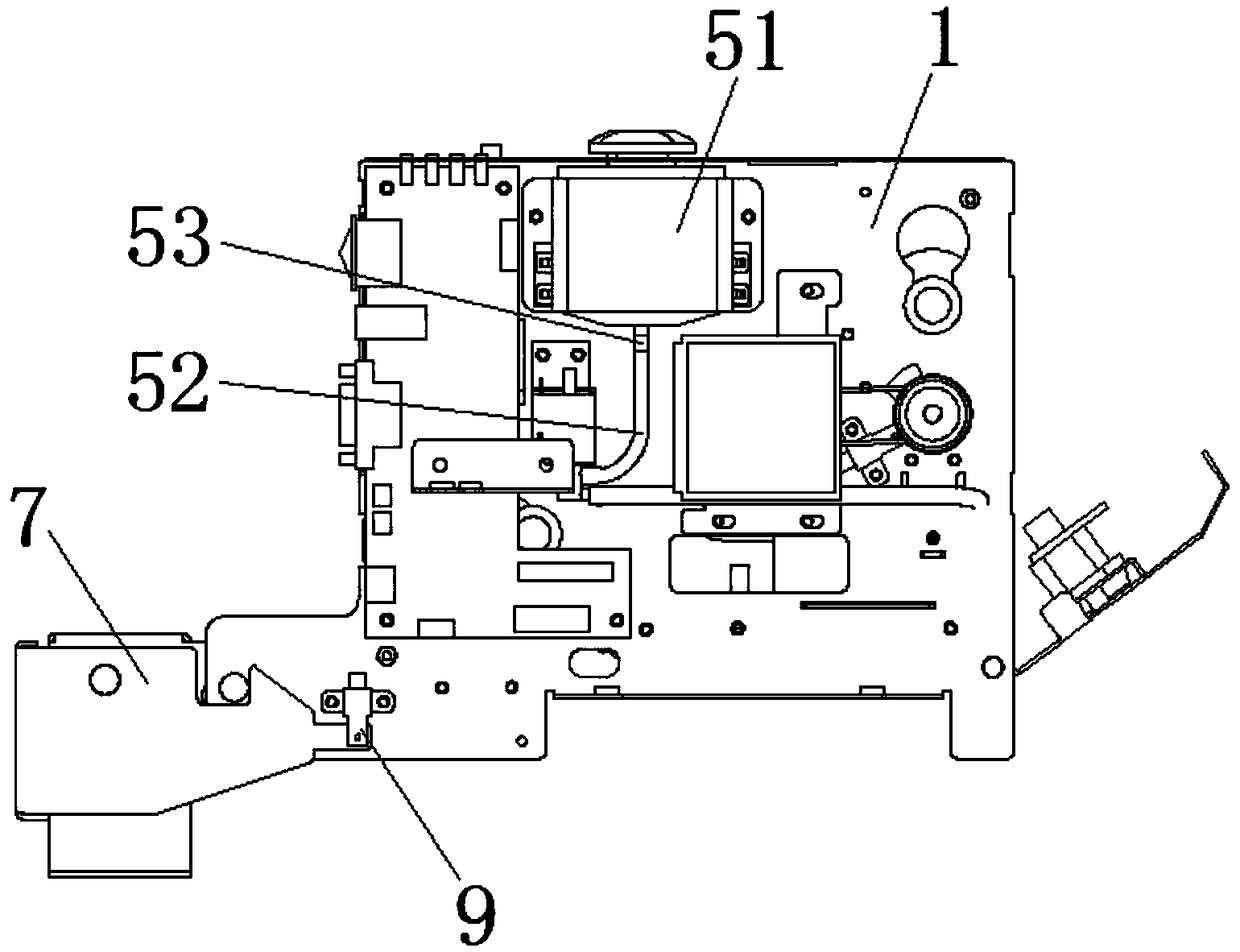

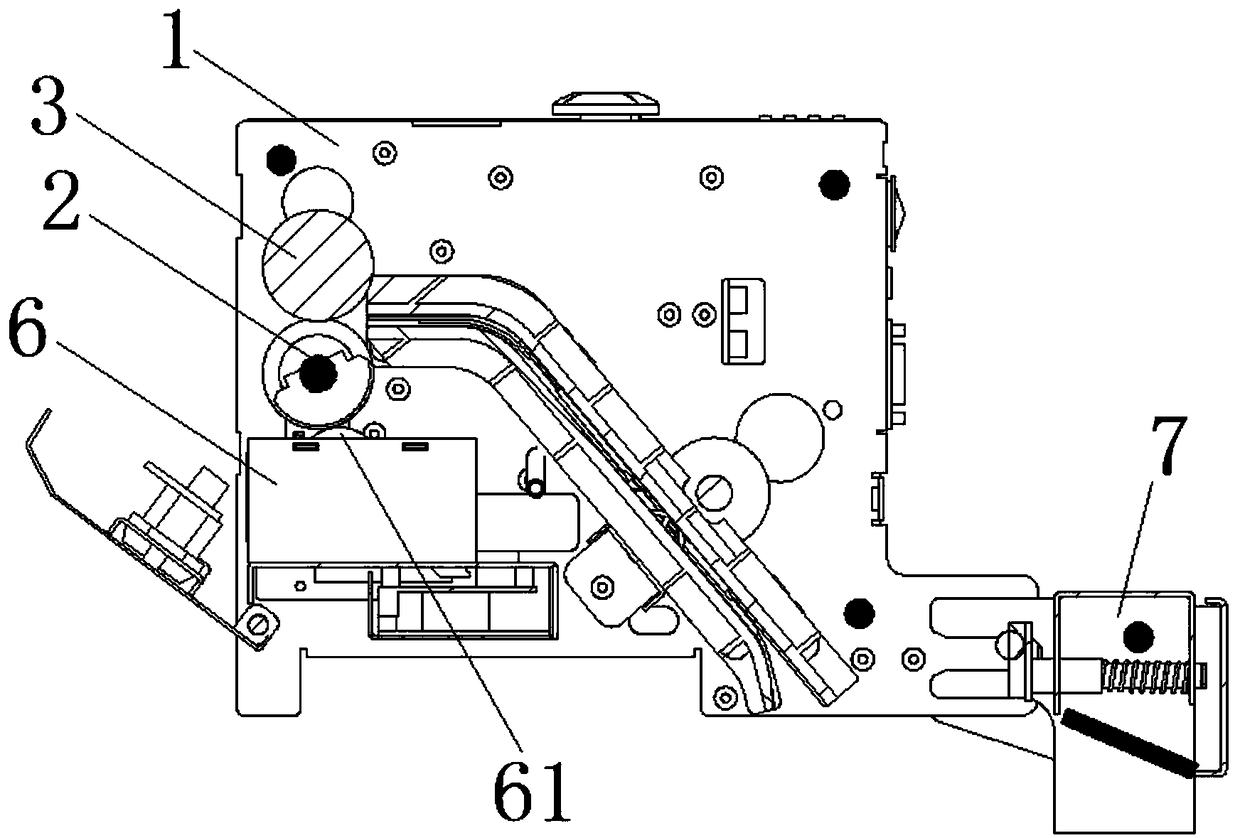

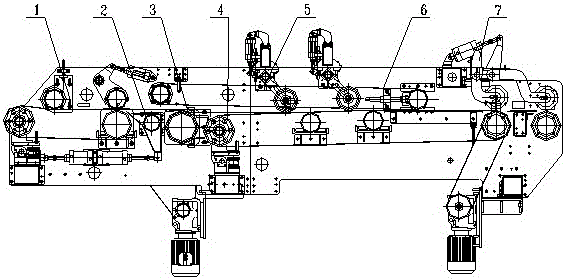

Conveyor system for pulp board single-knife cutting board paper machine

The invention relates to a conveying system of a single-cutter board cutting and paper tidying machine for a pulp board, which comprises a high-speed belt conveying device, a broken paper door device, a front paper feeding roller, a low-speed belt conveying device, paper jogging devices, a paper pressing device and a paper feeding device. The high-speed belt conveying device and a crosscutting device are adjacently arranged between left and right lateral plates; a hinged shaft of the broken paper door device is arranged on the left and right lateral plates; cylinder assemblies for driving a broken paper door to swing at both the sides are hinged with supports; the front paper feeding roller is adjacent to the broken paper door device; the low-speed belt conveying device is arranged at the lower position at the tail part of the conveying system and between the left and right lateral plates; the paper pressing device and two groups of paper jogging devices are all arranged above the low-speed belt conveying device; and two groups of paper pressing wheels of the paper feeding device are respectively pressed on a driving roll and a rear paper feeding roller of the low-speed belt conveying device.

Owner:中轻长泰(长沙)智能科技股份有限公司

Self-adhesive label paper jamming prevention device based on printing and using method thereof

InactiveCN113147168AAvoid Paper JamsReduces the likelihood of paper jamsCylinder pressesPlaten pressesDrive motorAdhesive

