Conveyor system for pulp board single-knife cutting board paper machine

A technology of conveying system and paper handling machine, applied in the field of papermaking equipment, can solve the problems of large deviation of squareness, low production efficiency, paper jam and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

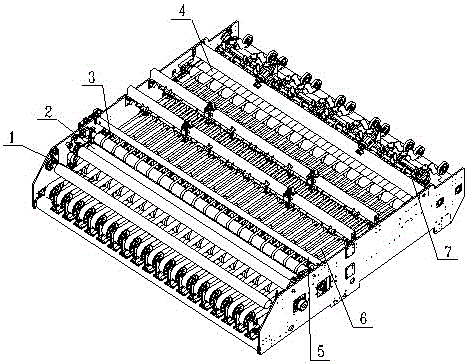

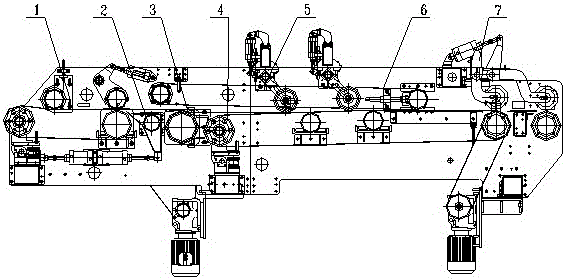

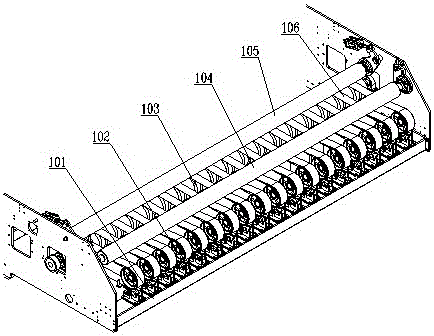

[0023] Figure 1 to Figure 9 An embodiment of the invention is shown.

[0024] like figure 1 and figure 2 Shown: The conveying part of the pulp board single-knife cutting board paper machine includes 1-high-speed belt conveying device, 2-broken paper door device, 3-front paper feeding roller, 4-low-speed belt conveying device, 5-paper bumping device, 6 - Paper pressing device, 7 - Paper feeding device. The cut pulp board falls from the cross-cutting device onto the high-speed belt conveying device and is quickly transported to the low-speed belt conveying device. After bumping into the jogging wheel of the jogging device, it is transported forward at the same conveying speed as the low-speed flat belt, and then The conveying speed of one pulp board is the same as that of the high-speed belt, so the conveying speed of the latter one is faster than that of the previous one, and the speed difference between the high and low speed conveyor belts makes the latter pulp board cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com