Method and system for preventing carbonate poisoning by heating catalyst in different blocks

A technology of catalysts and blocks, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as unacceptable power consumption costs, effective methods for poisoning, and no prevention of catalyst carbonates, etc., to extend life. , reduce spillage, low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

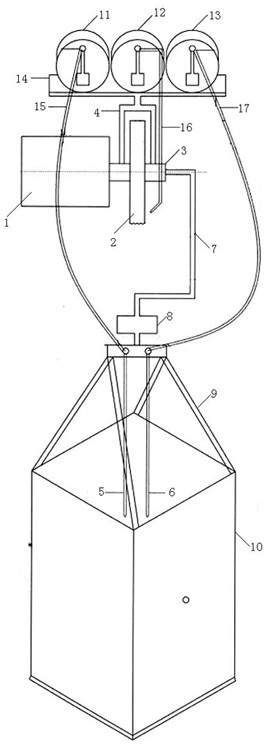

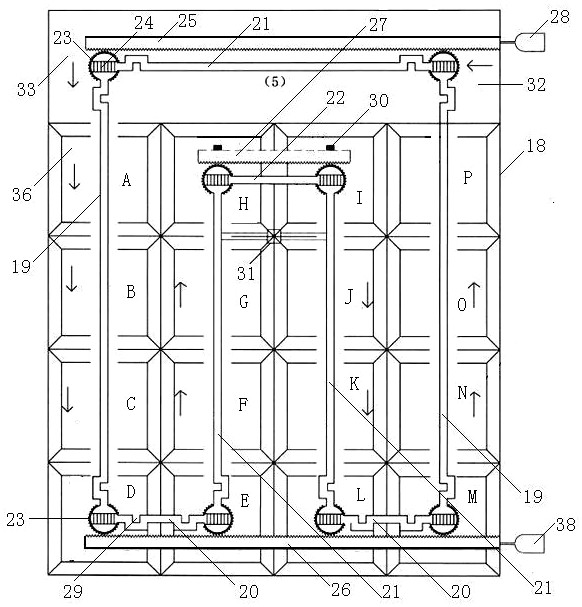

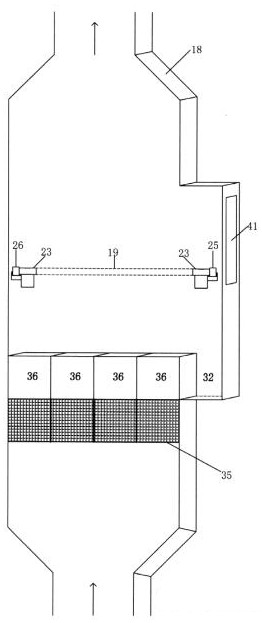

[0046] see figure 1 -10, the names of parts are as follows: motor 1, power cam 2, power cam bushing 3, frame body 4, hydrogen stainless steel tube 5, steam stainless steel tube 6, bow boom 7, rotary bearing 8, metal sling 9, heating barrel 10. Hydrogen tank 13, compressed air tank 12, steam tank 11, pallet 14, steam hose 15, compressed air stainless steel nozzle 16, hydrogen hose 17, catalyst box 18, long track 19, short track with space 20 , middle track 21, short track without space 22, steering gear 23, transfer gear 24, upper long drive rack 25, lower long drive rack 26, short track drive rack 27, No. 1 cylinder 28, space 29, short track Drive rack idler 30, rail support column 31, heating device return starting point channel 32, heating device starting point 33, heating barrel guardrail 34, catalyst 35, heating barrel 36, closing bevel 37, No. 2 cylinder 38, No. 3 cylinder 39 , power cam horizontal tooth 40, maintenance door 41.

[0047] see figure 1 -10. The method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com