The invention relates to the technical field of printing, and discloses a self-adhesive label paper jamming prevention device based on printing and a using method thereof. The self-adhesive label paper jamming prevention device comprises a device shell, anti-skid bases are fixedly installed on the two sides of the bottom end of the device shell, and a driving motor is arranged at the top end of the interior of the device shell. According to the self-adhesive label paper jamming prevention device based on printing and the using method thereof, in the printing process of printing equipment, a paper taking clamp can be driven by a driving motor to move in a reciprocating mode to take paper, and meanwhile due to the arrangement of a first pressing and bouncing switch, a touch strip, a second pressing and bouncing switch and an adjusting strip, the paper taking clamp can be closed to clamp a self-adhesive label when getting close to the printing equipment, the paper taking clamp can release the self-adhesive label when getting away from the printing equipment, the self-adhesive label falls into a paper containing hopper, and therefore the paper jamming condition is avoided, the paper jamming prevention advantage is achieved, and the problem that for existing self-adhesive label equipment, jammed paper needs to be taken out by related personnel when the paper is jammed is solved.

Owner:苏州市正名印刷科技有限公司

Gas chromatograph and its data processor

InactiveCN103144441BLow failure ratePrevent fallingTypewritersOther printing apparatusGear wheelPaper dust

The invention discloses a data processor comprising a printer, the printer comprises a support, a motor and a printer gear, wherein an output shaft of the motor penetrates through the support, and an outer shell of the motor is fixed on the support. The printer gear is connected with the output shaft of the motor, and a protective cover is further arranged on the support and surrounds the printer gear. The invention further provides a gas chromatograph provided with the data processor. Due