Patents

Literature

77results about How to "Reduce the amount of rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

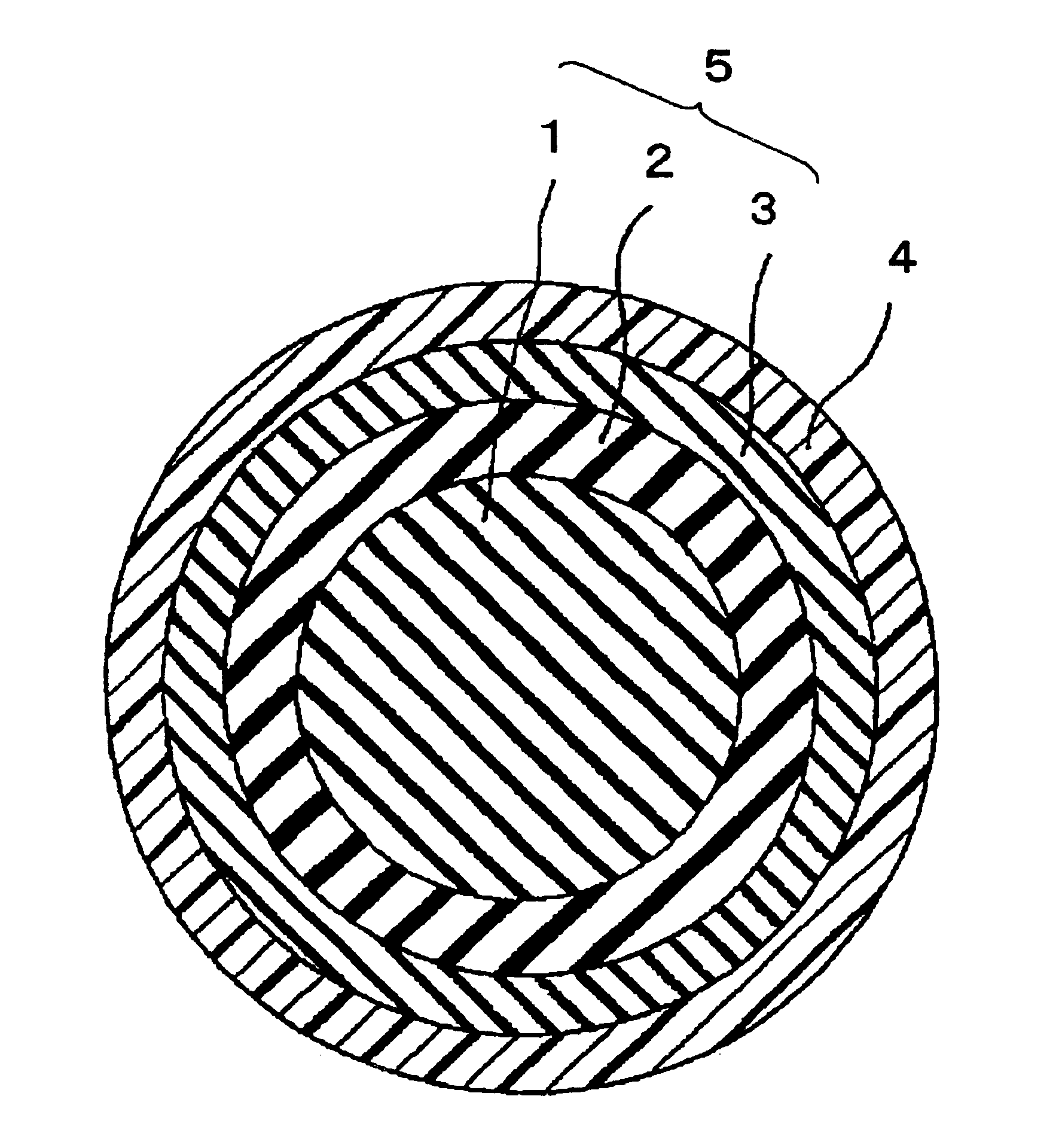

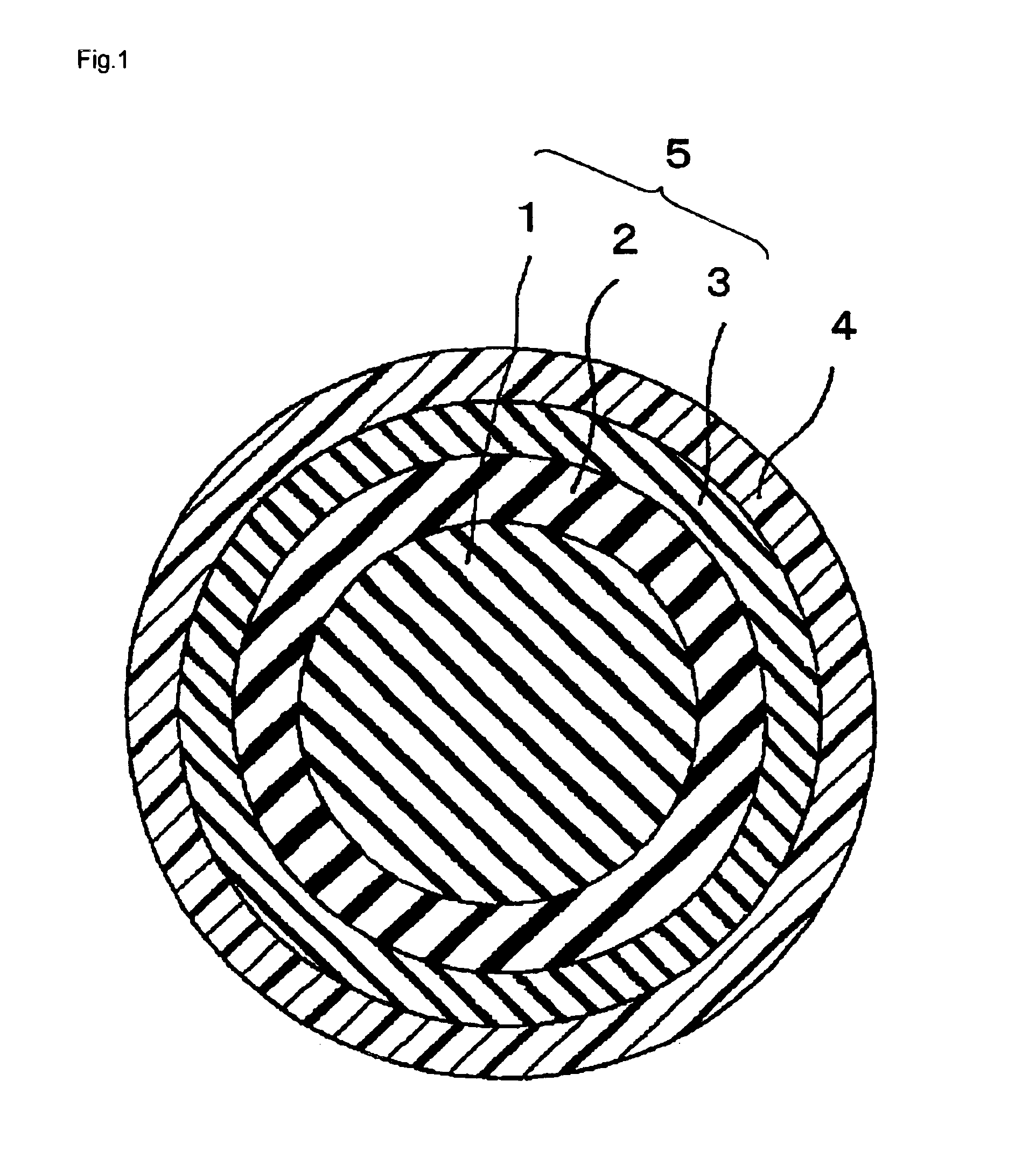

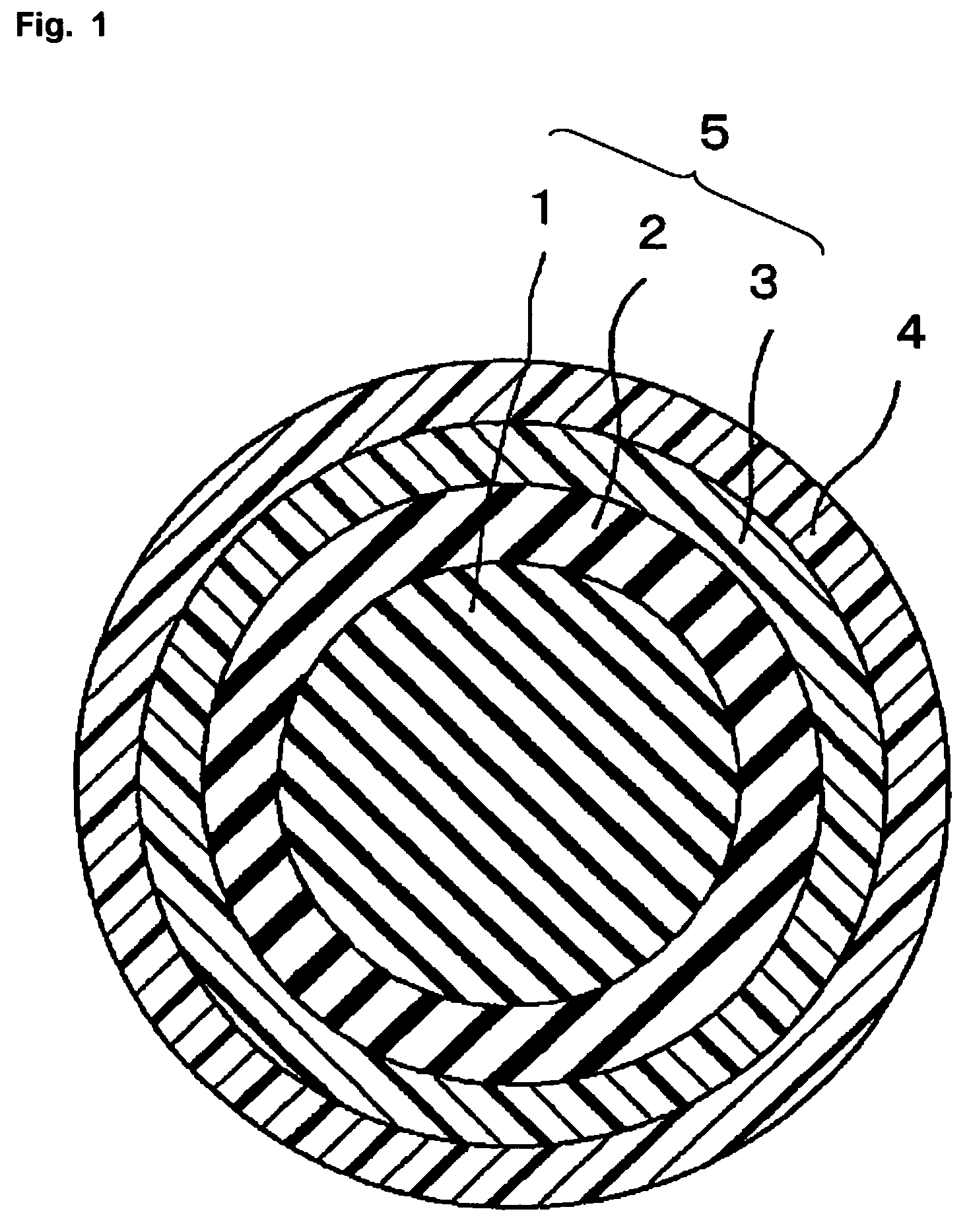

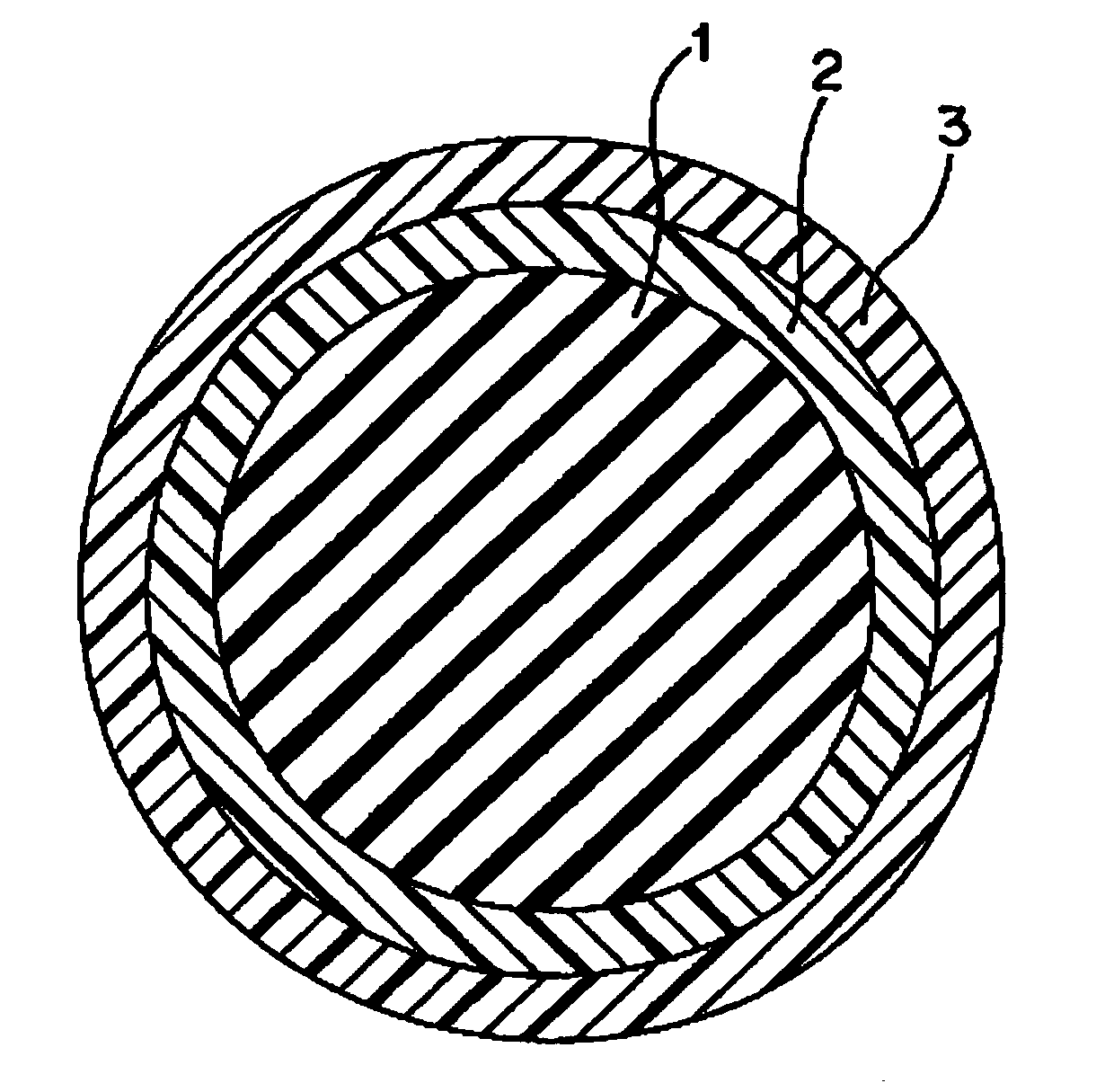

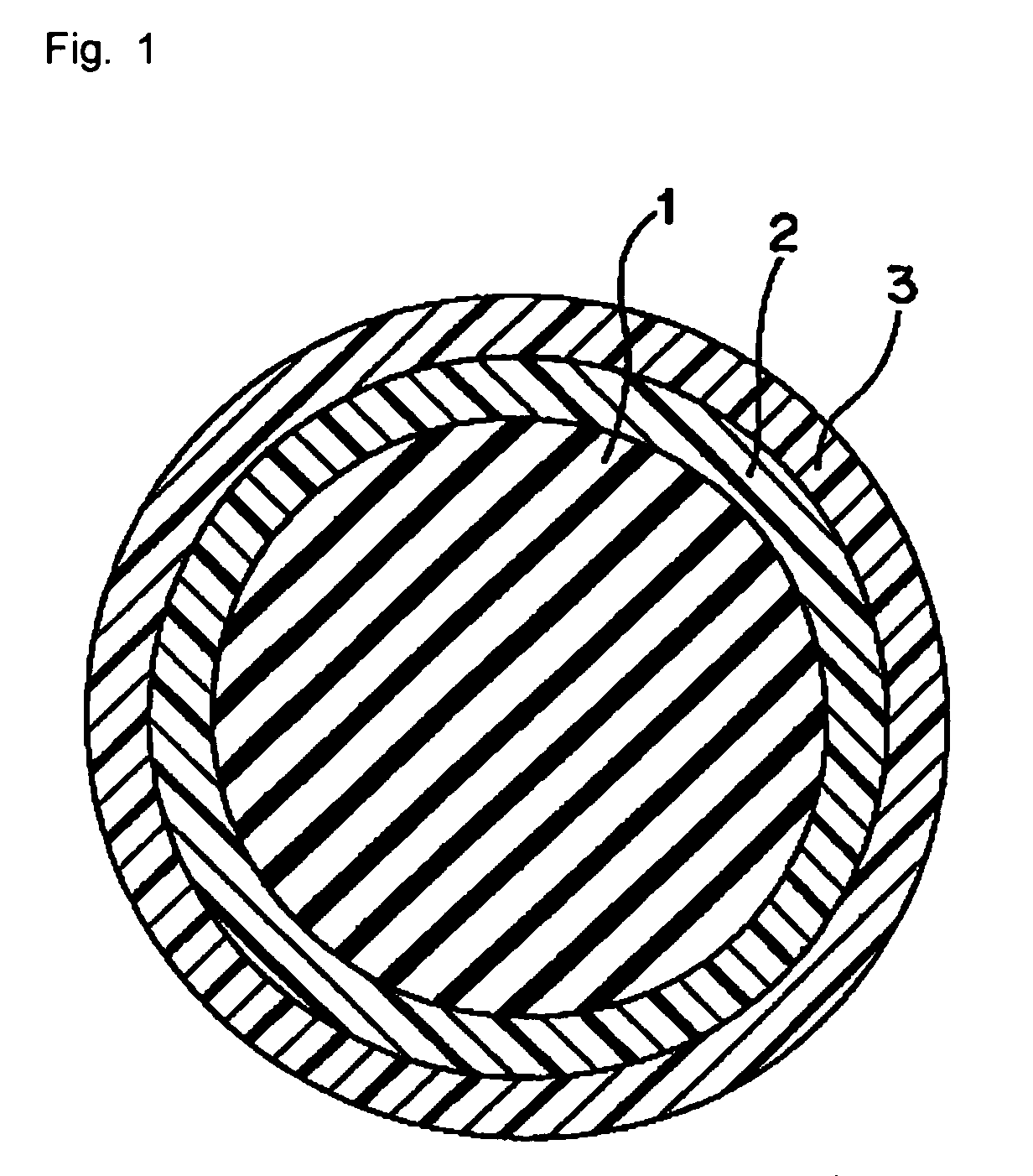

Multi-piece solid golf ball

InactiveUS6913548B2High trajectoryImprove flight performanceGolf ballsSolid ballsEngineeringGolf Ball

The present invention provides a multi-piece solid golf ball having excellent flight performance and good shot feel. The present invention relates to a multi-piece solid golf ball comprising a core consisting of an inner core, an intermediate layer and an outer layer, and a cover, wherein the inner core has a flexural rigidity (RI) of 20 to 80 MPa, a ratio (RM / RI) of a flexural rigidity of the intermediate layer (RM) to the (RI) is from 0.6 to 1.4, a flexural rigidity of the outer layer is higher than the (RI) by 70 to 500 MPa, and the intermediate layer is placed such that the a radius of the golf ball (rG), a radius of the inner core (rI) and a radius of a two-layer structured core obtained by forming the intermediate layer on the inner core (rT) satisfy the following two formulae:rI / rG≧0.70rT / rG≦0.83.

Owner:SUMITOMO RUBBER IND LTD

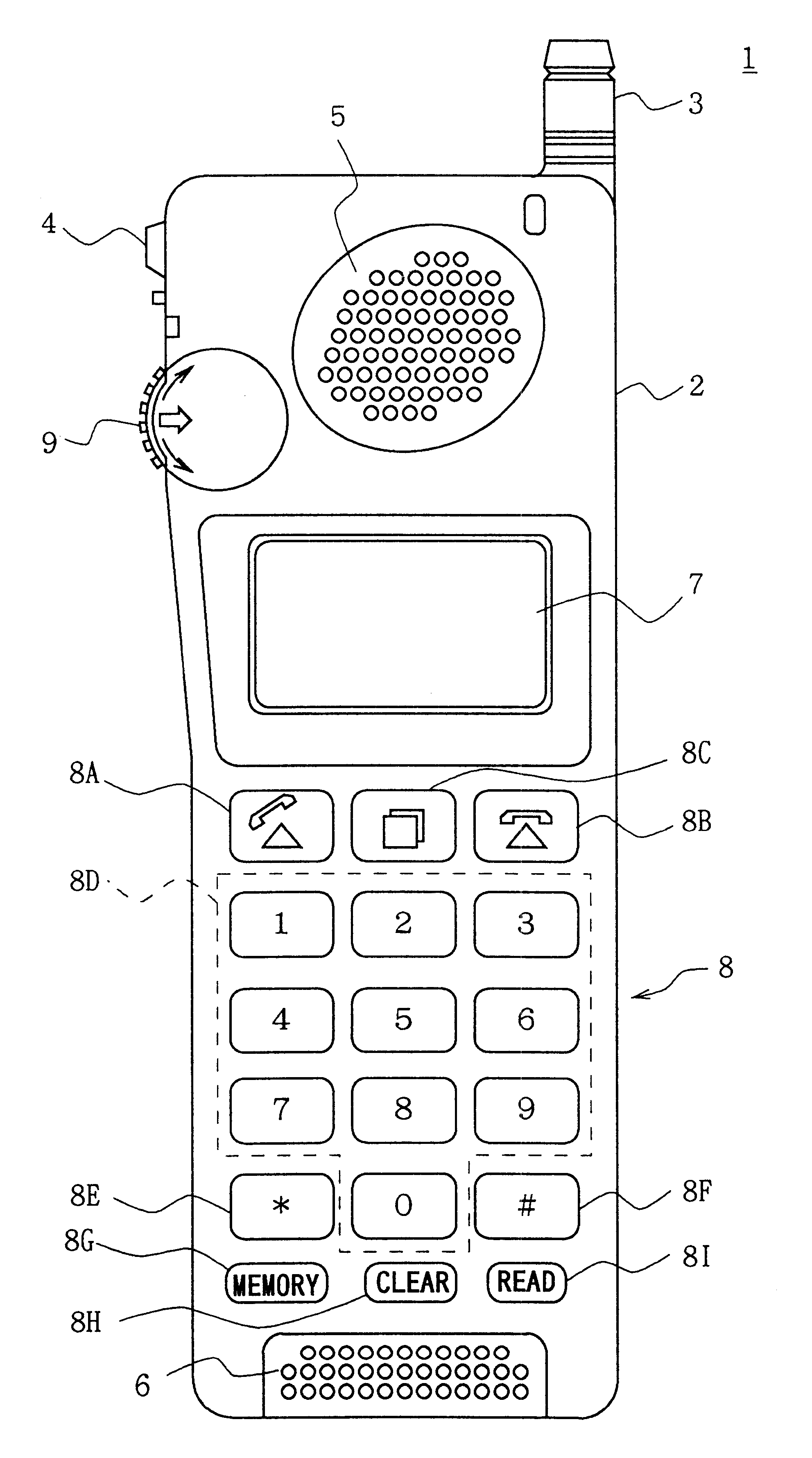

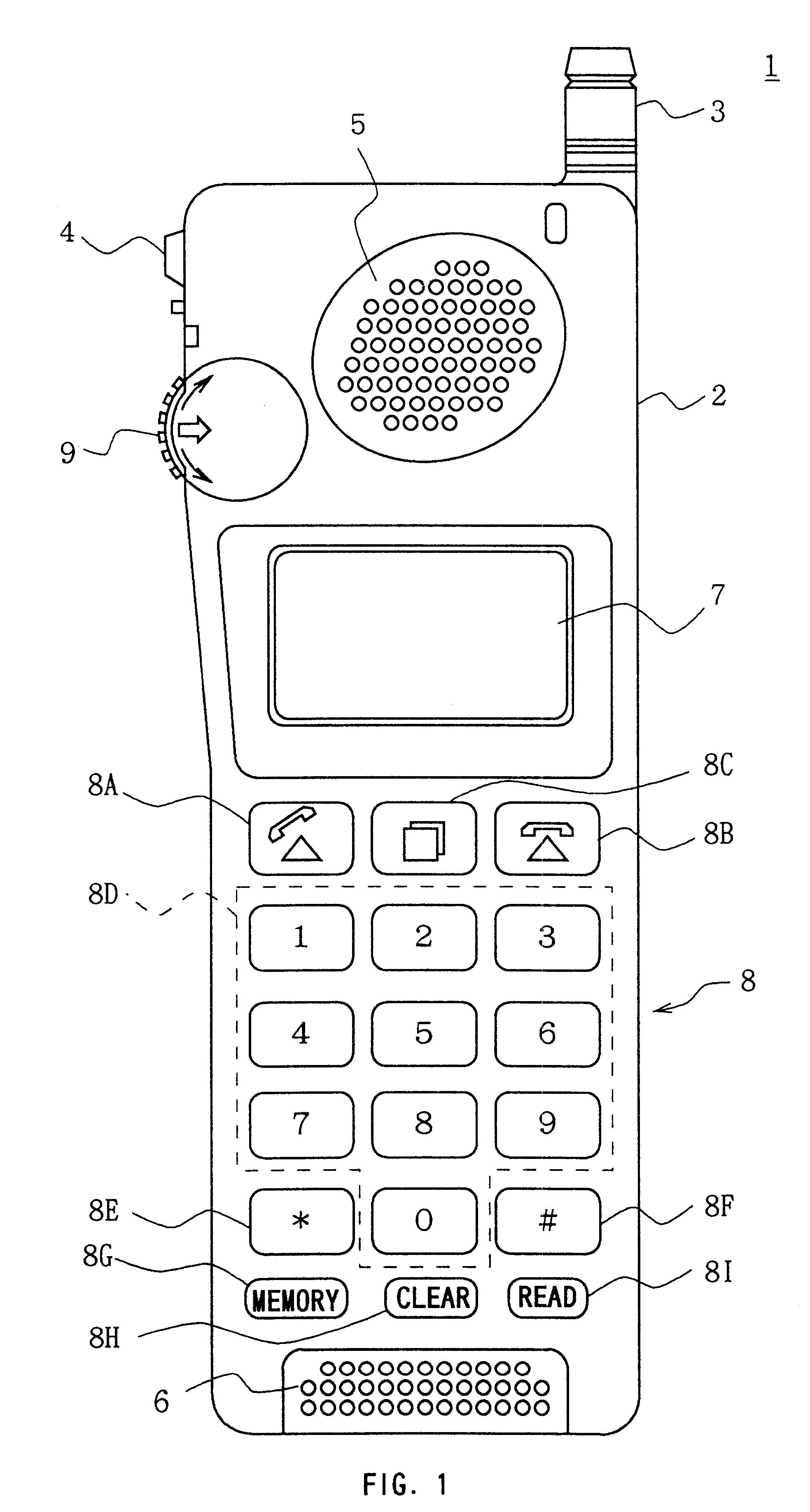

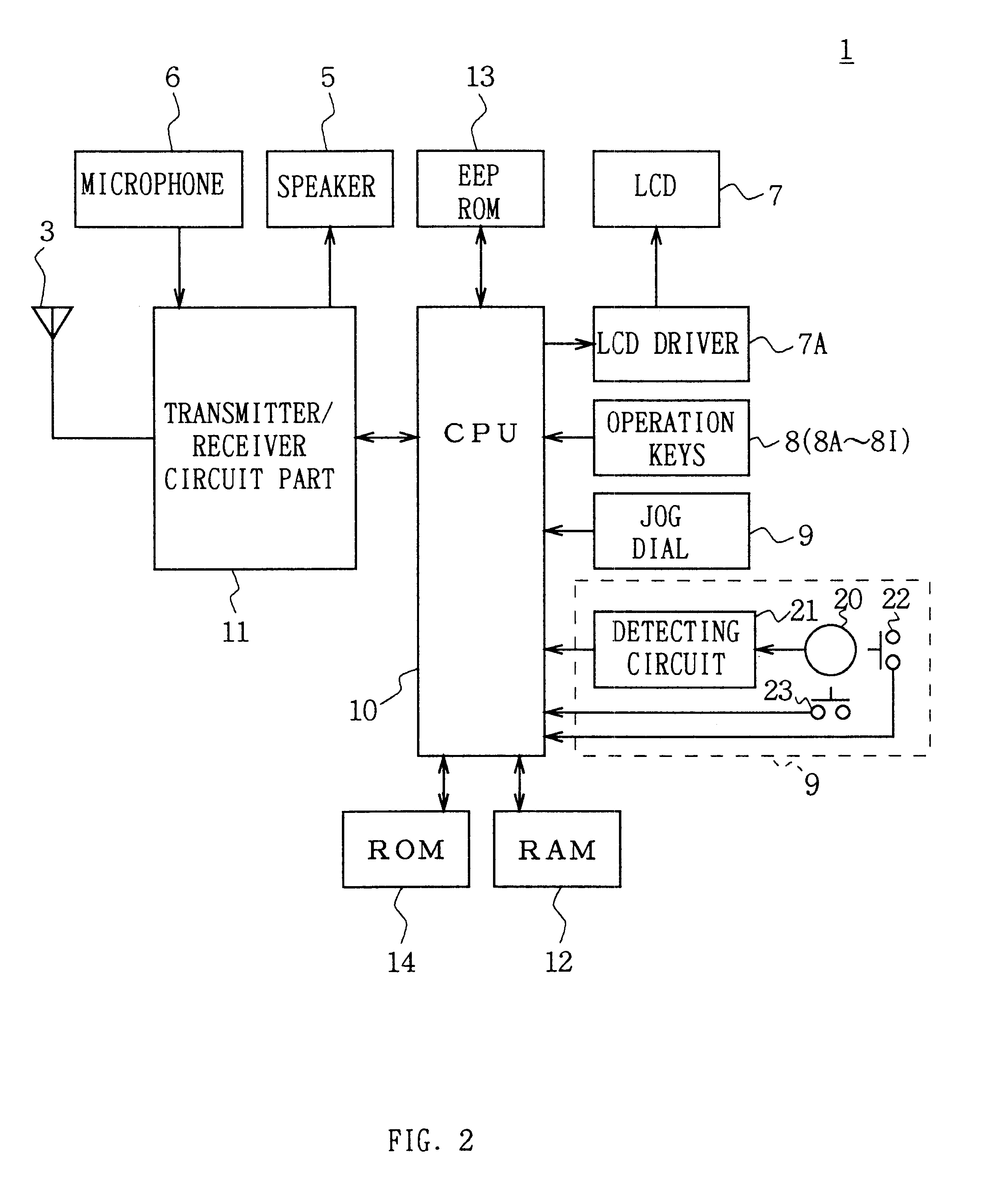

Communication terminal device and rotary operation key

InactiveUS6546231B1Easy to operateImprove usabilityInterconnection arrangementsCathode-ray tube indicatorsTerminal equipmentUsability

This invention relates to a communication terminal device. In order to realize a communication terminal device which improves the operational efficiency and the usability remarkably comparing to a conventional one, an operation key is designed to be rotated, pushed, and slid, and the movement direction or the movement amount of the cursor can be changed when the operation key is slid, so that the cursor can reach at a desired item quickly. As a result, the rotating amount to reach at a desired item can be reduced comparing to a conventional one. Therefore, a communication terminal device which improves the operational efficiency and the usability remarkably comparing to the conventional one can be realized.

