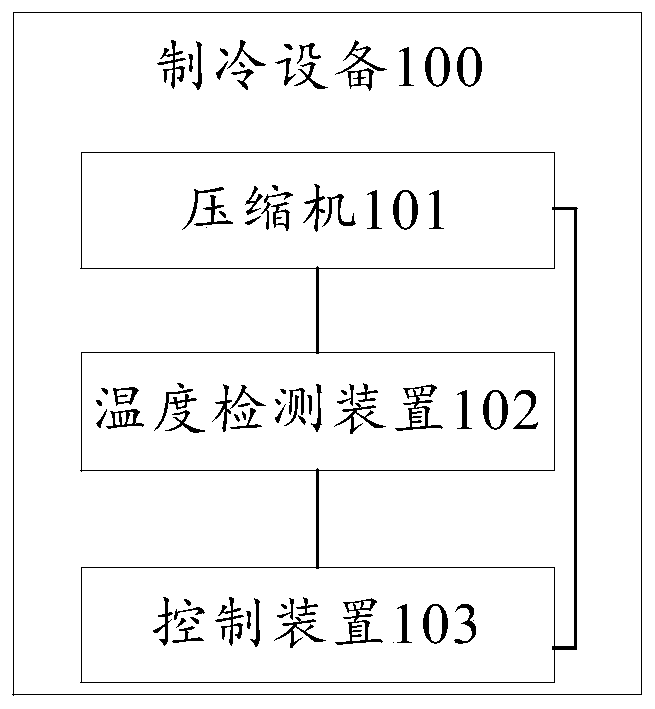

Refrigeration equipment and shutdown control method of compressor of refrigeration equipment

A technology of refrigeration equipment and control method, applied in the field of compressor control, can solve the problems of shell bump and impact, poor user experience, loud noise, etc., to avoid noise problems and improve experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

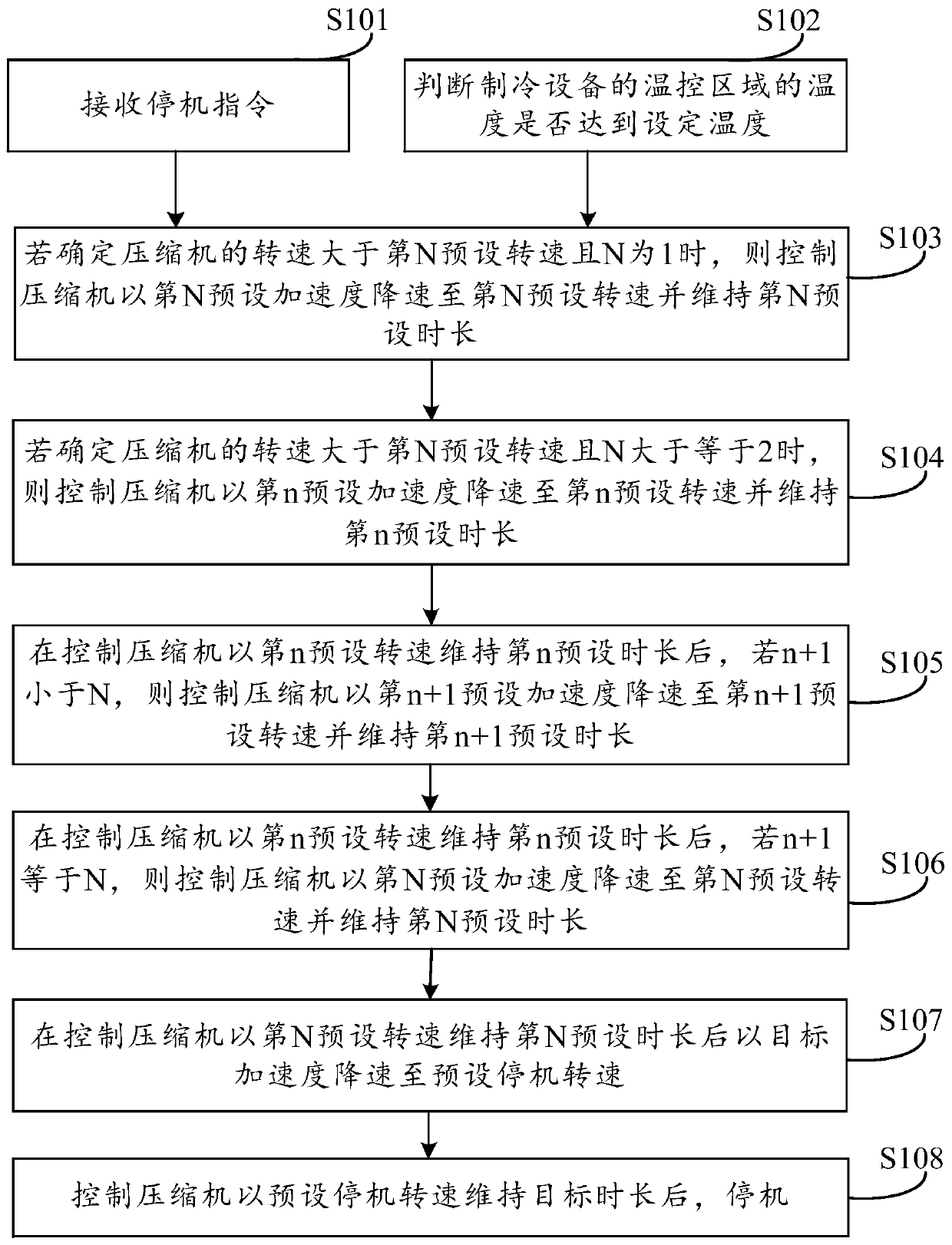

Embodiment 1

[0102] Embodiment 1: The target speed of a certain series of compressors is 4100R, the starting speed of the compressor is 2400R and the minimum speed of the series of compressors is 1200R, then the specific scheme for determining the preset shutdown speed and target acceleration is as follows:

[0103] It is preliminarily determined that the preset stop speed is the minimum speed of the compressor 1200R, and the N value is taken as 1, that is, a two-stage step stop scheme is adopted, and the first preset acceleration is 180R / S, that is, 3r / s 2 (acceleration unit), the first preset speed is 2400R, the first preset time length is 3 seconds, and the target acceleration is 120R / S or 2r / s 2 , with a target duration of 3 seconds.

