Conveying structure for plastic packaging paper printing

A technology of conveying structure and wrapping paper, applied in printing, printing presses, rotary presses, etc., can solve the problems of serious warping of plastic wrapping paper, creases of plastic wrapping paper, affecting printing work, etc., so that the heating of the paper body is more reasonable. , Reduce warping, reduce the effect of printing machine jam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

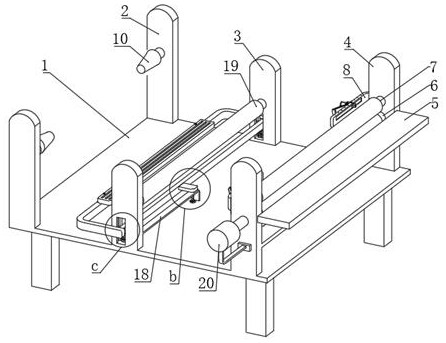

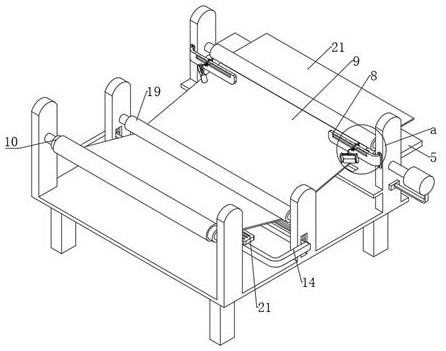

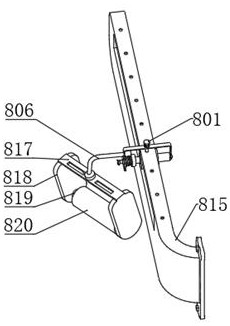

[0030] Such as Figures 1 to 7 As shown, a transmission structure for plastic packaging paper printing includes a connecting base 1, and the upper surface of the connecting base 1 is fixedly equipped with a first mounting frame 2, a second mounting frame 3, and a third mounting frame 4, one of which is a third mounting frame. The outside of mounting frame 4 is equipped with motor 20 by motor fixing frame, and the output end of motor 20 is fixedly installed with driving roller 6, and the two ends of driving roller 6 are connected with the 3rd mounting frame 4 rotations, two 3rd mounting frames 4 A driven roller 7 is installed to rotate between them. The outer surfaces of the driven roller 7 and the driving roller 6 are rollingly connected with the surface of the paper body 9. One end of the paper body 9 is installed on the electric paper tube installation cone 10 through the paper tube. On the inner side of one of the second mounting brackets 3, a screw mounting frame 18 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com