Owner:SONY CORP

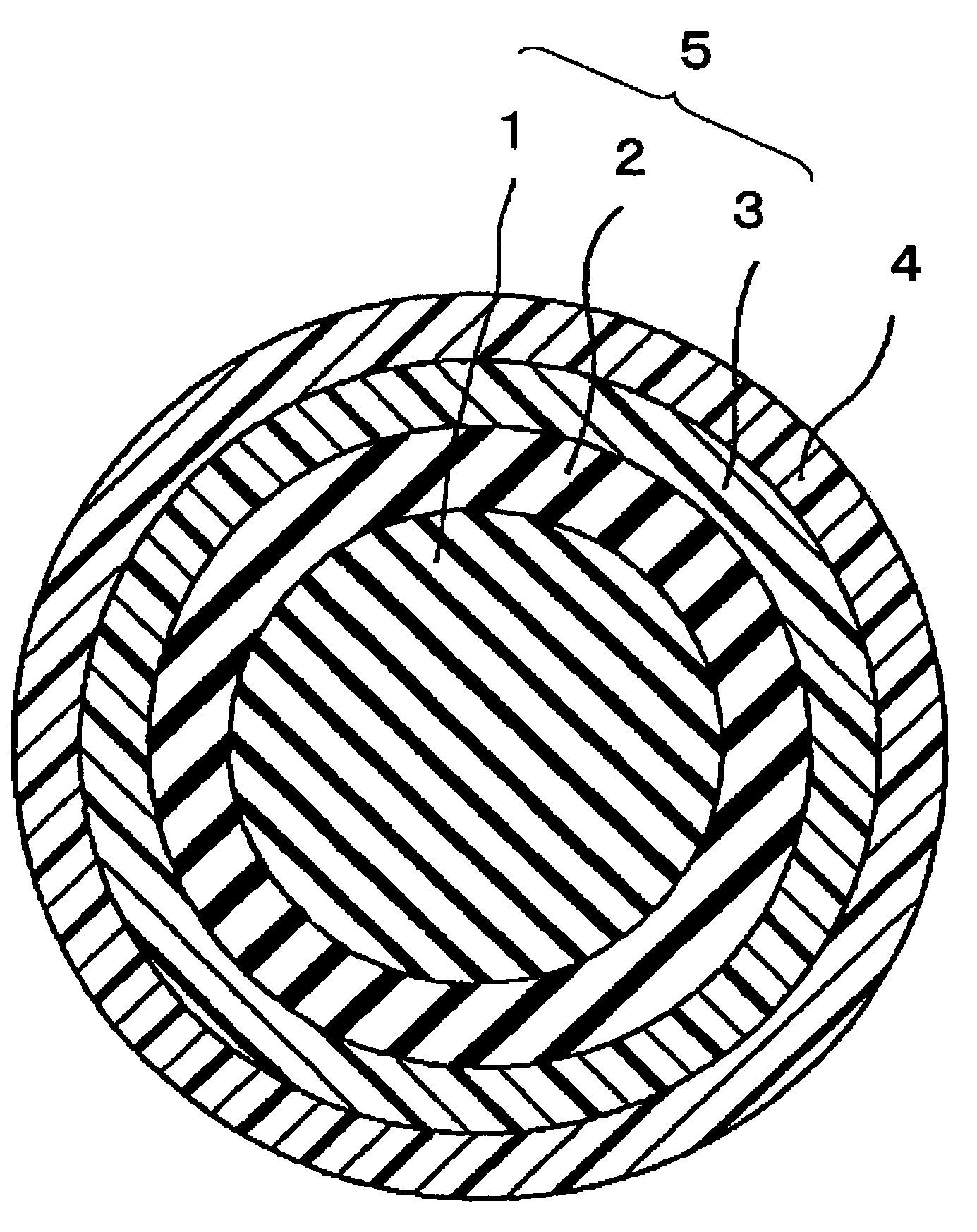

Multi-piece solid golf ball

The present invention provides a four-piece solid golf ball having excellent flight performance and good shot feel at the time of hitting. The present invention relates to a four-piece solid golf ball comprising a core, an intermediate layer formed on the core, an outer layer formed on the intermediate layer and a cover covering the outer layer, wherein the core has a surface hardness in JIS-C hardness of 67 to 85, a JIS-C hardness of the intermediate layer is higher than the surface hardness of the core, and a JIS-C hardness of the outer layer is higher than the hardness of the intermediate layer.

Owner:SUMITOMO RUBBER IND LTD

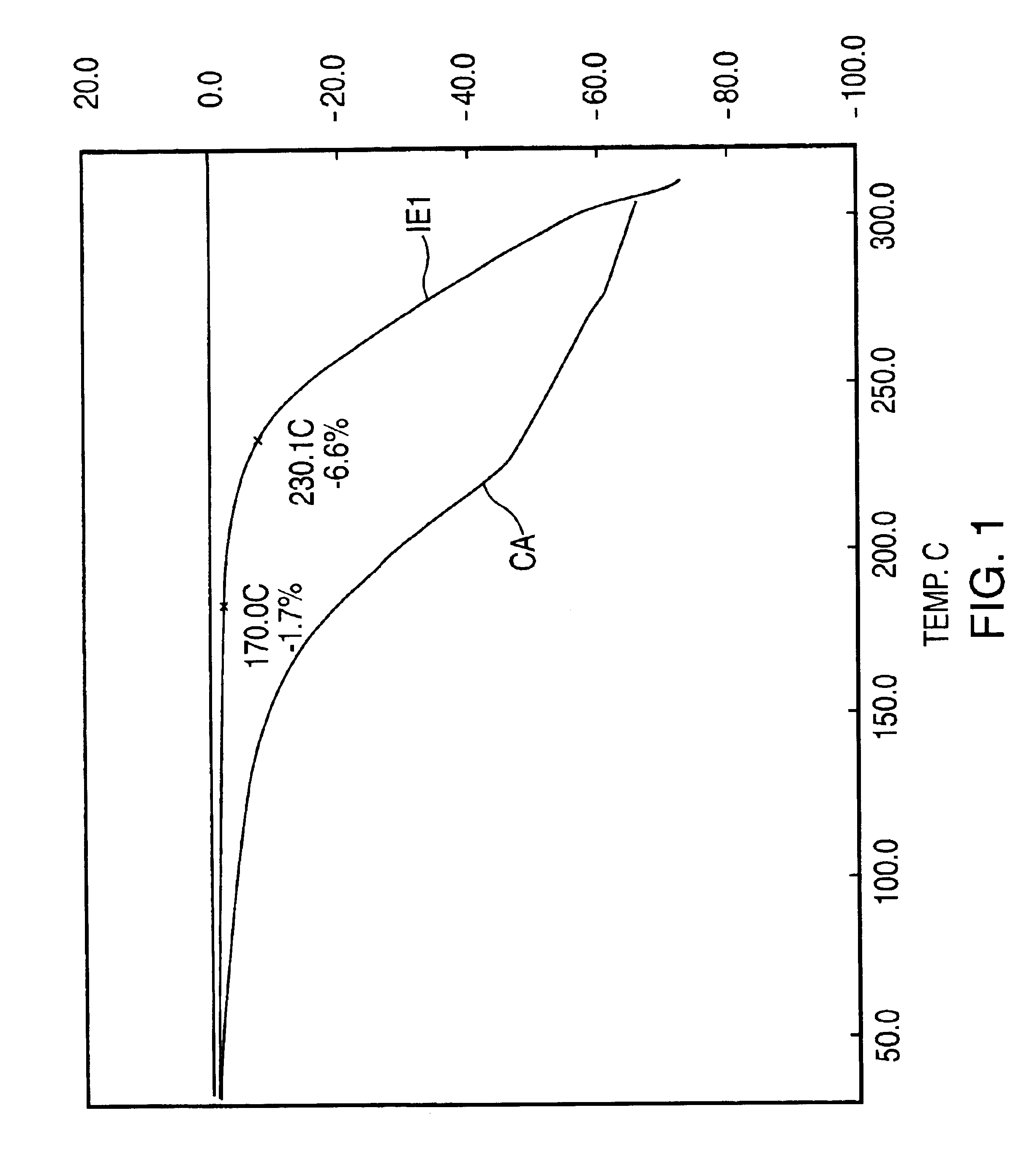

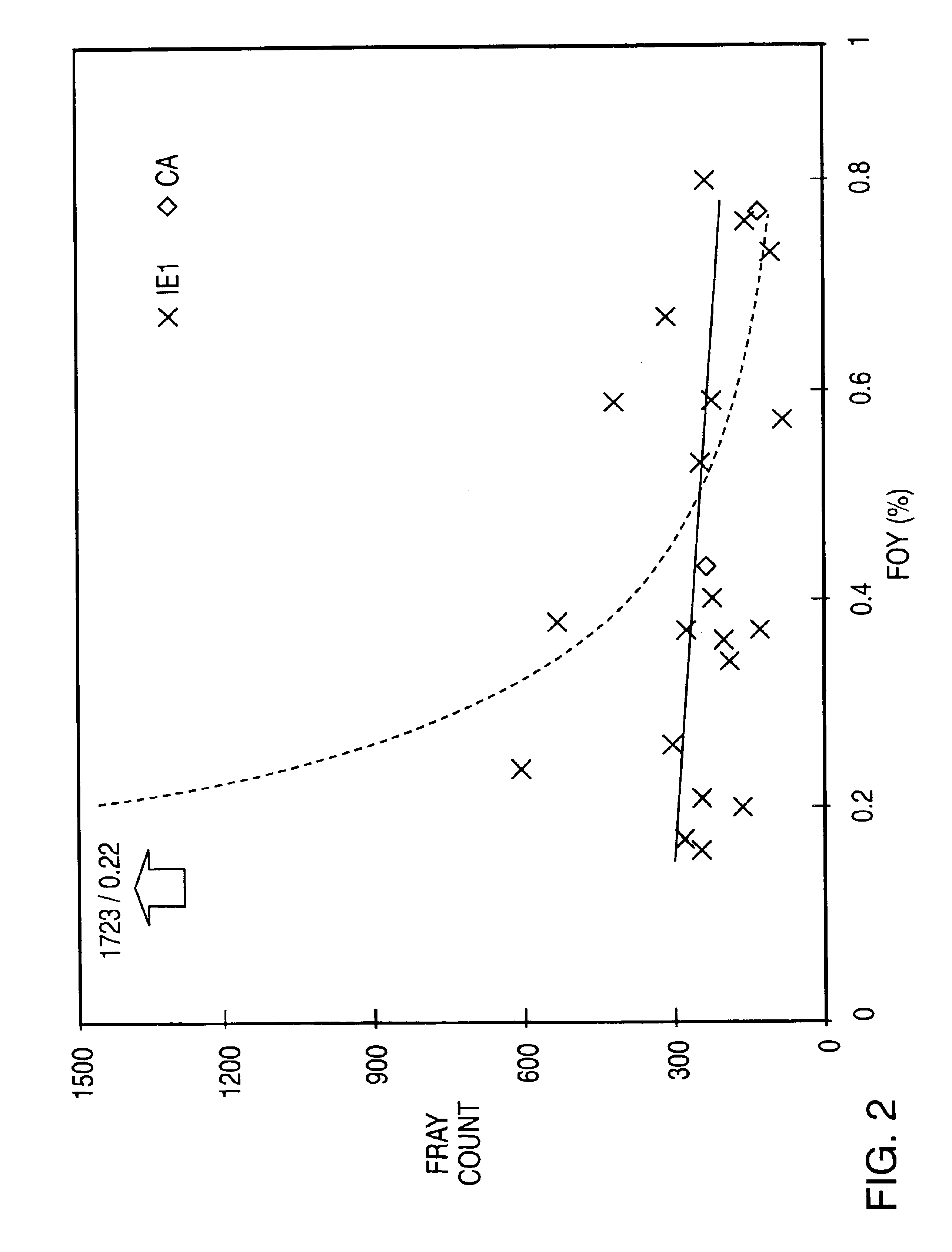

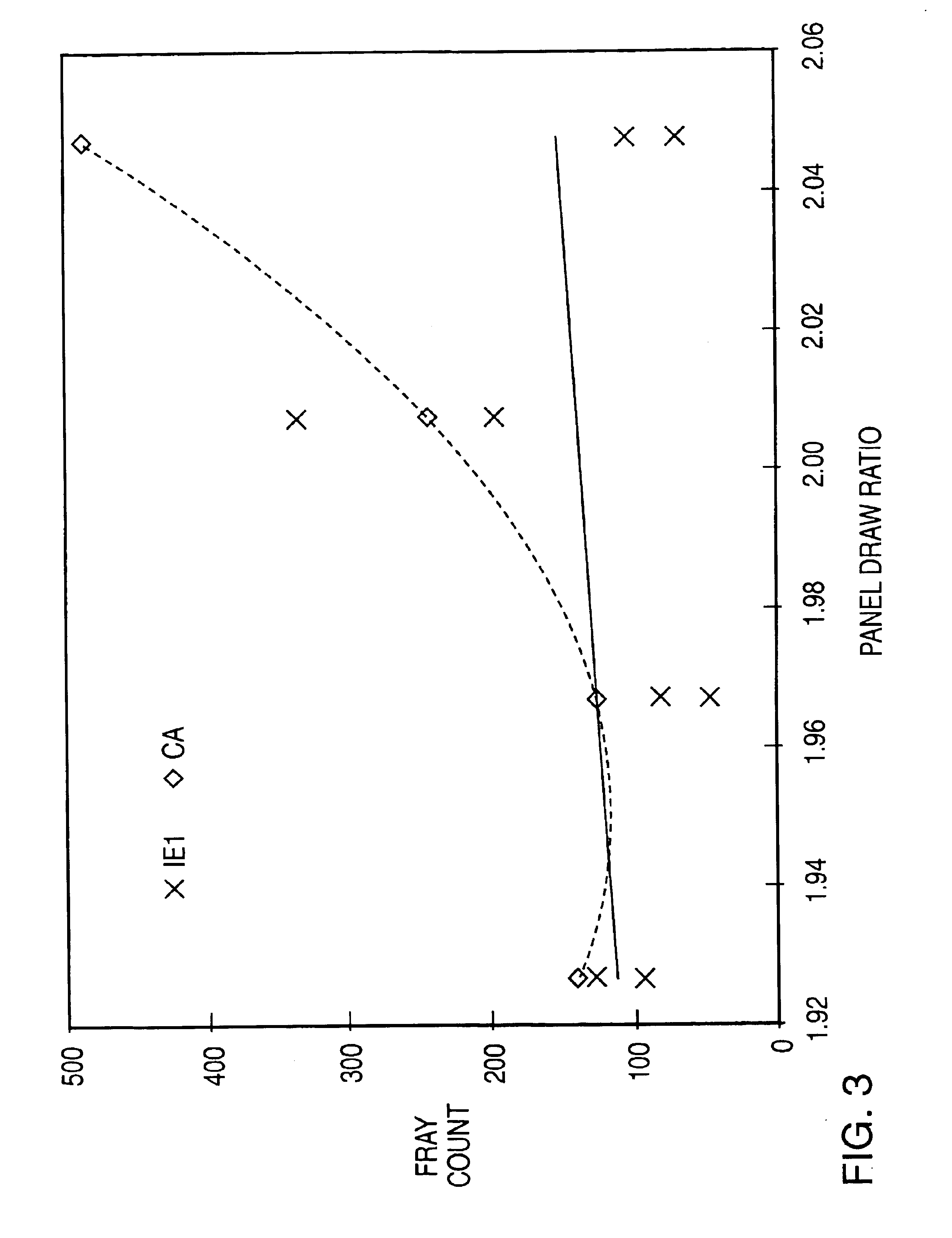

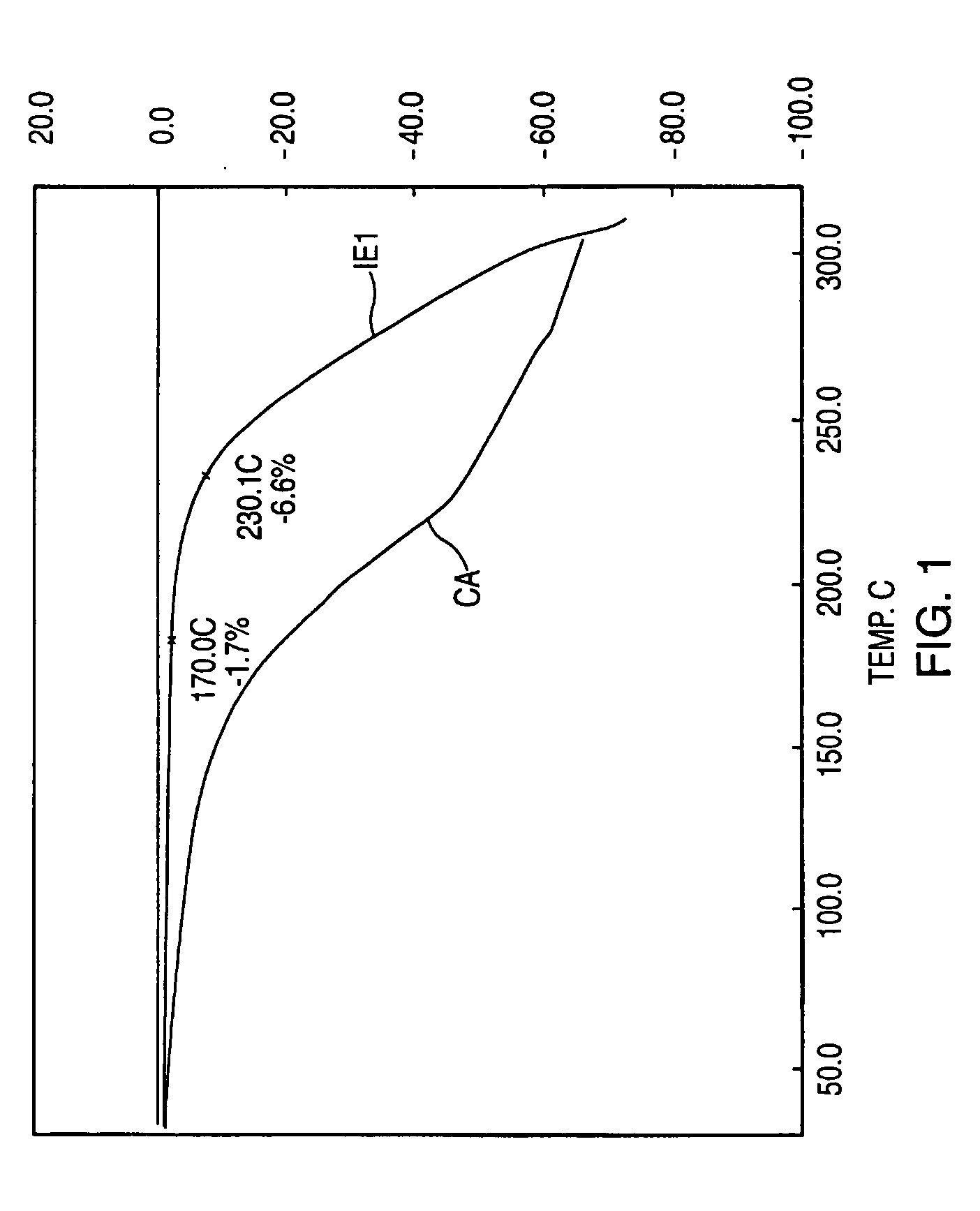

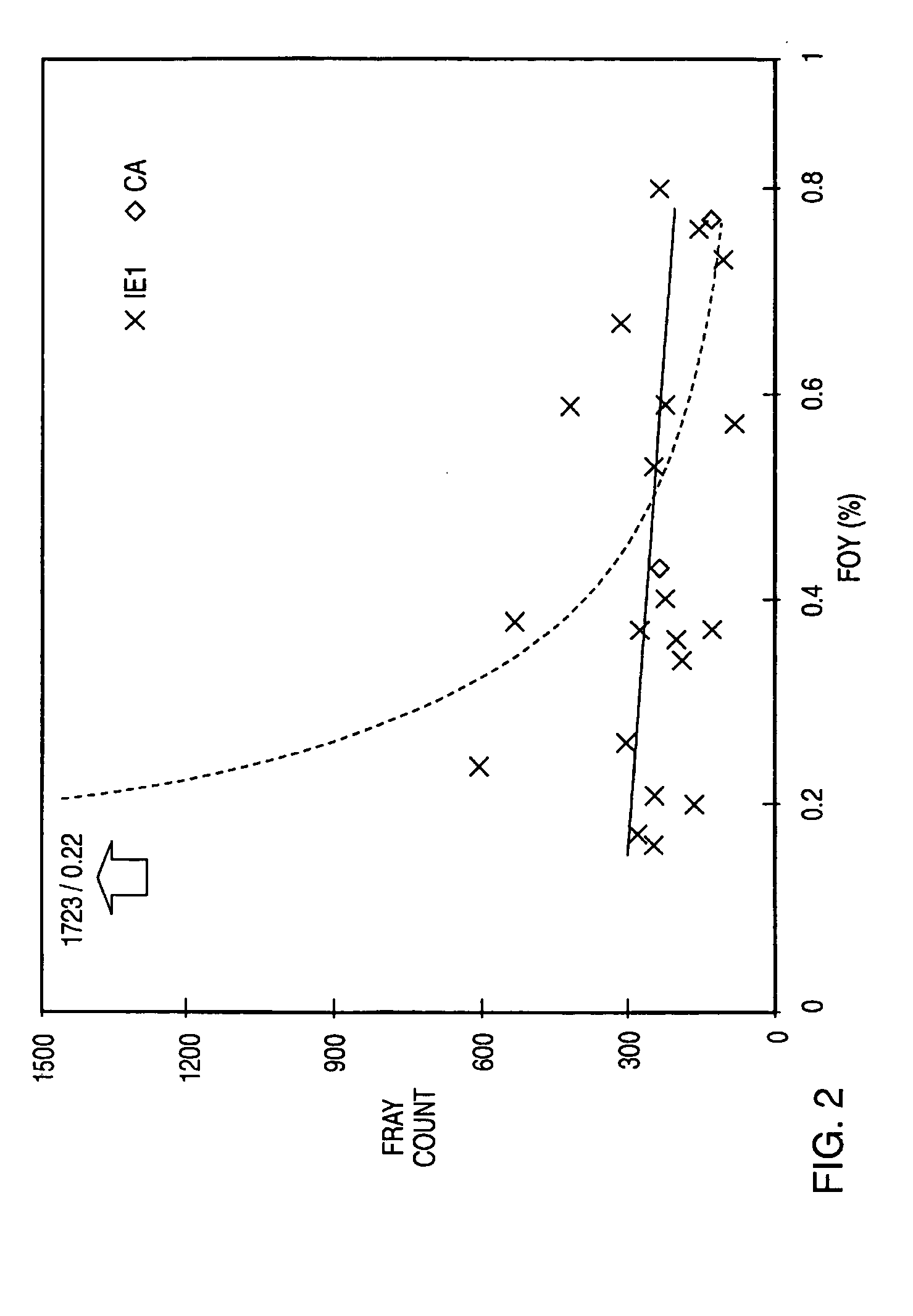

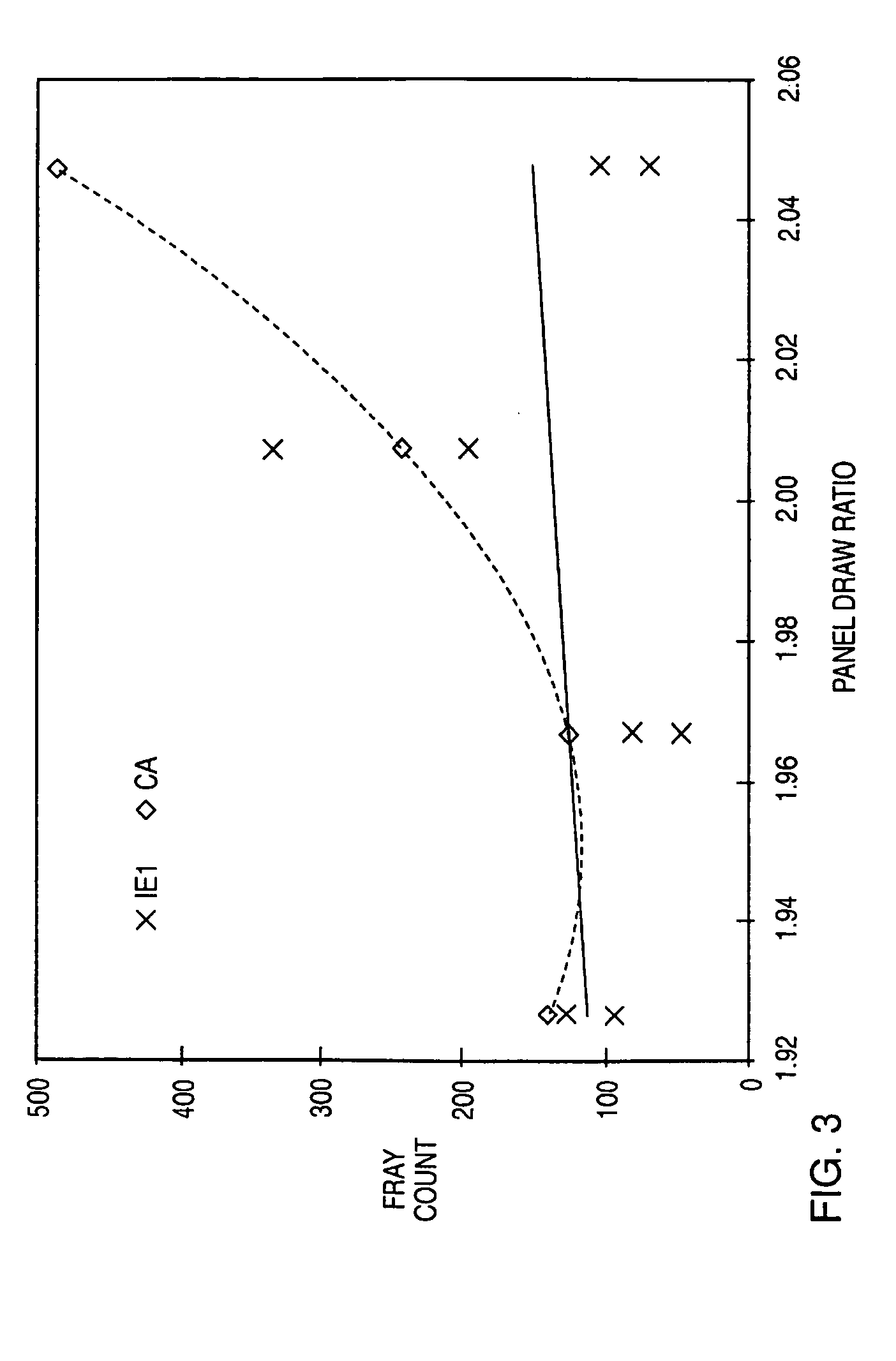

Process for making a yarn having a spin finish

InactiveUS6908579B2Enhances yarn processabilityImprove mechanical qualityFibre typesPneumatic tyre reinforcementsYarnEngineering

A spin finish which enhances yarn processability and contributes to improved yarn performance. The spin finish is advantageous when compared with conventional spin finishes applied to industrial yarn because the present spin finish enhances yarn processability as evidenced by low forming, improved mechanical quality at lower amounts of spin finish per yarn, improved mechanical quality at higher draw ratios, and minimal depositing. It also improves yarn performance as evidenced by improved strength and wicking.

Owner:FIBER INNOVATORS INT LLC

Spin finish

InactiveUS20050142360A1Easy to processLow fumingFibre typesSynthetic resin layered productsHydrogenHydroxy group

The present spin finish composition comprises at least about 10 percent by weight based on the spin finish composition of components (a) and (b) having the formula R1—(CO)x—O—(CH(R2)—CH2—O)y—(CO)z—R3 wherein each of R1 and R3 is selected from the group consisting of hydrogen or an alkyl group having from one to 22 carbon atoms or an alkylene hydroxy group having from one to 22 carbon atoms, x is zero or one, R2 may vary within component (a) or component (b) and is selected from the group consisting of hydrogen or an alkyl group having from one to four carbon atoms, y is zero, or from one to 25, and z is zero or one, in component (a), x and z are equal to zero and the average molecular weight of component (a) is less than or equal to 1,900 and if R2 varies, component (a) is a random copolymer; and in component (b), at least x or z is equal to one or component (b) is a complex polyoxyethylene glyceride-containing compound having greater than 10 polyoxyethylene units; up to about five percent by weight based on the spin finish composition of component (c) of an ethoxylated silicone; and at least about one percent by weight based on the spin finish composition of component (d) having the formula R4(CH2O(CO)aR5)b wherein R4 is —C— or —COC—; a is 0 or 1; R5 is —H; from —CH3 to —C18H37; or —CH(R6)—CH2O; b is 4 or 6; and R6 is —H or —CH3 or —H and —CH3 in a ratio of 10:90 to 90:10. The present spin finish composition may be used on industrial yarn.

