Patents

Literature

36results about How to "Smooth shutdown" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halt control method and system of hybrid power vehicle

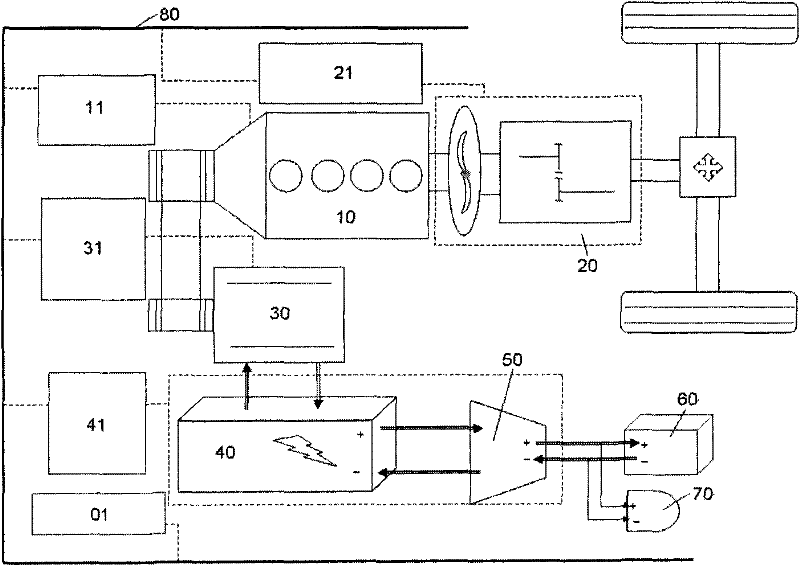

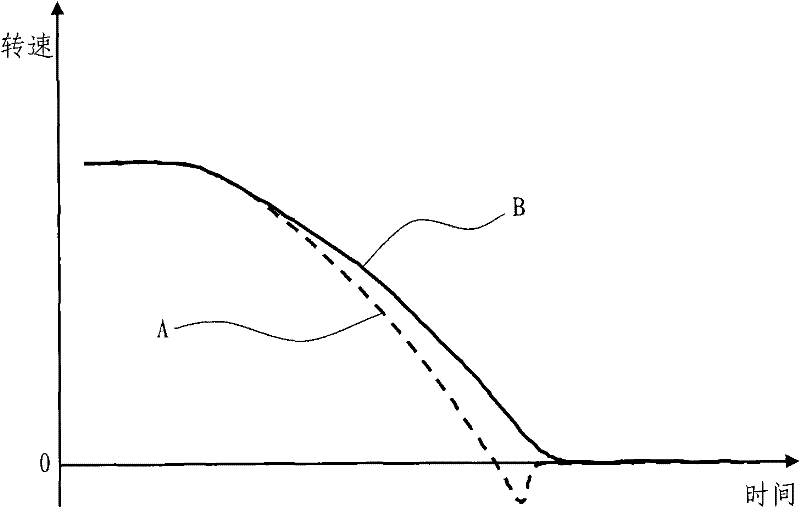

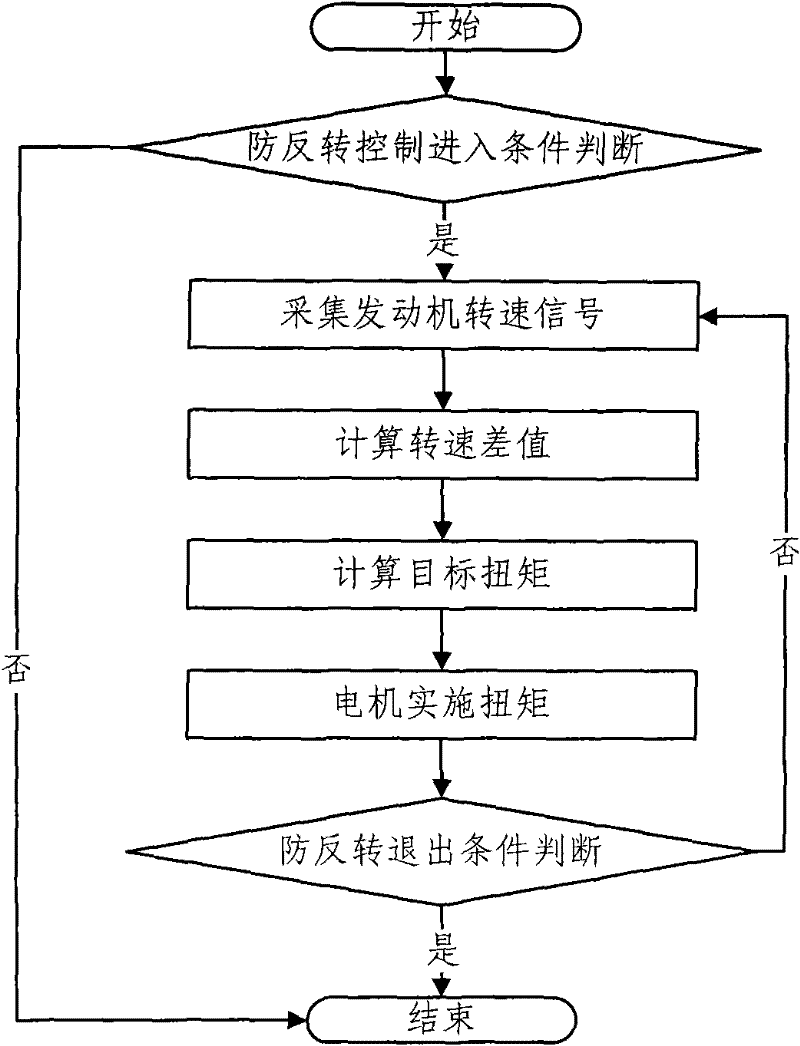

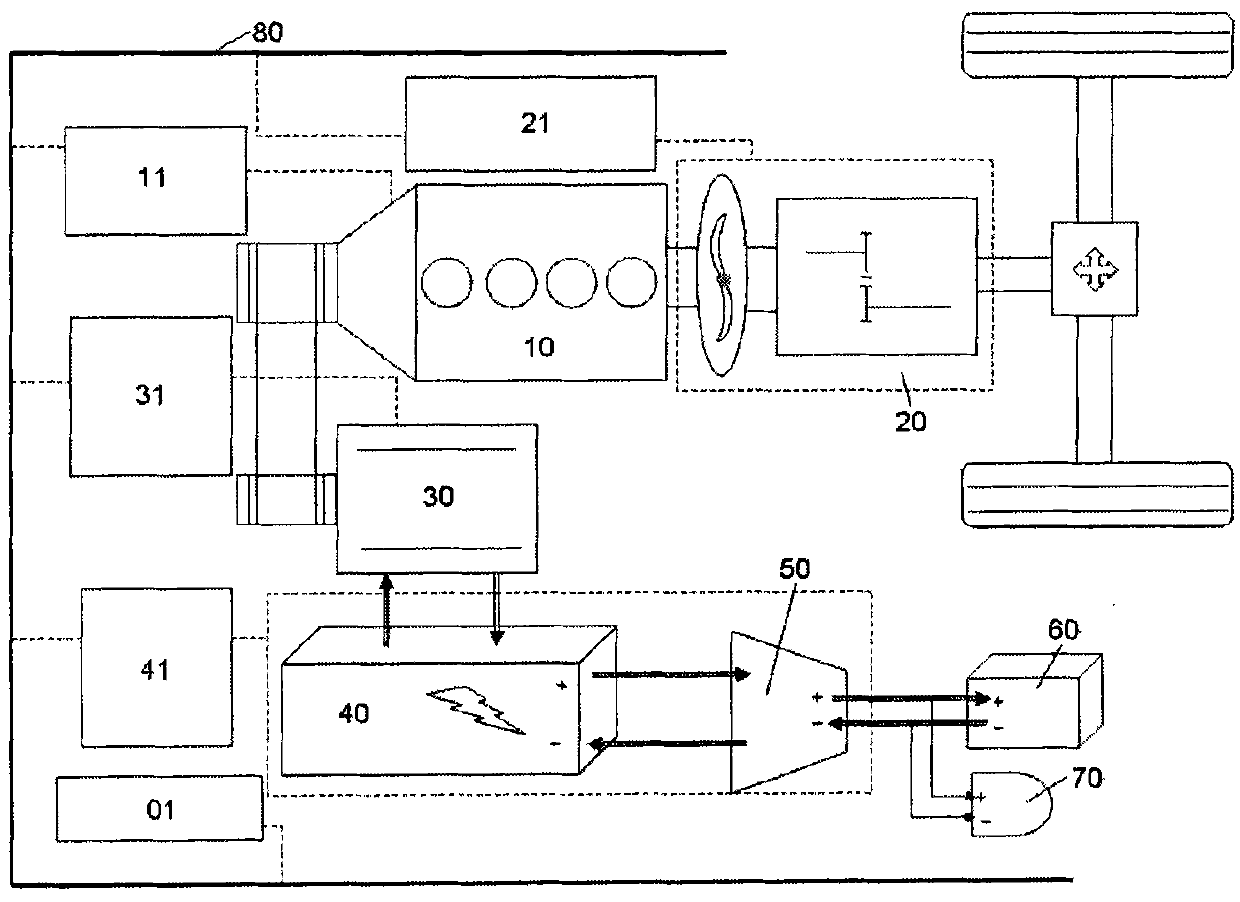

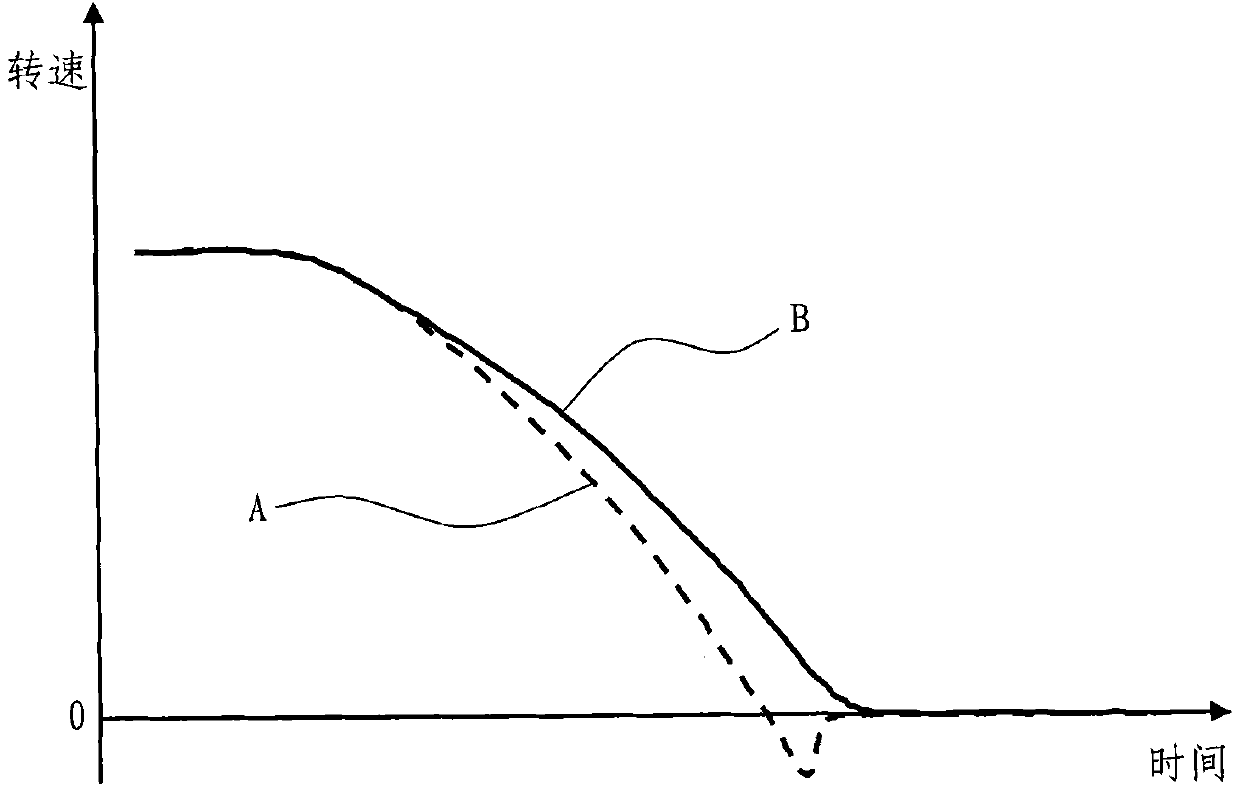

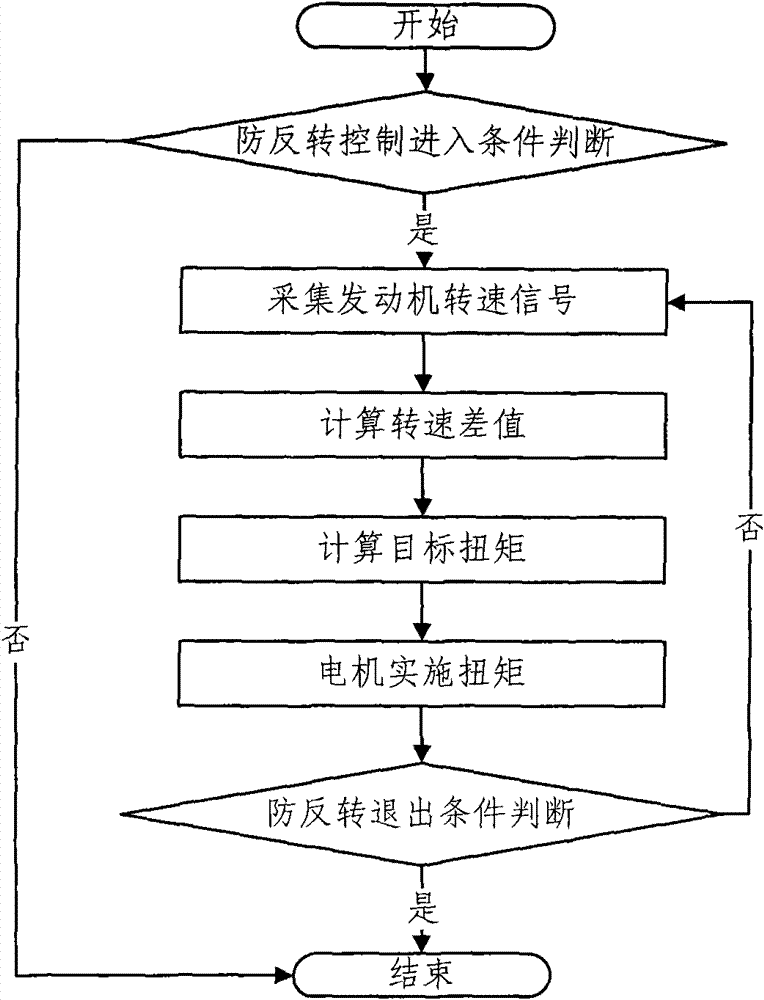

The invention discloses a halt control method and system of a hybrid power vehicle. The halt control method comprises the steps of: judging a reversal-preventing control entry condition; if according with the reversal-preventing control entry condition, controlling an engine to prevent from reversing, wherein the control step comprises the procedures of detecting in real time to obtain an engine rotating speed signal of reflecting a rotating speed of an engine; comparing the rotating speed signal of the engine with a preset ideal rotating speed of the engine to obtain a rotating speed difference; calculating the rotating speed difference through a PID controller to obtain a theoretical target motor output torque, calculating according to the theoretical target motor output torque to obtain an actual target motor output torque needing being implemented by a motor, sending a command for implementing the actual target motor output torque to the motor; and implementing the actual target motor output torque by the motor, and acting the torque implemented by the motor to the engine. Therefore, the reversal of the engine before automatic halt can be prevented.