[0104] Specifically, when the ambient temperature of the refrigeration equipment reaches above 37 degrees Celsius, its compressor starts, and the speed is increased from the starting speed of 2400R to the target speed of 4100R. When the temperature reac...

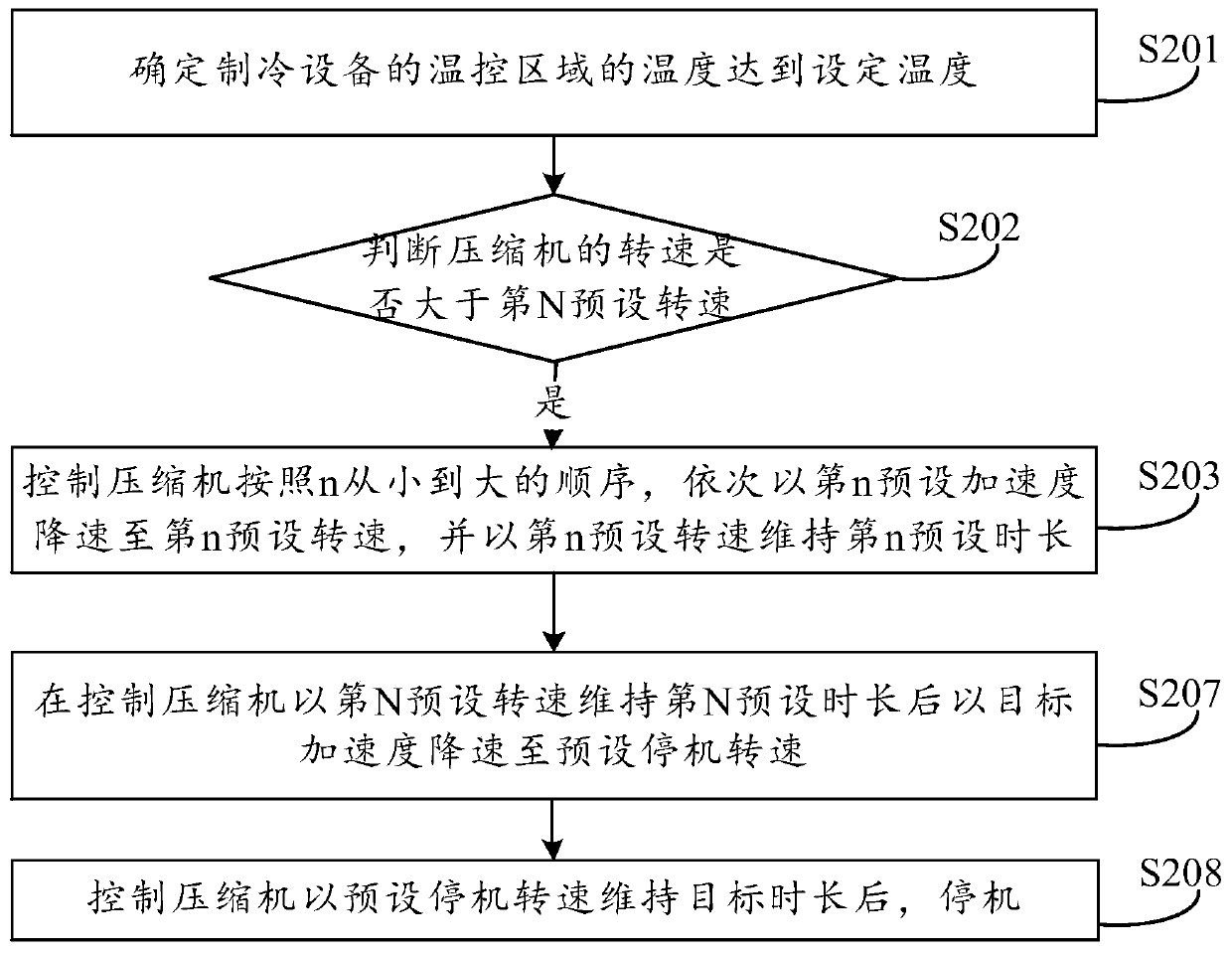

Embodiment 2

[0114] Embodiment 2: The target speed of a certain series of compressors is 4100R, the starting gear of the compressor (rotation speed for oiling) is 2400R, and the minimum speed of this series of compressors is 1200R. Three kinds of shutdown methods are respectively used for shutdown tests.

[0115] refer to Figure 13 , provides a broken-line graph of the shutdown vibration value of three different shutdown schemes, where the vertical axis is the vibration value (unit m / s 2 ), and the abscissa is the number of experimental groups. Specifically, scheme one is: control the compressor at 180R / S, that is, 3r / s 2 Decelerate the acceleration to 2400R, then directly at 120R / S or 2r / s 2 Decelerate the acceleration to 1600R, and stop after 3 seconds; the second plan is: control the compressor at 180R / S, that is, 3r / s 2 The acceleration directly decelerates to 1600R, and finally stops after 3 seconds; the third scheme is: control the compressor at 180R / S, that is, 3r / s 2 The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com