Owner:PERFORMANCE FIBERS

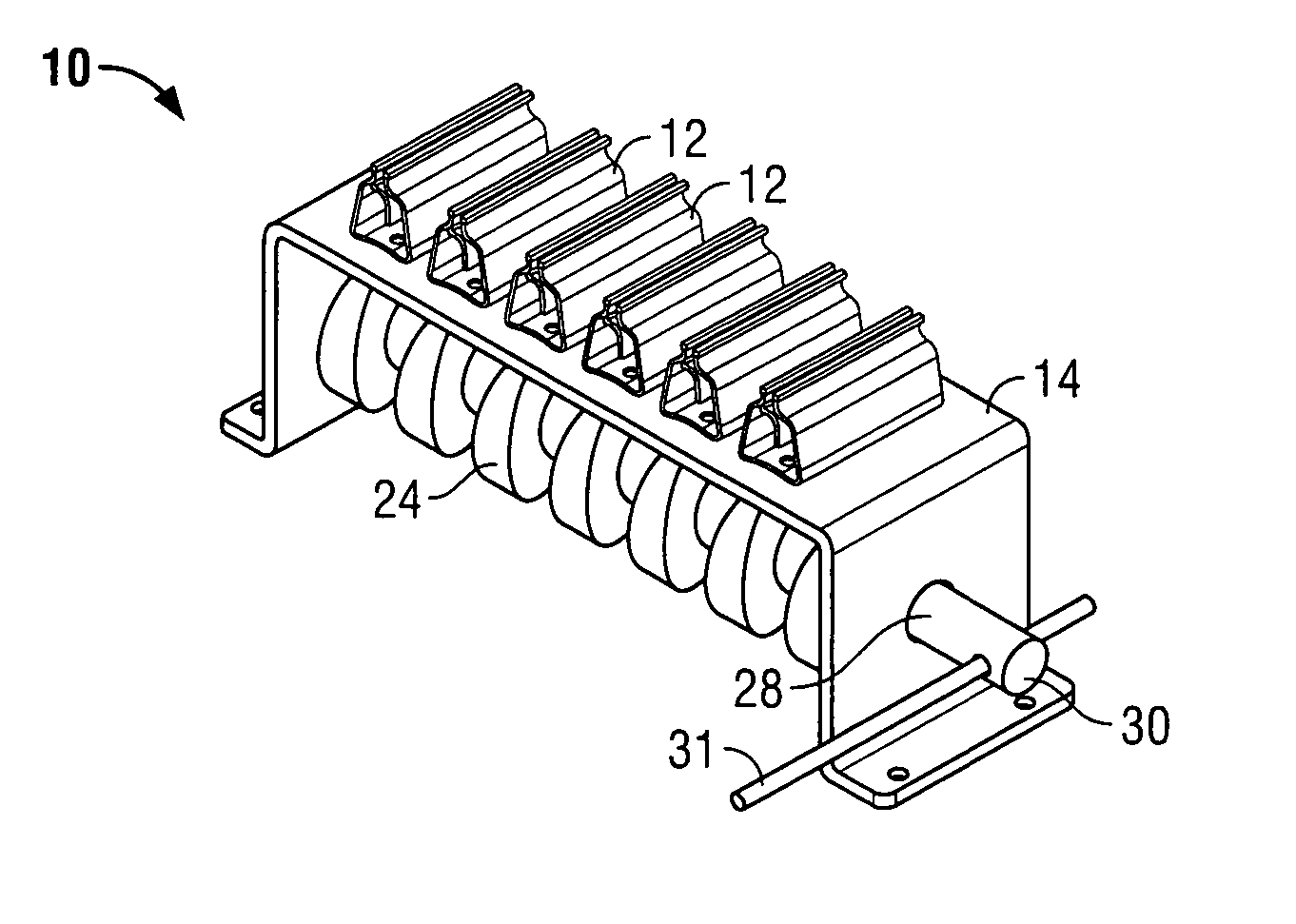

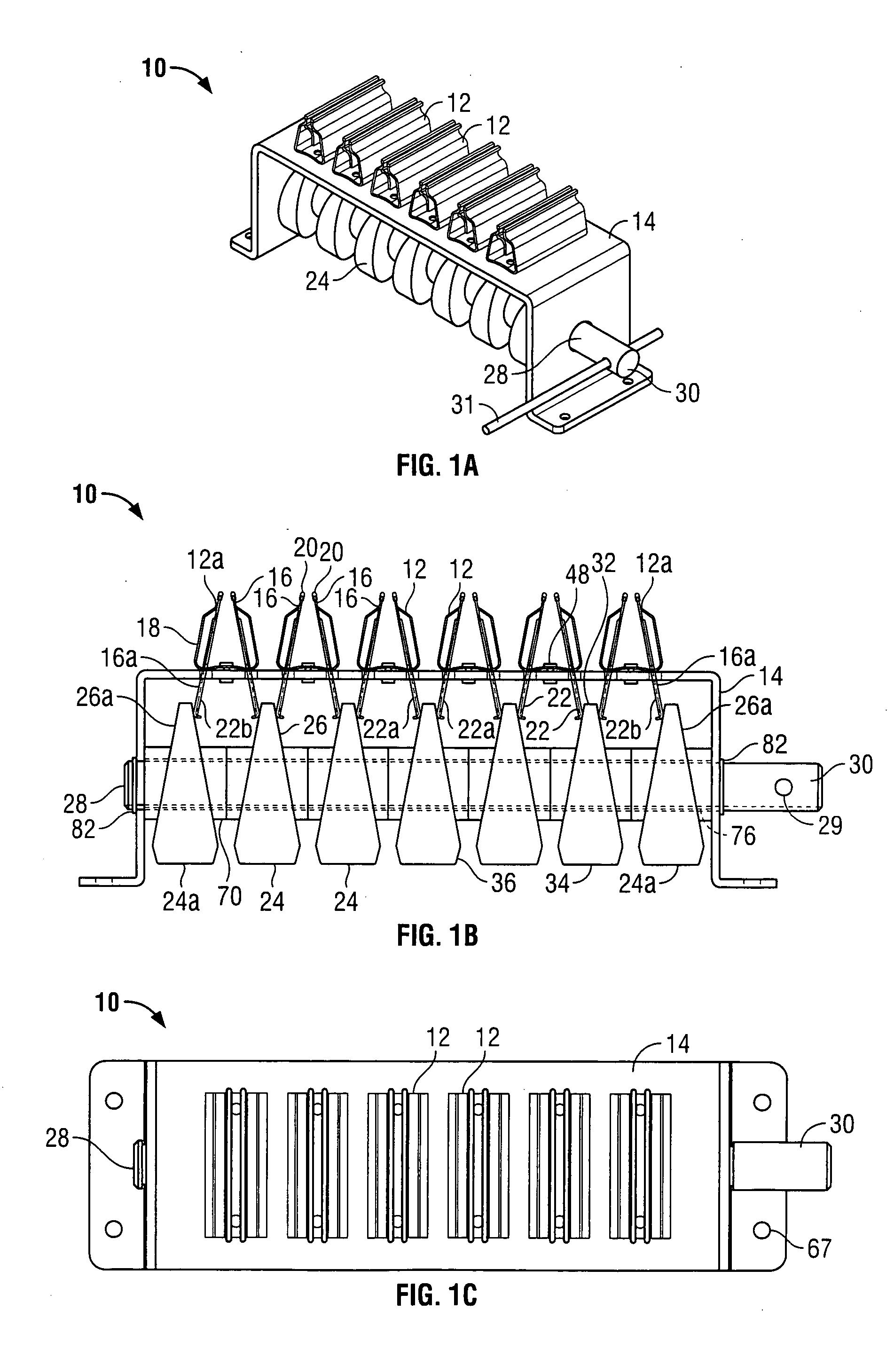

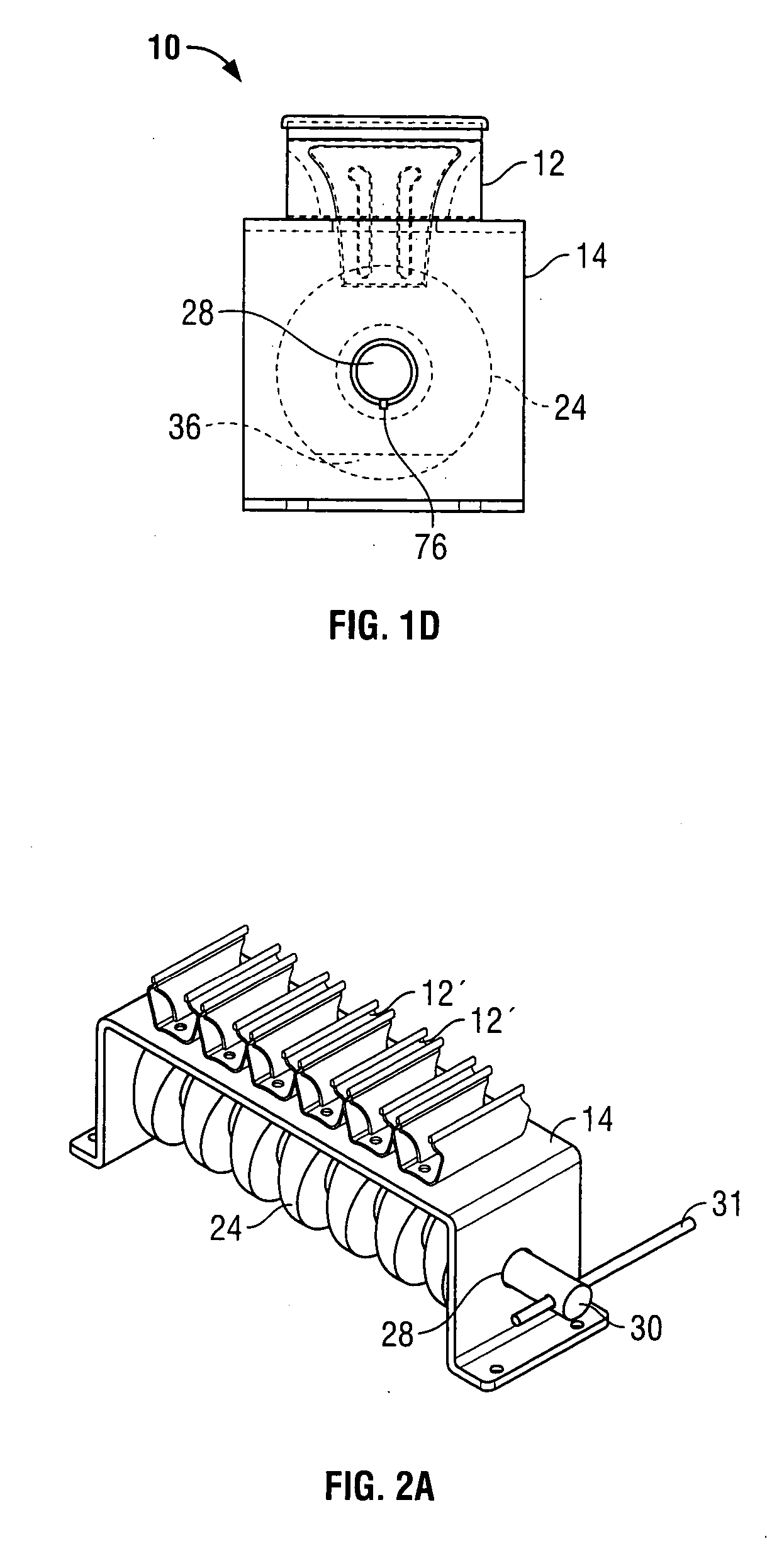

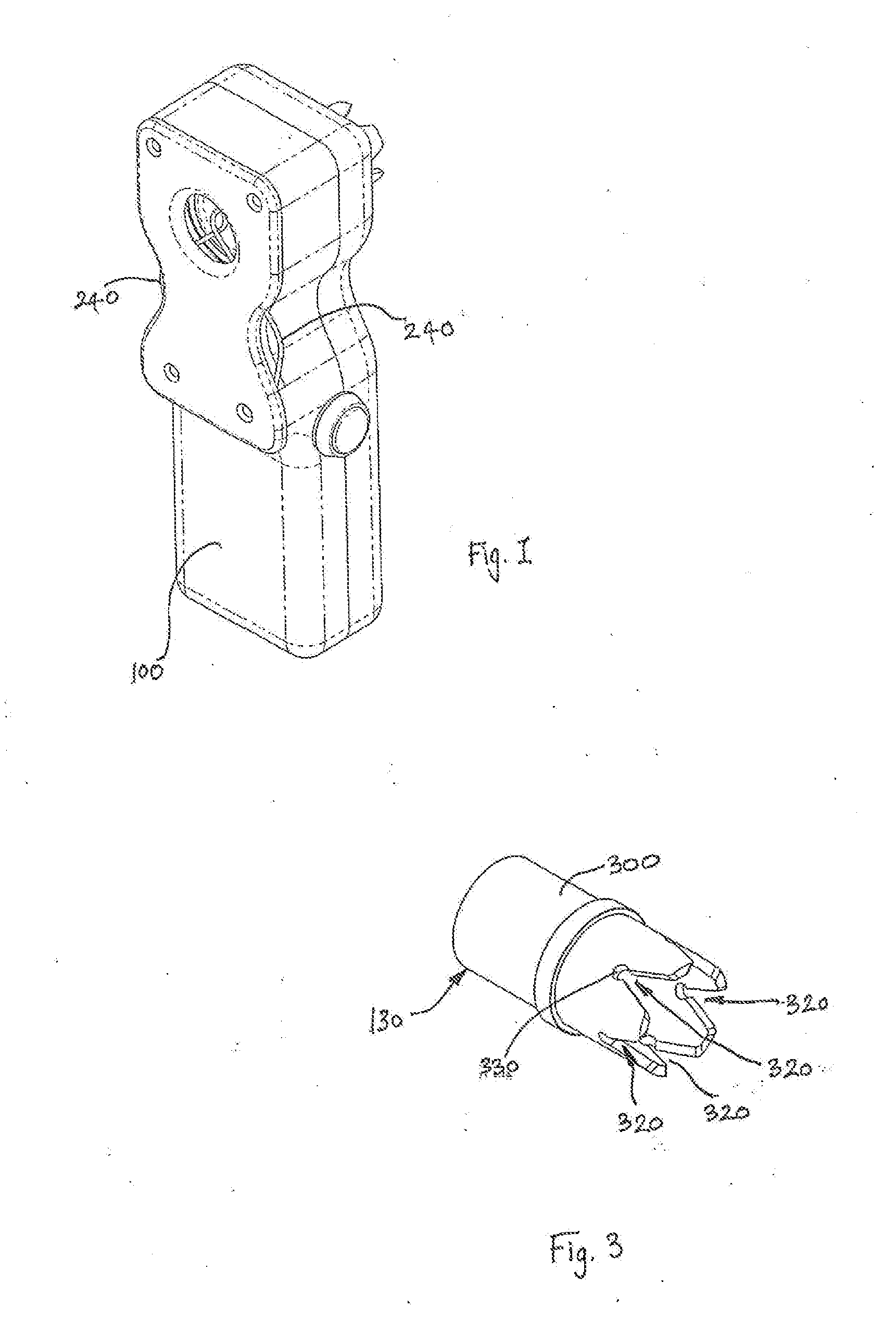

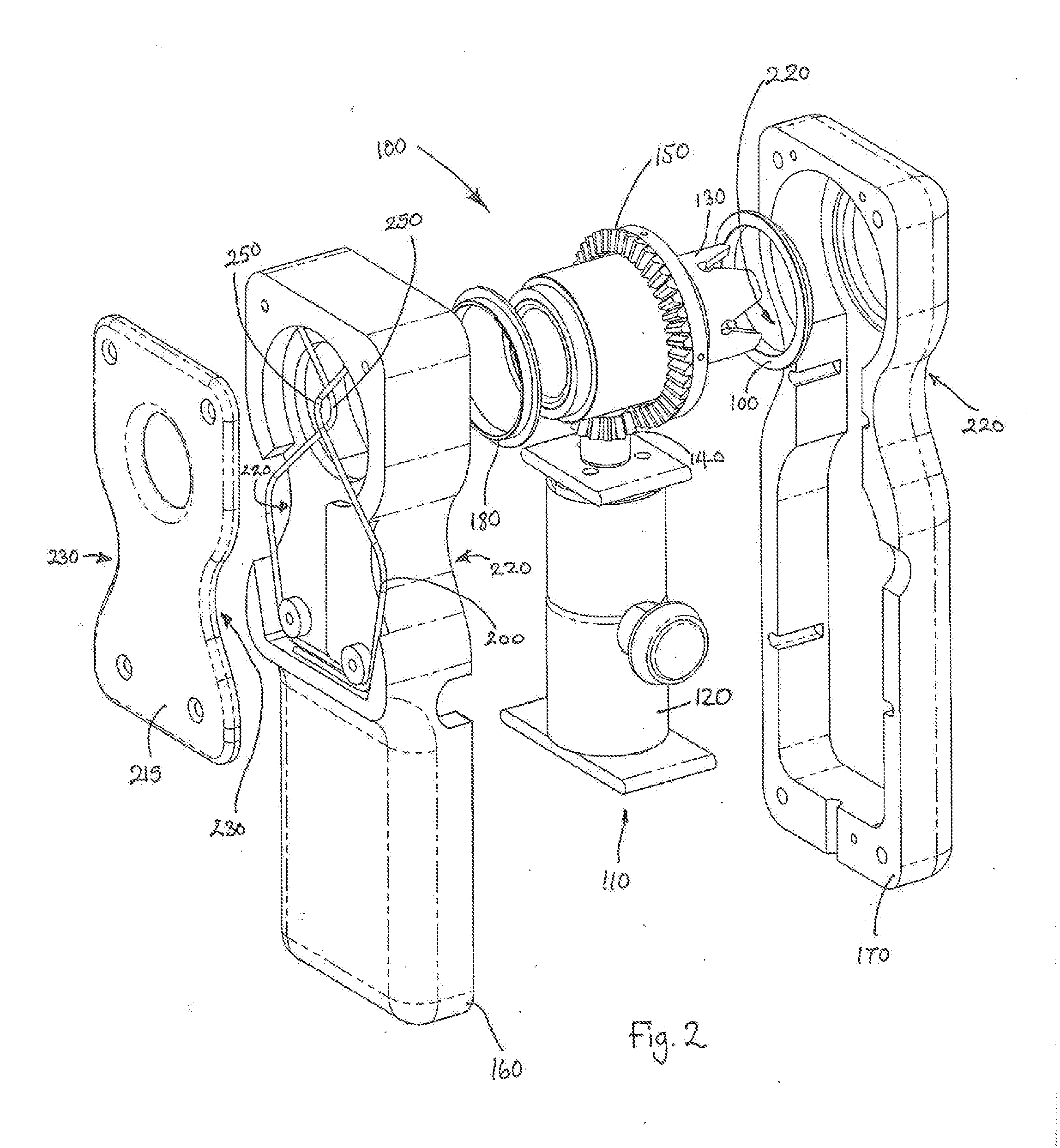

Compact clamping cartridge for panel-type products

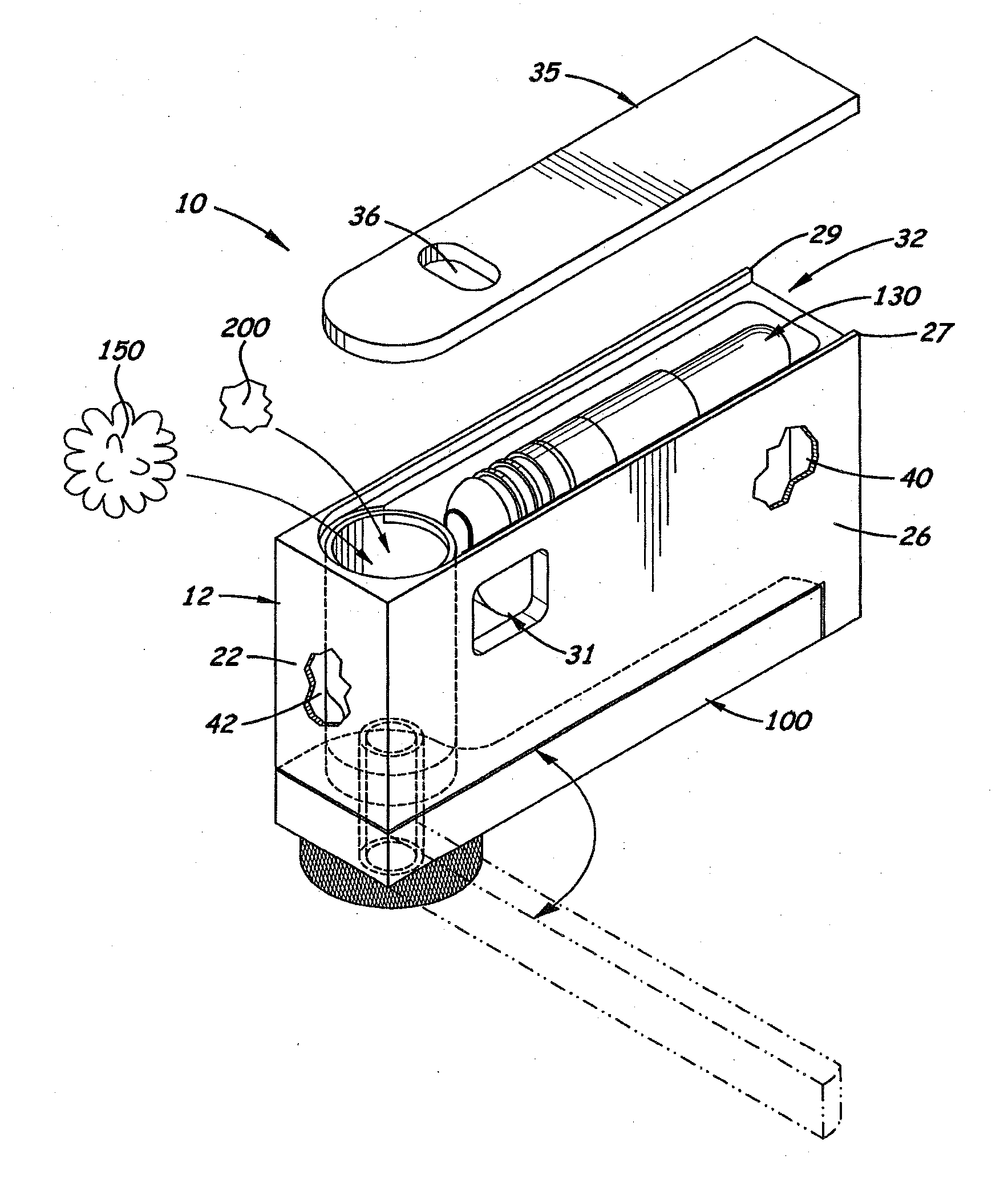

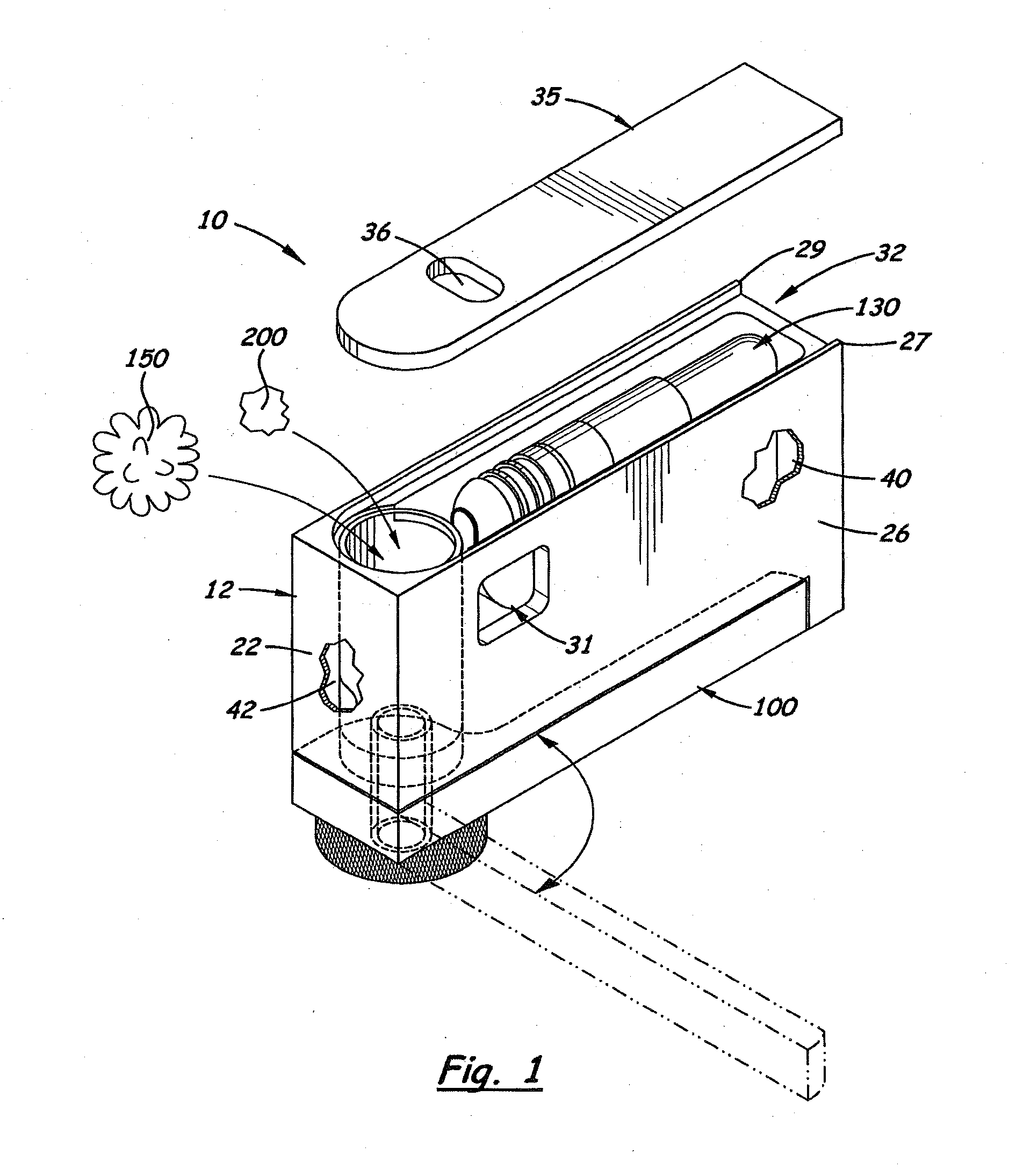

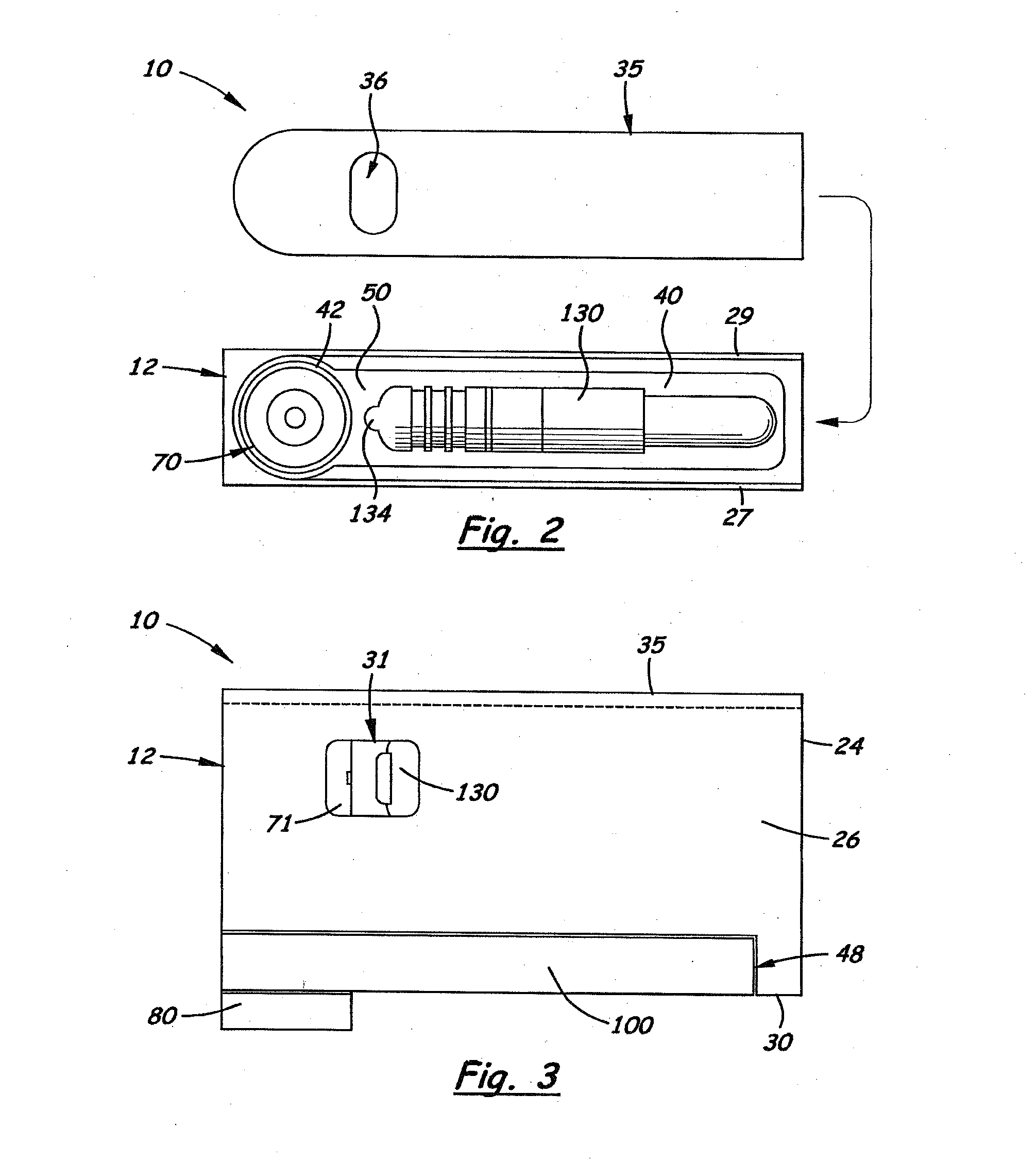

InactiveUS20050016894A1Reduce the overall heightReduce in quantityTray containersDamagable goods packagingActuatorFace sheet

A clamping cartridge is provided which comprises a plurality of clamping mechanisms spaced apart on a frame or chassis. The clamping mechanisms are generally oriented perpendicular to their direction of spacing. The clamping mechanisms are of the type which comprise a pair of relatively movable jaws which are normally biased towards one another such that they resist opening and which return to a closed or substantially closed condition in the absence of external forces. An actuator operable in association with the clamping mechanisms serves to open and close the jaws of the clamping mechanisms in unison. The actuator includes a series of rotatable tapered cylindrical cam wheels disposed on a rotatable cam shaft to ultimately effect opening and closing of the clamps, which cam wheels are disposed generally within the clamps. By providing apertures or slots in the jaws of the clamps to accommodate the cam shaft, a considerable reduction in the height of the cartridge can be realized. The cam shaft is rotatably supported in bearings and a detachable handle is provided with which the shaft can be rotated. While the clamps are closeable in unison, they are individually self-adjusting so the extent of closure for each clamp is dependent on the thickness or presence of an inserted article. The clamping cartridges are useful in a variety of applications requiring clamping of one or more articles in a side-by-side relationship. One such application is a transportation / storage rack which includes a plurality of aligned horizontal and vertical clamping cartridges for clamping the edges of glass panels.

Owner:1546300 ONTARIO

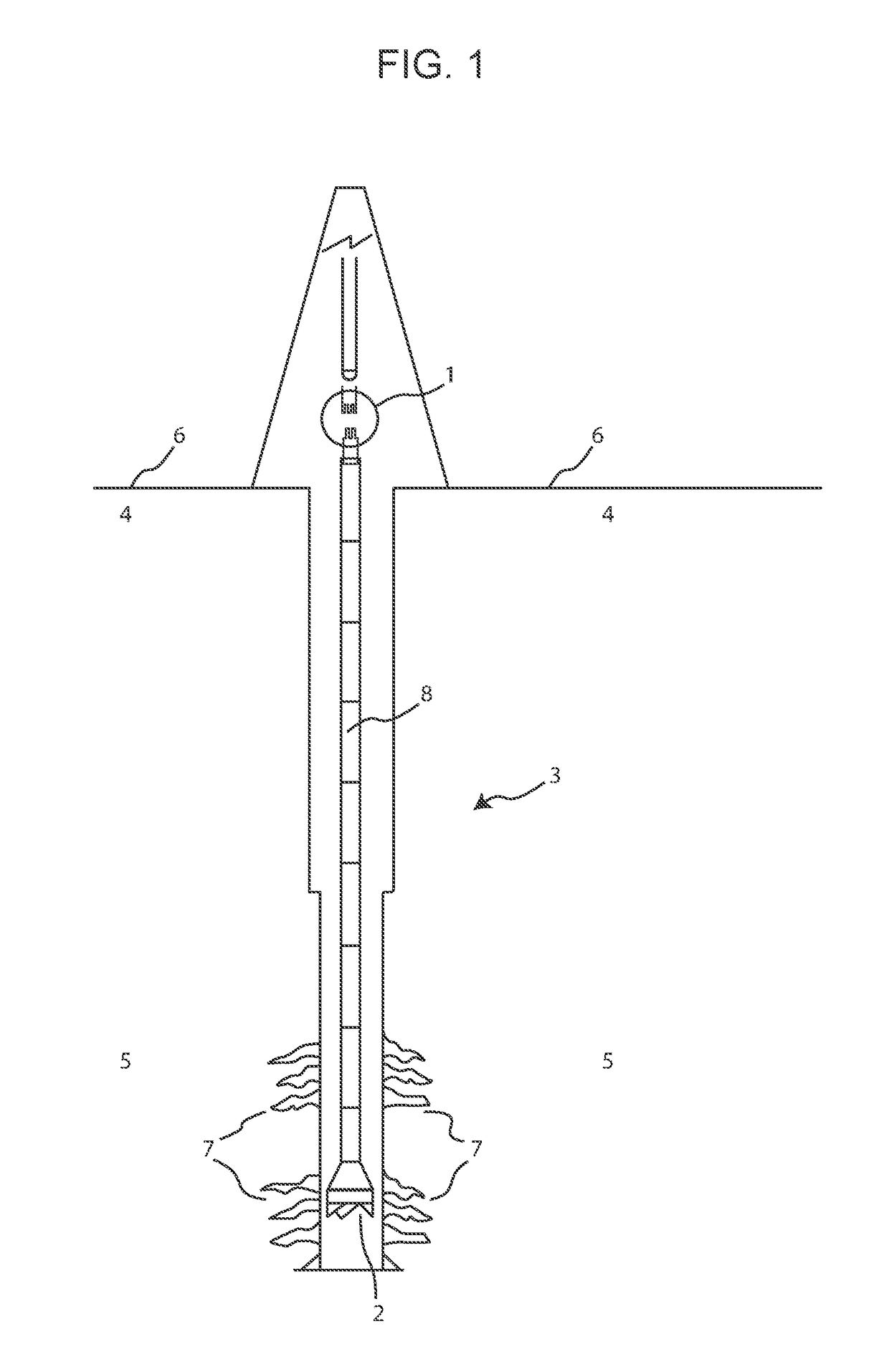

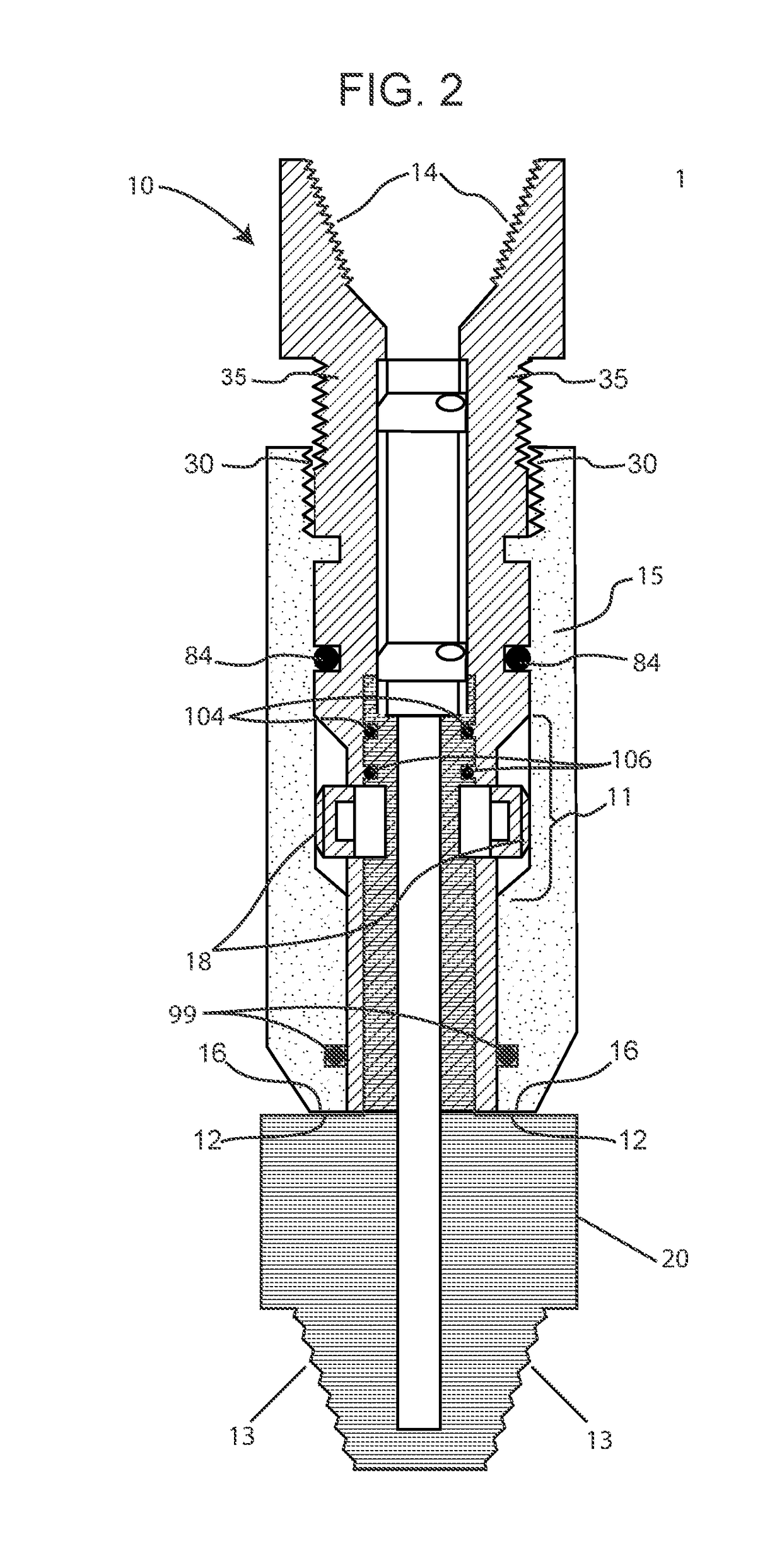

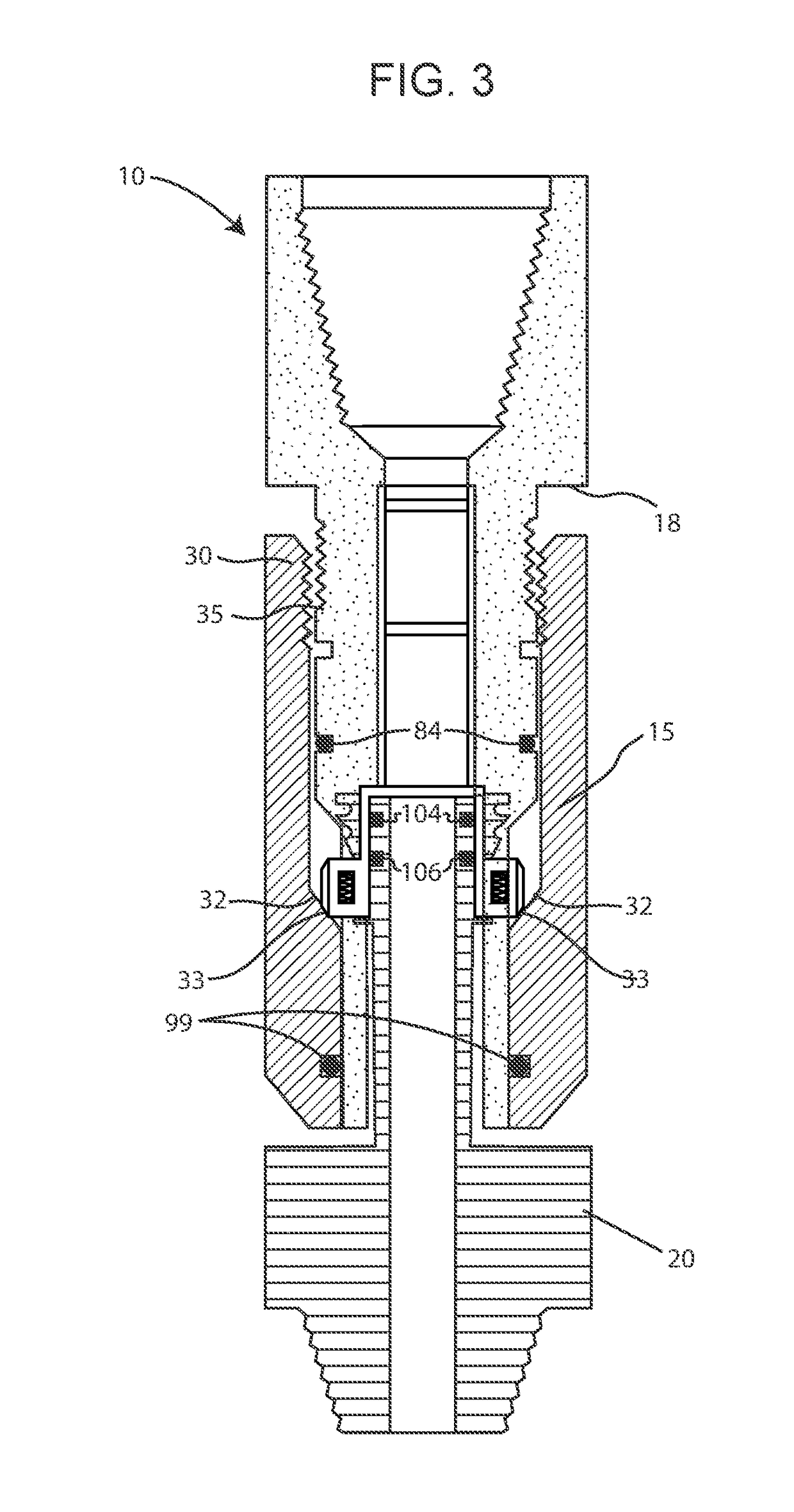

Manual Pipe Valve Connector for Jointed Pipe Connections with Quick Release Check Valve Assembly and Uses Thereof