Owner:SAIC MOTOR

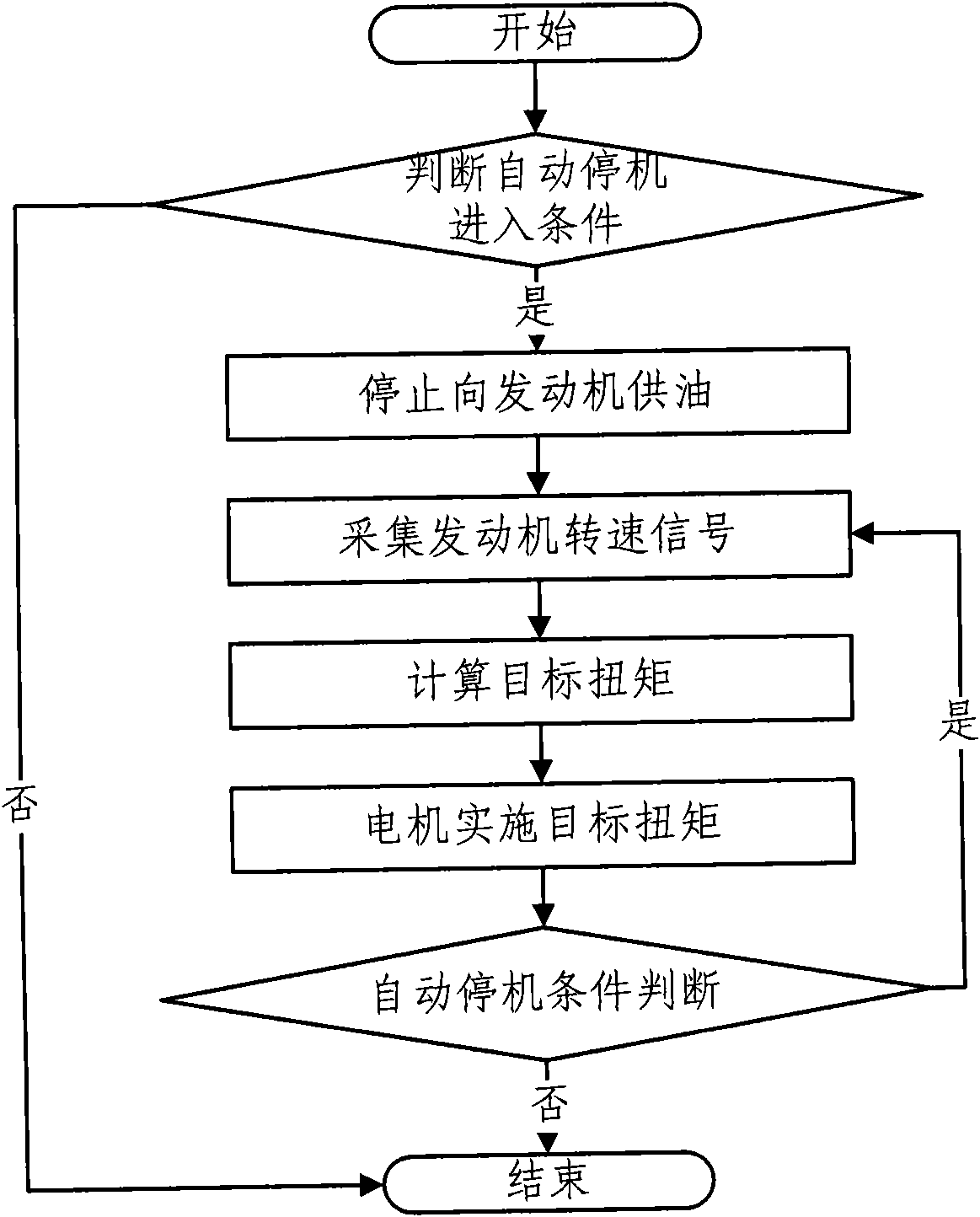

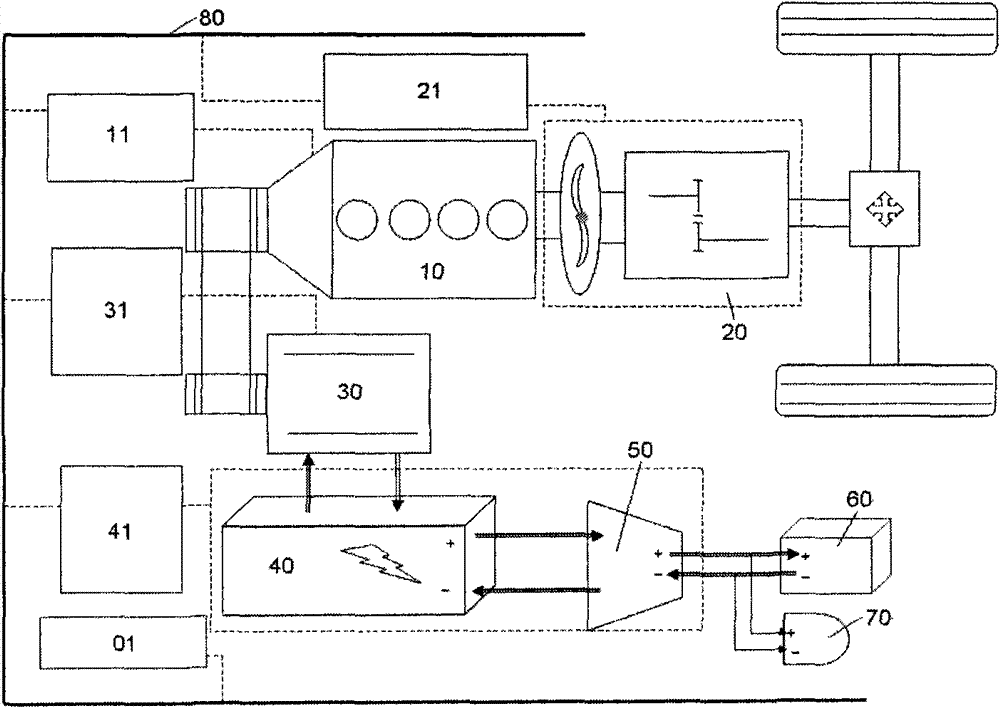

Automatic halt control method and system for hybrid power vehicle

ActiveCN102556048AImprove featuresSmooth shutdownHybrid vehiclesControl engineeringElectric machinery

The invention discloses an automatic halt control method and system for a hybrid power vehicle. The control method comprises the following steps: judging whether a system conforms to a condition for entering an automatic halt working condition; if so, performing a step of stopping supplying oil to an engine; and after oil is stopped to supply to the engine, immediately performing the following control steps of protecting the engine from inversion: detecting and obtaining an engine revolving speed signal which reflects the engine revolving speed in real time, according to the engine revolving speed signal, calculating to obtain a practical target motor output torque which needs to be implemented by the motor, sending a command for implementing the practical target motor output torque to the motor, implementing the practical target motor output torque by the motor according to the command, and acting the torque implemented by the motor to the engine, thus the engine is protected from inversion before automatic halt.

