A kind of slag making material for submerged arc furnace

A submerged arc furnace and slag making technology, applied in the field of metallurgy, can solve the problems of erosion of carbonaceous furnace lining, damage to the furnace lining, cracking of the furnace lining, etc., and achieve the effects of improving sintering strength, avoiding cracking, and heating up evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

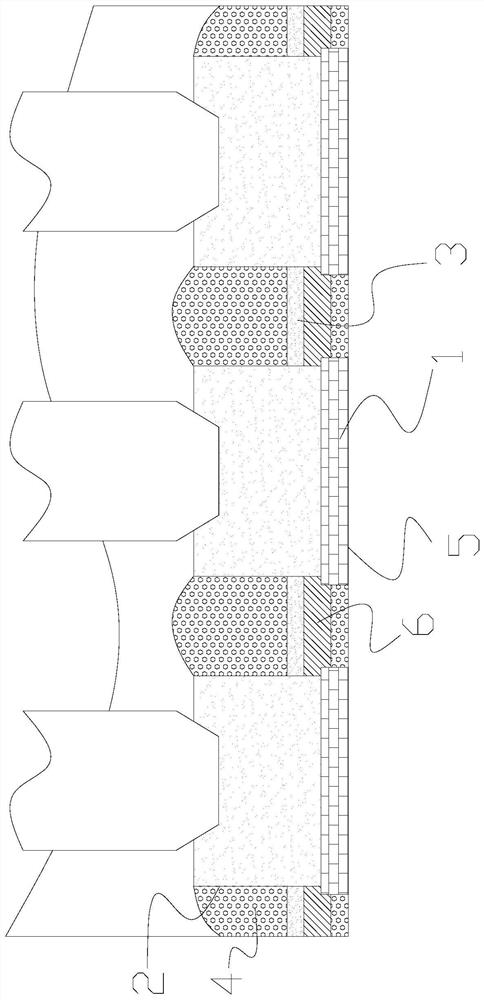

Image

Examples

Embodiment Construction

[0032] Processes without specific parameters indicated in the embodiments of the present invention are usually carried out according to conventional conditions or conditions suggested by the manufacturer, and equipment or raw materials not marked with specific models are usually conventional equipment or raw materials in the metallurgical field.

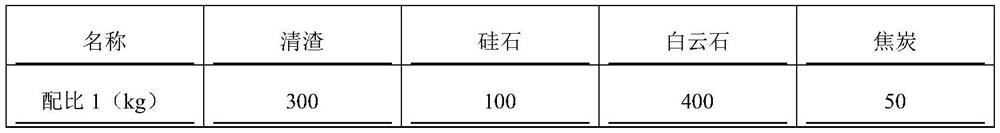

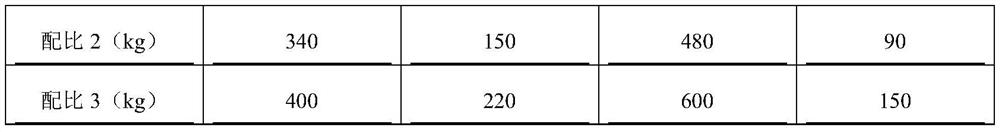

[0033] The cleaning slag that the present invention selects is usually the slag that steelmaking enterprise smelts manganese steel, is made of 10-18wt%Mn, 20-50wt%SiO 2 , 10-40wt% CaO, 5-15wt% MgO, 10-30wt% Al 2 o 3 Composition, crushed to a particle size of 60-80mm, SiO in the silica used 2 content ≥ 95%, crushed to a particle size of 40-60mm, the fixed carbon content in the coke used is ≥ 86%, crushed to a particle size of 40-60mm, and the used dolomite is composed of 20-30wt% SiO 2 , 20-40wt% CaO, 10-30wt% MgO, and the balance is composed of impurities, which are crushed to a particle size of 40-60mm.

[0034] Slagging material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com