ActiveUS20190003265A1Expedient and efficient makeupExpedient and efficient and breakoutDrilling rodsConstructionsThreaded pipeCoiled tubing

The present invention provides a novel clutch connector assembly for jointed pipe, threaded pipe, coiled tubing or any threaded or non-threaded pipe for a bottom hole assembly that eliminates the need to use screw threads to mate two pipes or mechanical assemblies, harbors a spring-loaded mechanical locking system in addition in to a pressure-activated, component protectant system, requires no significant tools, other than an Allen wrench or similar screw setting device, permits distributed torque loading, allows for movement in either a clockwise or counter clockwise rotational direction through interlocking castellations and presents a removeable and replaceable valve assembly preventing retrograde hydrocarbon advancement through a drilling pipe.

Owner:MCLAUGHLIN STUART

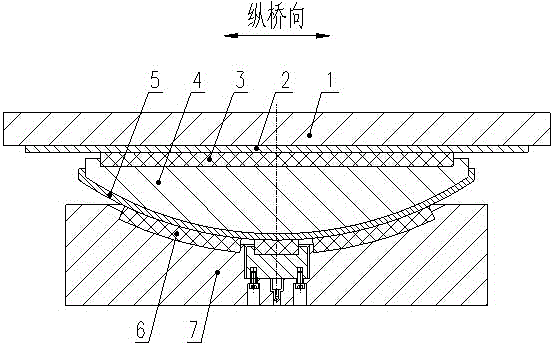

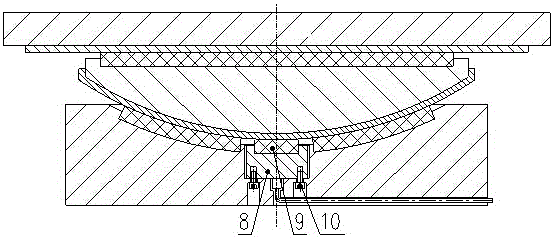

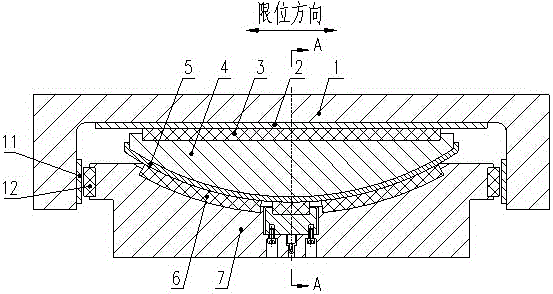

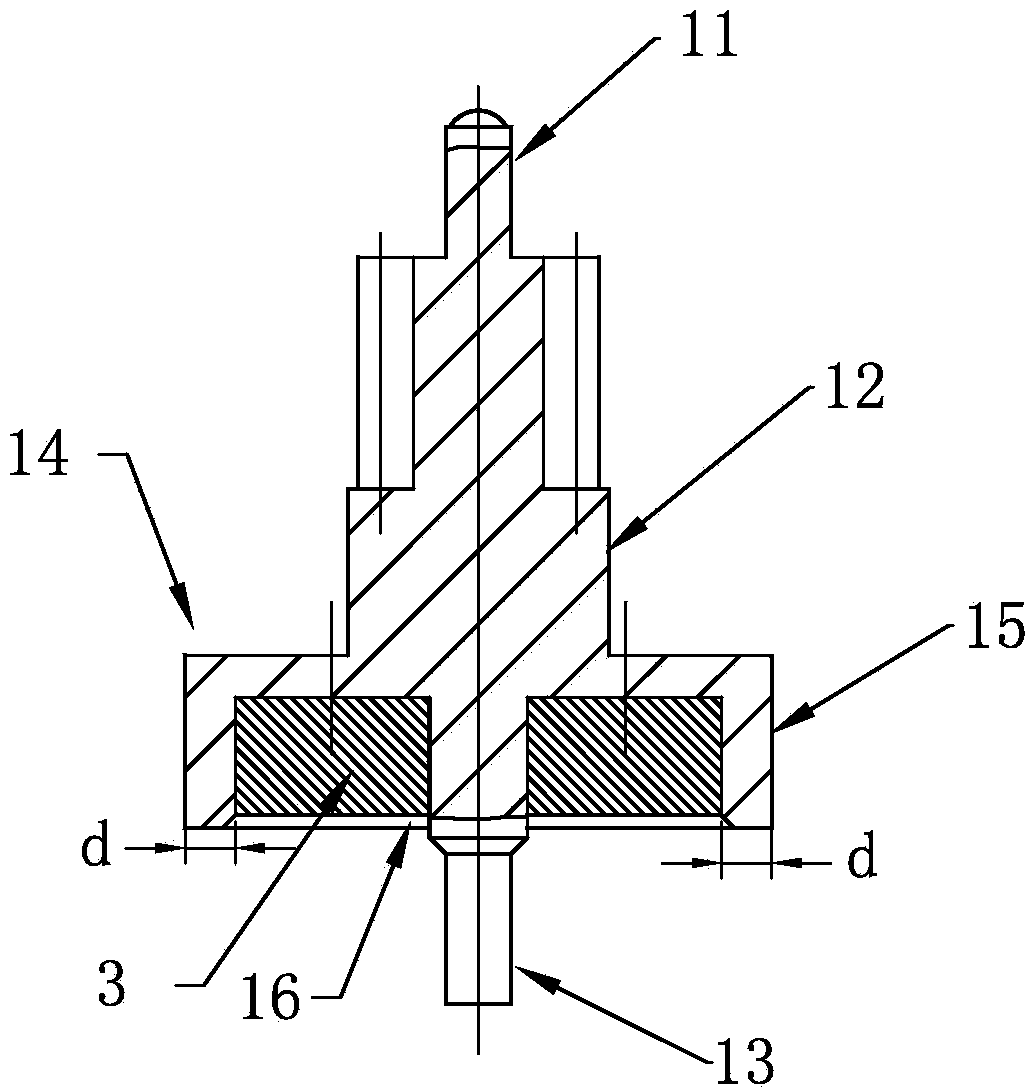

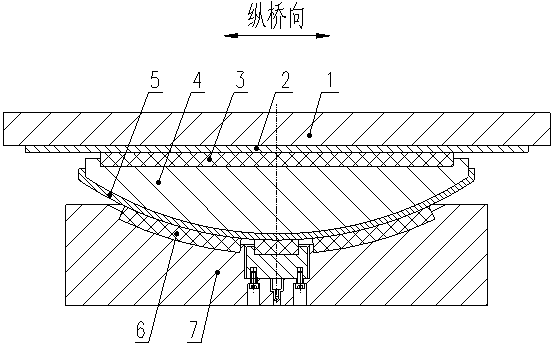

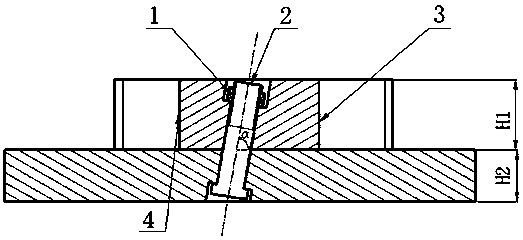

Vertical force measurement type bridge bearing and force measuring method thereof

ActiveCN106192739ARealize the function of vertical force measurementSolve the problem of vertical force measurementBridge structural detailsApparatus for force/torque/work measurementSize increaseEngineering

The invention relates to a vertical force measurement bridge bearing and a force measuring method thereof. Through measurement and whole demarcation of local stress, the whole stress of the bearing is determined. The bridge bearing is simple in structure, size increase and weight increase are small, force measurement is reliable, the vertical force measurement function of the bridge bearing can be realized, the vertical force measurement difficult problem of the bearing is solved, and technical support is provided for bridge monitoring.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

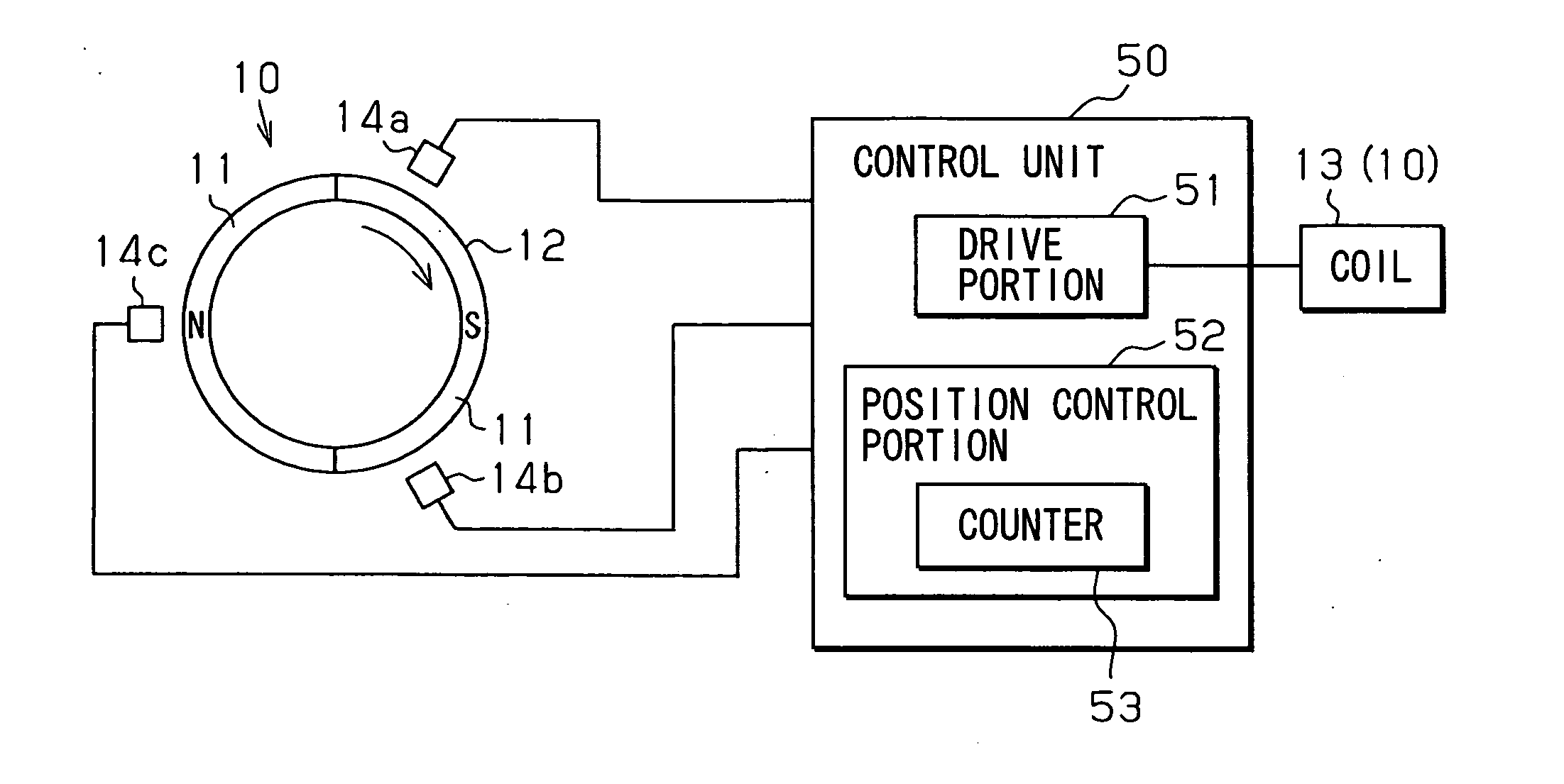

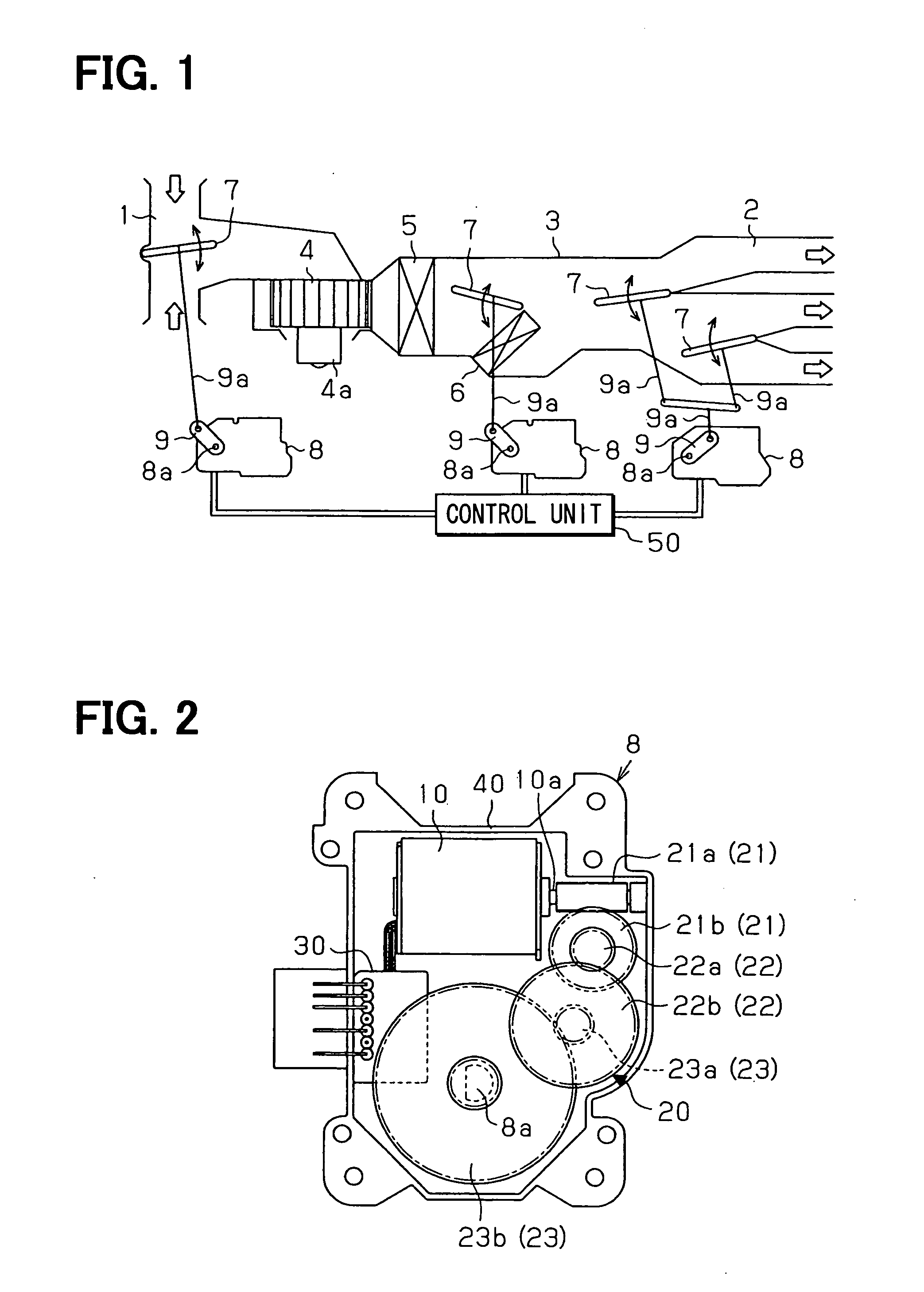

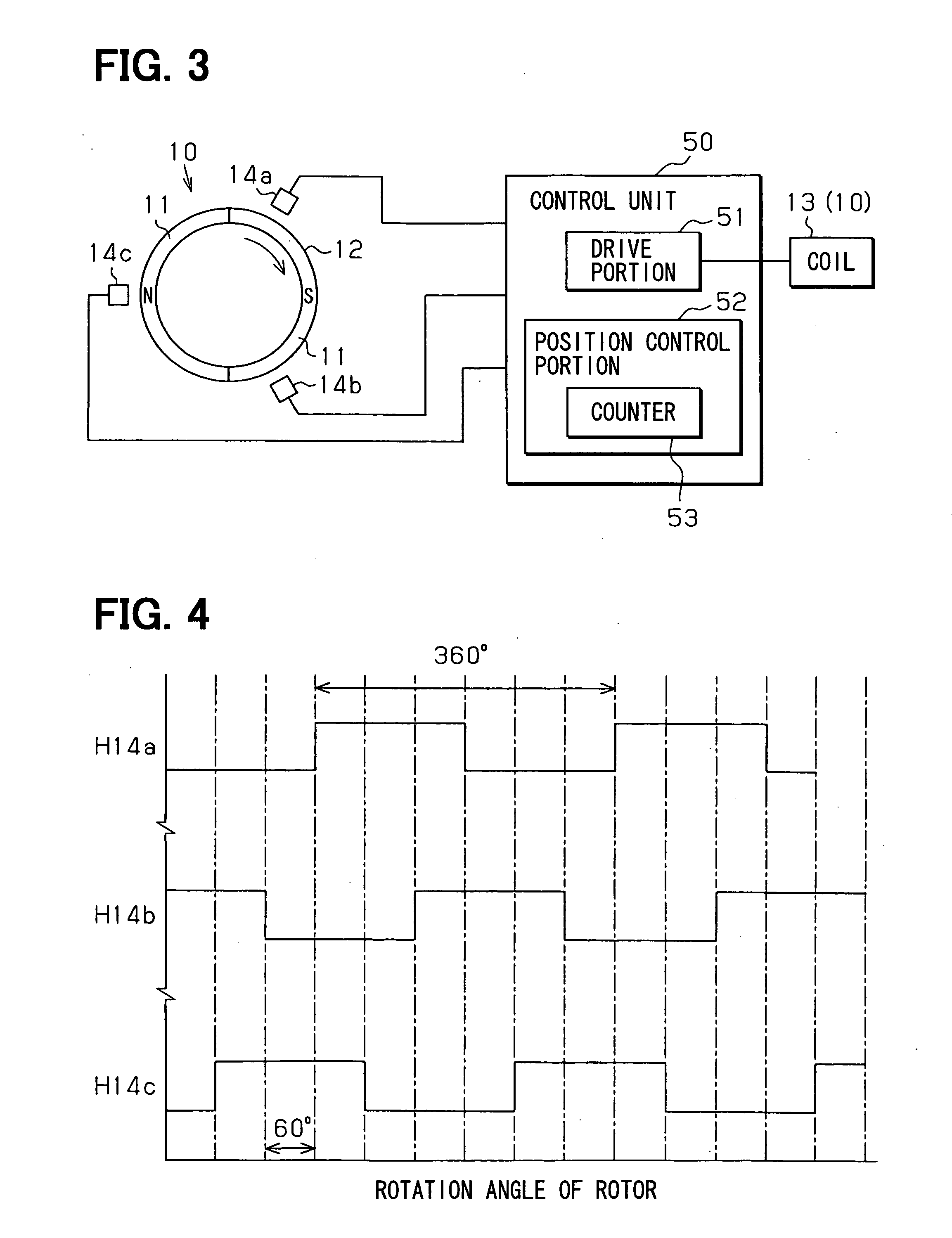

Motor actuator

InactiveUS20060164030A1Small sizeEasy to controlAir-treating devicesMotor/generator/converter stoppersBrushless motorsHall element

A motor actuator for actuating a driven member includes a control unit and a brushless motor, which includes a coil, a magnet and a hall element. The coil generates a magnetic field when being energized. The magnet rotor is rotatable in the magnetic field generated by the coil. The hall element detects a variation in the magnetic field due to rotation of the magnet rotor. Then, the hall element outputs an output signal according to the variation in the magnetic field. The control unit detects a relative position between the magnet rotor and the coil based on the output signal outputted from the hall element, and controls energization of the coil based on the relative position. Furthermore, the control unit detects a location of the driven member, and controls the brushless motor to drive the driven member based on a rotation amount of the magnet rotor.

Owner:ASMO CO LTD +1

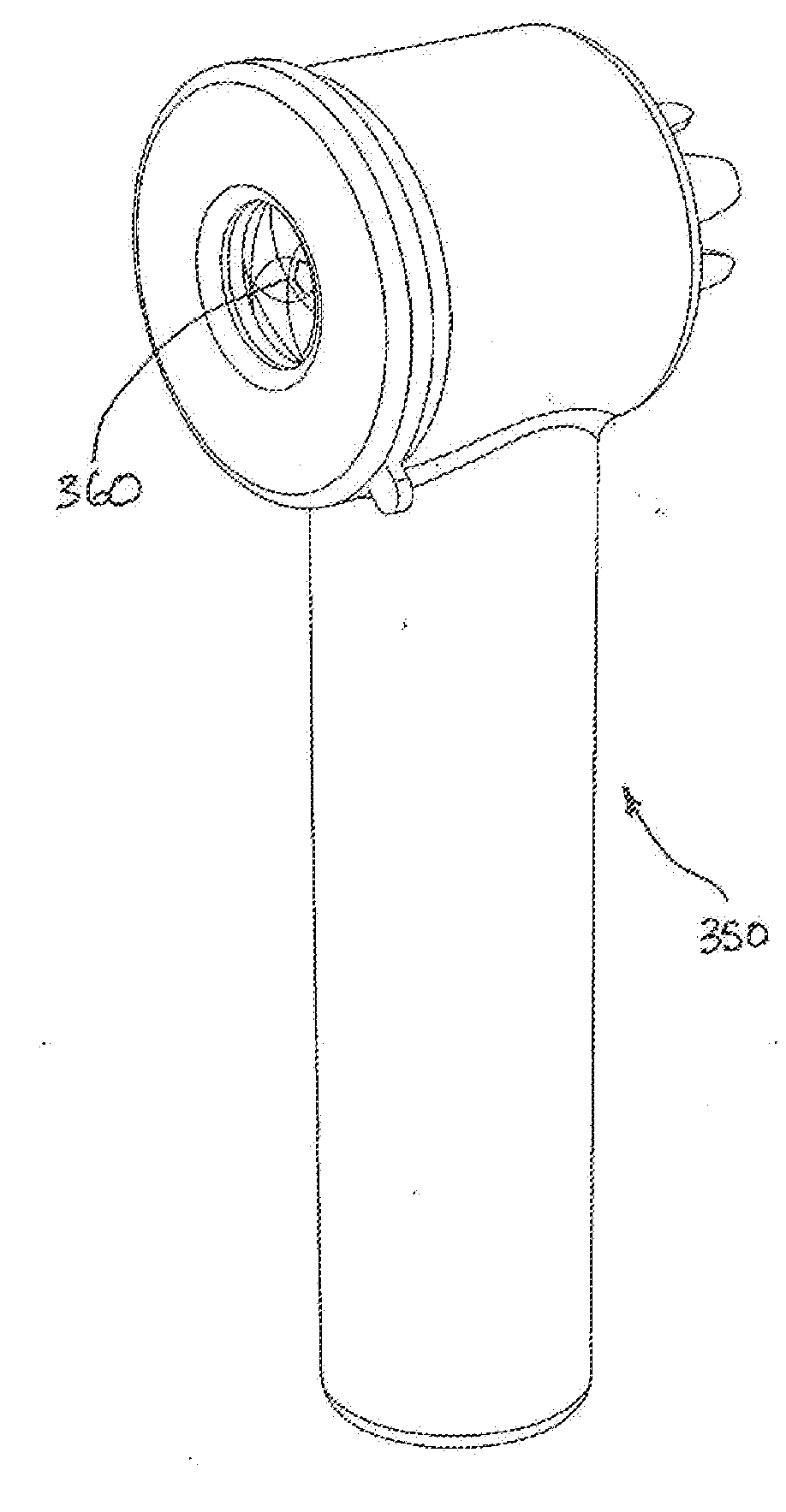

Hair care apparatus

InactiveUS20120325262A1High densityImprove tightnessCurling devicesHair dryingTWISTED HAIREngineering

An apparatus for dreadlocking hair comprising a motor and a means for holding or engaging a strand of hair. The holding means is rotated by the motor, so that the strand of hair is twisted into a dreadlock, that is, a twisted bundle of hair where hair on the surface of the bundle describes a purely helical path, at least in a newly dreadlocked part of the strand.

Owner:PALOCK

Auto Igniting Smoking Pipe

InactiveUS20100186758A1Easy to useEasy to packTobacco pipesTobacco devicesEngineeringBiological activation

A smoking pipe comprising an elongated body with a removable chassis located therein. Located on the chassis is a lighter with an activation switch and flame opening located on one end. The lighter is positioned in the chassis so that the lighter's flame opening is located adjacent to the upper bowl on the bowl assembly also mounted on the chassis. Formed over the upper bowl are air openings which allow heated hot gas to enter the bowl and vaporize or burn material placed therein Rotatably mounted on the lower neck on the bowl assembly is a ratchet. Attached to the ratchet is an elongated mouthpiece. The ratchet which includes a cam surface with a hook formed thereon that engages the distal end of a pawl. The proximal end of the pawl sits in a receiving cavity form a moveable head also mounted on the chassis that selectively presses against the activation switch on the lighter. The relative locations of the cam surface, smoke bores on the bowl assembly, and the mouthpiece are designed so that less movement of the mouthpiece is required to activate the lighter.