Owner:SAIC MOTOR

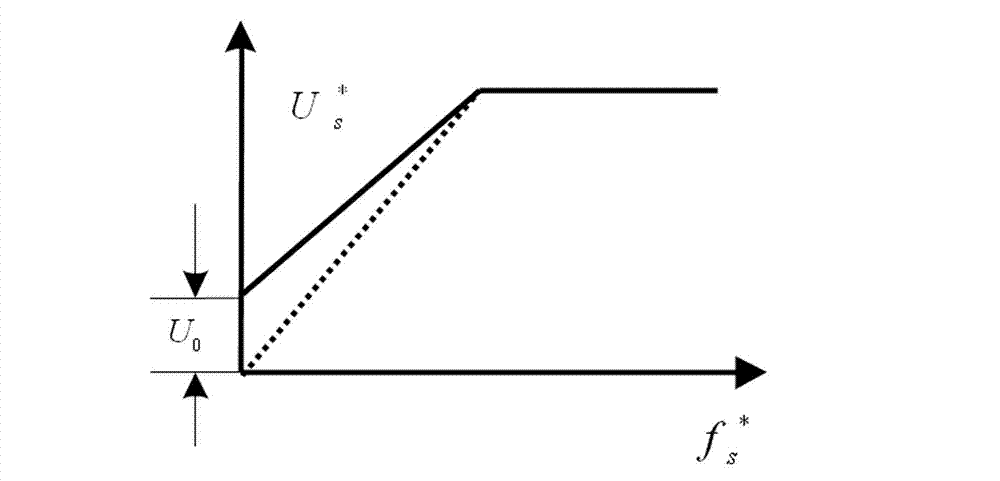

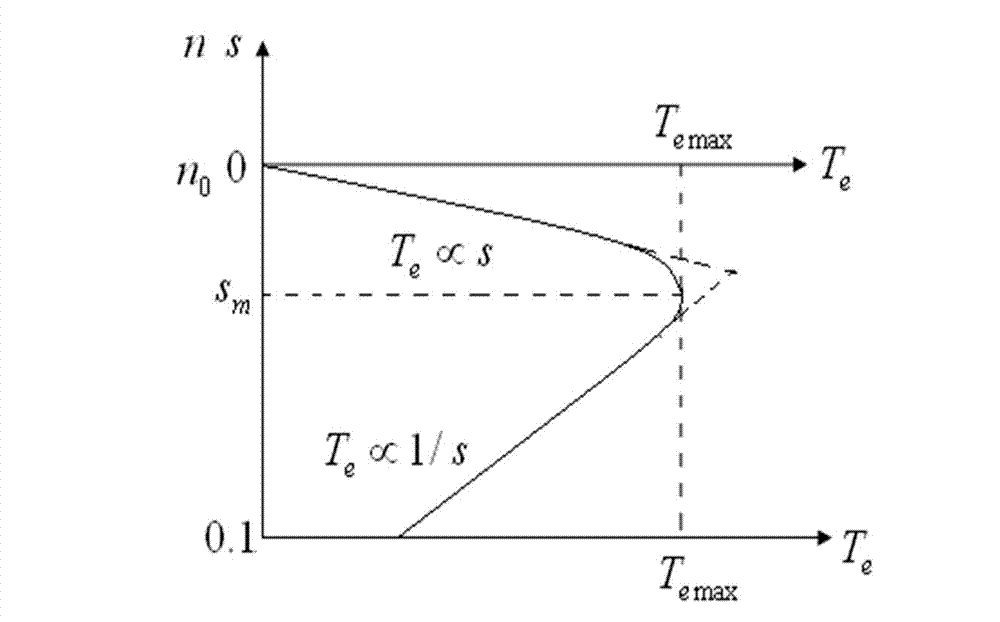

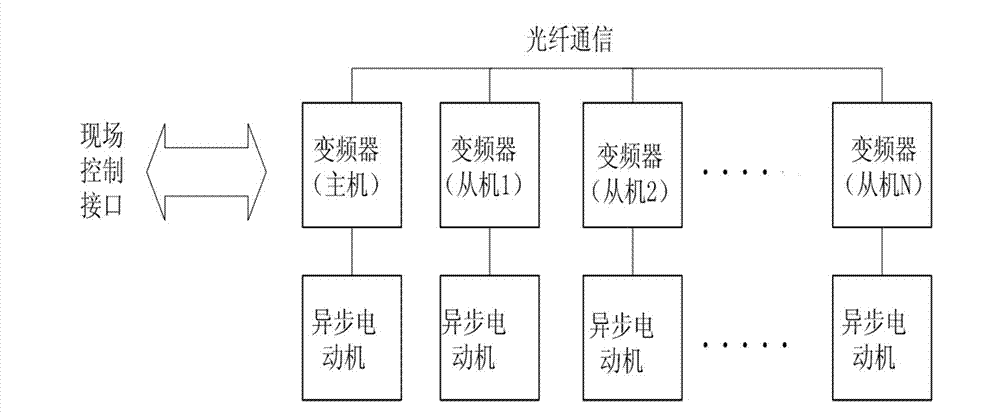

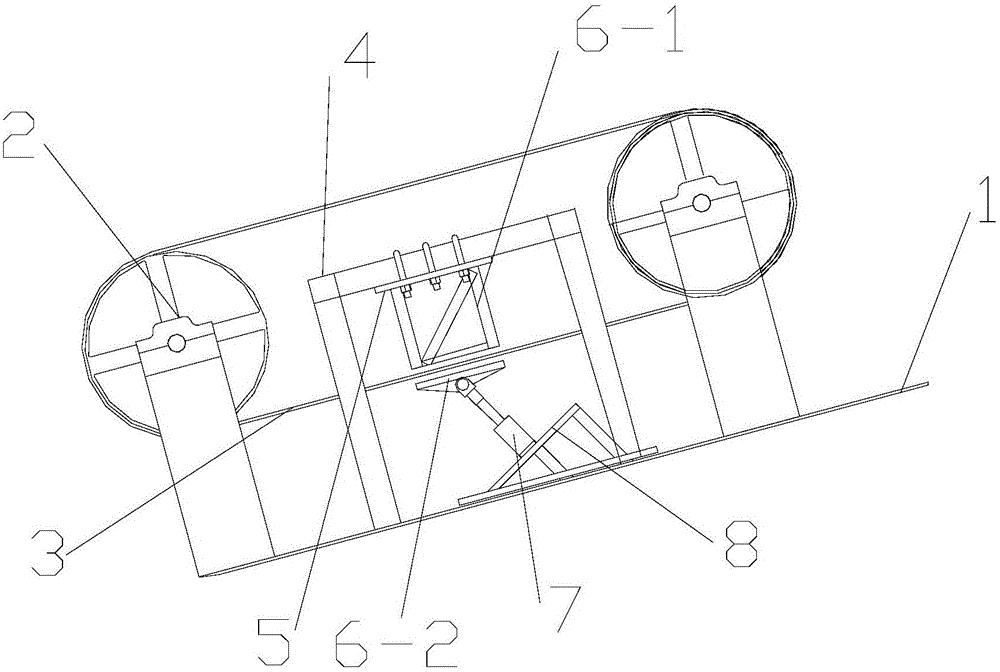

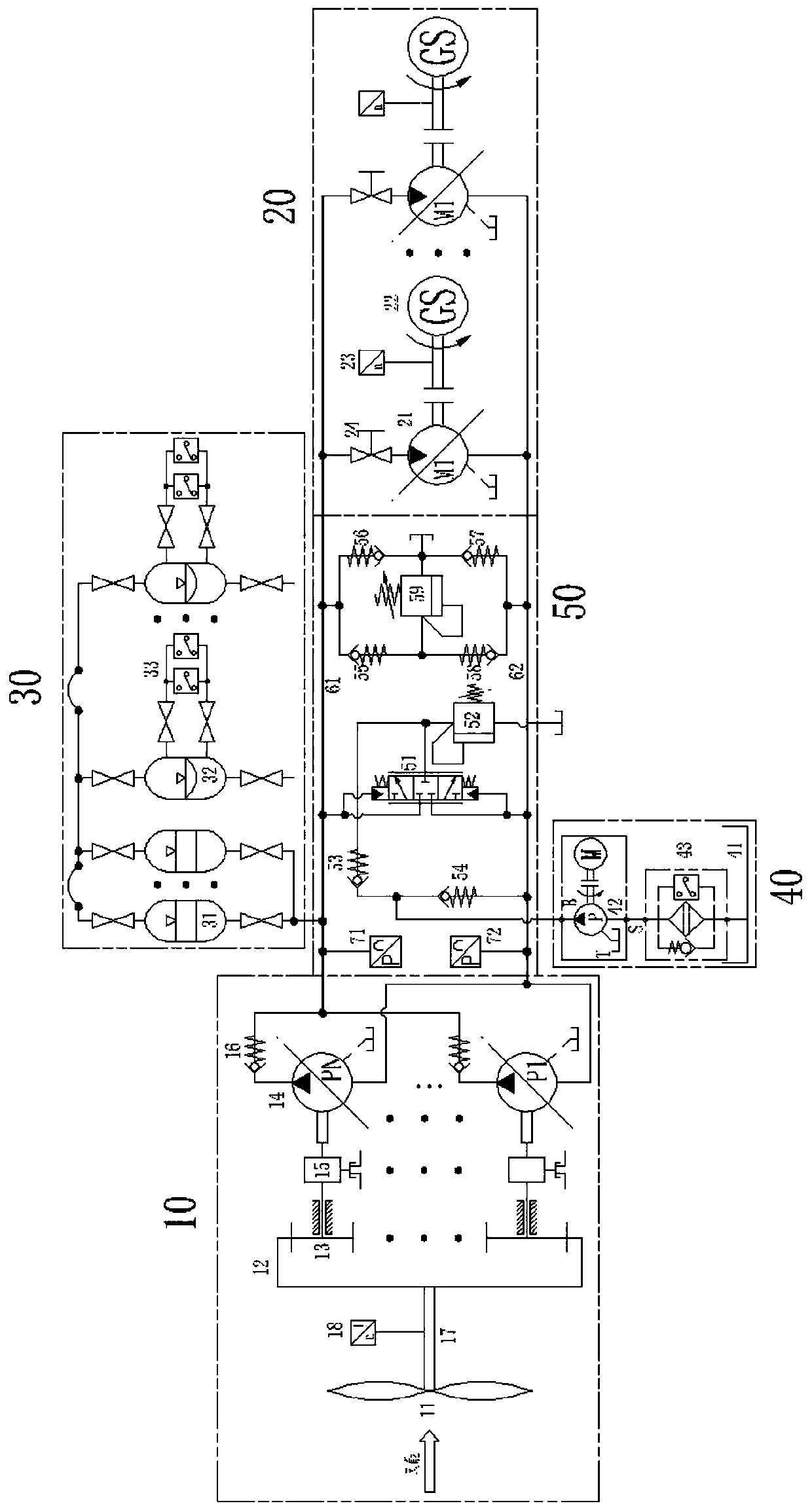

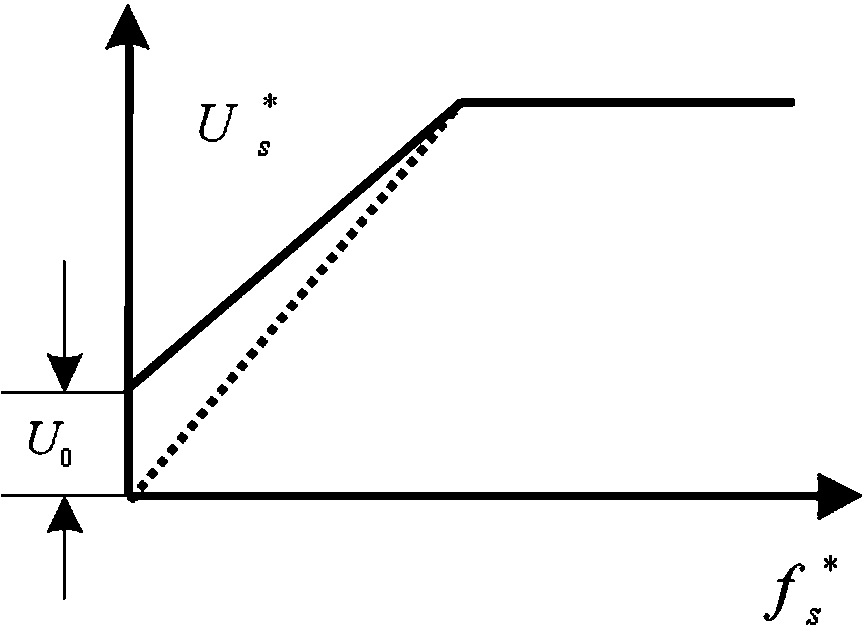

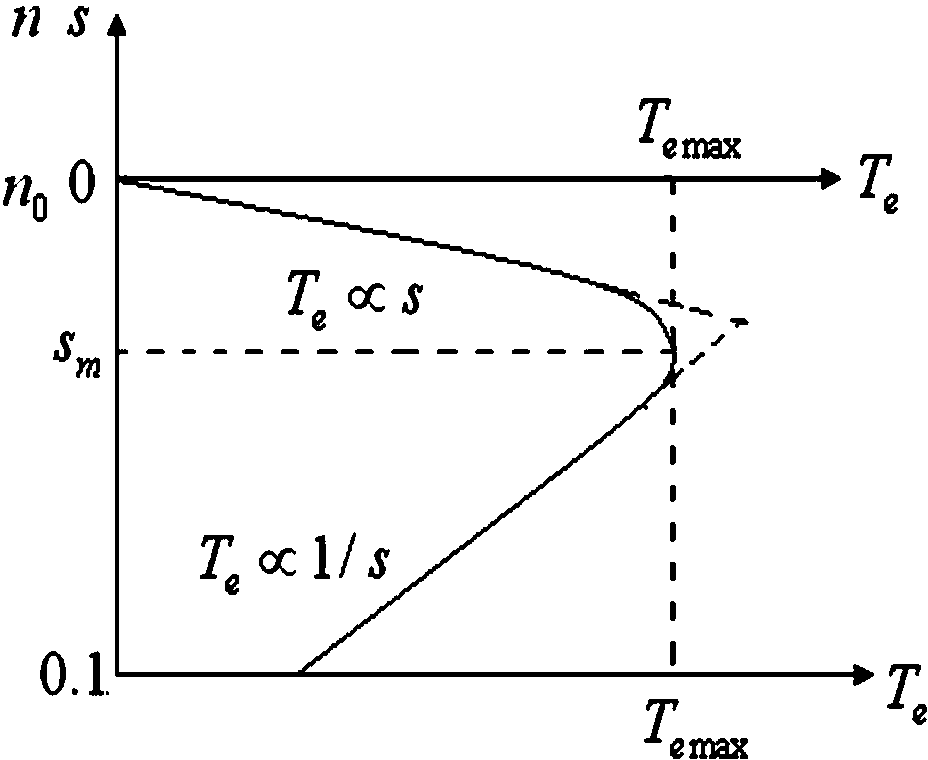

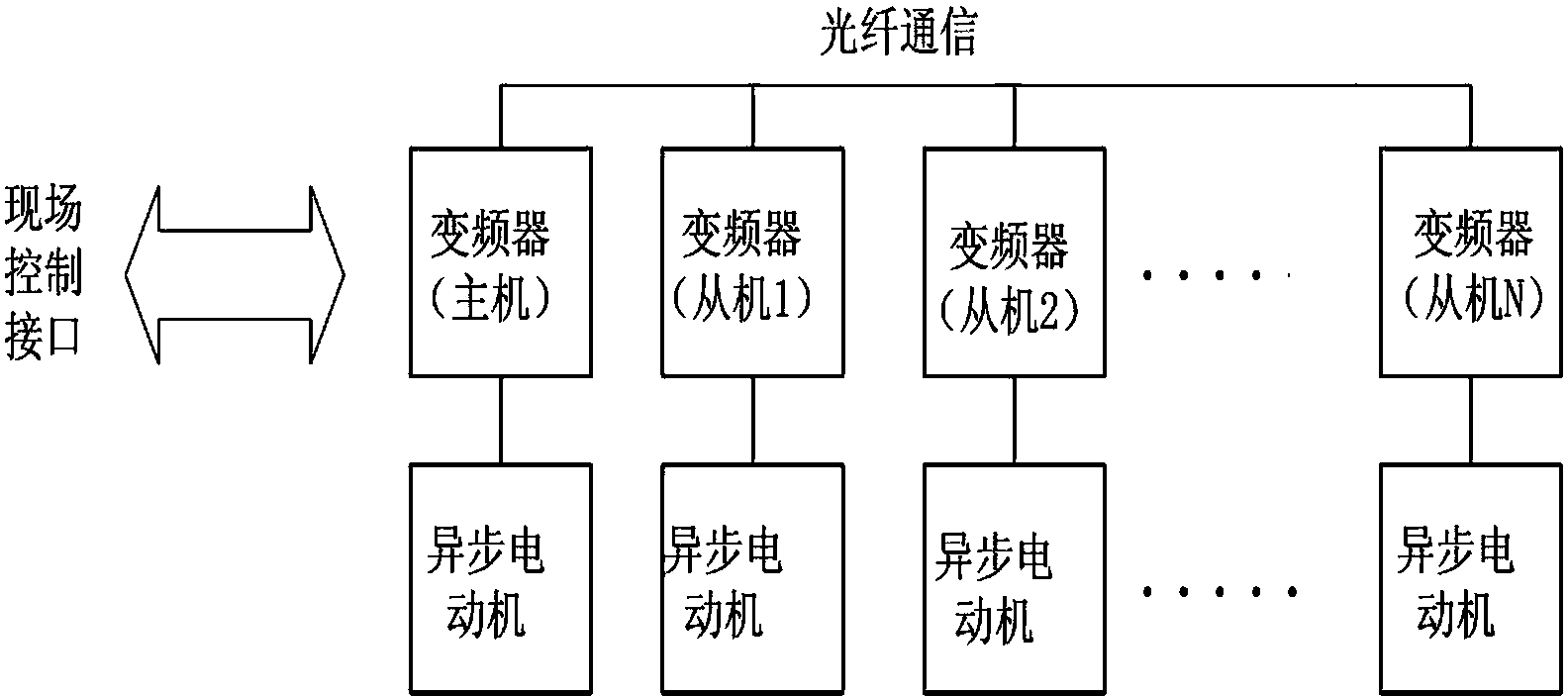

Constant voltage frequency ratio control system and constant voltage frequency ratio control method of multi-motor driving belt conveyor

ActiveCN103112702AThe output frequency is the sameConsistent output torqueControl devices for conveyorsFrequency changerElectric machine

The invention discloses a constant voltage frequency ratio control system of a multi-motor driving belt conveyor, wherein each motor is controlled through an independent frequency converter, a primary frequency converter and each secondary frequency converter are connected through a communication line, and each frequency converter can detect active current. Startup procedures of a constant voltage frequency ratio control method of the multi-motor driving belt conveyor include multiple steps, wherein a step a is that startup signals are received and broadcasted; a step b is that the multi-motor driving belt conveyor is started in a constant voltage frequency ratio control mode; a step c is that the secondary frequency converters are in operation; a step d is that whether the active current is in an allowed range is detected; and a step e is that frequency of each secondary frequency converter is adjusted. Operation procedures of the constant voltage frequency ratio control method of the multi-motor driving belt conveyor include multiple steps, wherein a step g is that operation frequency and the active current are broadcasted; a step h is that the active current is judged; and a step i is that the frequency is adjusted. Shutdown procedures of the constant voltage frequency ratio control method of the multi-motor driving belt conveyor include multiple steps, wherein a step j is that shutdown signals are received and broadcasted, and a step k is that the multi-motor driving belt conveyor is stopped in the constant voltage frequency ratio control mode. Through the constant voltage frequency ratio control system and the constant voltage frequency ratio control method of the multi-motor driving belt conveyor, all the motors basically have the same output torque, and therefore the problem that the motors are at the same rotating speed but have different output torque due to the facts that rotary drums are different in size and the sizes of belt wrap angles are not constant is solved, and the multi-motor driving belt conveyor is enabled to be started and stopped stably and can operate with high efficiency.

Owner:XINFENGGUANG ELECTRONICS TECH CO LTD

Shut-down method of coal tar hydrotreating process

ActiveCN101089139APrevent precipitationEasy to cleanHydrotreatment operations starting-upCoal tarReaction system

The present invention discloses shut-down method of coal tar hydrotreating process. After the coal tar hydrotreating reaction is finished, the shut-down oil containing polar matter is first pumped into the reaction system for cleaning the pipeline and the reactor, and conventional shut-down oil is then added into the apparatus. Compared with available technology, the present invention has the advantages of complete cleaning of the reaction apparatus and capacity of ensuring the fluent shut-down.

Owner:CHINA PETROLEUM & CHEM CORP +1

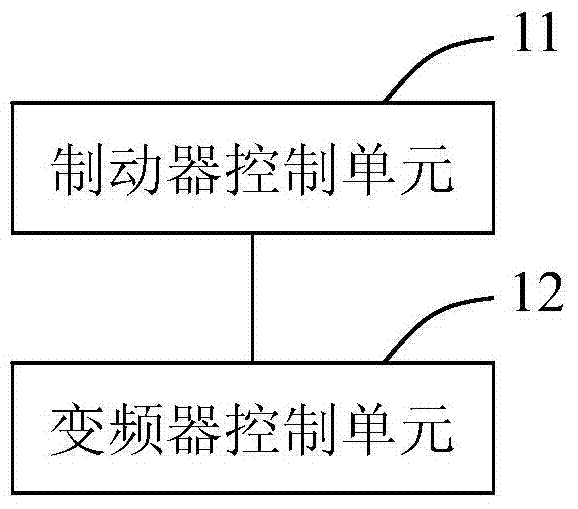

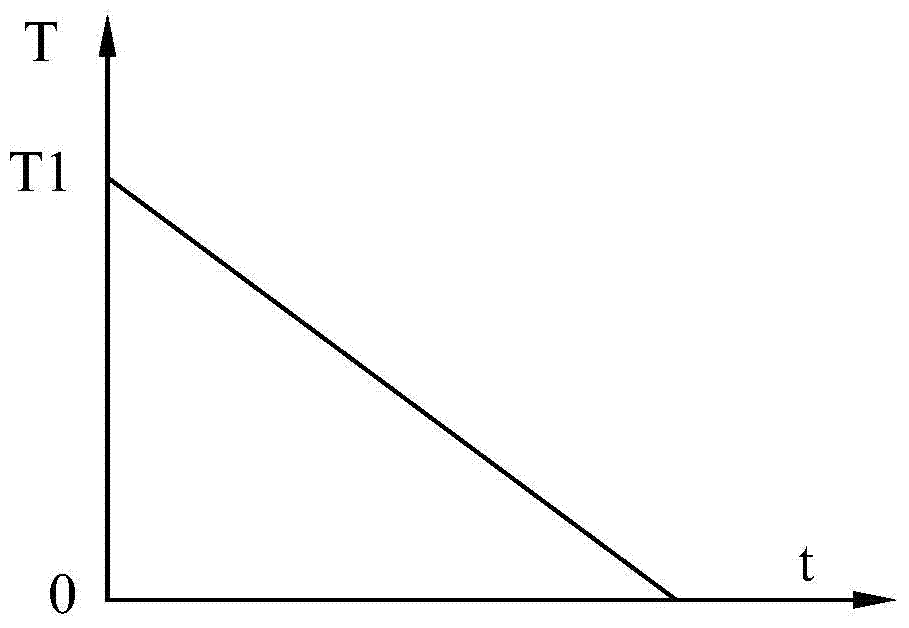

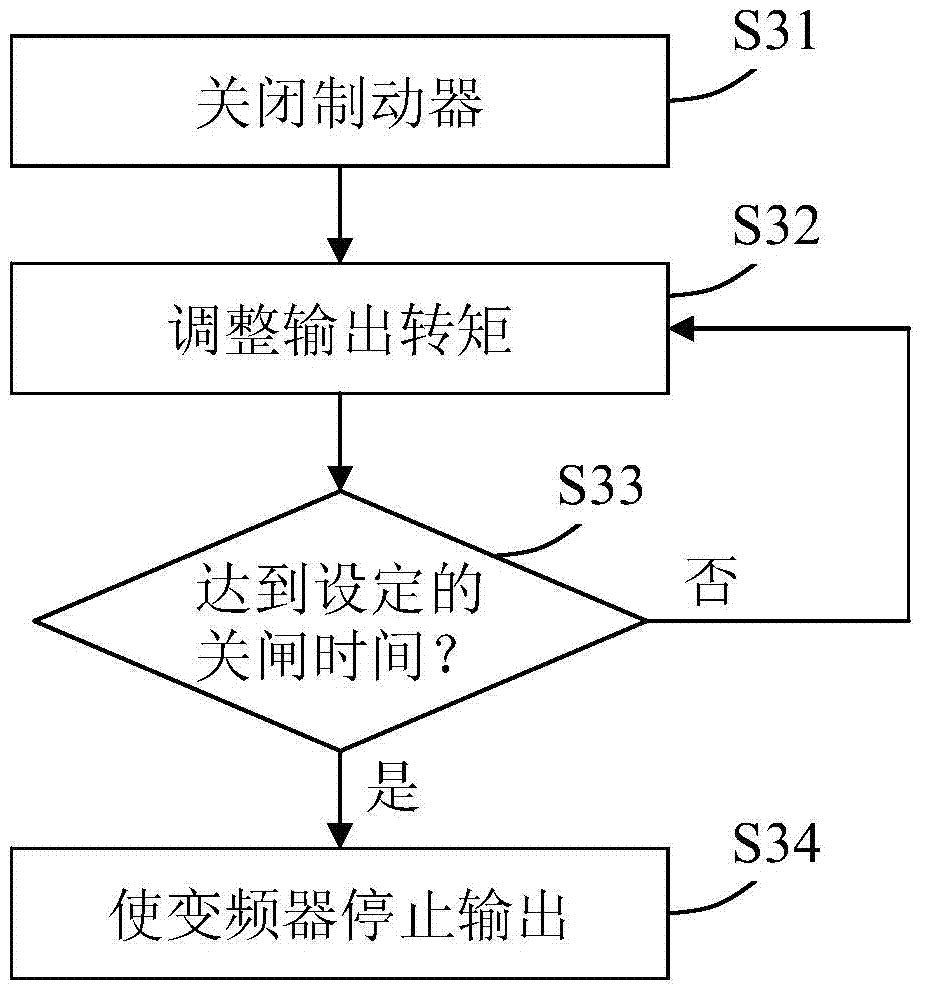

Brake control system and brake control method for construction lift

The invention provides a brake control system for a construction lift. The construction lift is driven by a motor controlled by a frequency converter, and the brake control system comprises a brake control unit and a frequency converter control unit; the brake control unit is used for outputting a gate closing instruction to a brake when a shutdown command is received; the frequency converter control unit is used for adjusting output torque of the frequency converter in real time according to gate closing time, and the output torque is reduced along with elapsing of the gate closing time. The brake control system has the advantages that the output torque of the frequency converter is adjusted in real time in brake procedures, a brake pad of the brake can be stably combined with a motor shaft, jittering is prevented, and accordingly a lift car can be stably shut down under the control of the brake control system.