to the fact that the protective cover is arranged on the support and surrounds the printer gear, paper scraps brought down in a paper feeding process can be effectively prevented from falling on the printer gear, and the occurrence rate of the paper-jam phenomenon can be reduced, so that the fault rate of the gas chromatograph is reduced, and maintenance cost is reduced.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM

Paper pressing device

InactiveCN101643155BReduce contact areaReduce frictionElectrographic process apparatusPictoral communicationRolling resistancePulp and paper industry

The invention relates to a paper pressing device which comprises a front cover and a rear cover which can be mutually fastened with the front cover, wherein the front cover comprises an inner wall and can be rotatably opened or fastened relative to the rear cover. The paper pressing device further comprises a press fit component which is fixedly arranged on the inner wall of the front cover, and the press fit component comprises a pressing and holding piece and at least one roller, wherein the pressing and holding piece comprises a fixing end and an elastic supporting arm which is connected to one side of the fixing end and is elastically bent relative to the fixing end; the elastic supporting arm is provided with at least one set of fixing sheets, and each set of the fixing sheets are provided with a set of corresponding shaft holes; and the rollers penetrates in the shaft holes of the fixing sheets and can roll relative to the shaft holes. The rollers of the paper pressing device and paper have rolling friction, and a contact area between the rollers and the paper is small, thus the frictions of the rollers and the paper can be reduced so as to reduce paper jam phenomena.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com