Owner:JONES MIKE

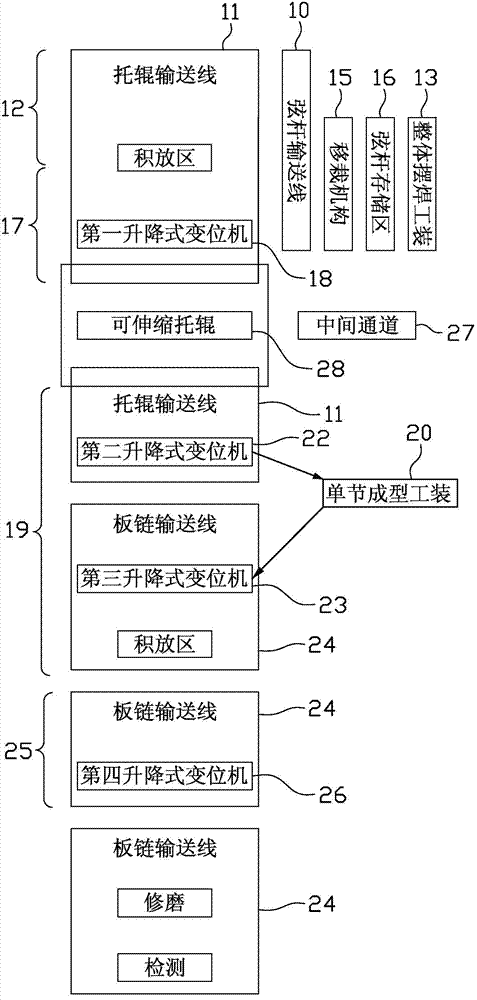

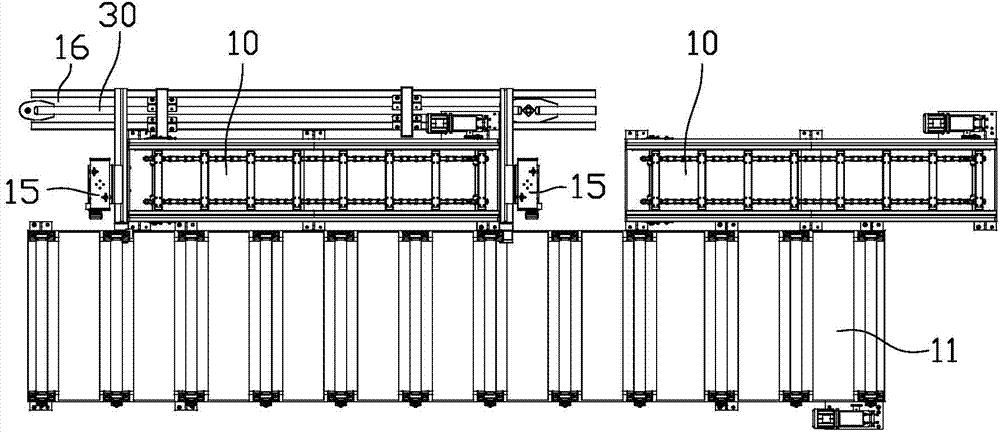

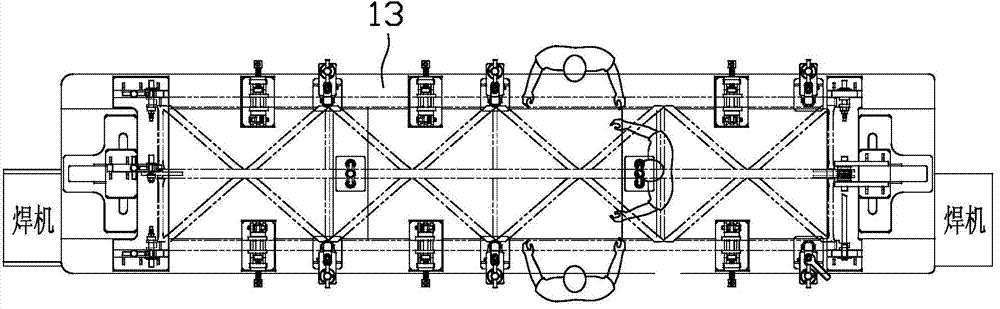

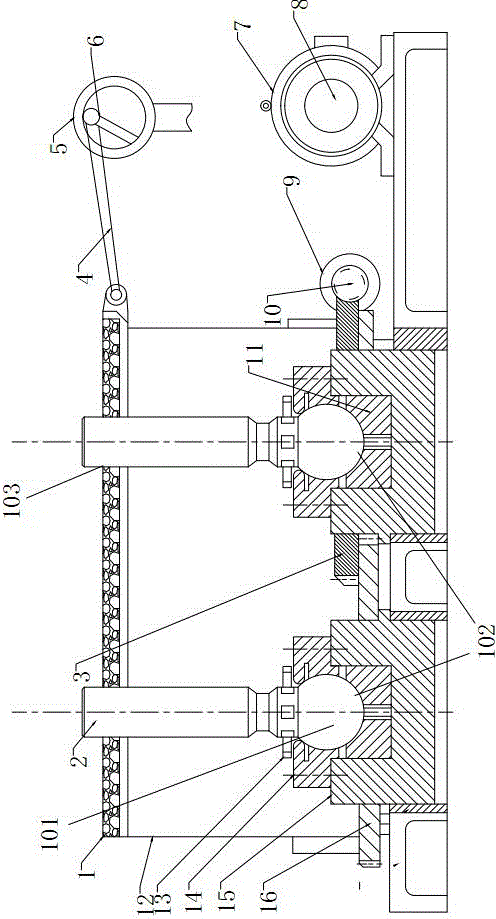

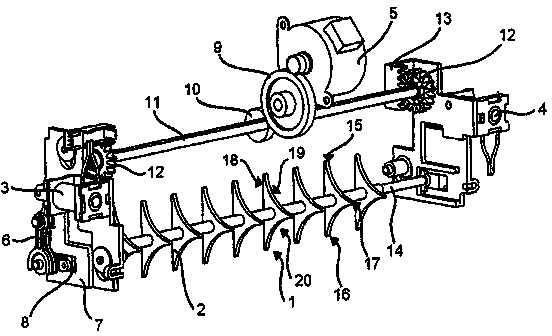

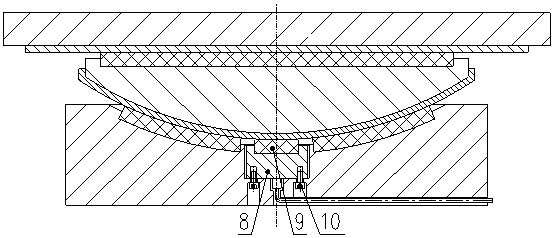

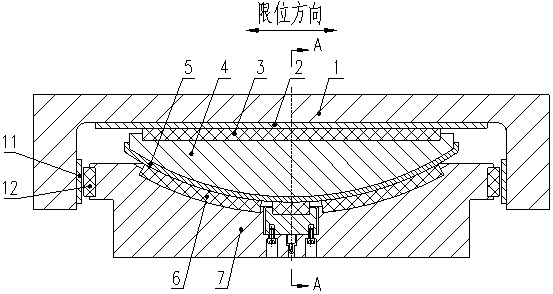

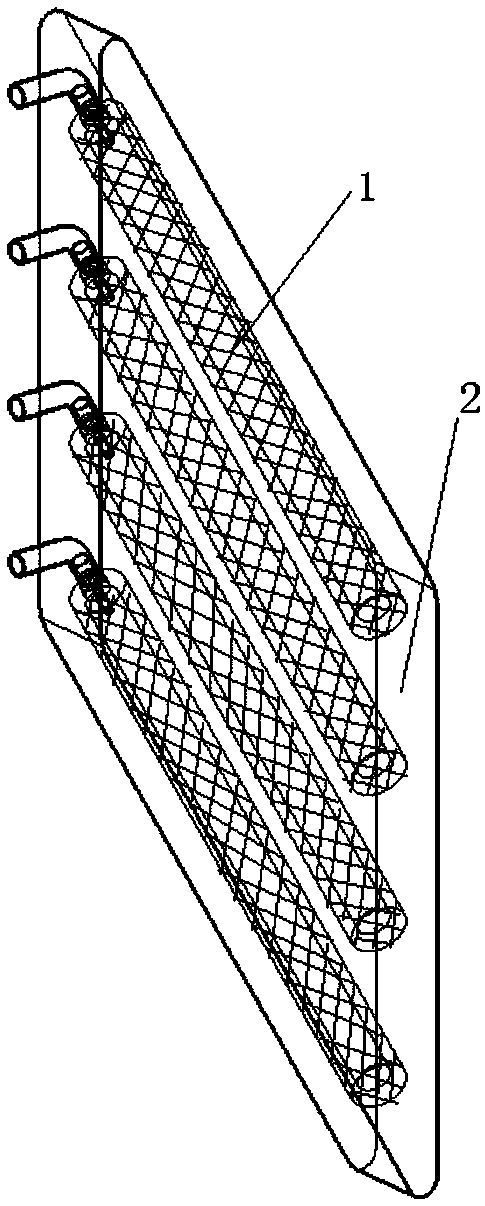

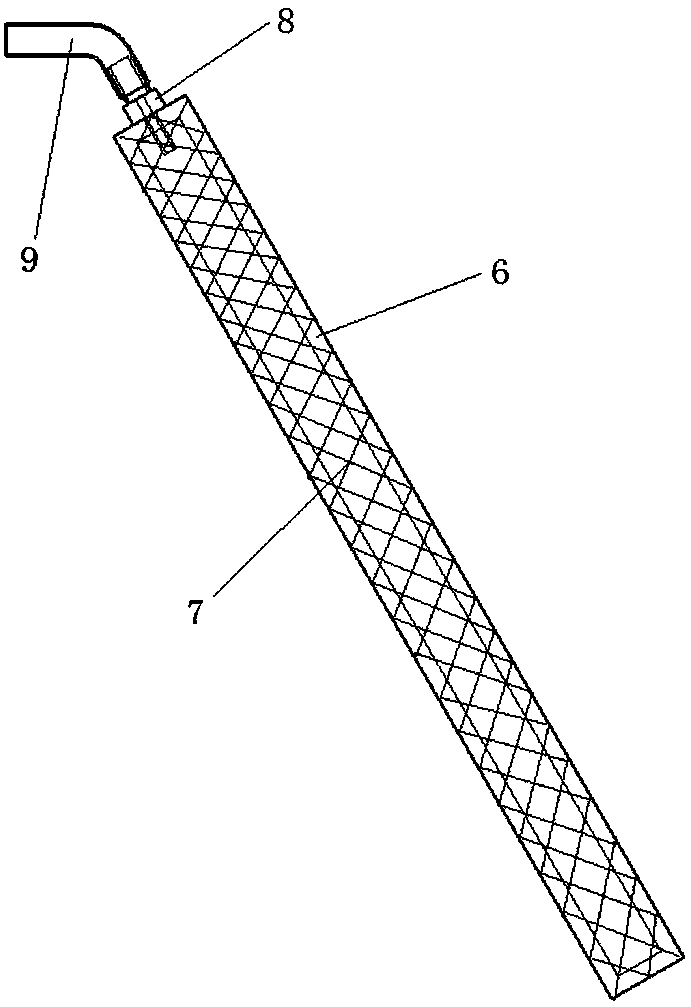

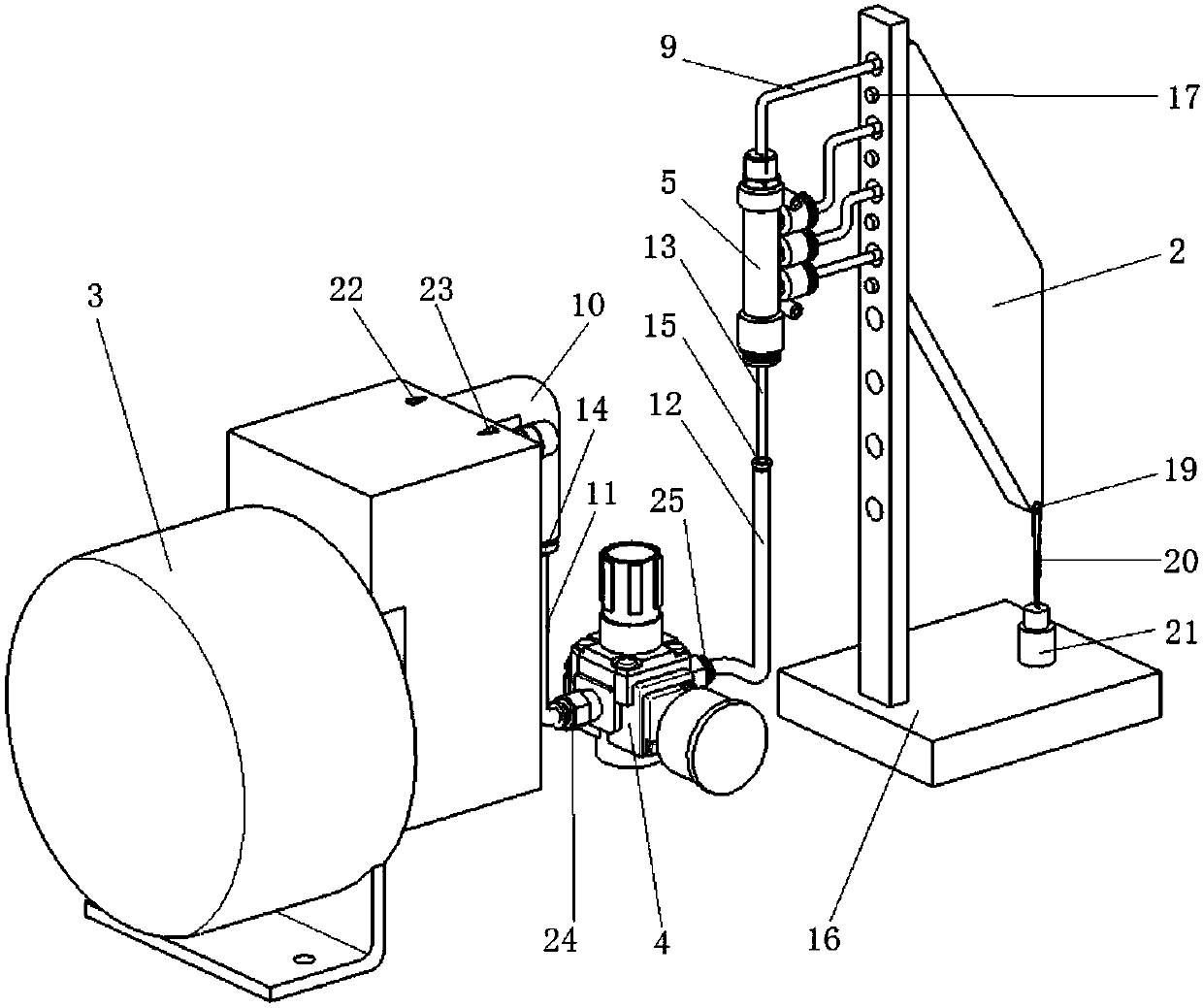

Assembly line production method for single crane boom and assembly line production device

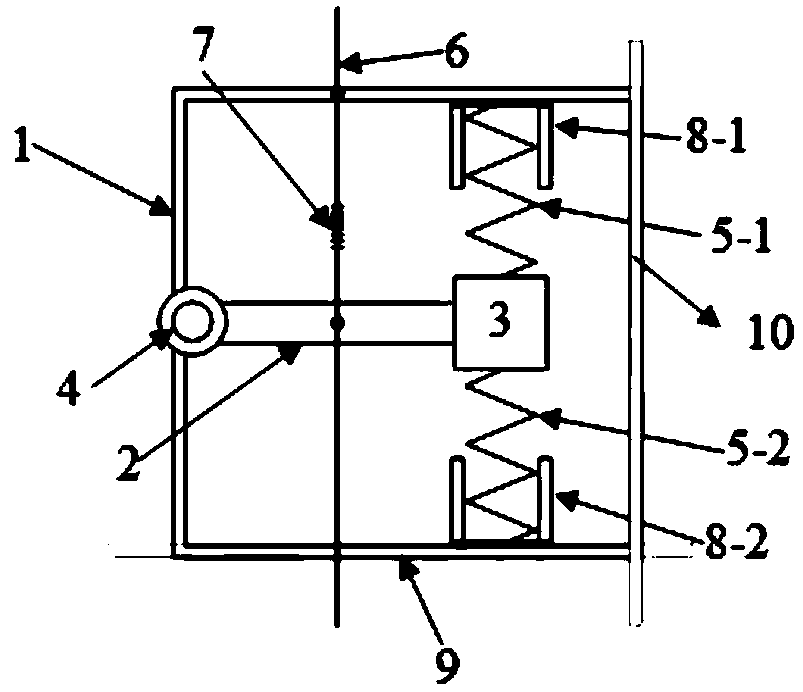

ActiveCN103692096ARealize automated productionReduce the amount of rotationWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringAssembly line

The invention discloses an assembly line production method for a single crane boom. The assembly line production method comprises the following steps of hanging an upper chord member and two lower chord members to a chord member conveying line for conveying the chord members, wherein one end of the upper chord member and one end of each of the lower chord members are welded with joints; when the chord members are conveyed to a swing welding station, feeding the chord members and a web member to an overall swing welding tool for performing swing arrangement and spot welding on all the parts to form a crane boom frame; hanging the crane boom frame from the overall swing welding tool to a carrying roller conveying line, conveying the crane boom frame to a crane boom frame welding station by the carrying roller conveying line, and firmly welding all the parts of the crane boom frame on the crane boom frame welding station; conveying the welded crane boom frame to a single section forming station through the carrying roller conveying line, hanging the crane boom frame to a single section forming tool, and spot-welding joints on the end parts, which are not provided with the joints, of the chord members to form a crane boom section; hanging the crane boom section from the single section forming tool to a plate chain conveying line, conveying the crane boom section to a crane boom section welding station by the plate chain conveying line, and firmly welding the joints and the chord members on the crane boom section welding station. The invention also provides an assembly line production device for the single crane boom.

Owner:ZOOMLION HEAVY IND CO LTD

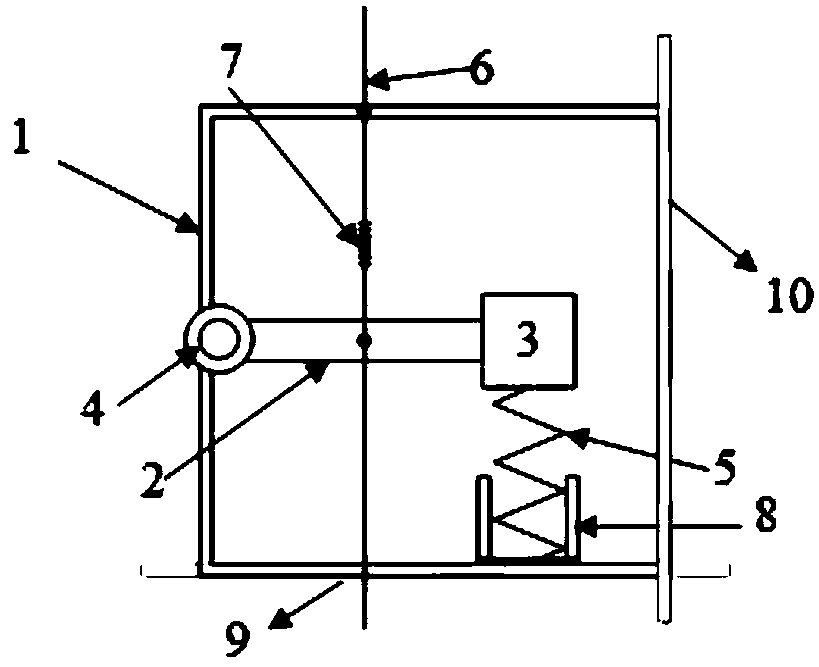

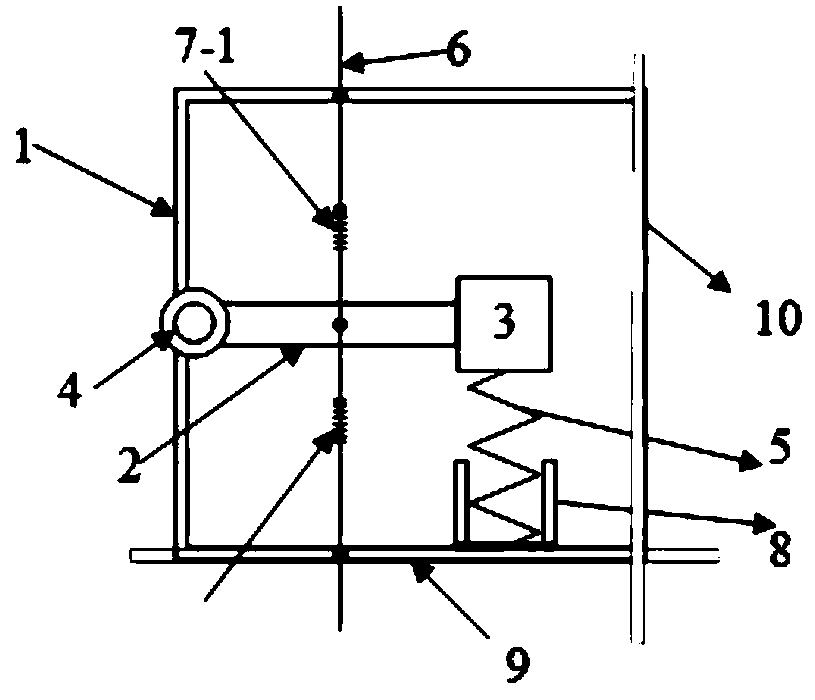

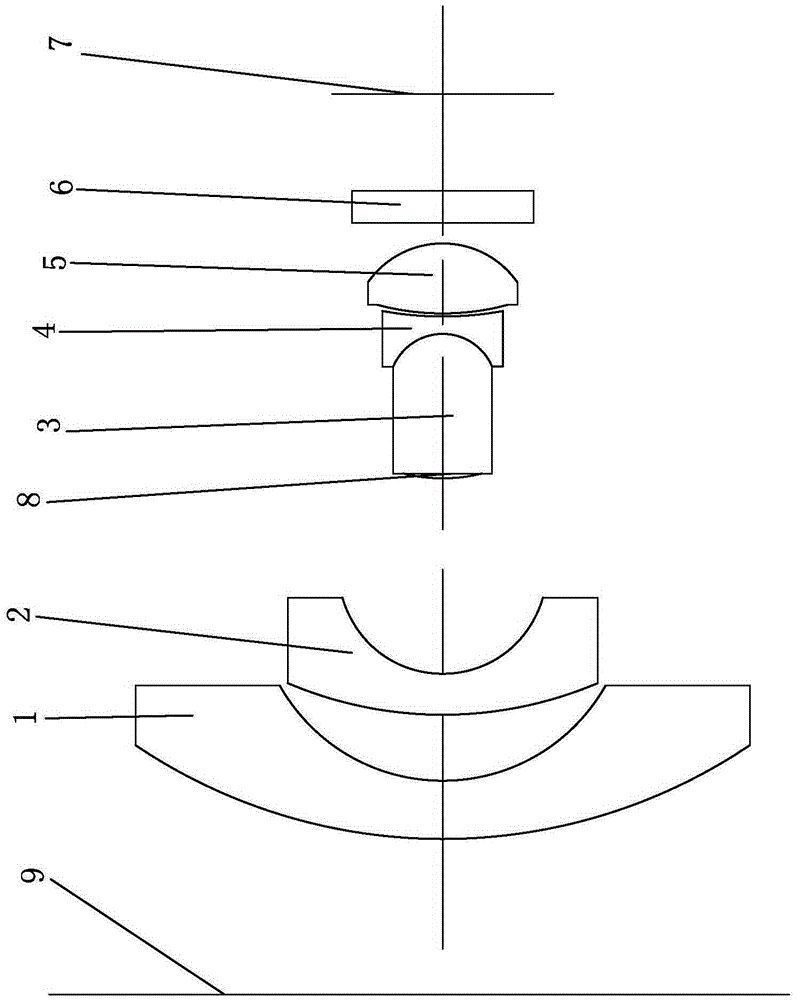

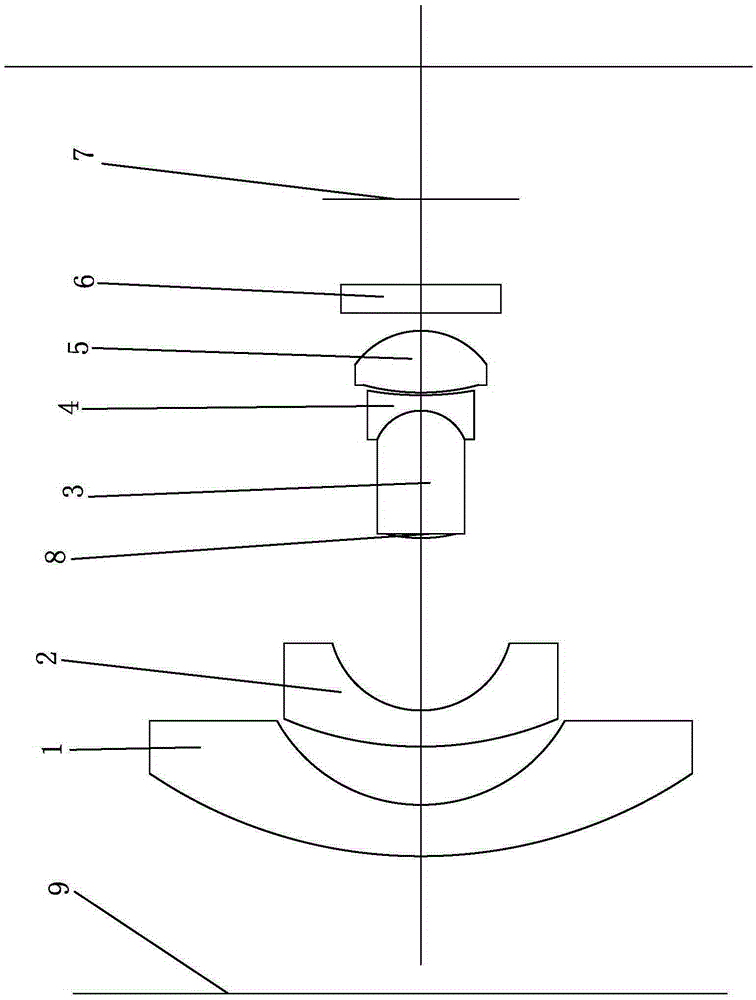

High-sensitivity fiber grating acceleration sensor

PendingCN108982916ASuppress lateral sensitivityHigh sensitivitySubsonic/sonic/ultrasonic wave measurementAcceleration measurementFiberGrating

The invention provides a high-sensitivity fiber grating acceleration sensor, which belongs to the technical field of vibration monitoring. The high-sensitivity fiber grating acceleration sensor comprises a measurement substrate A or a measurement substrate B, a rigid beam and a balance spring, wherein the balance position of the rigid beam is basically parallel with the measurement substrate A orbasically vertical to the measurement substrate B; one end of the rigid beam is hinged with a frame body fixedly connected with the measurement substrate A or the measurement substrate B through a rotating shaft, and the other end of the rigid beam is fixed with a mass block; one side of the rigid beam or the mass block is provided with the balance spring for enabling the rigid beam to be in a balance position; one side or two sides of the rigid beam is or re provided with one or two fiber gratings; and when the measurement substrate A or the measurement substrate B vibrates along with a monitored piece, the fiber grating can directly sense the vibration information of the rigid beam. The sensor sensitivity is improved obviously, the transverse sensitivity of the acceleration sensor can beeffectively suppressed, and the high-sensitivity fiber grating acceleration sensor has the advantages of simple structure, durability, not easy damage, small dynamic errors, accurate measurement, high sensitivity, high accuracy and high efficiency.

Owner:SHIJIAZHUANG TIEDAO UNIV

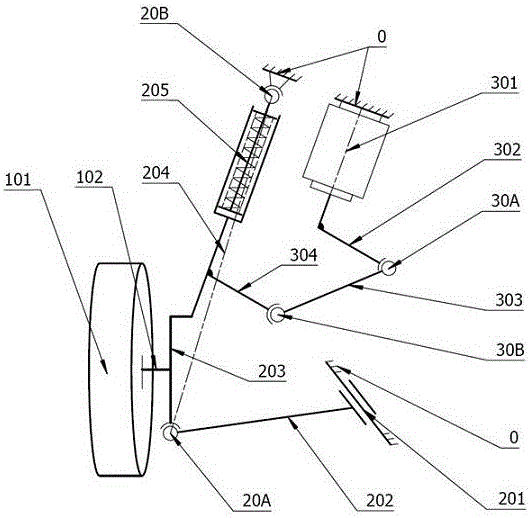

Double-crank transmission Macphersan wiring control independent steering system

ActiveCN106541986ALess impact on unsprung massLittle changeSteering linkagesElectrical steeringVehicle frameSteering angle

The invention provides a double-crank transmission Macphersan wiring control independent steering system which comprises a frame, wheels, an axle, a Macphersan suspension connecting rod guide mechanism, a steering motor and a space double-crank transmission mechanism. The system has the beneficial effects of being beneficial for manipulation stability of a vehicle and high in universality. The space double-crank mechanism is adopted, motor output power is transferred to a knuckle efficiently, and the knuckle can rotate around a main hinge pin line to achieve steering. By adjusting the length of a connecting rod, the wheel rotating amount caused by wheel hopping is reduced, kinds of key parts are reduced greatly, and the batch manufacturing cost is reduced. The system has the beneficial effects of being large in independent steering angle range of the wheels, simple in structure, reliable in work, convenient to assemble and low in cost.

Owner:TONGJI UNIV

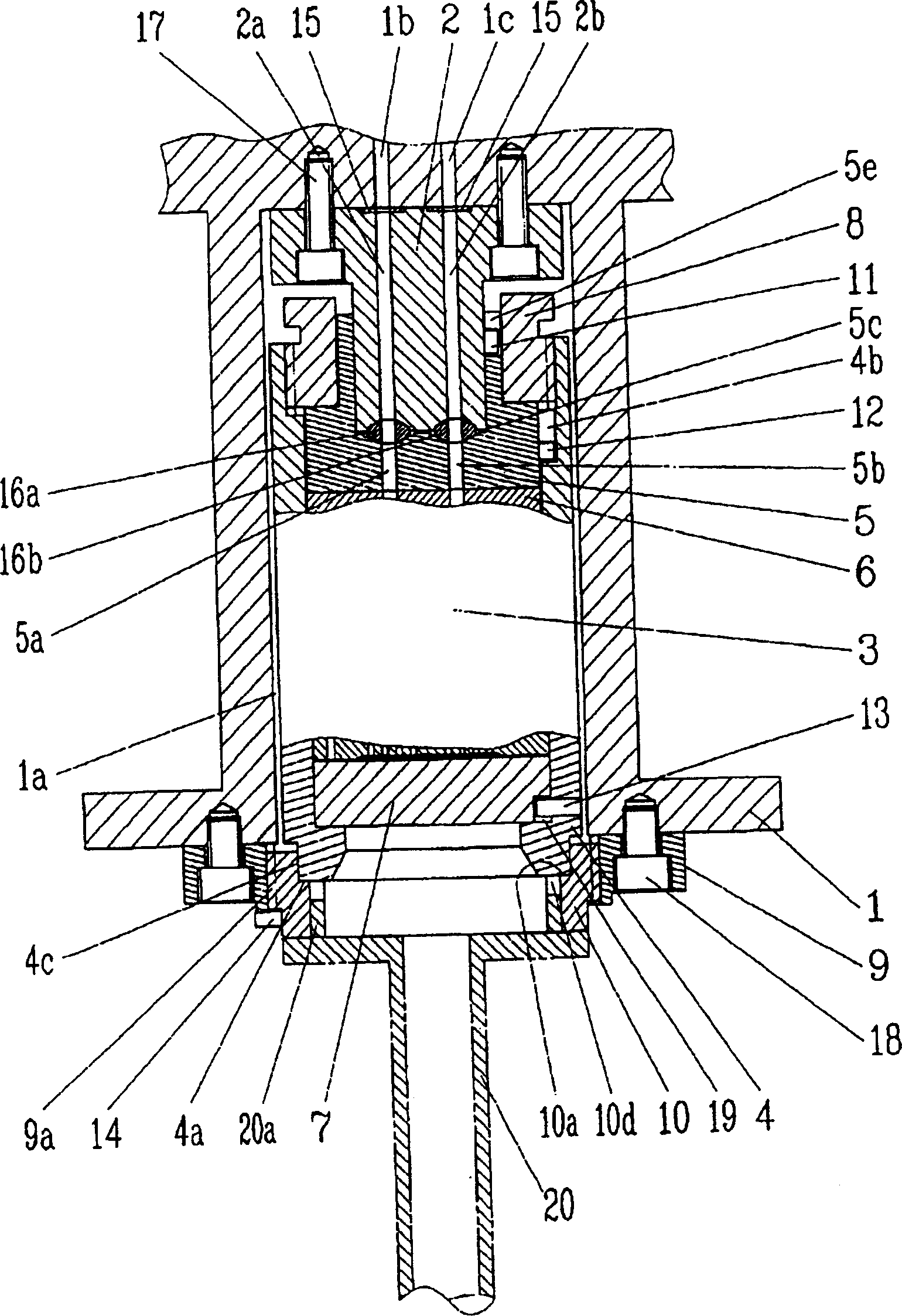

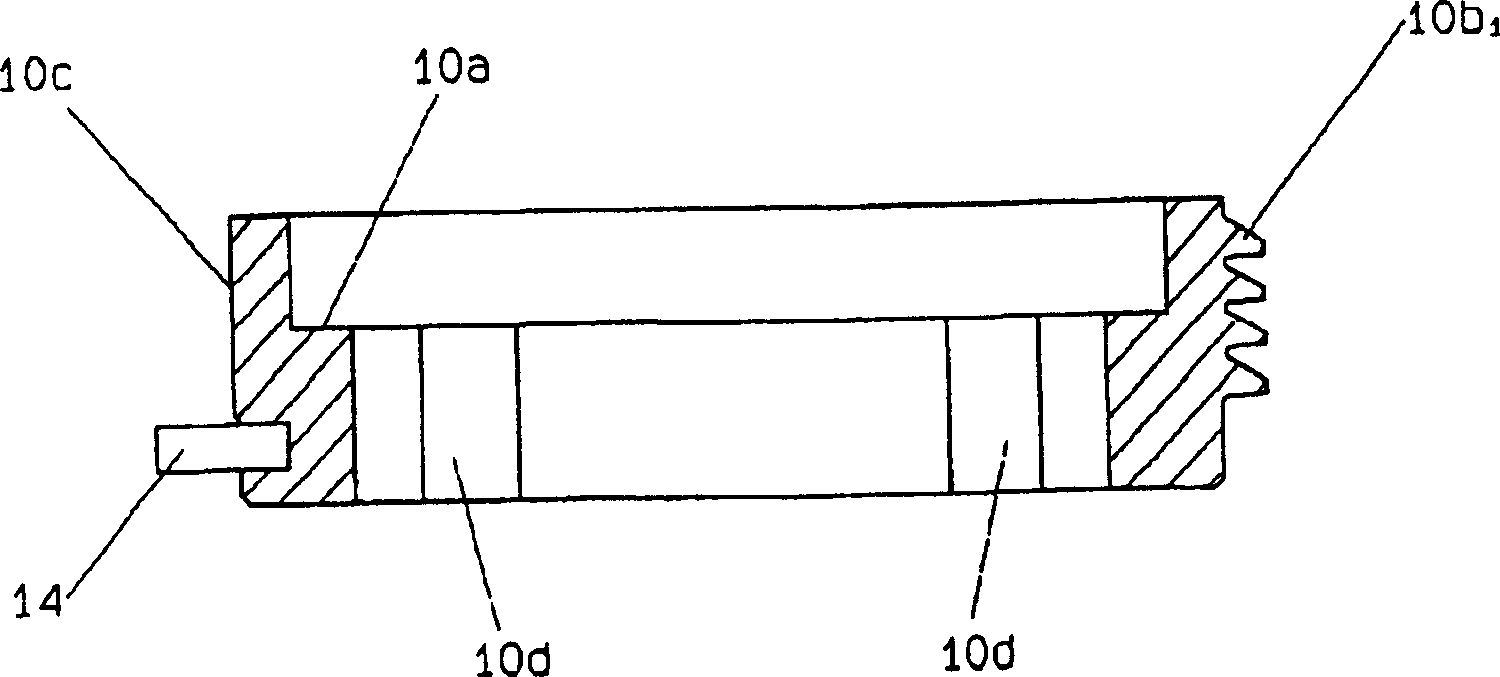

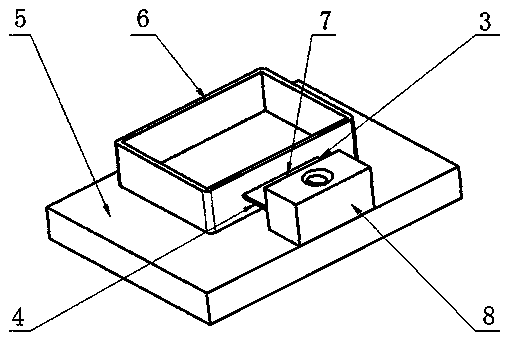

Melt spinning apparatus

InactiveCN1455031ADon't worry about damageEasy to handleSpinnerette packsMelt spinning methodsEngineeringPolymer

The invention provides a melt-spinning device which can prevent the damage to a pack body, can press up a spinning pack to mount the spinning pack in a spinning pack receiver without rotating the spinning pack, can surely coincide polymer passages each other even in a case of a plurality of the polymer passages, and can always arrange the nozzle of a spinneret at a fiber-arranging position optimizing the cooling of the fiber with a cooling gas flow. This melt-spinning device is assembled by preliminarily heating the spinning pack into which a polymer guide member 5 is incorporated, fitting the lower step portion 4c of the spinning pack body 4 into the holding face 10a of a holder 10 mounted on a spinning pack-mounting tool 20, placing inlet packings 16a, 16b on the polymer guide member 5, and pressing up the spinning pack-mounting tool 20 to insert the spinning pack 3 into the spinning pack receiver 1a, and threadedly engaging the holder 10 with a screw member 9 to hold the spinning pack 3 at a prescribed position.