Owner:SUZHOU INOVANCE TECH CO LTD

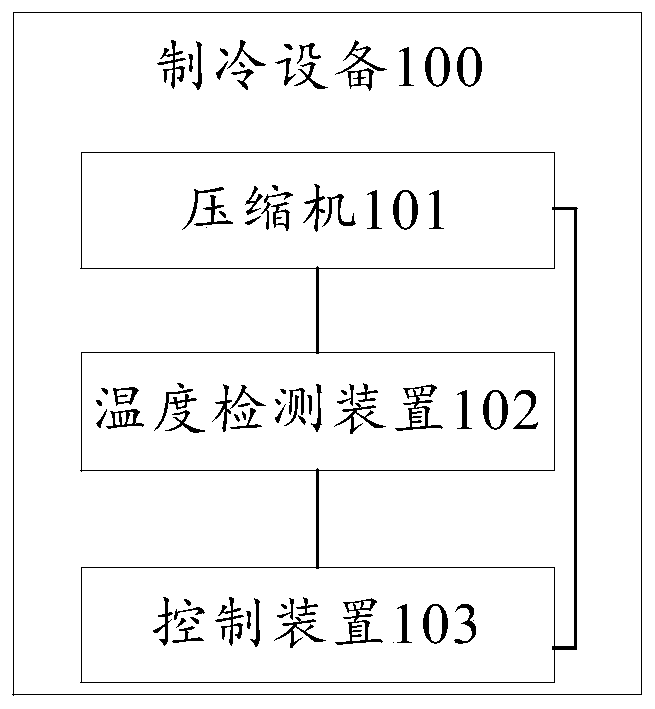

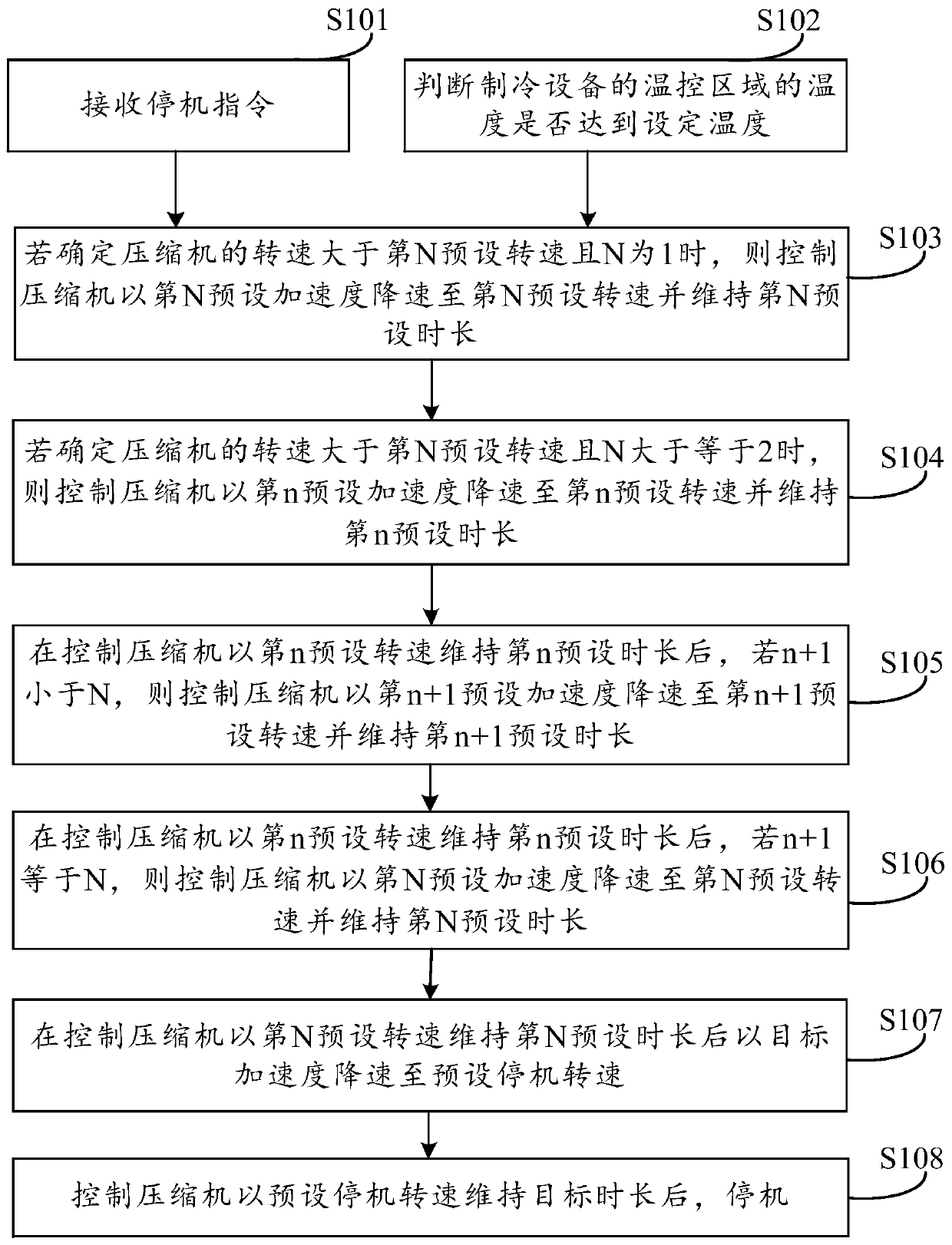

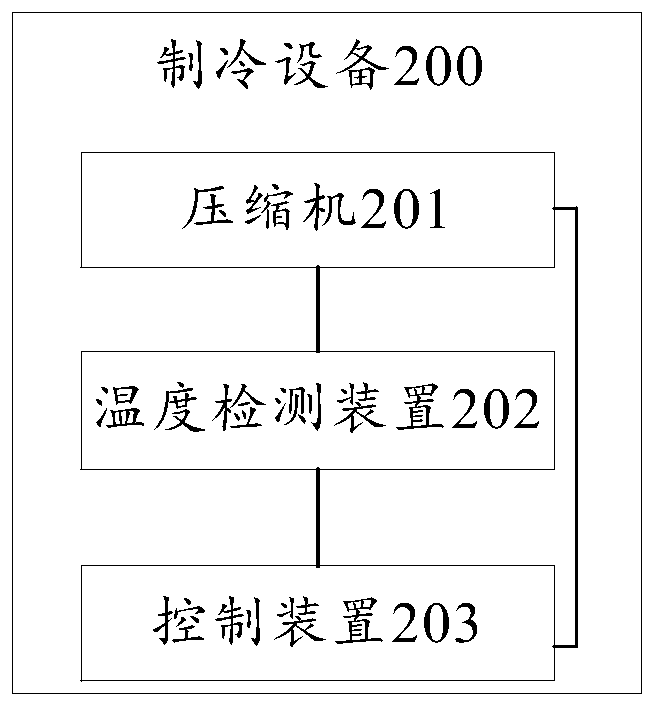

Refrigeration equipment and shutdown control method of compressor of refrigeration equipment

InactiveCN110953776AImprove experienceSolve the noiseRefrigeration safety arrangementRefrigeration plantTemperature control

The invention provides refrigeration equipment and a shutdown control method of a compressor of the refrigeration equipment, and relates to the field of compressors. The problem that when a machine core of the compressor collides with and impacts on a shell of the compressor at the shutdown moment, great noise is caused is avoided. The refrigeration equipment comprises a compressor, a temperaturedetection device and a control device; the temperature detection device is used for detecting the temperature of a temperature control area of the refrigeration equipment; and the control device is configured to be characterized in that if the rotating speed of the compressor is determined to be larger than the Nth preset rotating speed, the compressor is controlled to be sequentially deceleratedto the nth preset rotating speed by the nth preset accelerated speed according to the sequence of n from small to large and kept at the nth preset rotating speed for the nth preset duration, after thecompressor is controlled to be kept at the Nth preset rotating speed for the Nth preset duration, the compressor is decelerated to the preset shutdown rotating speed by the target accelerated speed,and after being controlled to be kept at the preset shutdown rotating speed for the target duration, the compressor is shut down.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

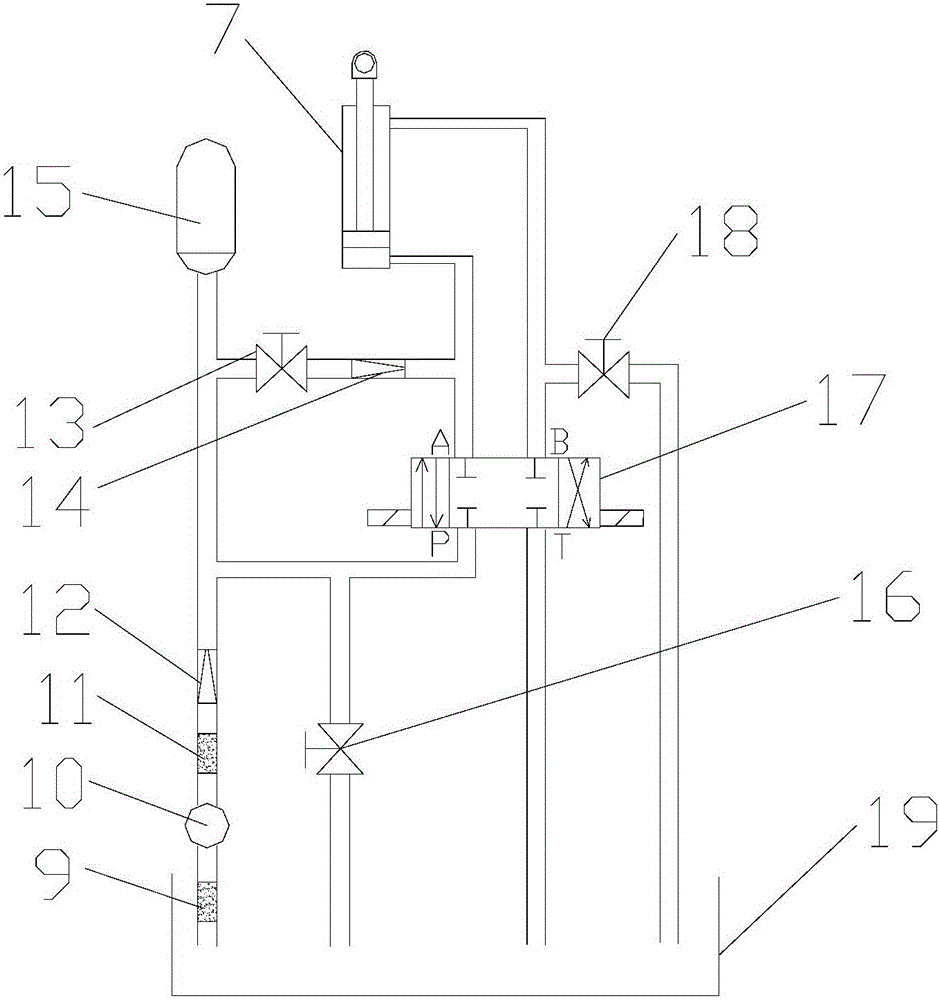

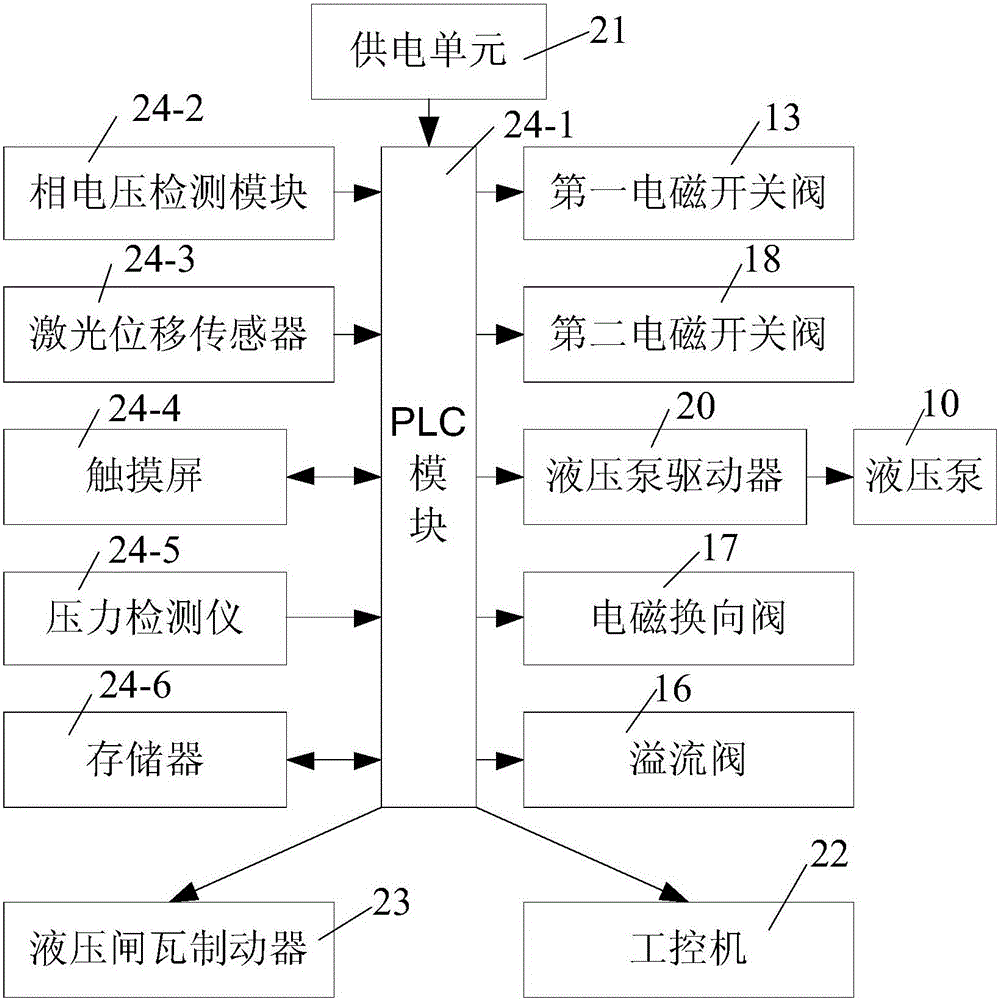

Anti-runaway protection system and method for downward belt conveyor

ActiveCN105947596AReduce shockEasy to useConveyorsControl devices for conveyorsPower gridEngineering

The invention discloses an anti-runaway protection system and method for a downward belt conveyor. The protection system comprises a damping device, a hydraulic execution subsystem and a control subsystem, wherein the damping device is used for braking running of the belt conveyor mounted on a downward inclined surface in parallel; the hydraulic execution subsystem is used for driving the damping device to move; the control subsystem is used for detecting and controlling the running state of the belt conveyor in real time; and the system is convenient to mount and operate. The protection method comprises steps as follows: 1, working condition information of the belt conveyor is acquired in real time, and the acquired information is stored and uploaded synchronously; 2, the revolving speed of a motor of the belt conveyor is analyzed and processed; 3, whether a power supply module of a power grid is powered off or not is judged; 4, the belt conveyor is controlled to brake and slow down intermittently; 5, the belt conveyor is controlled to shut down. The system is novel in design, the runaway phenomena of the belt conveyor can be detected and controlled, the belt conveyor can be protected to shut down stably under the condition of the power failure, the condition of runaway of the belt conveyor due to the dead weight of materials during the power failure can be avoided, and the use effect is good.

