Self-adhesive label paper jamming prevention device based on printing and using method thereof

A self-adhesive and label technology, which is applied to the general parts of printing machinery, printing, printing machines, etc., can solve the trouble of taking out paper jams and other problems, and achieve the effect of avoiding paper jams and reducing the possibility of paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0033] The following is a specific embodiment of a printing-based self-adhesive label anti-jam device.

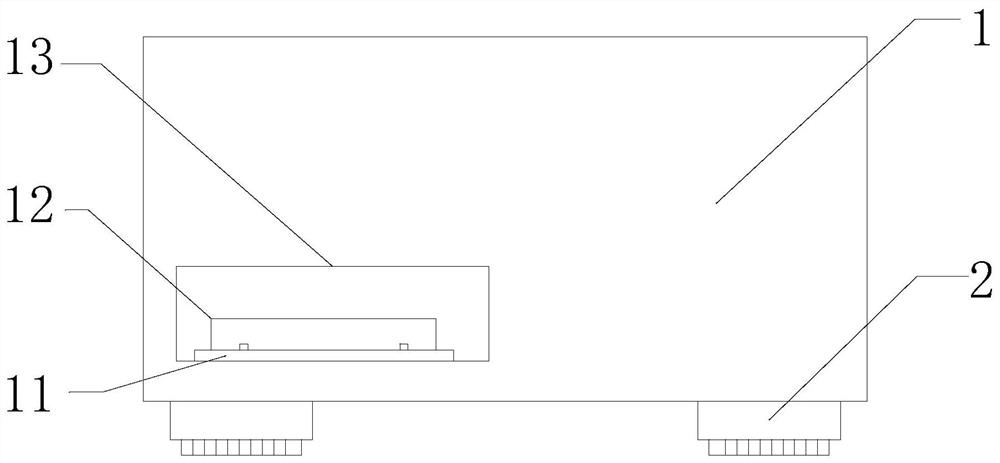

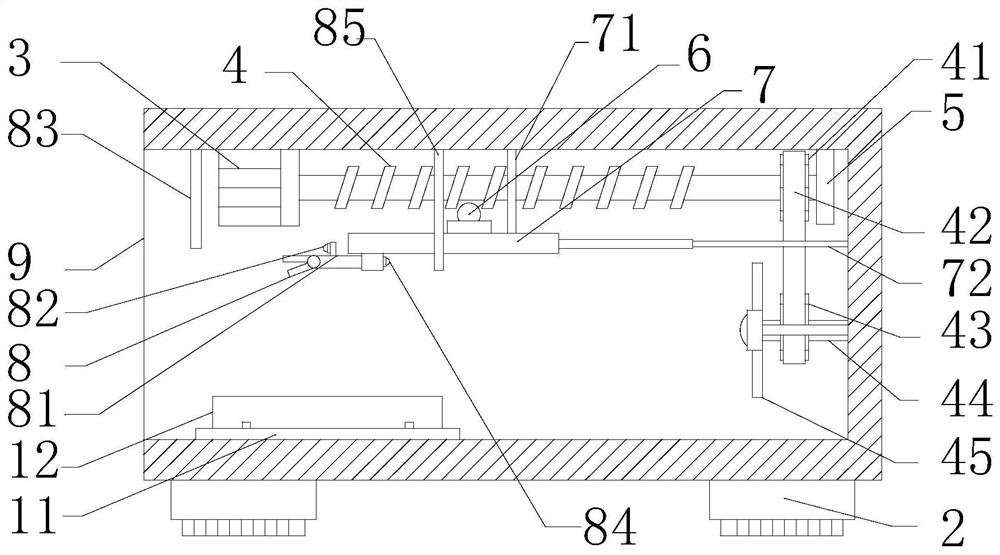

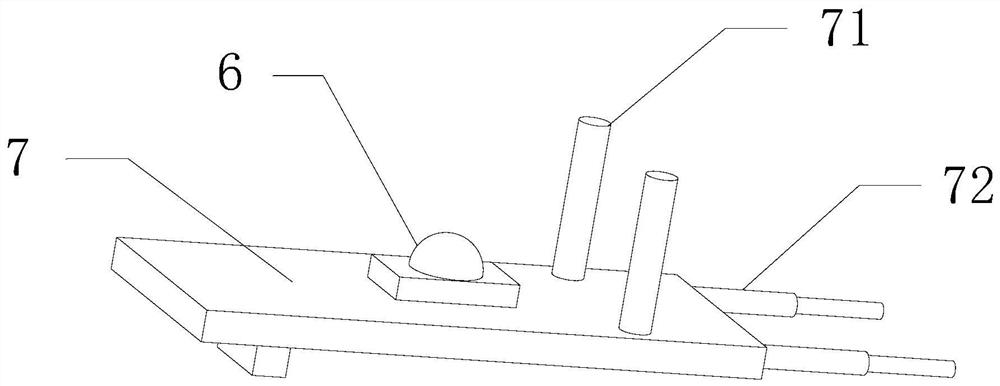

[0034] see Figure 1-3 , a self-adhesive label anti-jam device based on printing, including a device housing 1, both sides of the bottom end of the device housing 1 are fixedly equipped with anti-skid seats 2, and the inner top of the device housing 1 is provided with a drive motor 3 , the driving motor 3 is fixedly connected to the inner top wall of the device housing 1, the side of the driving motor 3 is connected to the worm 4, and the other end of the worm 4 is connected to the stable seat 5, and the stable seat 5 is connected to the inner top of the device housing 1. The wall is fixedly connected, the bottom end of the worm 4 is engaged with a synchronous ball 6, the bottom end of the synchronous ball 6 is fixedly connected with a synchronous seat 7, the bottom end of the synchronous seat 7 is fixedly installed with a paper picker 8, and the side of the device housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com