Owner:TORAY ENG CO LTD

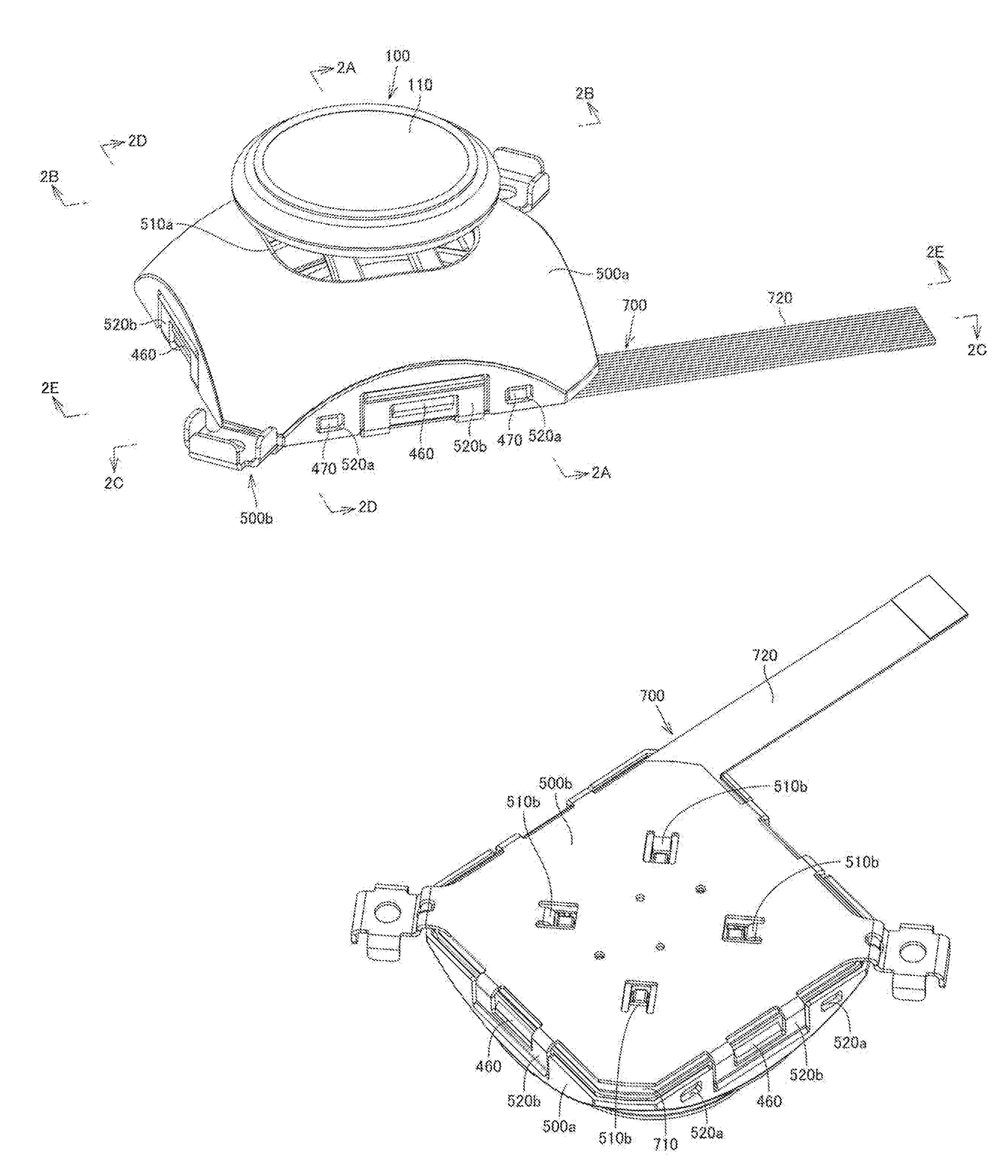

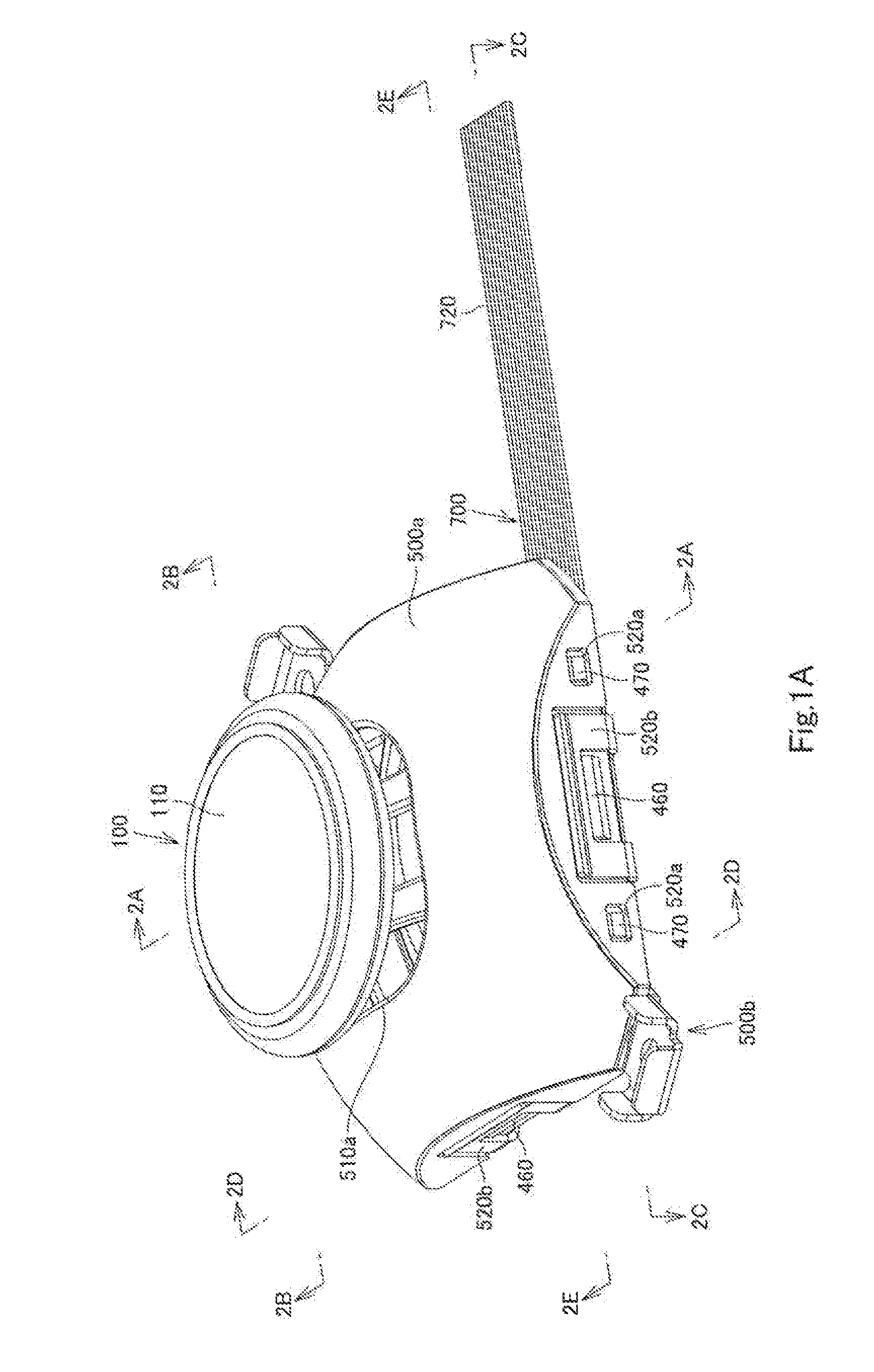

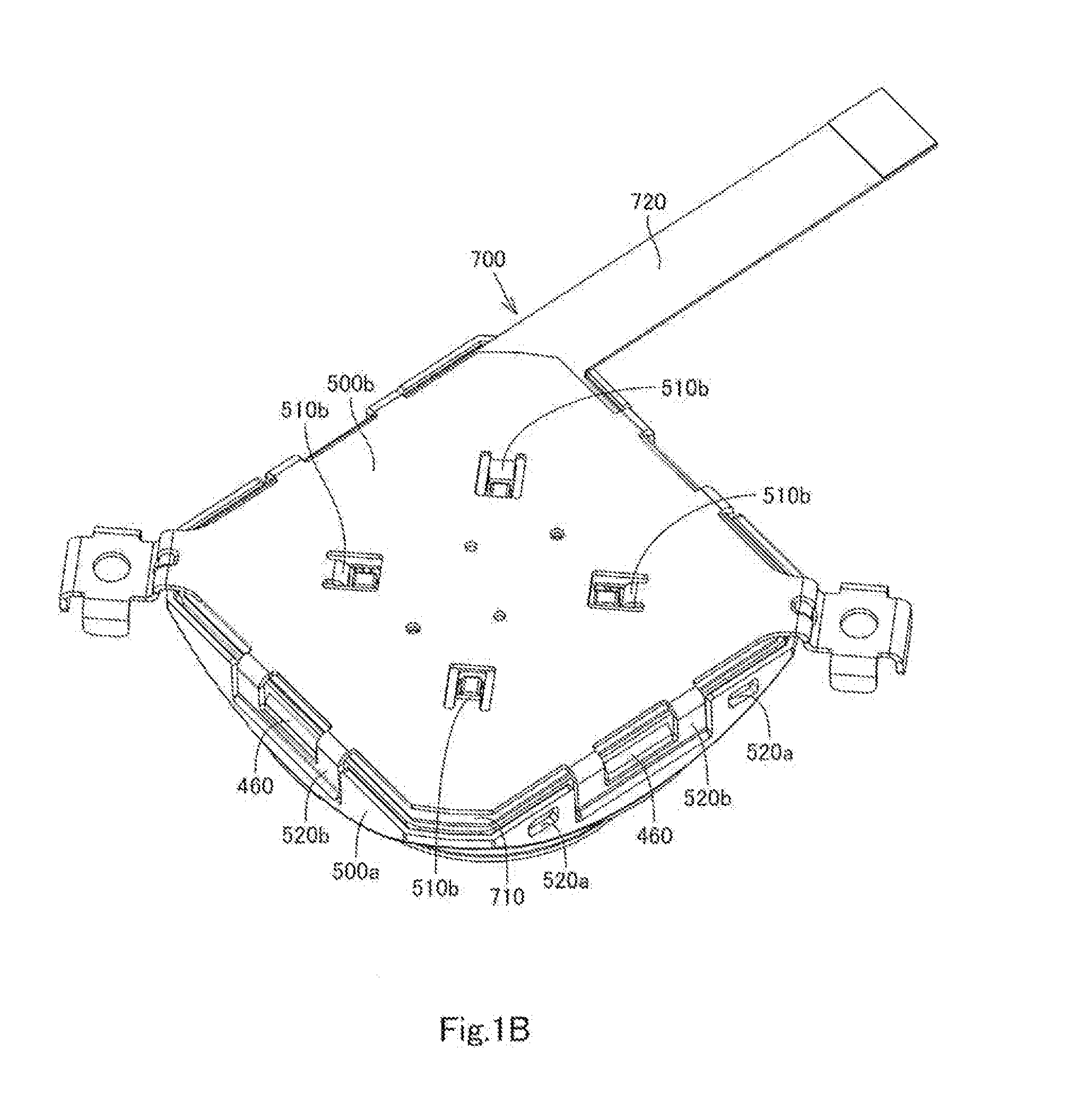

Multidirectional input device

ActiveUS20150198964A1Enhanced couplingWay stableManual control with multiple controlled membersMechanical apparatusEngineeringMechanical engineering

A multidirectional input device includes a mount, an operation lever, first and second interlocking members, and first and second detectors. The mount includes a support face of generally spherical convex shape. The operation lever is slidably supported on the support face. The first interlocking member receives the operation lever therethrough and is movable in a first direction in an arc-like manner in accordance with movement in the first direction of the operation lever. The second interlocking member crosses the first interlocking member, receives the operation lever therethrough, and is movable in a second direction in an arc-like manner in accordance with movement in the second direction of the operation lever the second direction crossing the first direction. The first detector can detect a direction and an amount of movement of the first interlocking member. The second detector can detect a direction and an amount of movement of the second interlocking member.

Owner:HOSIDEN CORP

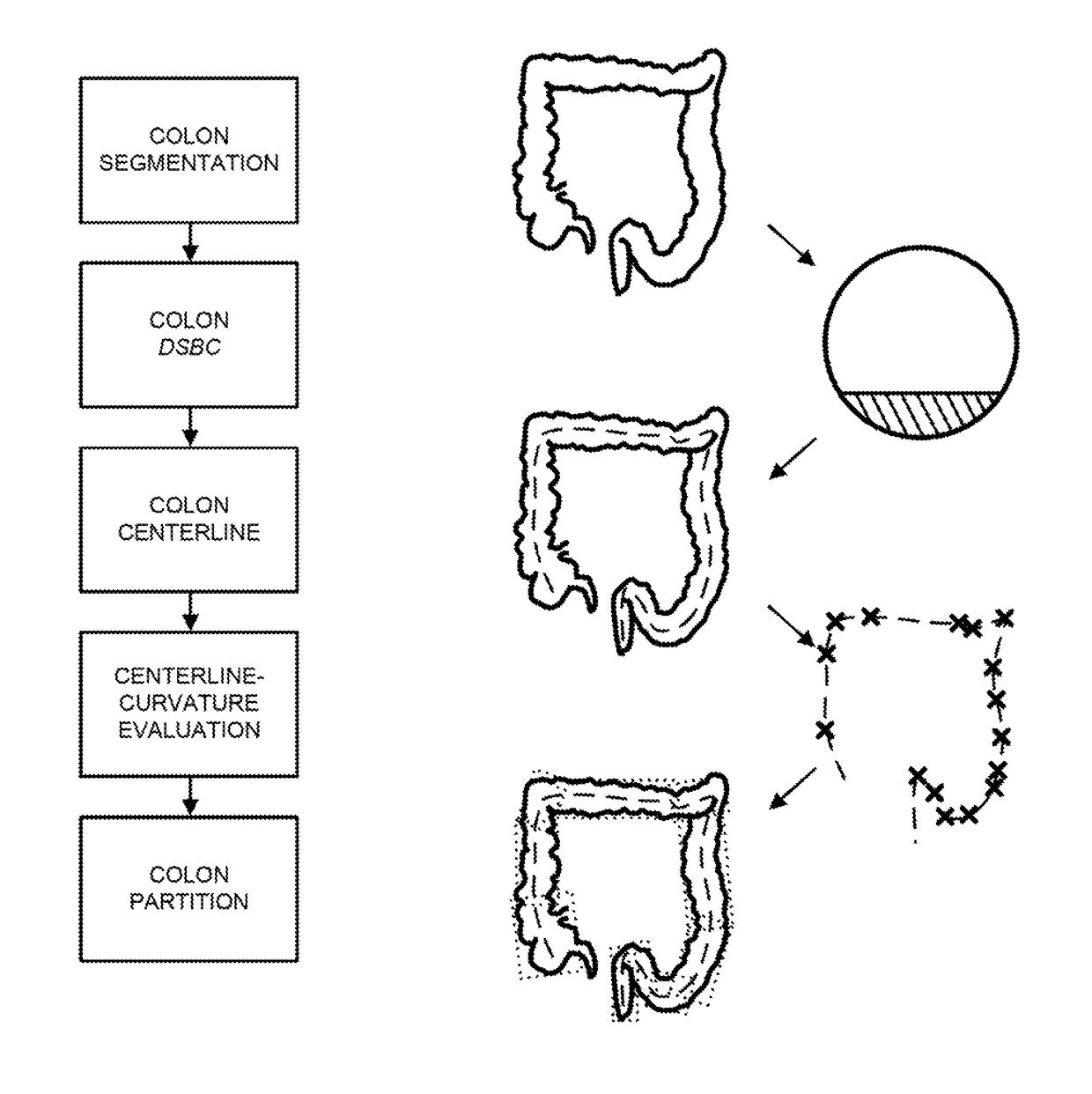

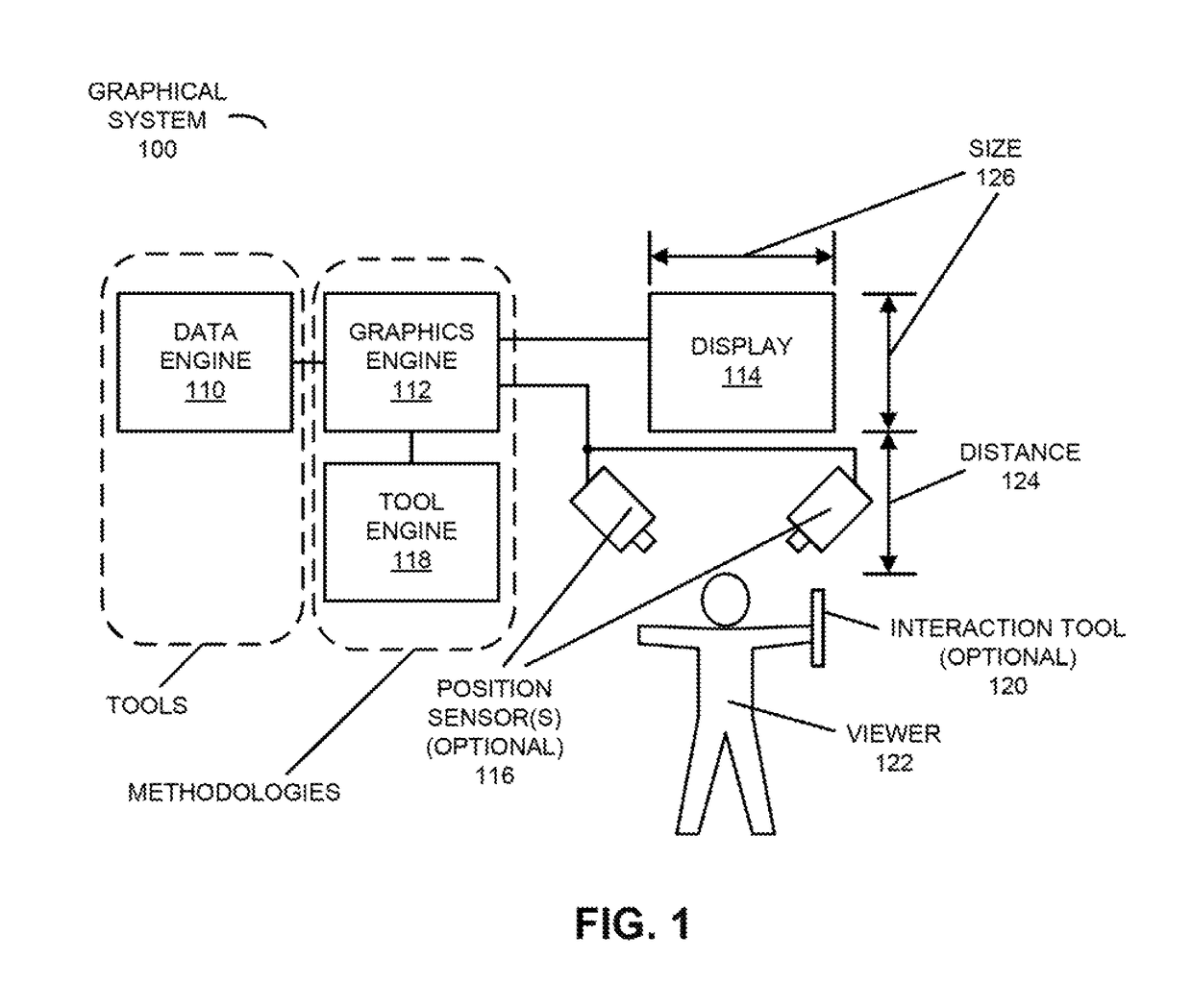

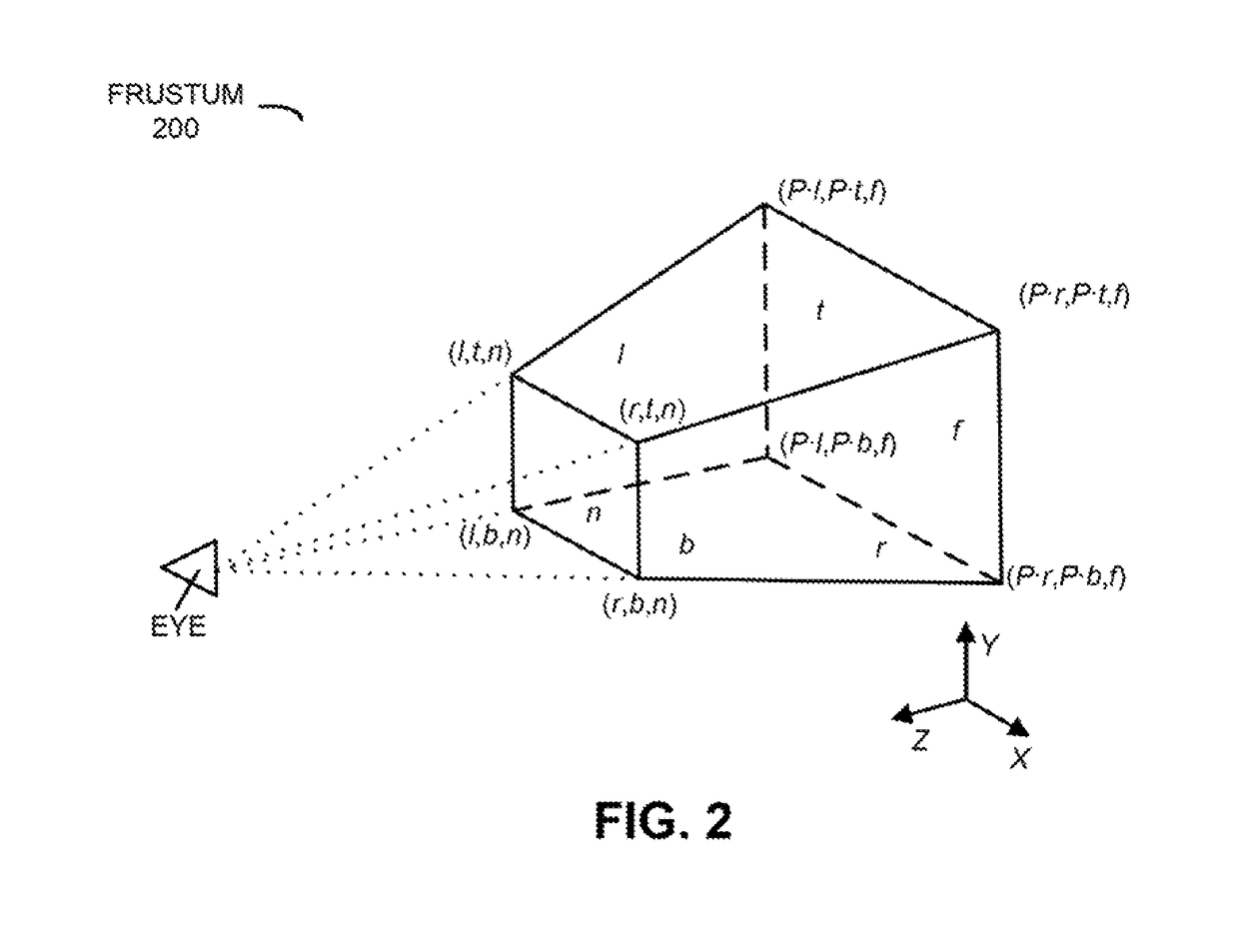

Enhanced computed-tomography colonography

ActiveUS9830700B2Reduce the amount of rotationEfficient analysisInput/output for user-computer interactionImage enhancementTortuosityImaging data

A computer system that segments a colon for a computed tomography colonography (CTC) is described. During operation, the computer system accesses imaging data having a spatial resolution. Then, the computer system identifies the colon lumen based on probabilities for different tissue classes in the imaging data. Moreover, the computer system segments the colon into subsegments based on an articulated object model that fits a tortuosity of the colon along a centerline of the colon, where the articulated object model includes values of an orthonormal basis set, curvature and torsion along the centerline, and where boundaries between subsegments are based on the curvature and the torsion. For example, a given boundary between a pair of subsegments may corresponds to or may be related to a minimum value of the curvature and a maximum value of the torsion over a length of the colon.