Owner:XIAN UNIV OF SCI & TECH

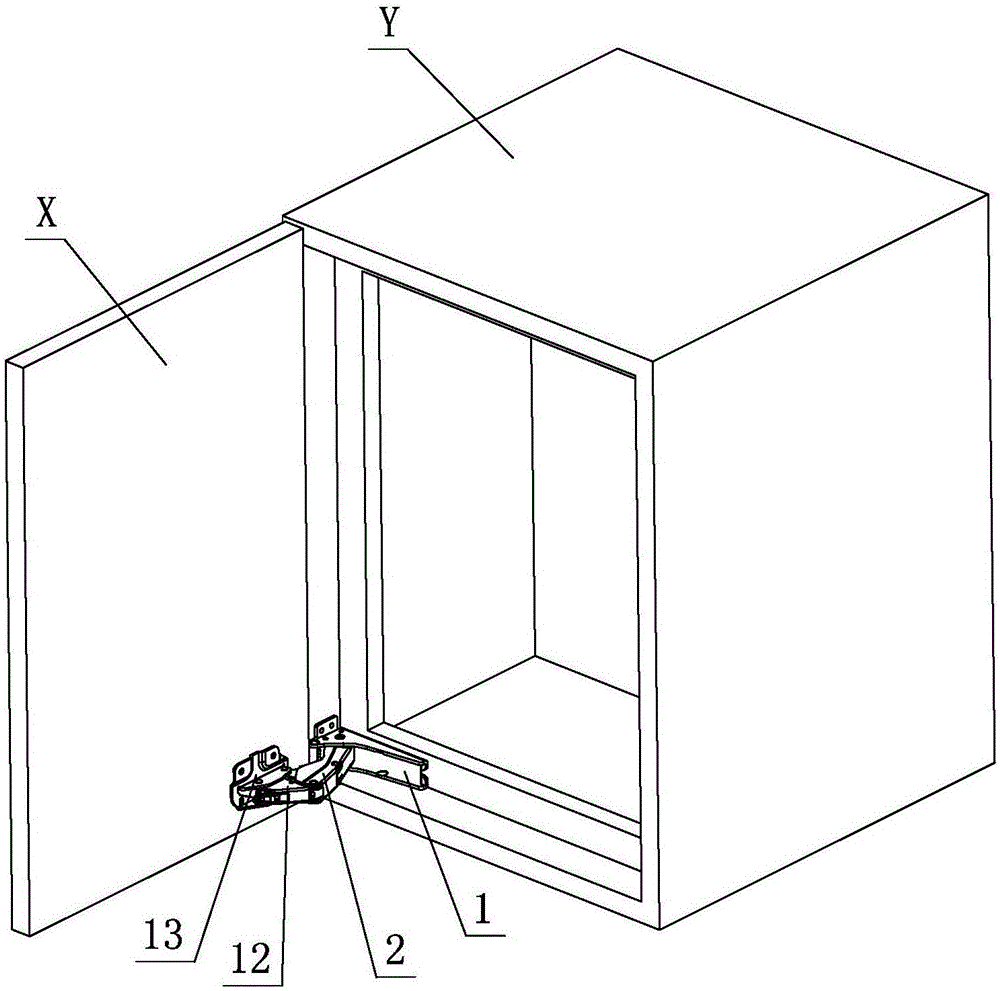

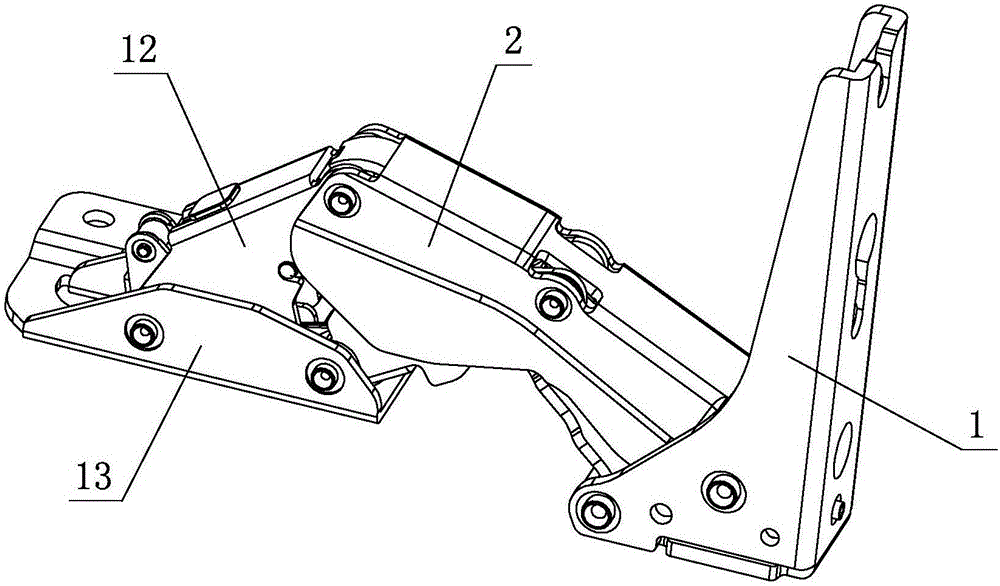

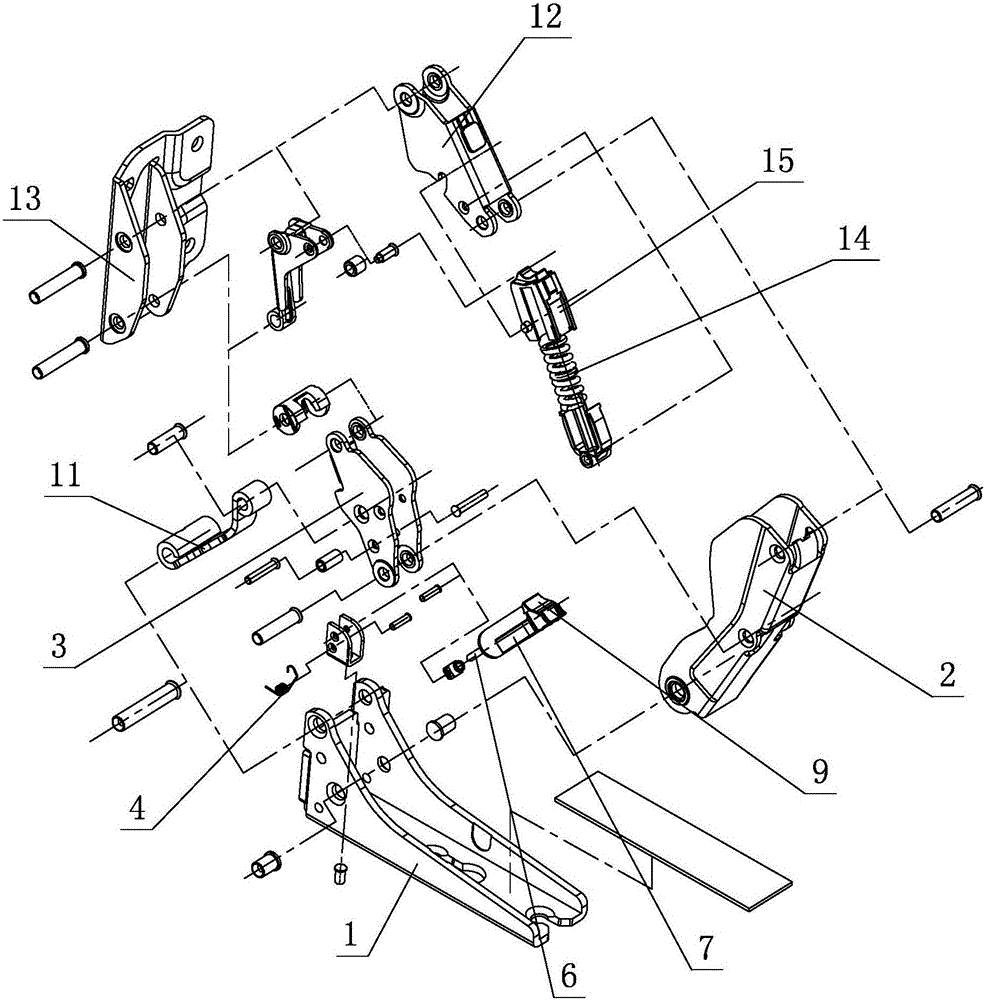

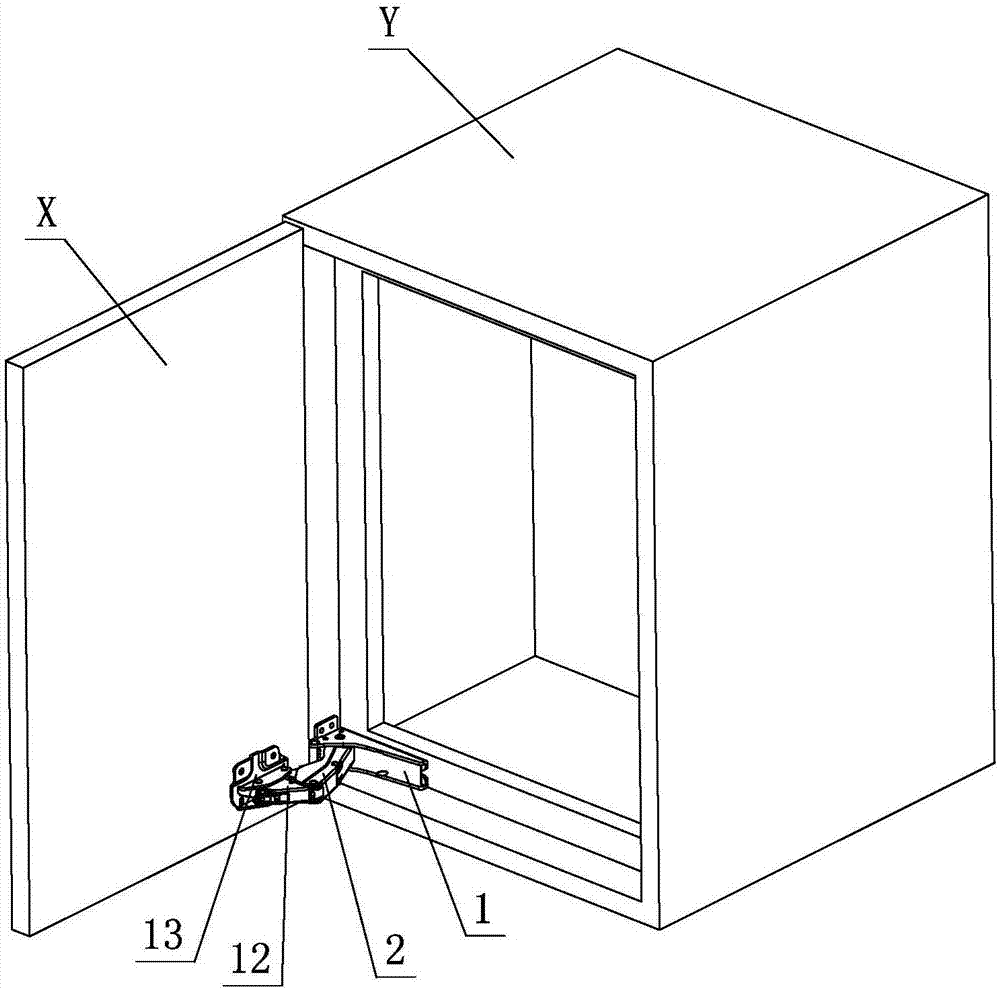

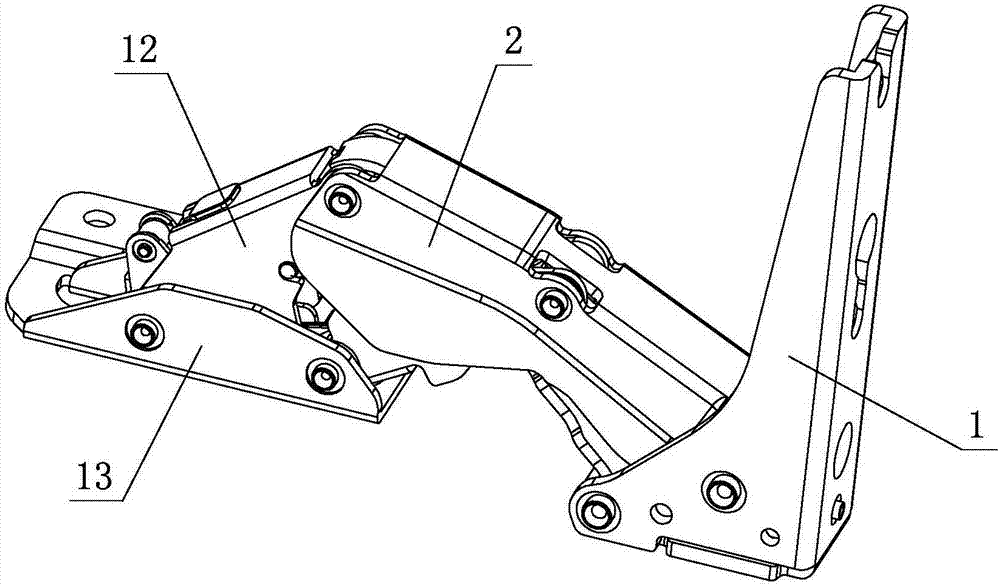

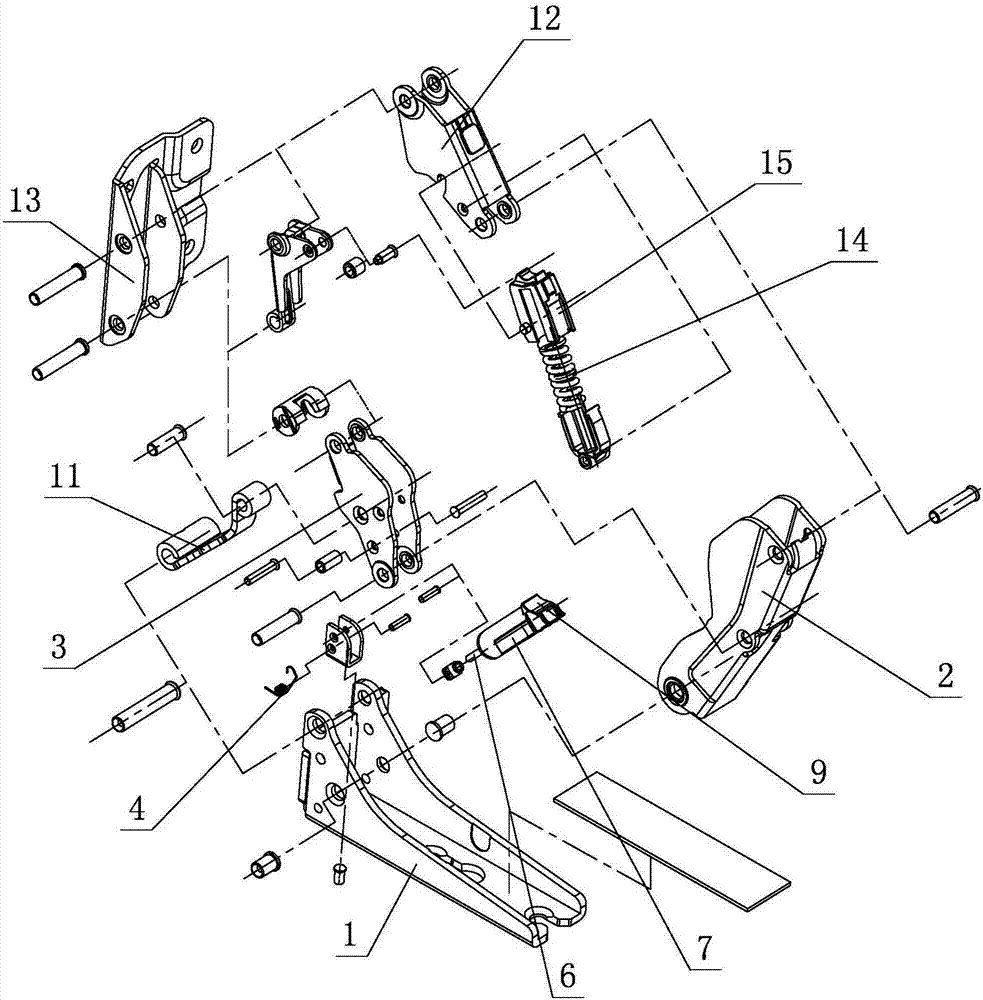

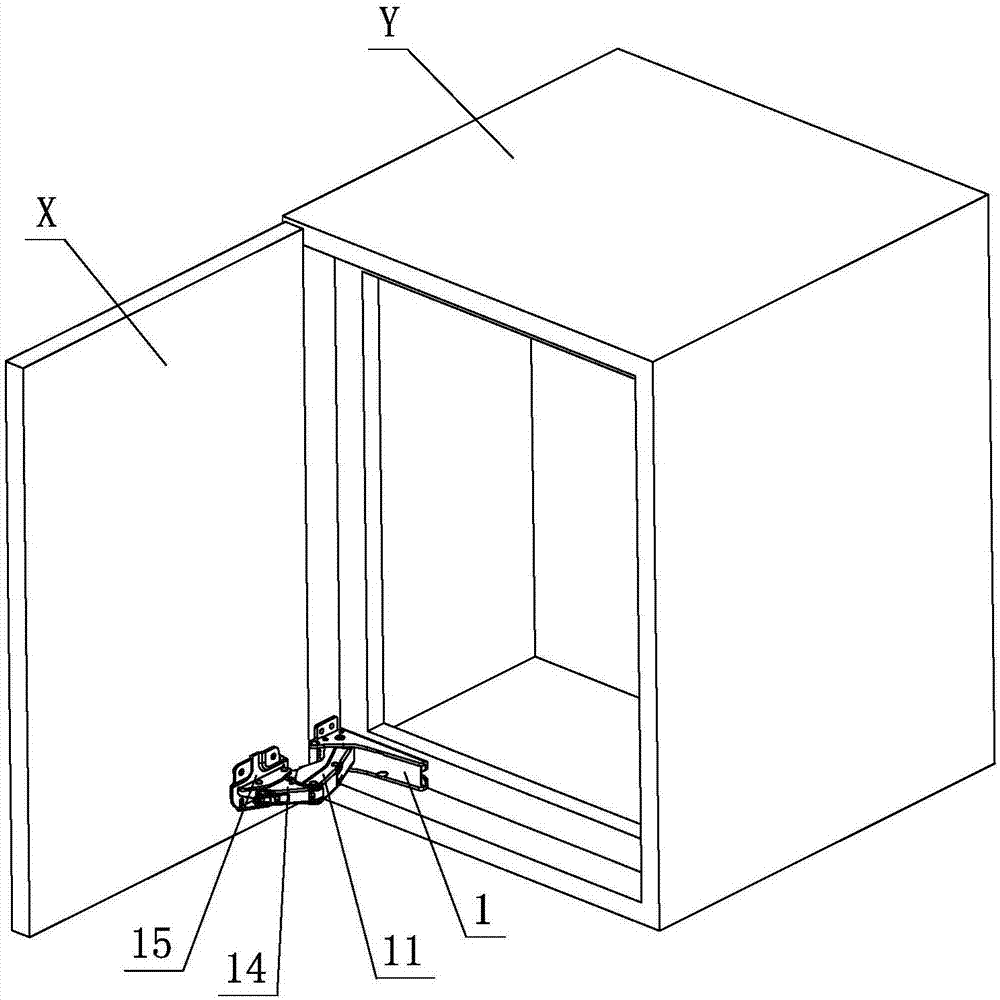

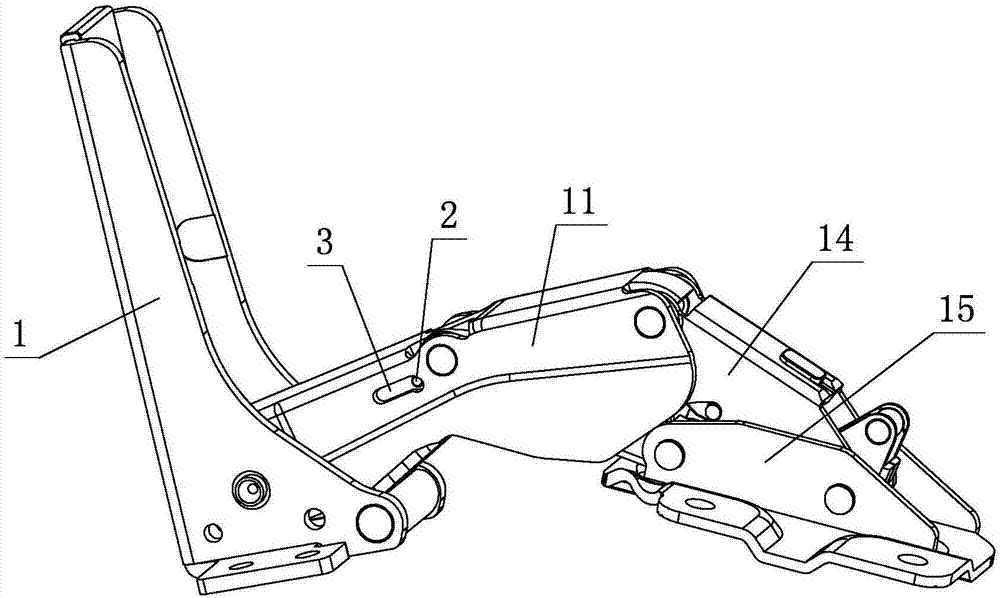

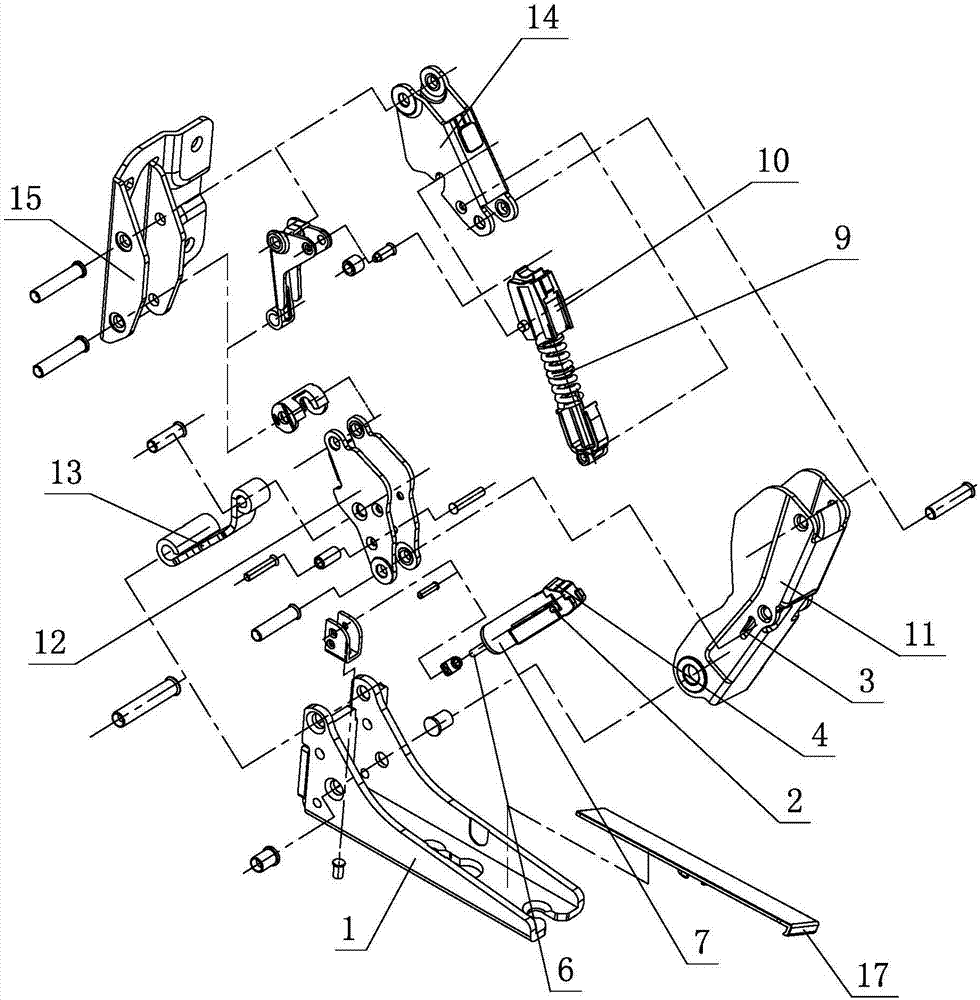

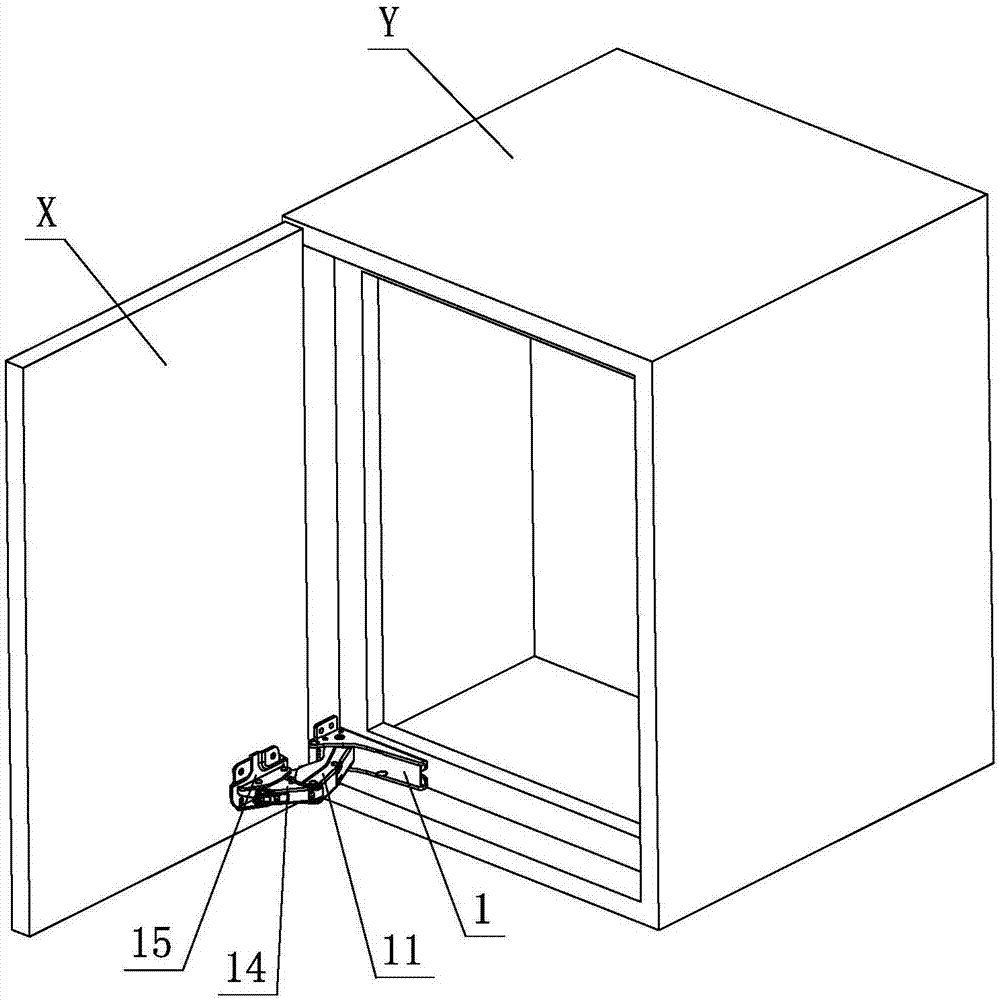

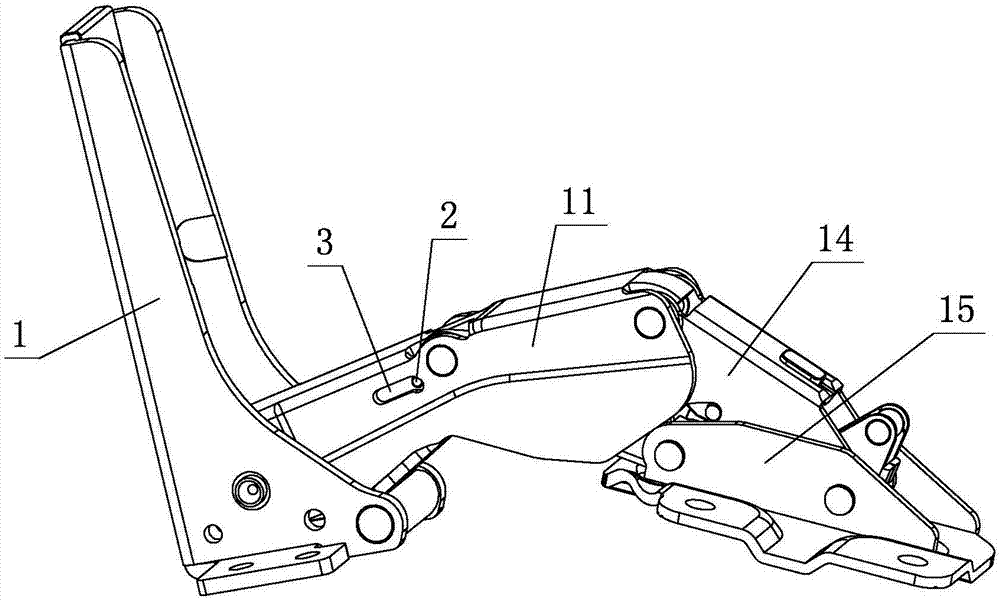

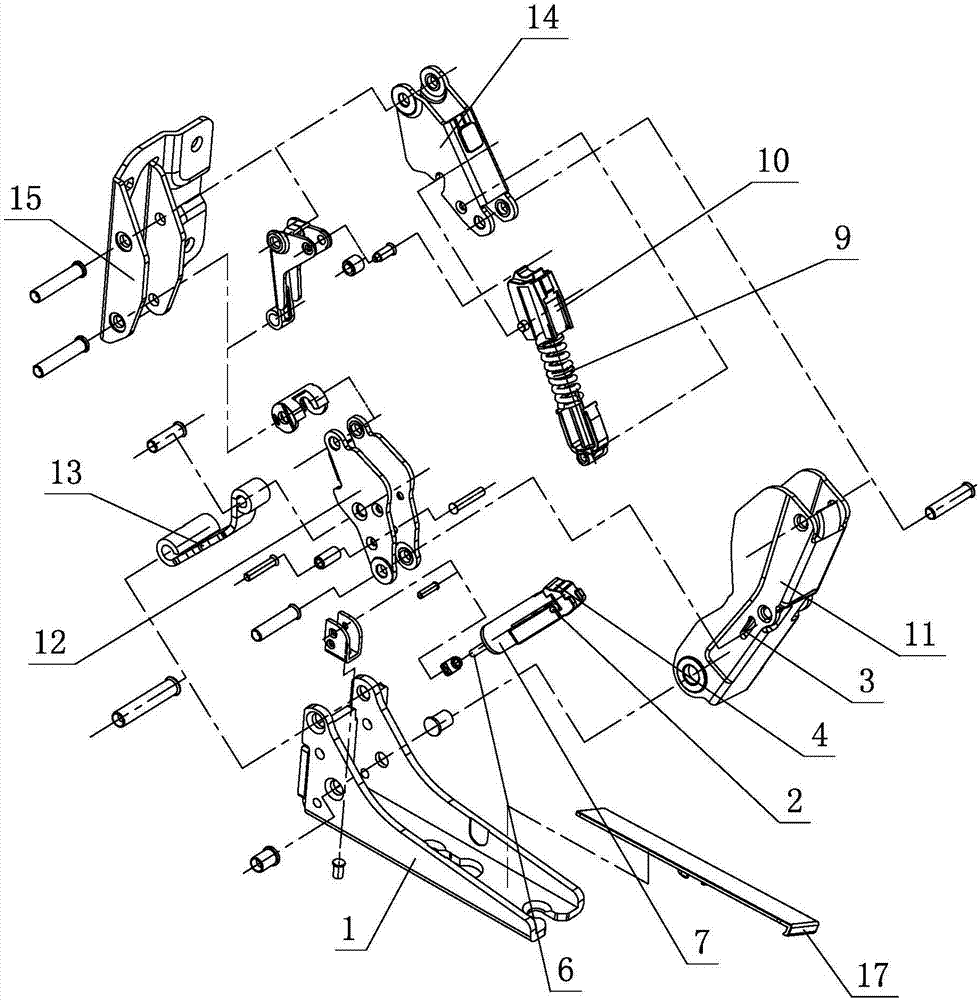

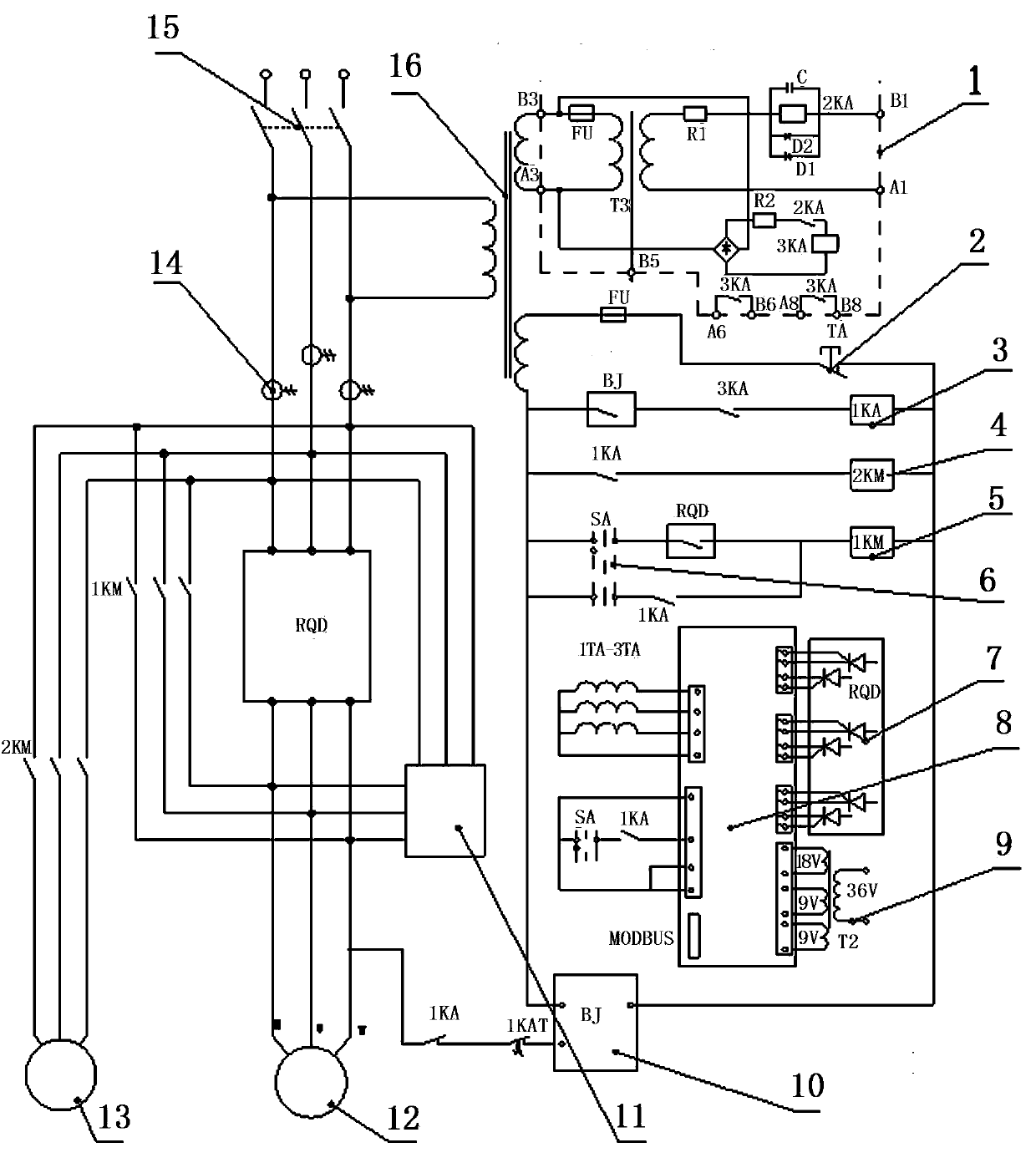

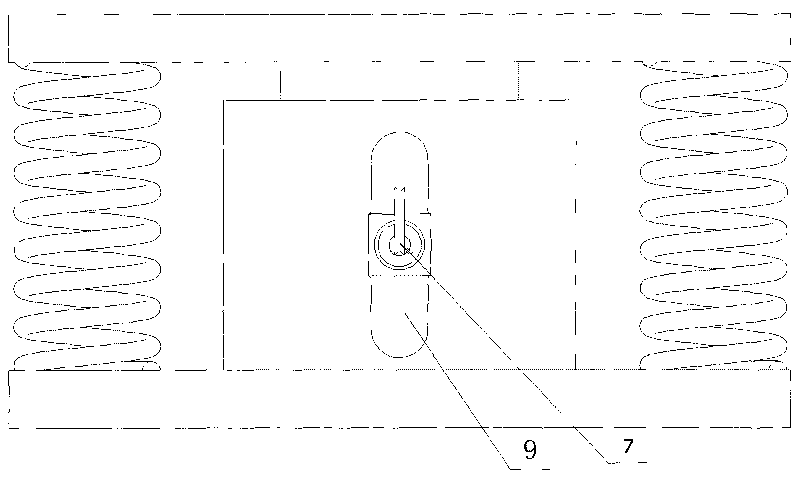

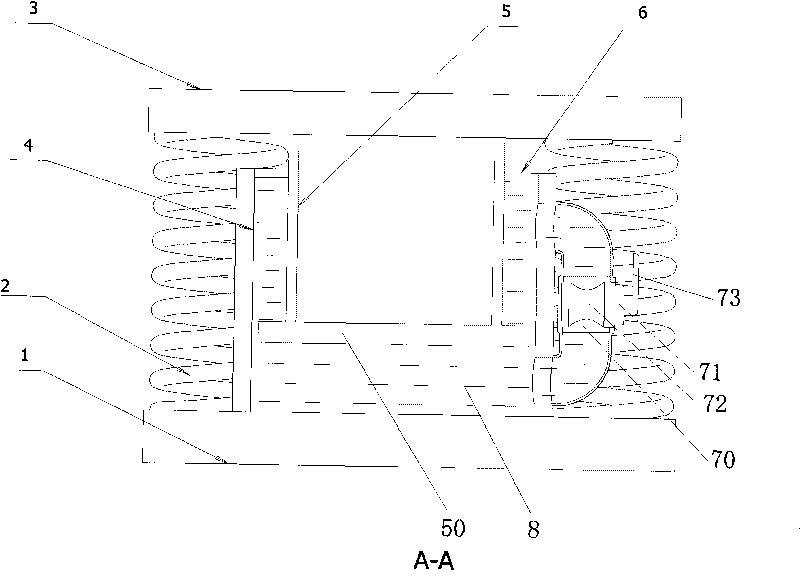

Damper opening and closing angle varying mechanism of hinge

ActiveCN106761110AWide range of usePrecise positioningBuilding braking devicesWing accessoriesControl theoryShock absorber

A damper opening and closing angle varying mechanism of a hinge comprises a blocking element, a connection element and a lever element which are in hinge fit with one another. A damper is arranged between the blocking element and the connection element. One end of the damper