Buffer paper pad machine with paper jam detection function

A technology of paper detection and detection mechanism, applied in the direction of preventing mechanical damage to containers, winding strips, sending objects, etc., can solve problems such as paper jams and machine damage, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

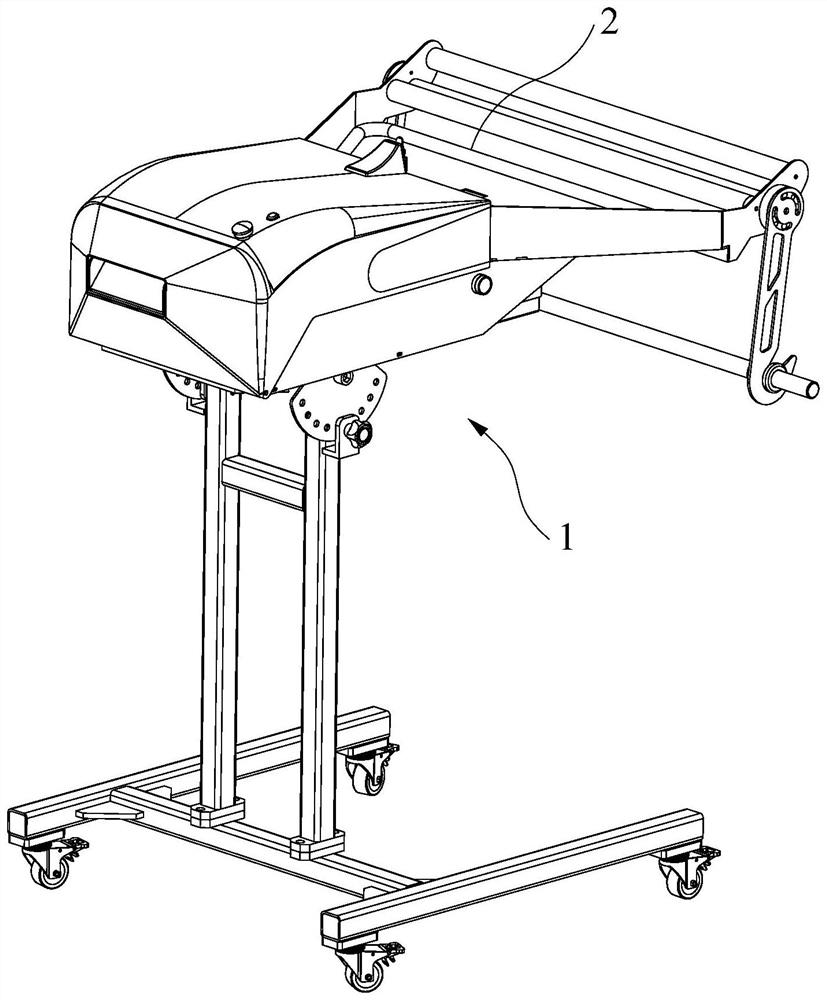

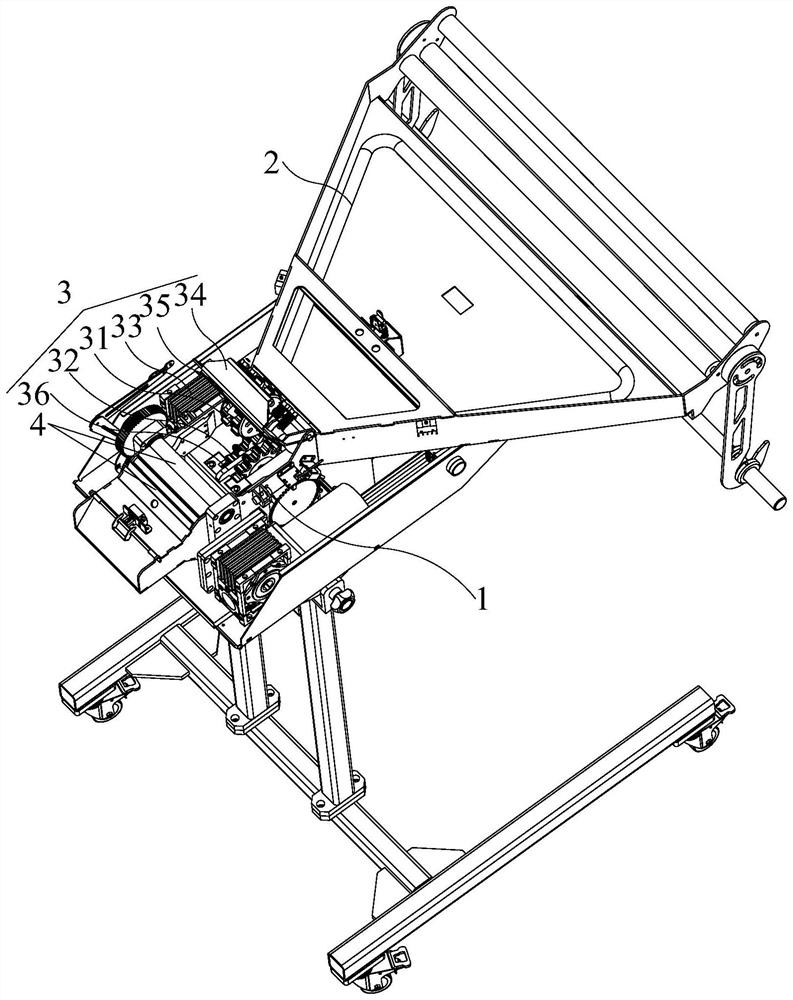

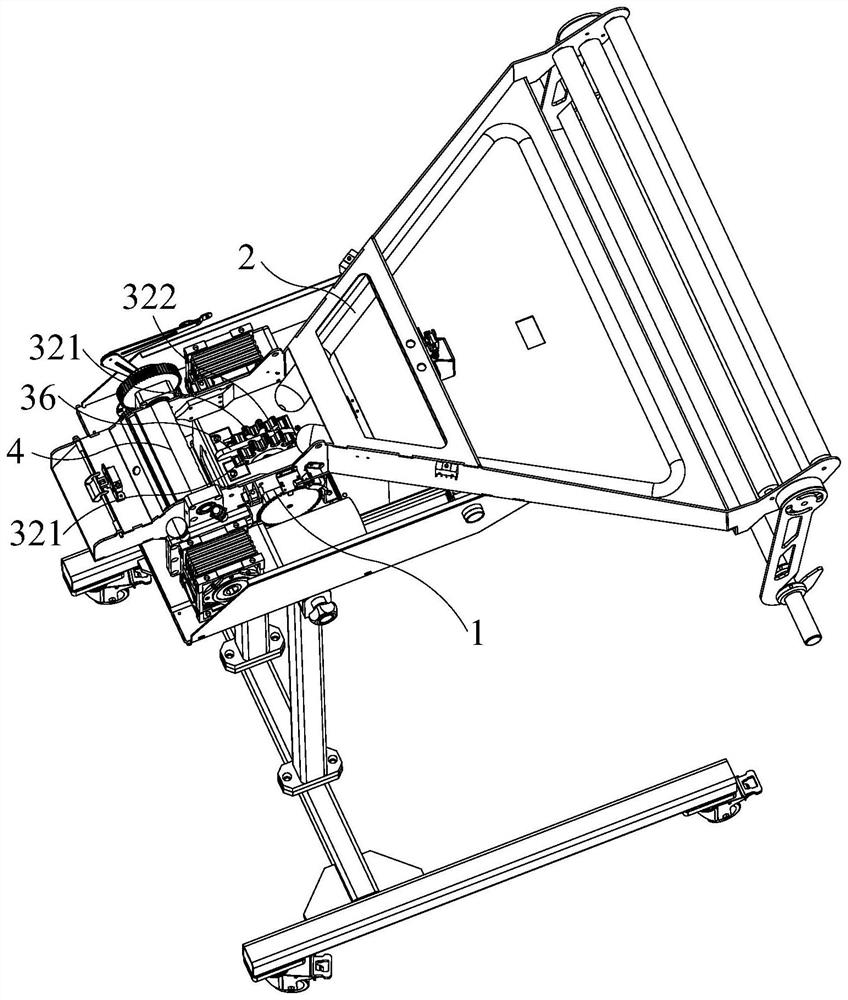

[0035] Such as Figure 1 to Figure 8 As shown, the present invention discloses a cushion paper pad machine with paper jam detection function, which includes a paper guide mechanism 2, a paper pressing mechanism 3 and a paper cutting mechanism 4 arranged in sequence on the frame 1; wherein the paper guide mechanism 2 is used for To make the paper folded according to the set method (that is, the two sides of the paper are folded towards the middle of the paper), the paper pressing mechanism 3 is used to squeeze the folded paper so that the folded paper is wrinkled to form a buffer pad, and the paper cutting mechanism 4 For cutting cushion paper pads. The paper pressing mechanism 3 includes an upper pressing wheel 31 and a lower pressing wheel 32 which are engaged with each other up and down; the upper pressing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com