Owner:YEE JUDY +2

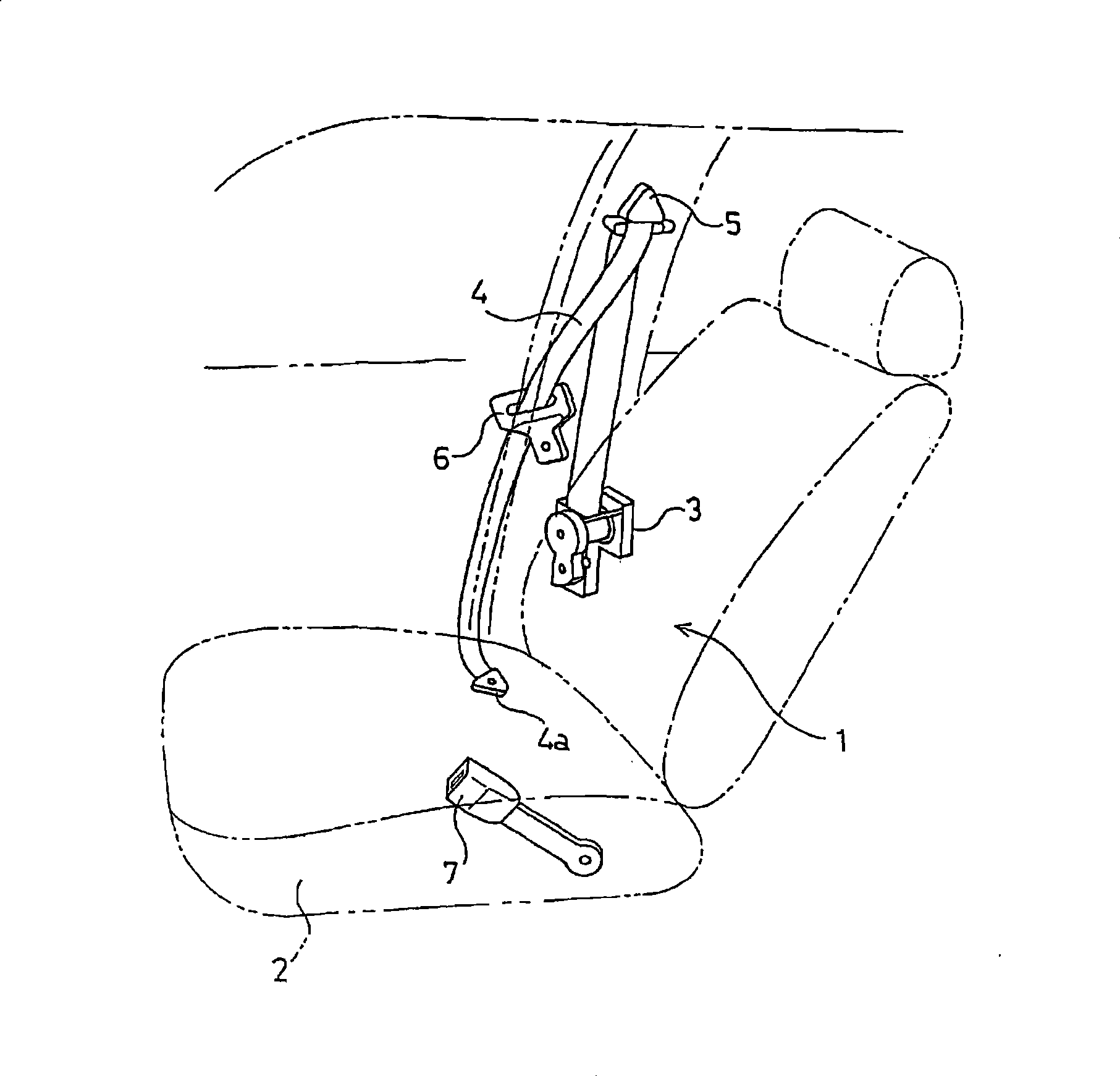

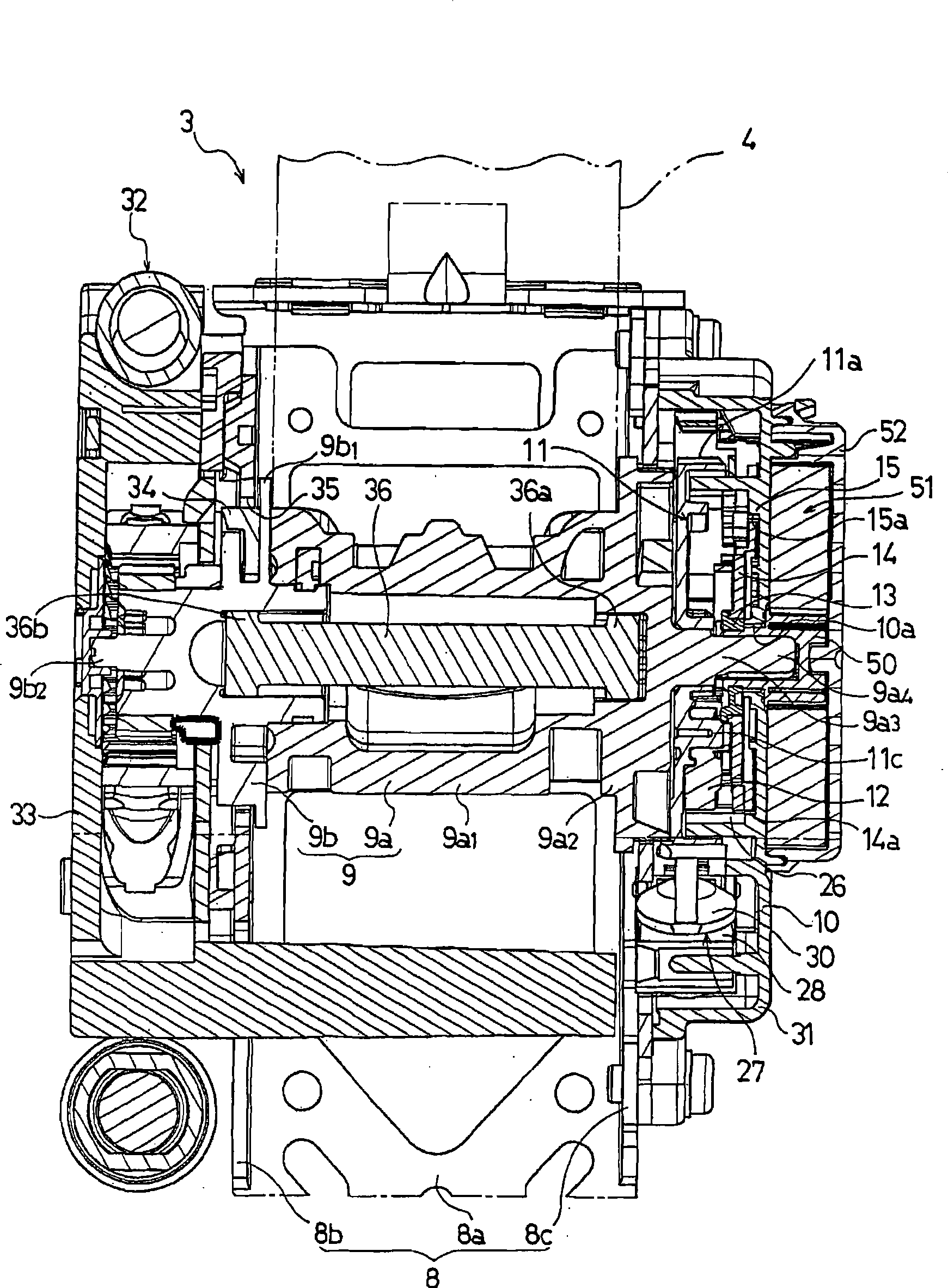

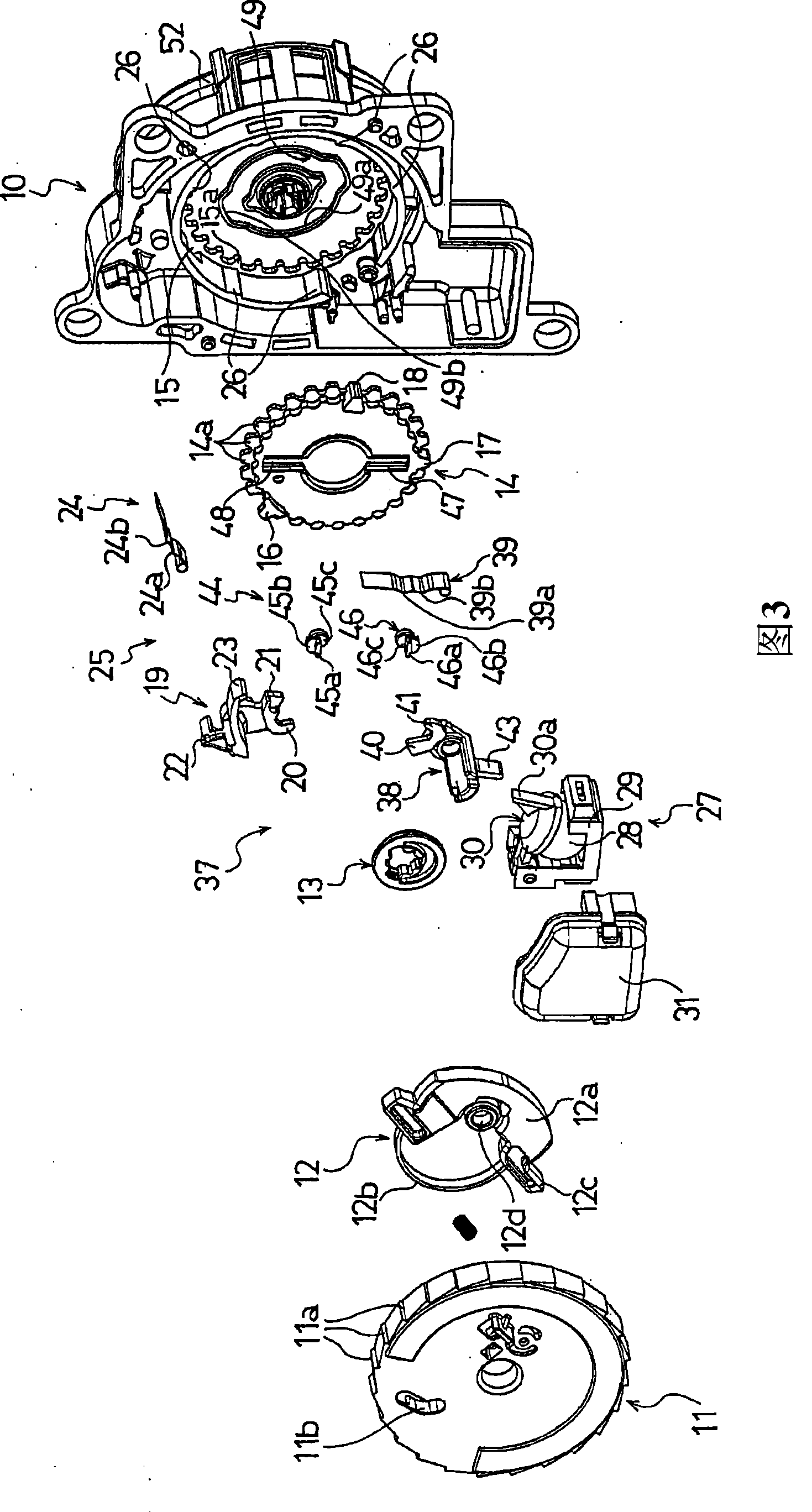

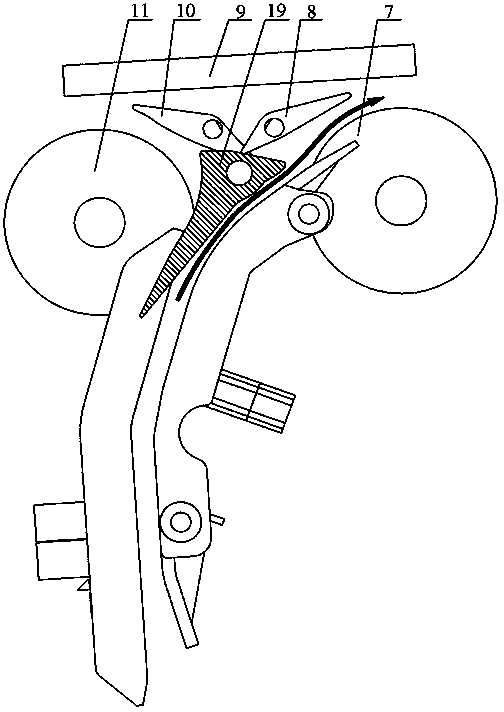

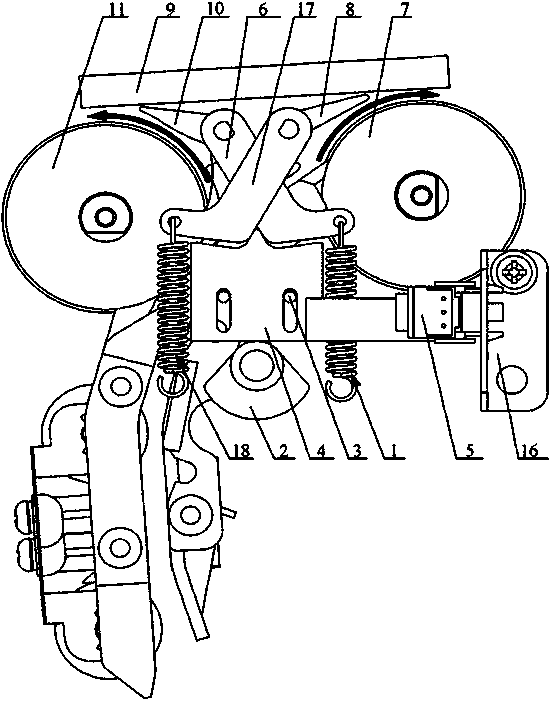

Seat belt retractor and seat belt apparatus employing the same

InactiveCN101380934AReduce the amount of rotationSimple structureBelt retractorsSeat beltEngineering

The inventive safety belt retractor and safety belt device including the safety belt retractor can effectually prevent end-locking caused by pulling out a sensor via the safety belt, and can form a structure preventing the end-locking with a smaller and compacter configuration. When an eccentric gear (14) rotates along with retraction or pull-out of the safety belt, a pair of stop components (45, 46) are controlled by a cam slot (49) provided on a casing (10), guide slots (47, 48) of the eccentric gear (14) along an ELR-ALR switching mechanism is movable in a diameter direction of a reel. At the time of approximately totally retracting the safety belt, the stop components (45, 46) are located in large-diameter side arc slots (49c, 49d), thus pressing inner circumference of a ring section (12b) to prevent swing of inertia wheels (12). Besides, in case of pulling out the completely-retracted safety belt by a prescribed amount, the stop components (45, 46) are located in small-diameter side arc slots (49a, 49b), thus not pressing the inner circumference of the ring section (12b) to enable free swing of the inertia wheels (12).

Owner:TAKATA CORPORATION

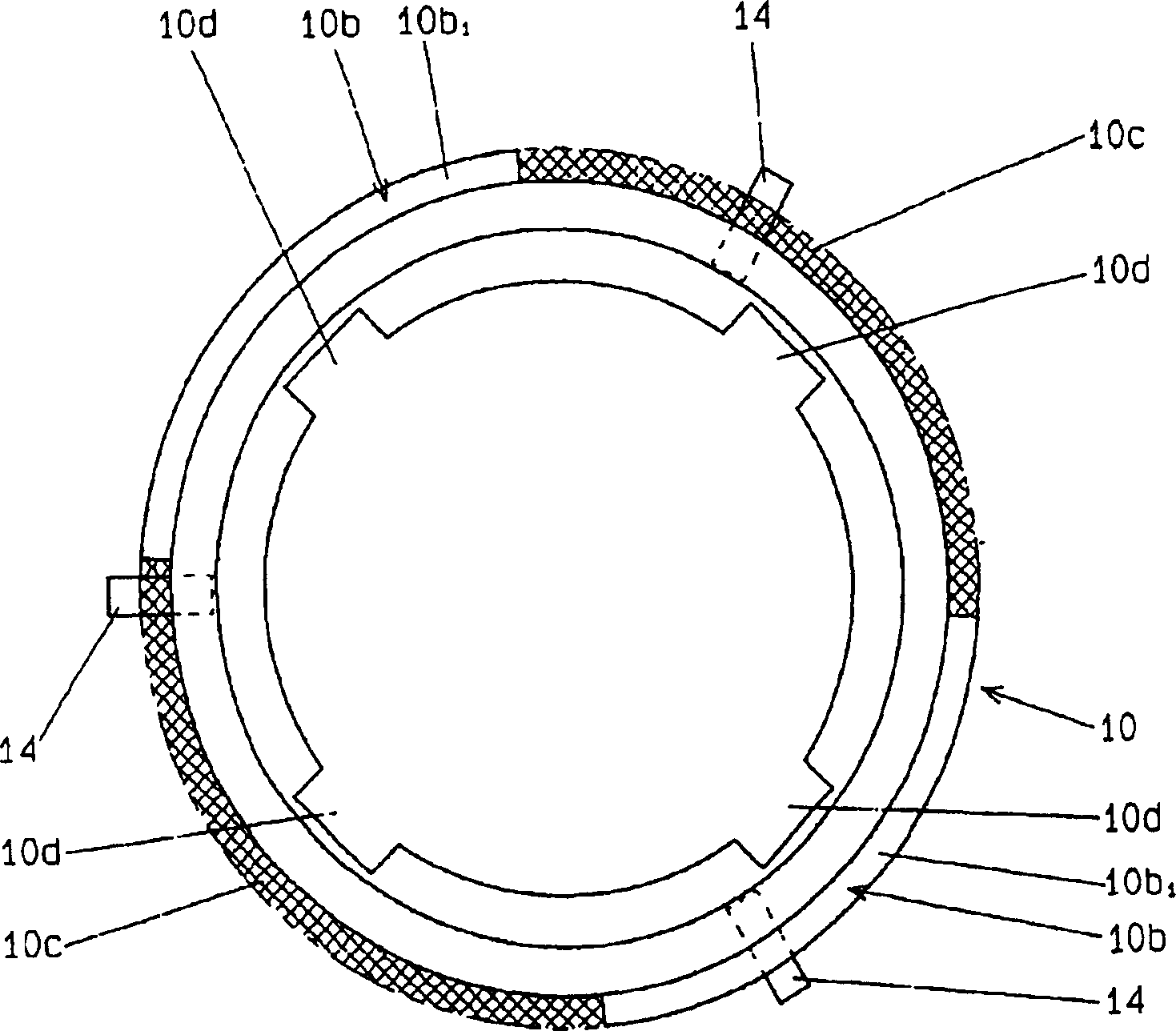

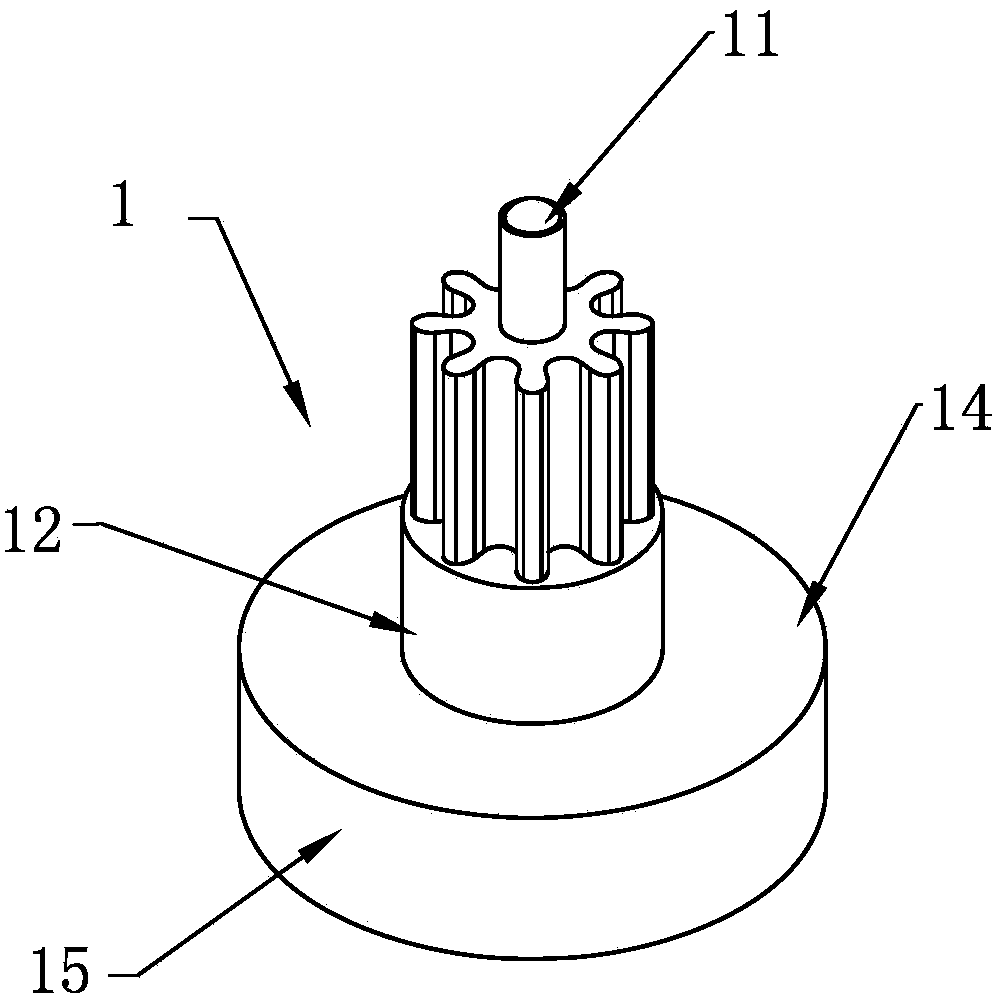

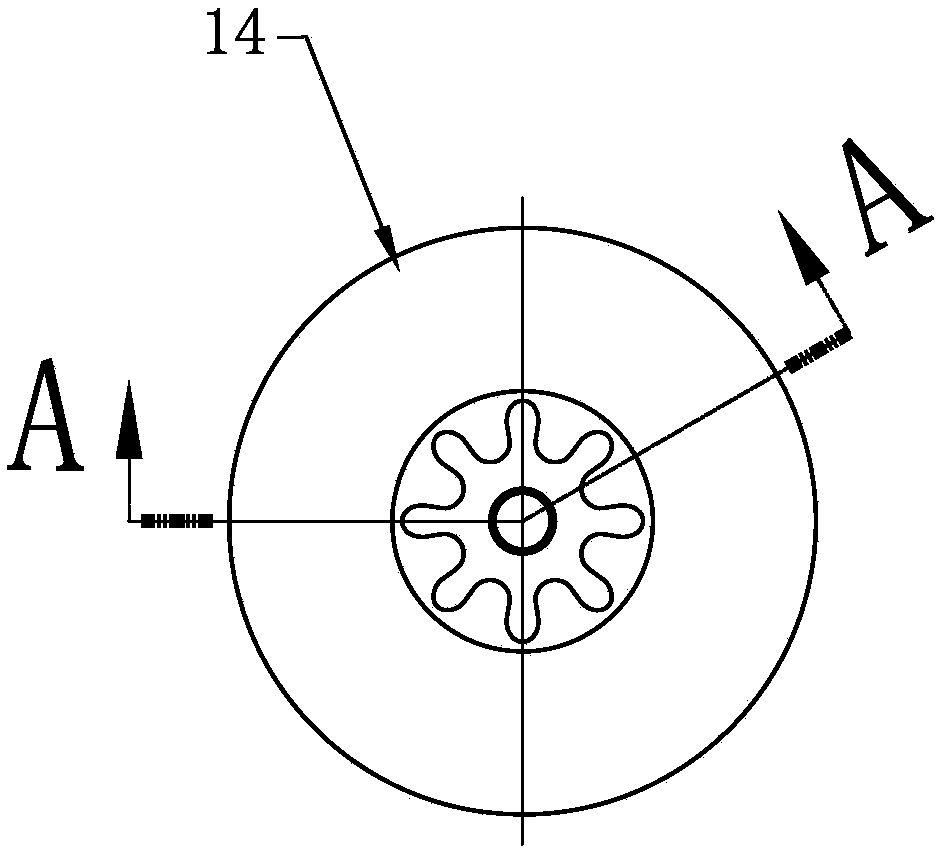

Quartz clock and watch rotor wheel

ActiveCN103840587AReduce the amount of rotationReduce the thickness of the wall 15Magnetic circuit rotating partsElectric windingEngineeringMechanical engineering

The invention discloses a quartz clock and watch rotor wheel which is low in starting voltage and power consumption. The rotor wheel comprises a wheel disc, wherein the edge of the cross section of the wheel disc is provided with at least three symmetric edge lugs which are the same in thickness, the outmost edges of all the edge lugs are located on the same excircle with the axis of the wheel disc as a center, and the wall thickness of the largest transverse portion of each edge lug is 0.01 mm-0.3 mm larger than that of other portions of the disc wall of the wheel disc. According to the rotor wheel, on the condition that injection molding is safely formed, the thickness of the disc wall of the wheel disc is effectively reduced, and accordingly the weight is correspondingly reduced, namely rotation inertia of the rotor wheel can be effectively reduced; due to the action of the edge lugs, during assembling, the inclination angle of the rotor wheel is smaller than the inclination angle of a rotor wheel which is assembled in the prior art. On the condition that identical materials and magnetic steel are used, the rotation inertia of the rotor wheel is effectively reduced, and accordingly the starting voltage and the power consumption are low; additionally, the rotation inertia is small, and accordingly the rotor wheel is reliable when moving.

Owner:吴中一

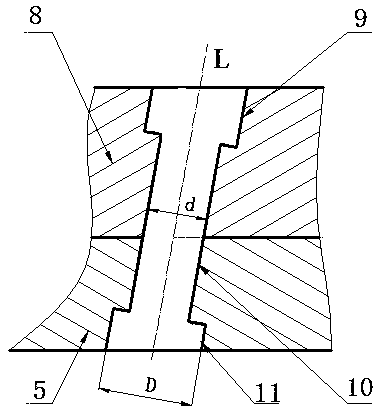

Crank press ball head screw and spherical bowl combined grinder

InactiveCN106737124AReduce the amount of rotationReduce speedLapping machinesEngineeringMachine press

The invention provides a crank press ball head screw and spherical bowl combined grinder. The grinder comprises a power source, a ball head driving mechanism and a spherical bowl driving mechanism, wherein the spherical bowl driving mechanism comprises a gear and worm mechanism, a second belt pulley, a spherical bowl support and a bowl opening baffle; grinding sand is placed in a spherical bowl cavity; a ball head end of the ball head screw is placed at the spherical bowl cavity and comprises a ball head and a ball head cover plate at the rear of the ball head; the bowl opening baffle limits the ball head end; the spherical bowl support rotates synchronously along with a worm gear; a worm of a gear and worm mechanism is connected with the second belt pulley and is driven by the second belt pulley; the ball head driving mechanism comprises a support, a third belt pulley and an eccentric connecting rod mechanism; the eccentric connecting rod mechanism drives the support to swing in a reciprocating manner; a positioning frame is arranged at the upper edge of the support; a positioning through hole is formed in the positioning frame; the body of the ball head screw penetrates in the positioning through hole; and when the support drives the body to swing, the ball head rotates at the bowl cavity in the left-right direction. The crank press ball head screw and spherical bowl combined grinder can be used for rapidly grinding the ball head of the ball head screw and the spherical bowl cooperated with the ball head.

Owner:FUZHOU UNIV

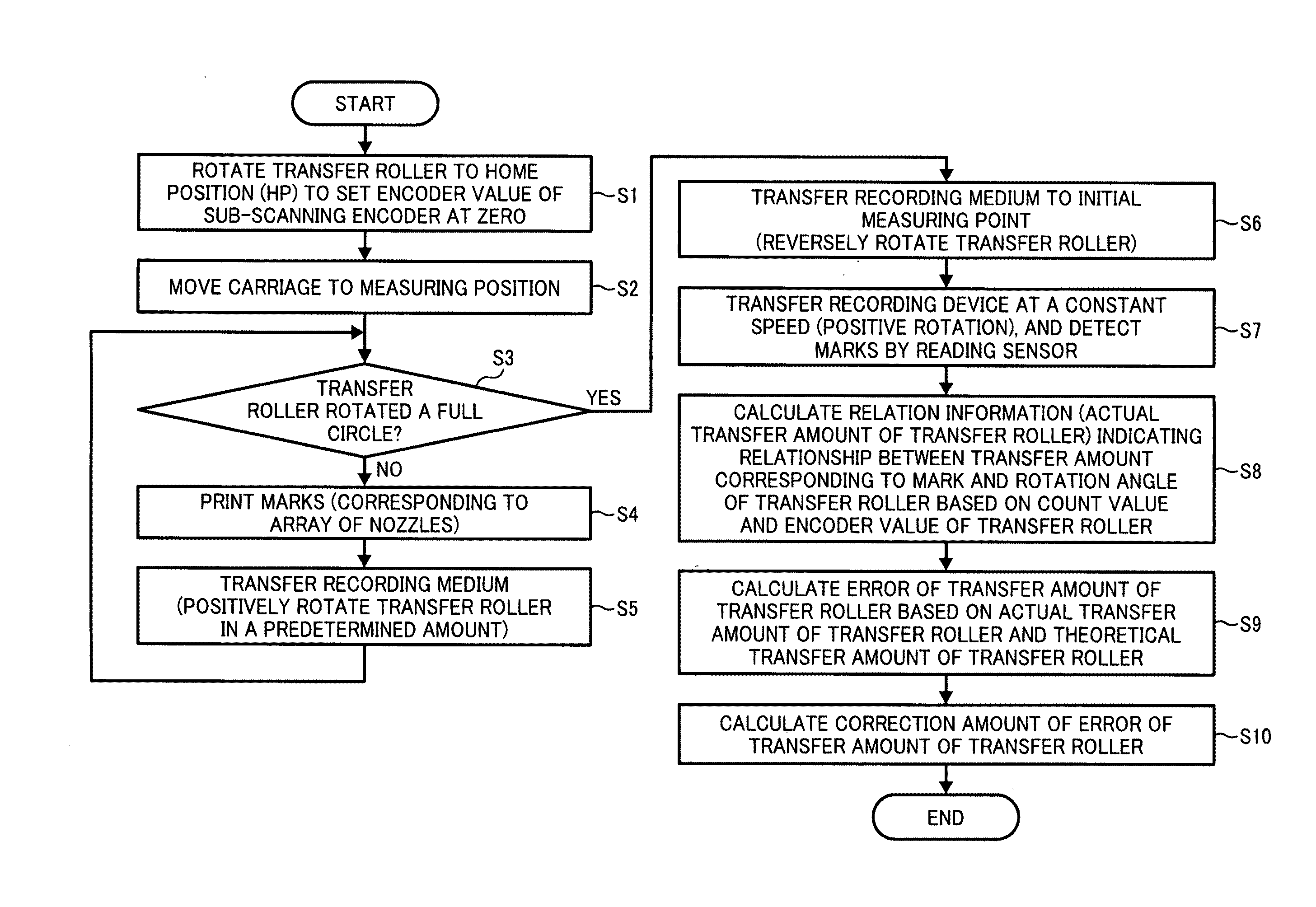

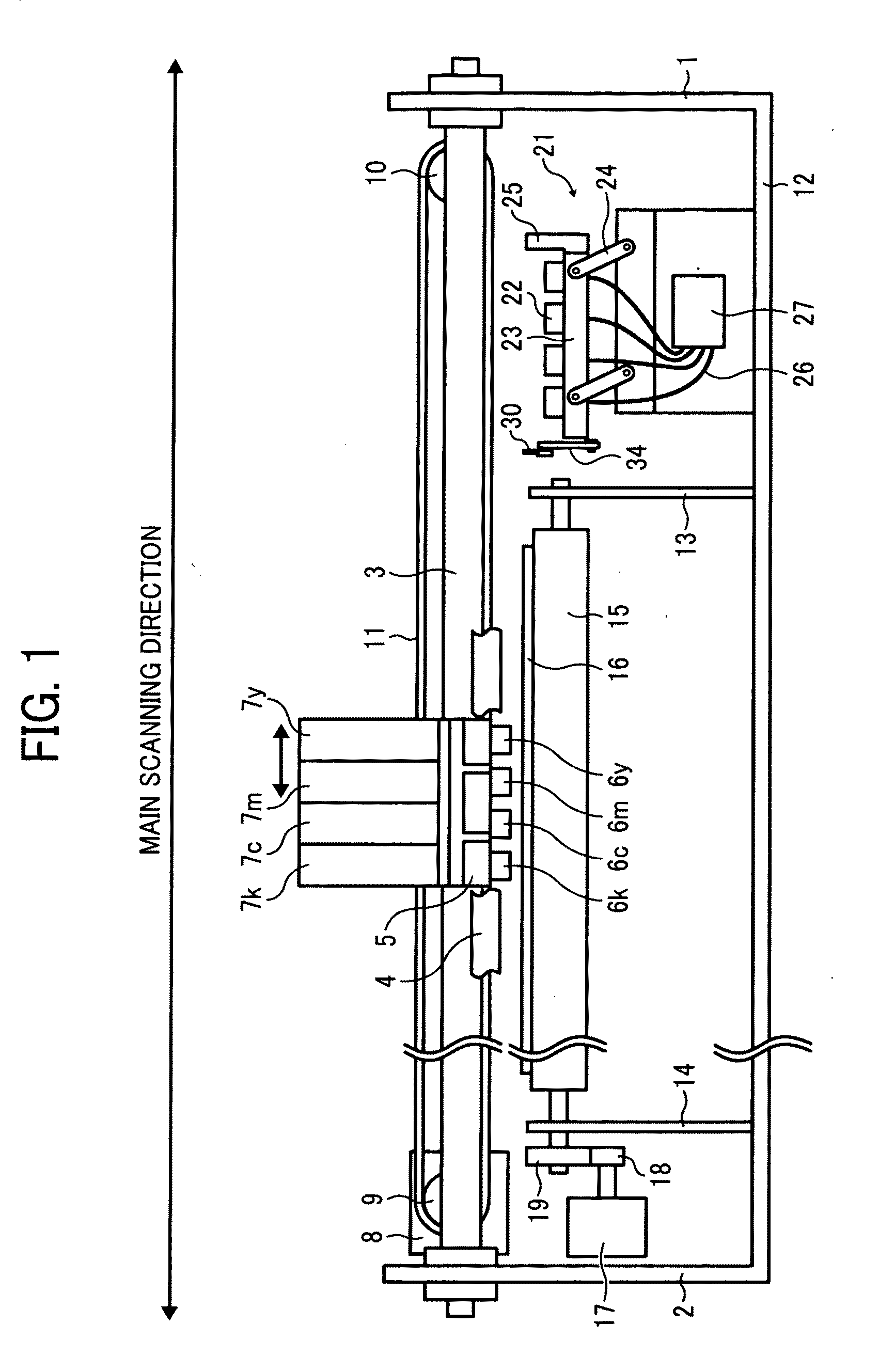

Recording device, control method, and recording medium

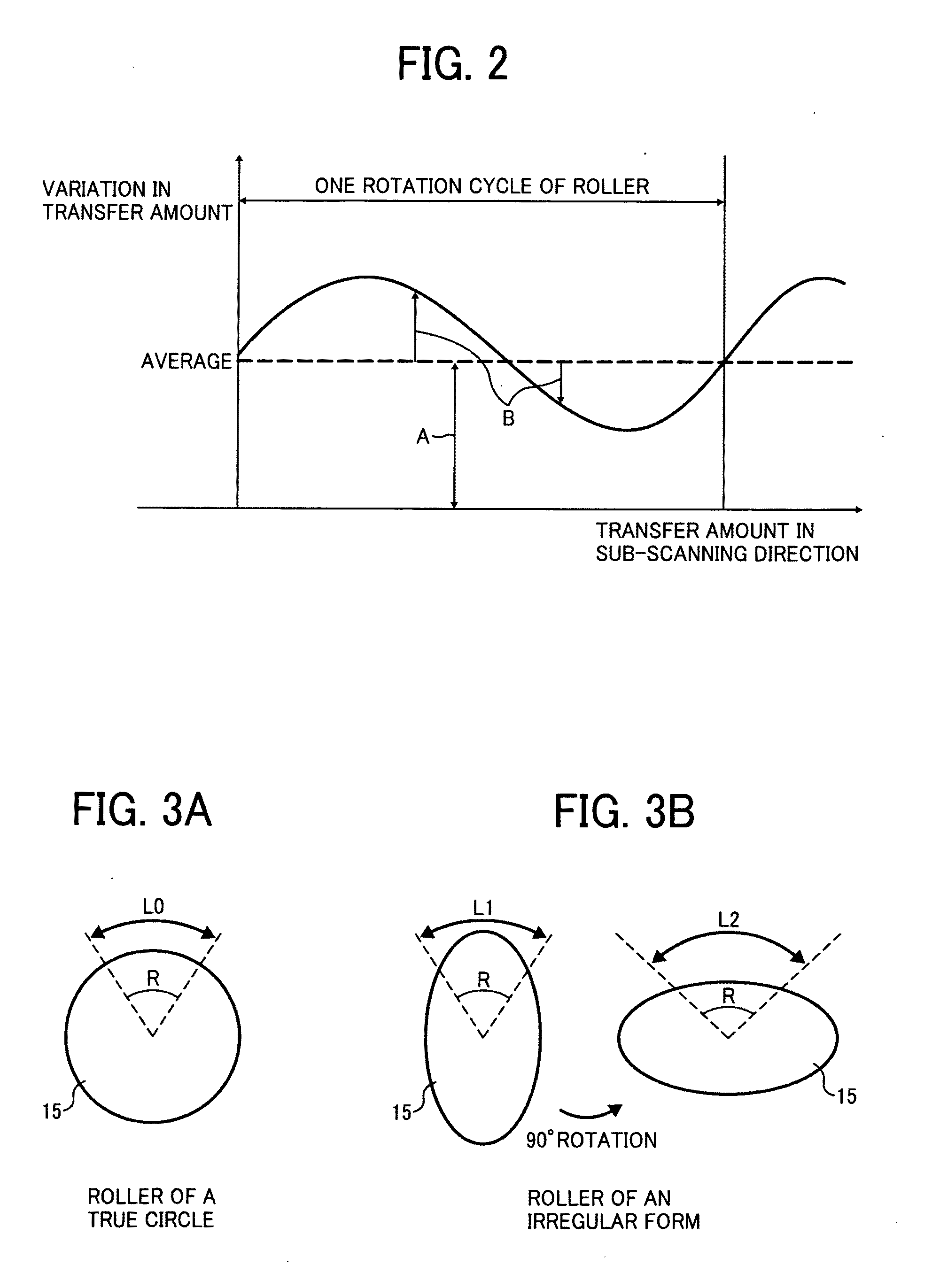

ActiveUS20100231632A1Reduce variationReduce the amount of rotationOther printing apparatusEngineeringRecording media

A recording device including a carriage head, a recording head installed onto the carriage head, the recording head having an array of nozzles that discharges ink on a recording medium, a transfer roller that transfers the recording medium in a direction along the array of nozzles, a control device that controls rotation of the transfer roller, a first detection roller that detects a rotation position of the transfer roller, and a second detection device that detects a mark printed on the recording medium by the recording head, the control device including a print control device that controls printing the marks on the recording medium in the direction along the array of nozzles from the array of nozzles of the recording head while the carriage and the transfer roller remain still, a calculation device that calculates a correction amount for use in correction of a rotation angle of the transfer roller according to a difference between an actual transfer amount of the recording medium by the transfer roller at a predetermined rotation position obtained by detection of the marks by the second detection device while the transfer roller is in rotation and a theoretical transfer amount of the recording medium at the predetermined rotation position, and a correction device that corrects the rotation angle of the transfer roller using the correction amount.