is rotationally arranged on the blocking element, and the other end of the damper abuts against the connection element. The connection element, the lever element and the damper are linked with one other relative to the blocking element when the hinge is opened or closed. When the hinge is closed by at least one certain angle, the lever element acts on the damper and drives the damper to slide on the connection element in a limited mode, the damper is compressed and generates damping force, and thus, damped closing of the hinge is achieved. Through the structure improvement, the damper opening and closing angle varying mechanism of the hinge has the characteristics that the structure is simple and reasonable, safety and reliability are achieved, production and implementation are easy, adjustment is fast, operation is convenient, the service life is long, practicability is high, and the opening and closing process is labor-saving, smooth, small in collision and low in noise.

Owner:伍志勇

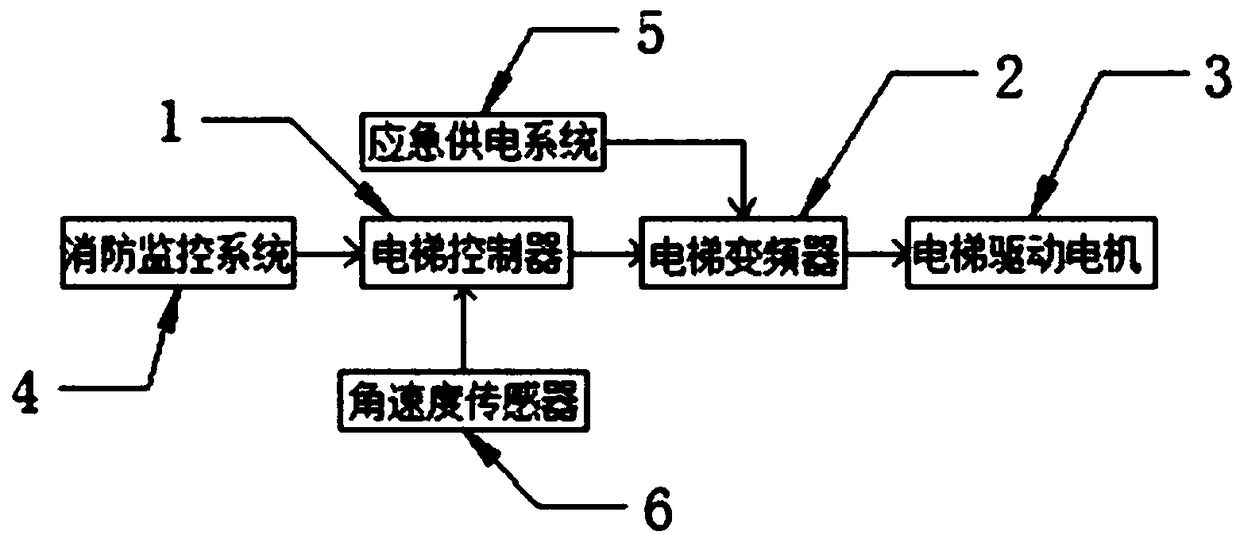

Safe elevator open-loop control machine

InactiveCN108163651AControls are simple and straightforwardEasy maintenanceElevatorsFrequency changerElectricity

The invention discloses a safe elevator open-loop control machine. The safe elevator open-loop control machine comprises an elevator driving motor, an elevator frequency converter, an elevator controller, an emergency power supply system and a fire-fighting monitoring system, wherein the elevator frequency converter is electrically connected with the elevator driving motor; a signal output end ofthe elevator controller is connected with a signal input end of the elevator frequency converter; a signal output end of the fire-fighting monitoring system is connected with a signal input end of theelevator controller; the fire-fighting monitoring system comprises a temperature sensor, a smoke sensor and an air quality monitor; the emergency power supply system comprises a power switch contactor and an emergency power supply; the emergency power supply is electrically connected with the power switch contactor; and a signal output end of the power switch contactor is connected with a signalinput end of the elevator frequency converter.