Owner:RICOH KK

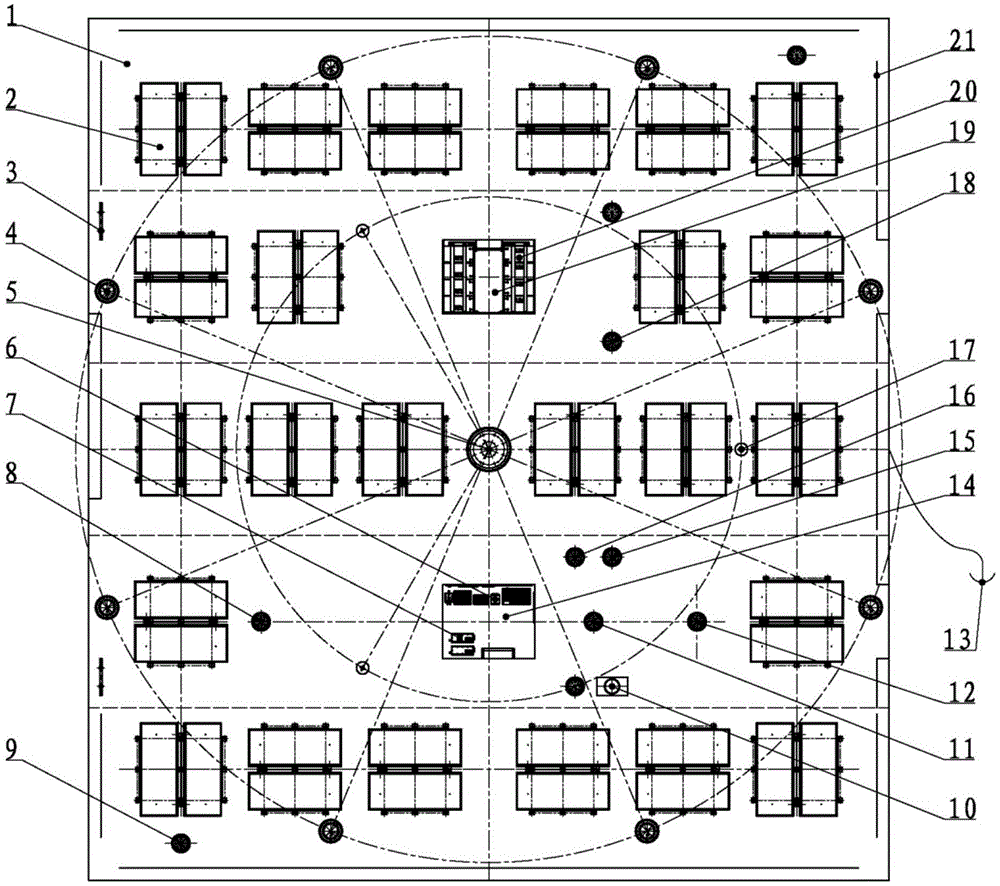

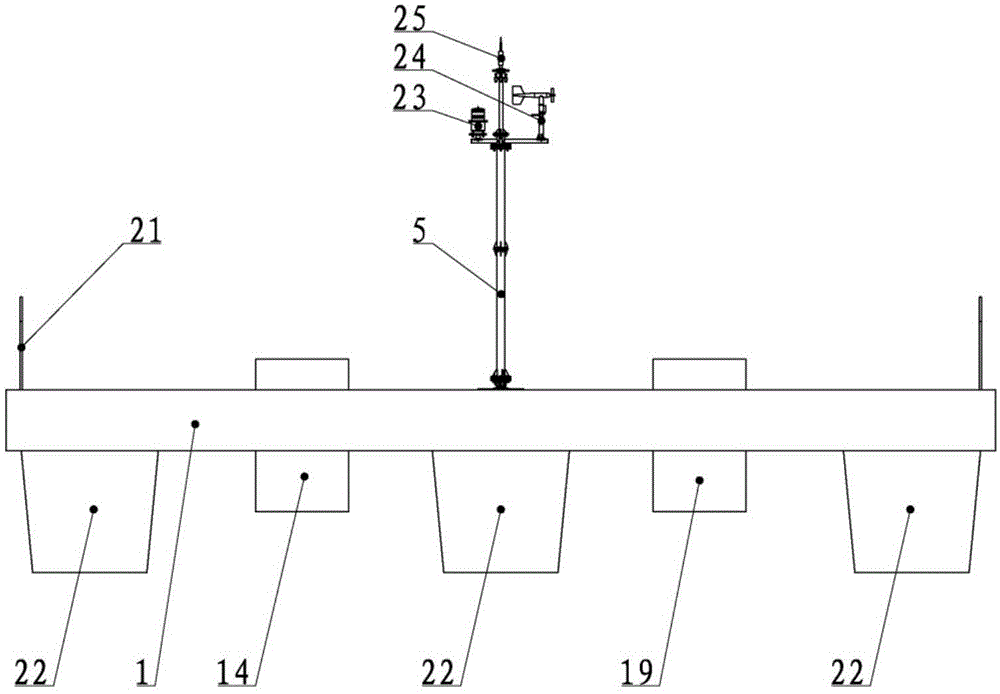

Buoy platform for ground-wave radar

InactiveCN105109626ALarge coverage areaImprove solution accuracyWaterborne vesselsBuoysSingle pointInstrumentation

The invention discloses a buoy platform for ground-wave radar, and belongs to the technical field of ground-wave radar. According to the platform, a plurality of small floating bodies are combined into a large floating body in a multihulled ship form, anchor chains are mounted in the direct flow direction of the floating bodies, and a buoy is prevented from rotating through single-point mooring. A ground-wave radar receiving antenna array is mounted on a deck, a ground-wave radar transmitting antenna is mounted in the center of the deck of the buoy platform, and the transmitting antenna is tightened and fixed to the deck through three chemical fiber ropes, and provided with a lightning rod and a beacon light. A closed instrument cabin and a battery cabin are symmetrically embedded in the deck, a solar cell array is further mounted on the deck, and the deck is provided with various communication antennas and sensors. A mounting platform of the ground-wave radar is transferred to the buoy platform from the land and an island, the arrangement and detection range of the ground-wave radar is widened, and the ground-wave radar can be mounted in any sea area.

Owner:ZNPL OCEAN DETECTION SYST ENG

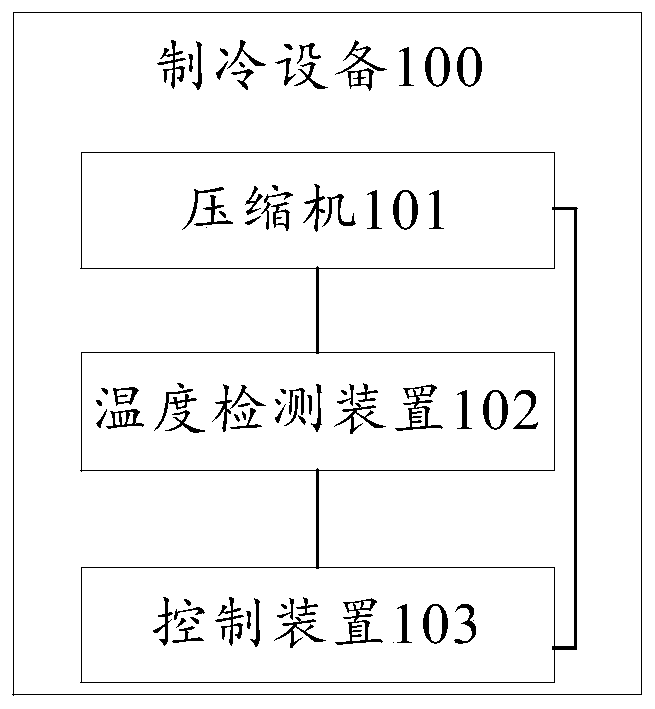

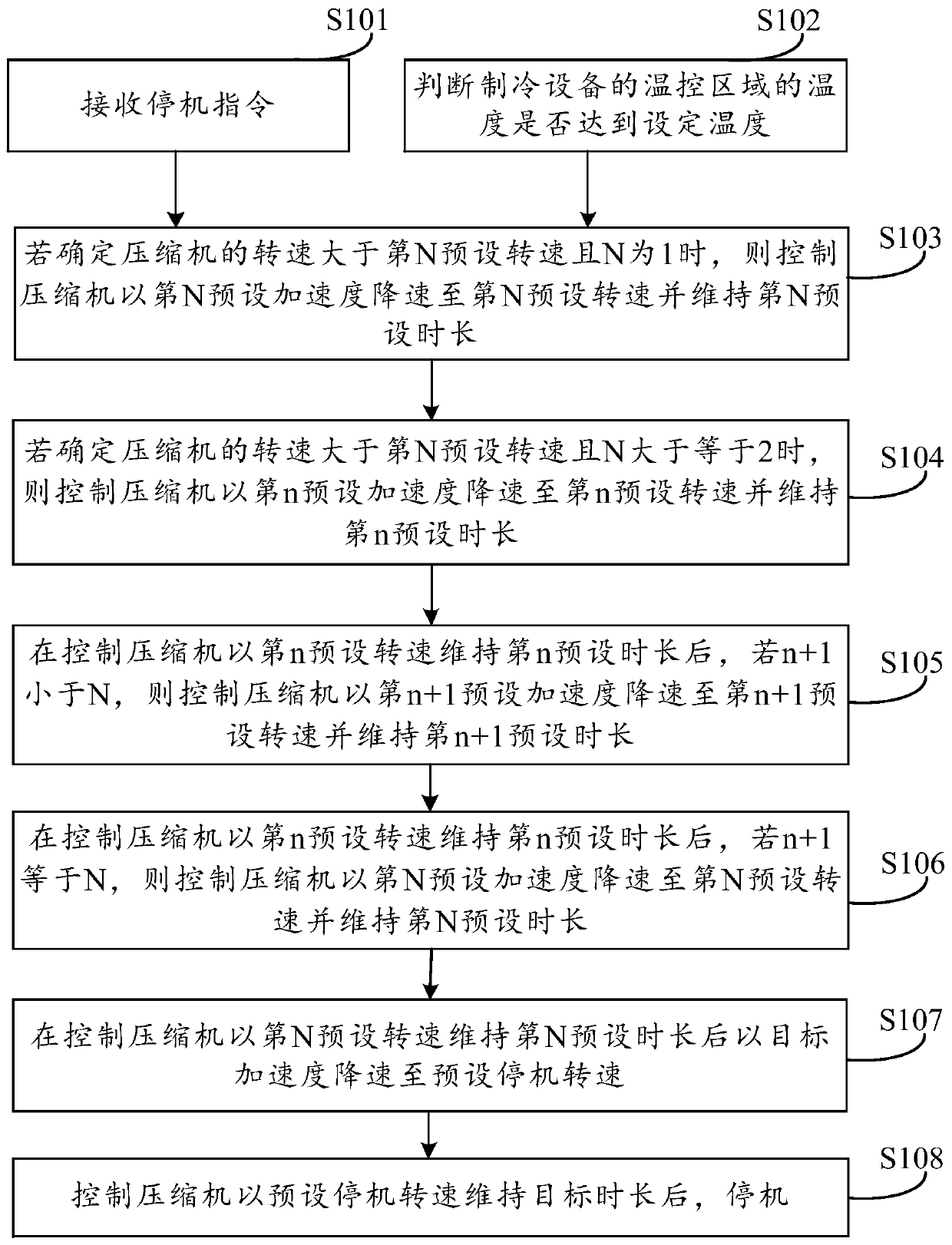

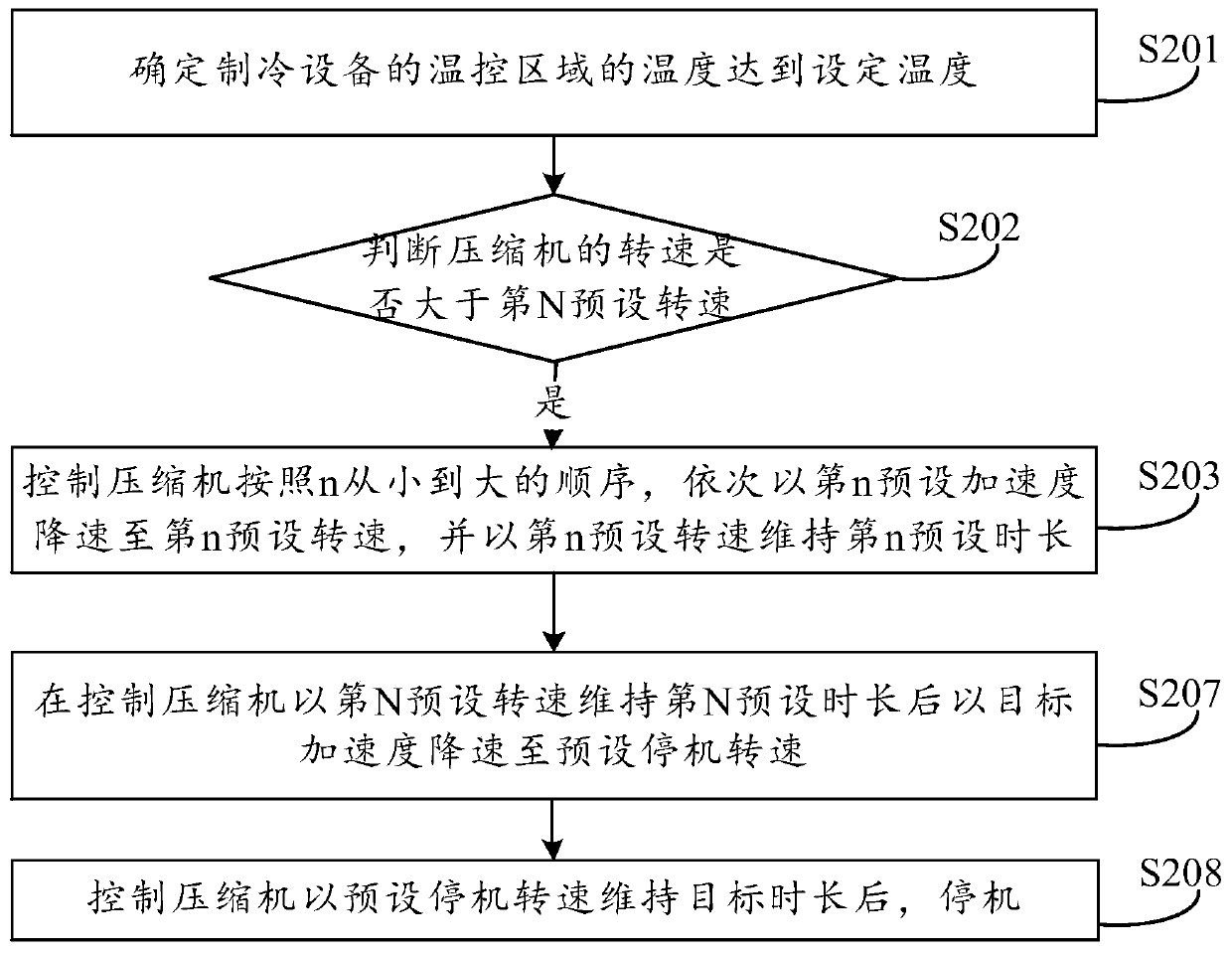

Refrigeration equipment and shutdown control method of compressor of refrigeration equipment

InactiveCN110953776AImprove experienceSolve the noiseRefrigeration safety arrangementRefrigeration plantTemperature control

The invention provides refrigeration equipment and a shutdown control method of a compressor of the refrigeration equipment, and relates to the field of compressors. The problem that when a machine core of the compressor collides with and impacts on a shell of the compressor at the shutdown moment, great noise is caused is avoided. The refrigeration equipment comprises a compressor, a temperaturedetection device and a control device; the temperature detection device is used for detecting the temperature of a temperature control area of the refrigeration equipment; and the control device is configured to be characterized in that if the rotating speed of the compressor is determined to be larger than the Nth preset rotating speed, the compressor is controlled to be sequentially deceleratedto the nth preset rotating speed by the nth preset accelerated speed according to the sequence of n from small to large and kept at the nth preset rotating speed for the nth preset duration, after thecompressor is controlled to be kept at the Nth preset rotating speed for the Nth preset duration, the compressor is decelerated to the preset shutdown rotating speed by the target accelerated speed,and after being controlled to be kept at the preset shutdown rotating speed for the target duration, the compressor is shut down.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

Ultra-wide field optical system

The invention discloses an ultra-wide field optical system. A first lens, a second lens, a third lens, a fourth lens, a fifth lens, an optical filter and a plate are arranged successively from the object side to the image surface; a diaphragm is arranged between the second lens and the third lens; the focus of the first lens is f1; the focus of the second lens is f2; the focus of the third lens is f3; the focus of the fourth lens is f4; and the focus of the fifth lens is f5, wherein 2<f1 / f2<3, -2<f3 / f4<-1, and -2<f4 / f5<0. The ultra-wide field optical system can solve the problem about compression of field of view of an ultra-wide field lens, and can effectively reduce the height of a wide angle light on the main surface of the lens so as to reduce the whole length of the lens and reduce the construction tolerance sensitivity, and can enable the whole imaging surface of the lens to be uniform, to be high in luminance and to be large in aperture and can enable the stop number of the lens to achieve F2.0 so that the ultra-wide field imaging being greater than 220DEG can be realized.

Owner:UNION OPTECH

Multidirectional conveying guider for flaky materials

InactiveCN103879824AReduce the amount of rotationSimple structureArticle deliveryEngineeringMechanical engineering

The invention discloses a multidirectional conveying guider for flaky materials. The multidirectional conveying guider comprises a channel plate assembly and a reversing blade assembly. Multidirectional channels are formed on the channel plate assembly, the different channels on the channel plate assembly can be closed or opened by the reversing blade assembly, the reversing blade assembly is driven by a bidirectional electromagnet, the bidirectional electromagnet is driven by a power motor via a screw, and accordingly an optional channel on the channel plate assembly can be opened. The multidirectional conveying guider has the advantages that the bidirectional electromagnet and the power motor are matched with each other, so that the multidirectional channels can be selected, the multidirectional conveying guider is simple in structure and small in size, the work complexity can be greatly lowered, and the production and maintenance costs can be effectively reduced; the bidirectional electromagnet can work safely and quickly, and accordingly the multidirectional conveying guider is favorable for improving the work efficiency; movement is transmitted via the screw, so that the control precision of the multidirectional conveying guider can be effectively improved, and influence of errors of the motor can be prevented.

Owner:广州智萃电子科技有限公司

A vertical force-measuring bridge bearing and its force-measuring method

ActiveCN106192739BReduce the influence of vertical forceReduce rotation frequencyBridge structural detailsApparatus for force/torque/work measurementSize increaseEngineering

A vertical force-measuring bridge bearing and its force-measuring method, through the measurement of local force and overall calibration, the overall force of the bearing is determined, the structure is simple, the increase in size and weight is small, the force measurement is reliable, and the bridge support can be realized The vertical force measurement function of the support can solve the problem of vertical force measurement of the support and provide technical support for bridge monitoring.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Driving-and-transmission integrated musculoskeletal driver and performance testing device thereof

PendingCN107655674AGuaranteed constant volumeNo frictionMachine part testingPhysical medicine and rehabilitationAir pump

The invention discloses a driving-and-transmission integrated musculoskeletal driver and a performance testing device thereof. The musculoskeletal driver is composed of muscle fiber imitated driving units and a flexible matrix. The shape of the flexible matrix and structures and spatial arrangement of the muscle fiber imitated driving units are designed according to the spatial structure of a realmuscle, thereby forming a muscle fiber imitated driving unit matrix and packaging in the flexible matrix. For testing function of the musculoskeletal driver, a driving air source is supplied to the musculoskeletal driver by an air pump, a pressure regulator and a pipeline. A load is applied to the musculoskeletal driver, thereby making the muscle fiber imitated driving units contract. In each contraction, motion of the musculoskeletal driver is recorded by a digital camera, and a relation among thickness of the musculoskeletal driver, the rotation magnitude of the muscle fiber imitated driving units and a load is measured, thereby obtaining a transmission ratio of the musculoskeletal driver. The performance testing device is used for verifying the driving-and-transmission integrated performance of the musculoskeletal driver and an automatic speed change characteristic according to load change.

Owner:JILIN UNIV

False boss for part numerical control machining

InactiveCN109605082AReduce displacementReduce the amount of rotationPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses a false boss for part numerical control machining. The boss is connected with a part and comprises a boss body, a connecting edge and a pressing bolt, wherein the boss body isarranged on a tool, the connecting edge is arranged on the boss body and is parallel to the side, close to the boss body, of the tool, and the pressing bolt is used for fixing the boss body and the tool; a pressing screw hole is formed in the boss body, and a step through hole communicating with the pressing screw hole is formed in the tool; the pressing bolt sequentially penetrates through the step through hole and the pressing screw hole; an included angle alpha is formed between the center line of the pressing screw hole in the length direction and a plane on the side, close to the boss body, of the tool, the included angle alpha is smaller than 90 degrees, and the center line of the step through hole in the length direction and the center line of the pressing screw hole in the length direction are located on the same straight line; and a large end of the step through hole is away from the boss body. According to the false boss, part damage caused by rotation and displacement of thefalse boss can be effectively prevented.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

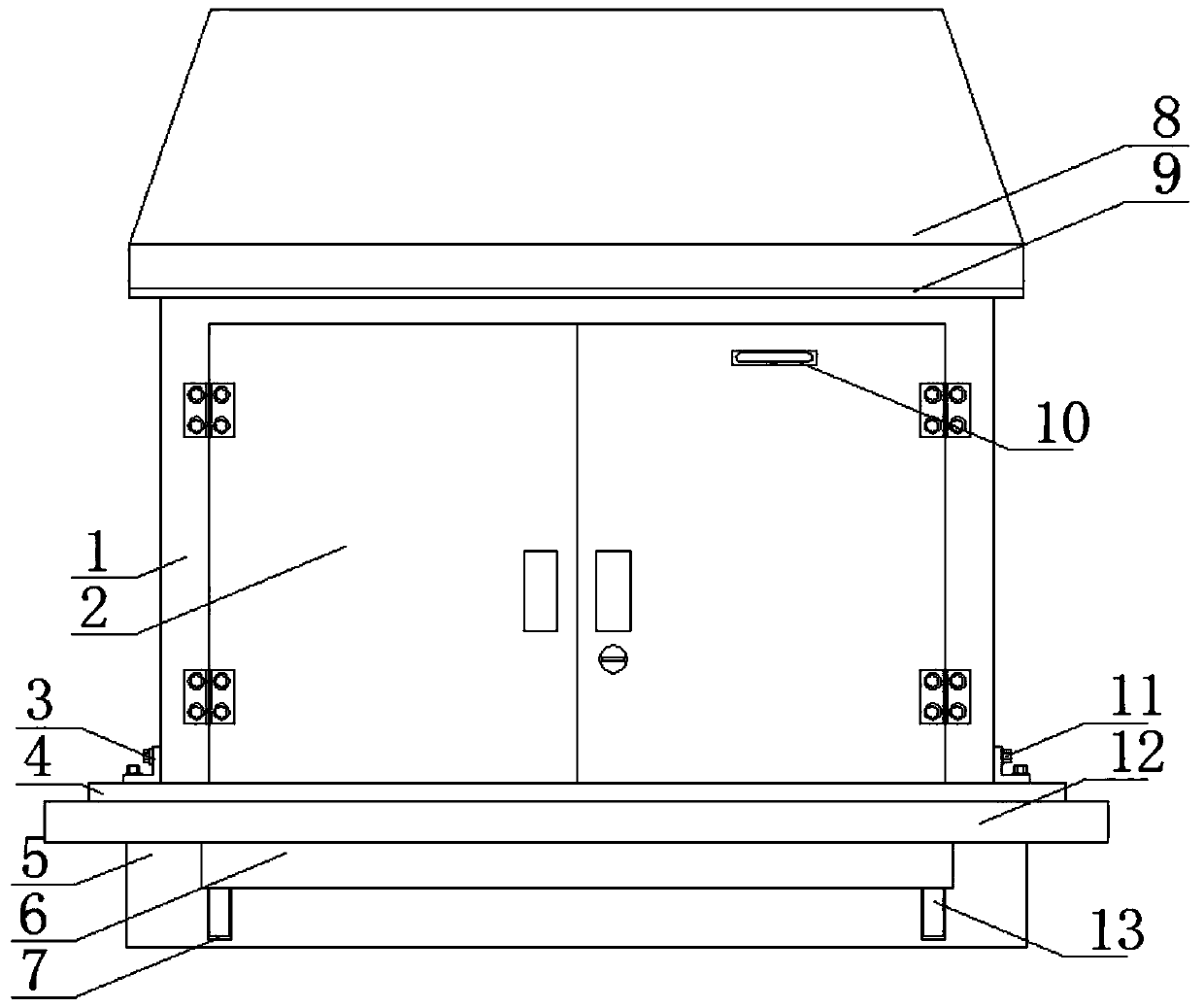

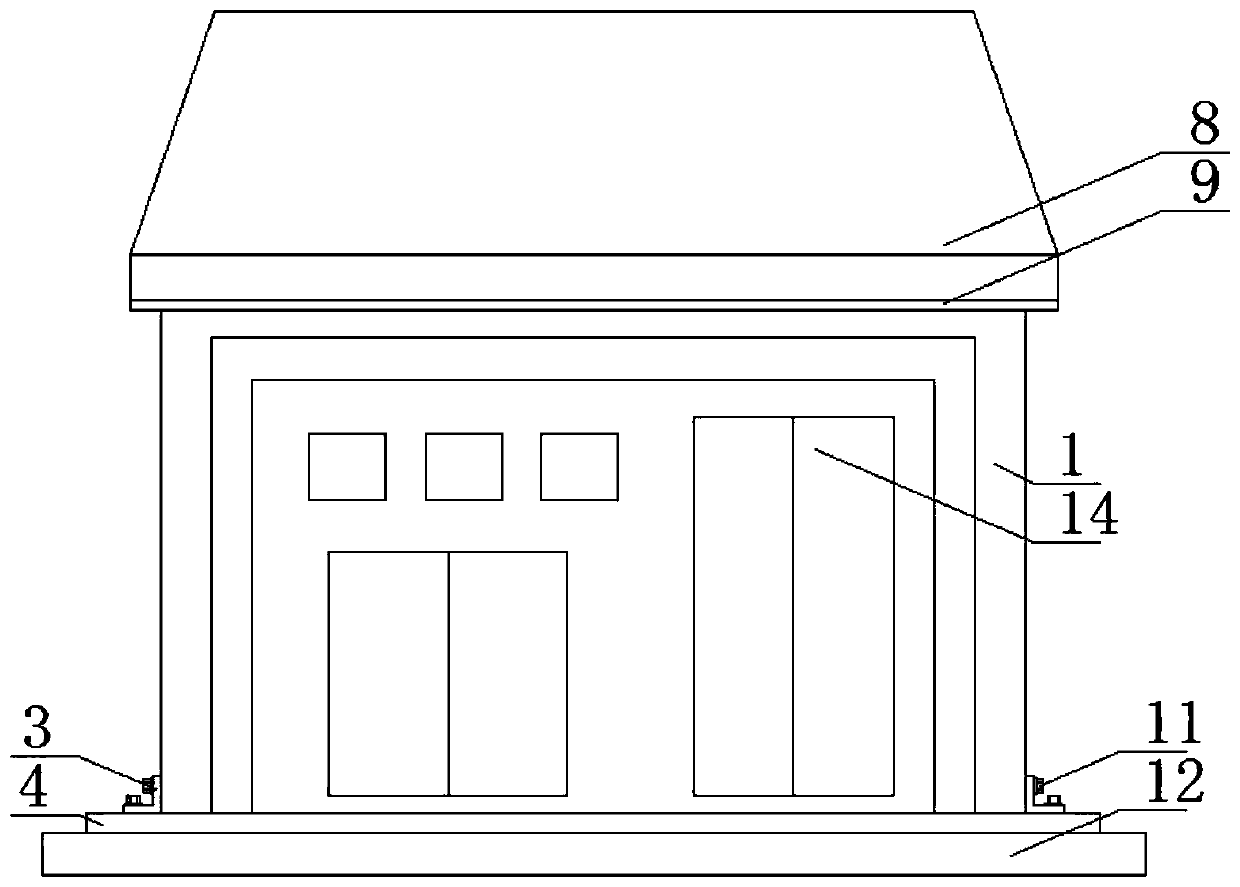

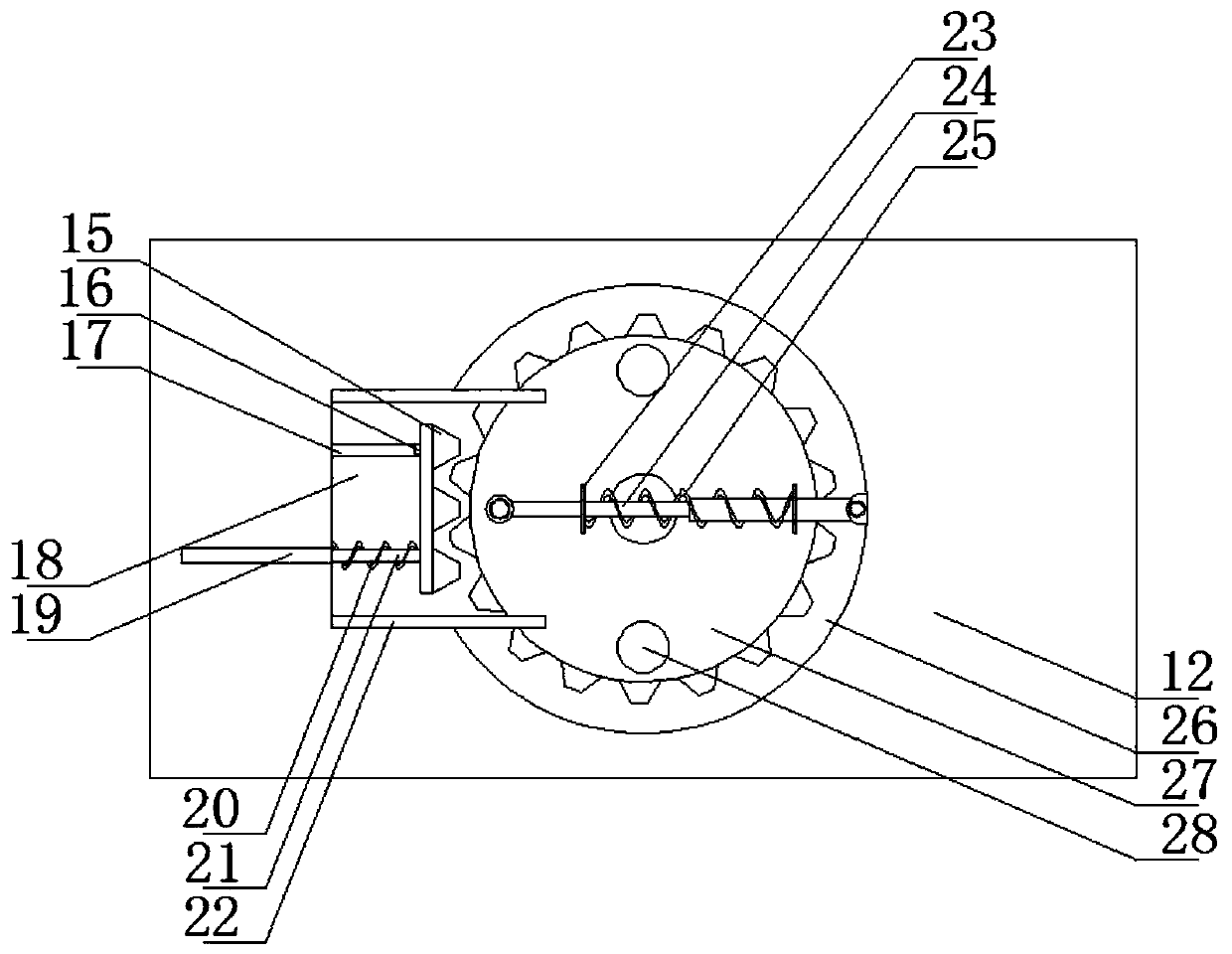

High-low voltage prefabricated substation with good protection performance

ActiveCN111313271AReduce the temperatureEasy to operateSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsLow voltageGear wheel

The invention discloses a high-low voltage prefabricated substation with good protection performance. The high-low voltage prefabricated substation comprises a bearing plate, a groove is formed in anupper end of the bearing plate, a first gear is rotatably connected to a bottom in the groove, a first notch is formed in a side wall of one end in the groove, a moving groove is formed in the first notch, and a reset mechanism is arranged in the moving groove. The situation that rain and snow easily enter a box body due to the fact that a side wall of the box body is opened in the past is avoided; the heat dissipation capability can be well ensured; a machine body can be ensured to be in an adaptive working temperature environment; meanwhile, a baffle and the box body can be connected into awhole; the baffle is prevented from rotating at will and can be effectively matched with the box body to isolate the machine body from the external environment, when foreign object collision occurs, the box body and the baffle can prevent the machine body from directly bearing collision, external force is counteracted in a deflection and movement mode, it is guaranteed that the machine body is notdamaged, the normal operation of the machine body is guaranteed, and the service life of the machine body is prolonged.

Owner:SHENZHEN XIDE ELECTRIC

Multi-piece solid golf ball

InactiveUS7901300B2Increase flight distanceHigh launch angleGolf ballsSolid ballsEngineeringGolf Ball

The present invention provides a multi-piece solid golf ball, of which flight distance is improved by accomplishing high launch angle and low spin amount, when hit by golfers, who swing a golf club at low head speed, using a middle iron club to a driver. The present invention relates to multi-piece solid golf ball comprising a center, an intermediate layer formed on the center and a cover covering the intermediate layer, wherein the intermediate layer is formed from only one material having a flexural stiffness of 400 to 5,000 MPa.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com