Owner:广州梯安电梯有限公司

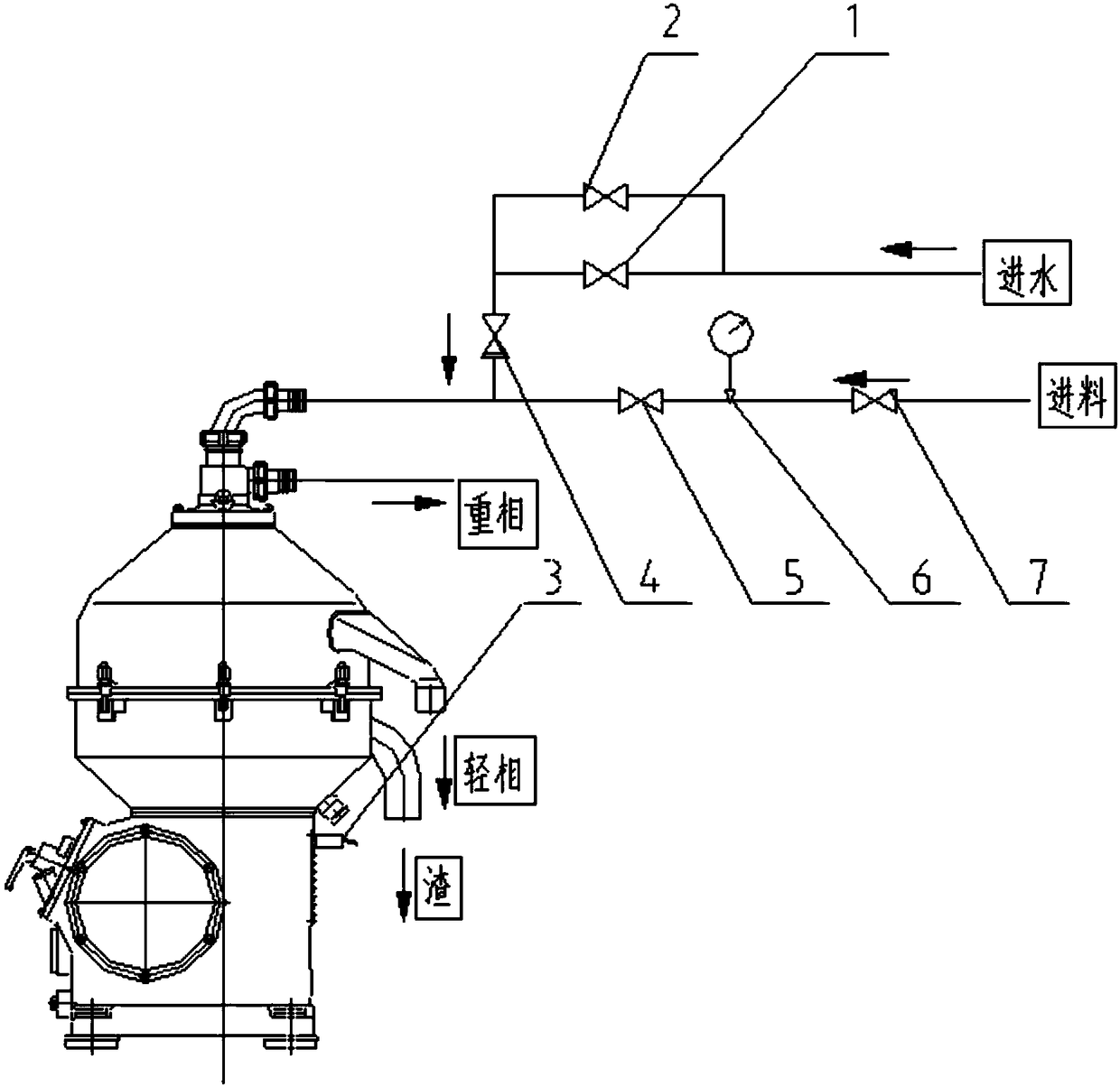

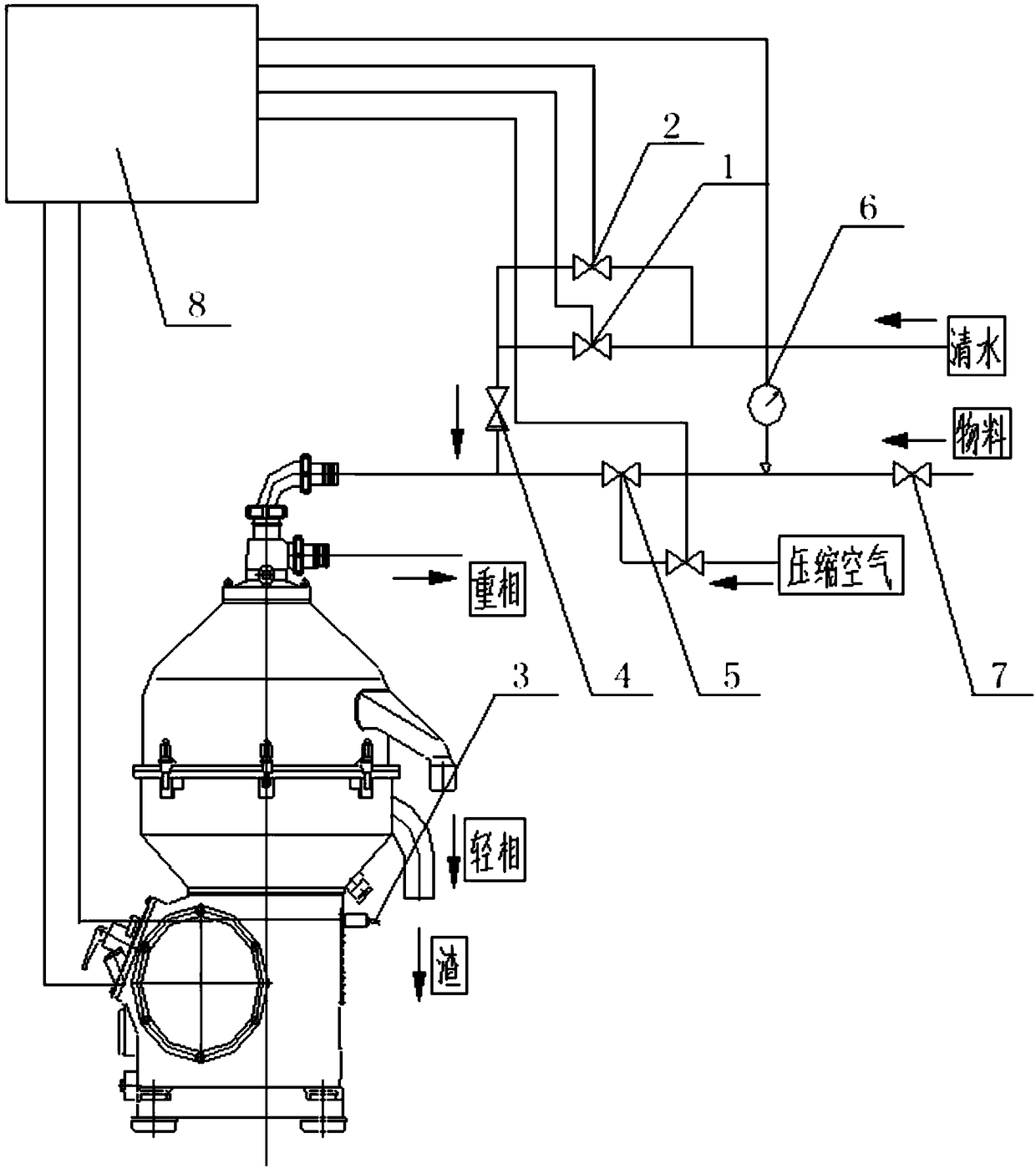

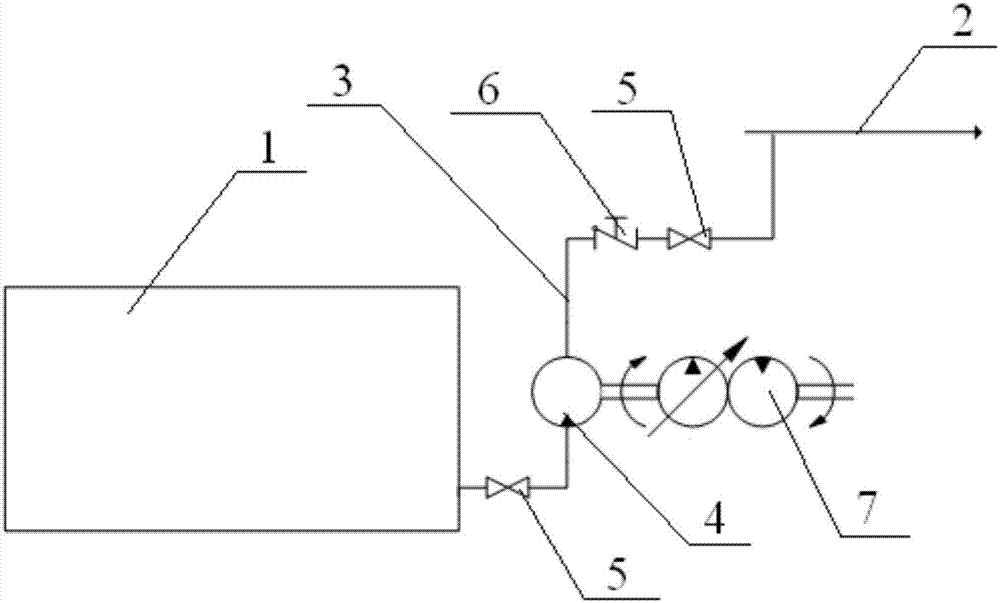

Nozzle type disc separator blockage prevention system and control method thereof

PendingCN108722689AEffective detection of blockageTroubleshootingCentrifugesSolenoid valveEngineering

The invention provides a nozzle type disc separator blockage prevention system which comprises a nozzle type disc separator, wherein a feed pipe joint of the nozzle type disc separator is connected with actuating mechanisms composed of multiple valves in sequence by virtue of a feed pipeline. The nozzle type disc separator comprises a manual ball valve, a pneumatic V-type switching ball valve anda check valve arranged in sequence along a feed direction of the feed pipeline, wherein the check valve is connected with a cleaning pipeline; a first solenoid valve and a second solenoid valve are connected in parallel on the cleaning pipeline; a detection module used for detecting fluid flow is arranged between the manual ball valve and the pneumatic V-type switching ball valve. According to thenozzle type disc separator blockage prevention system disclosed by the invention, whether nozzle blockage occurs in the machine operating process can be effectively detected by a vibrating sensor, and coping response is made in time. The machine failure can be eliminated to enable the machine to continuously enter a normal operating state by feeding cleaning water.

Owner:CSSC NANJING LUZHOU MACHINE

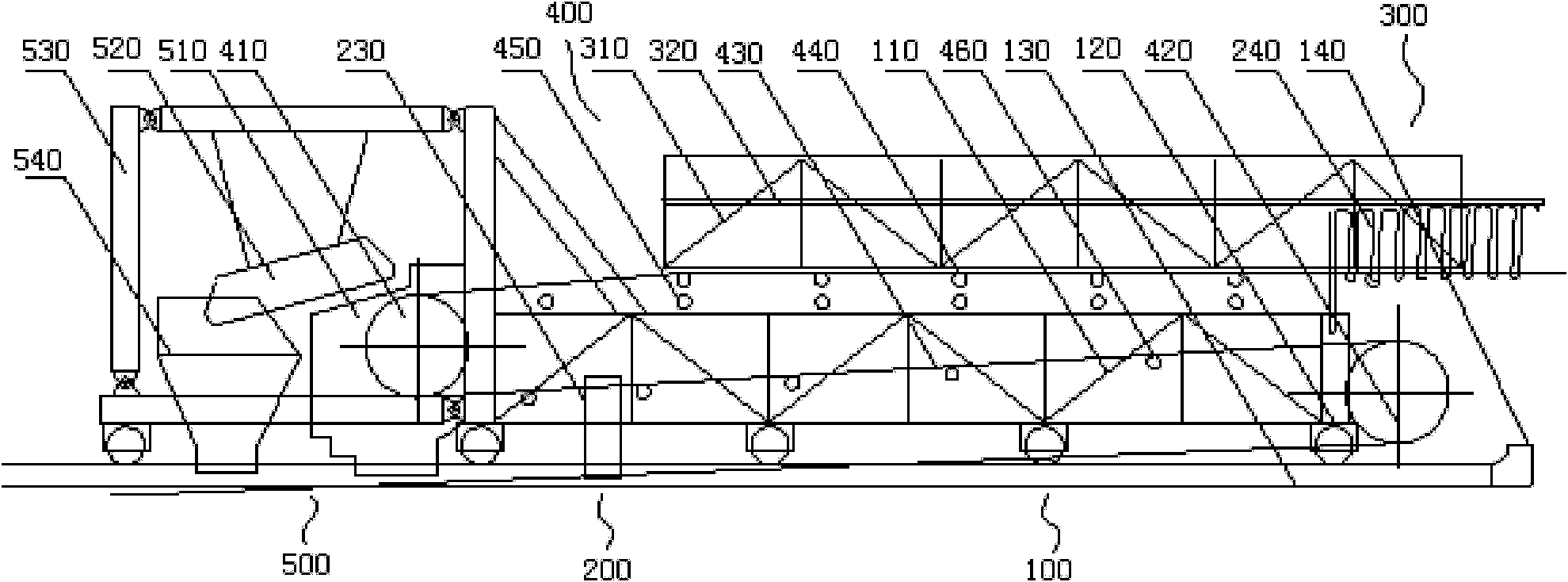

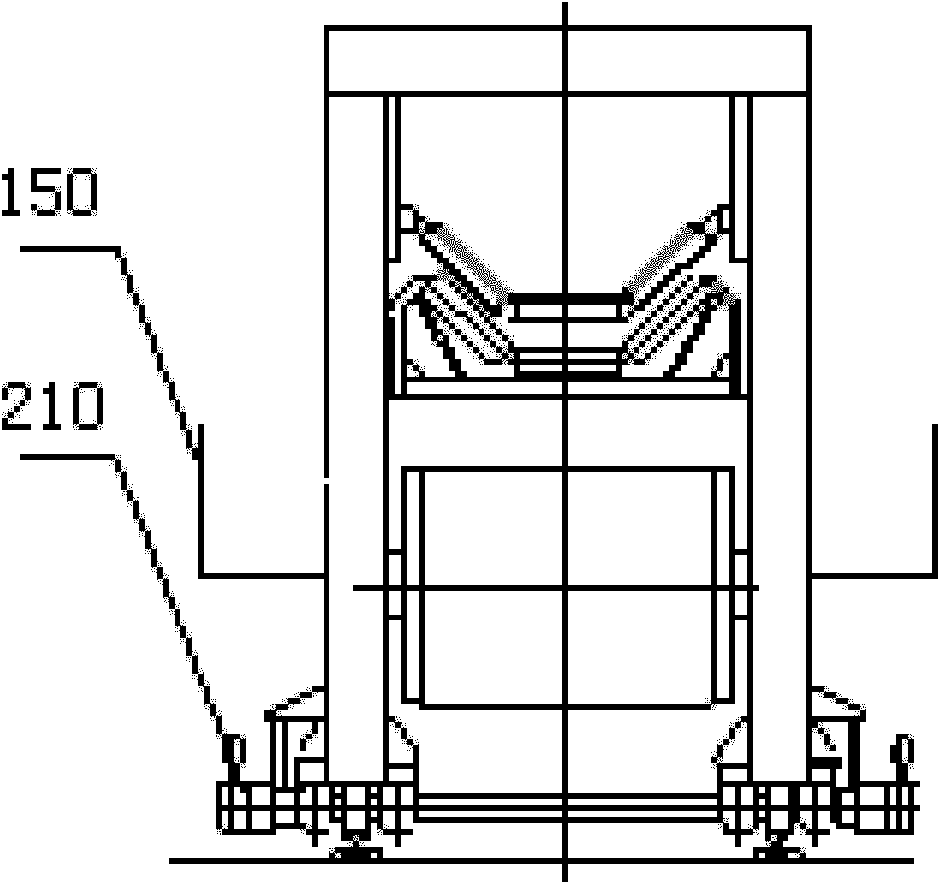

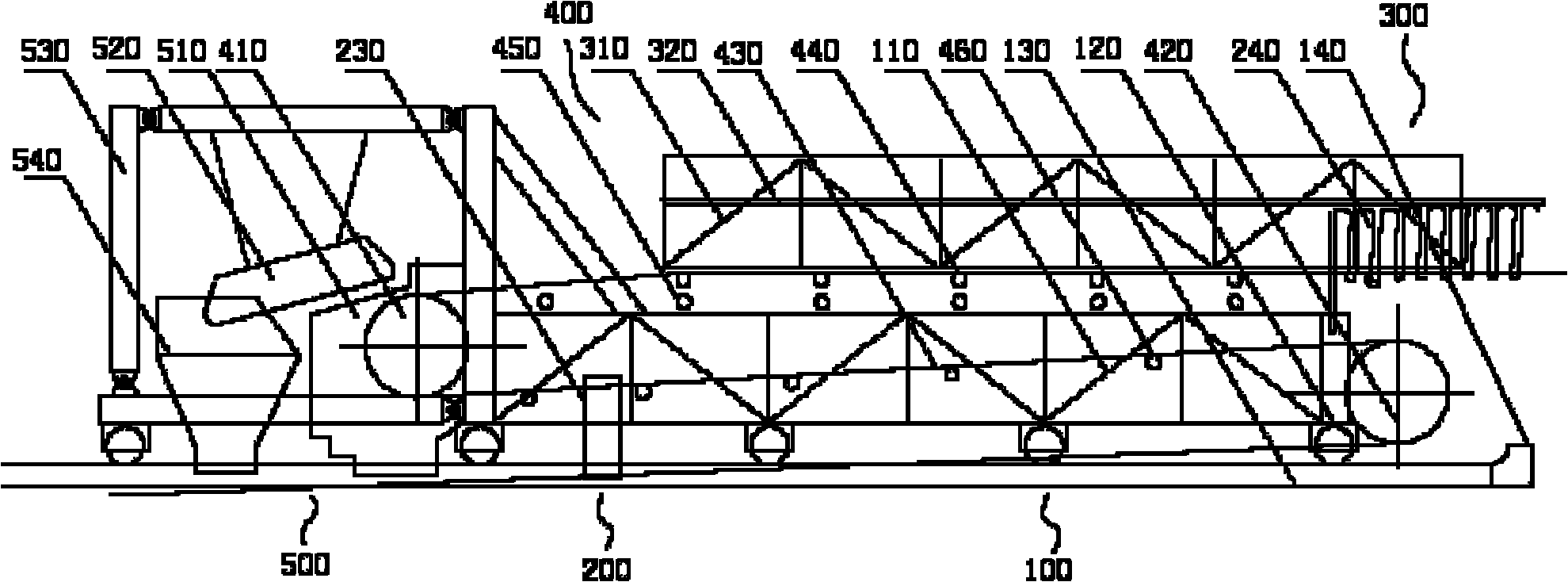

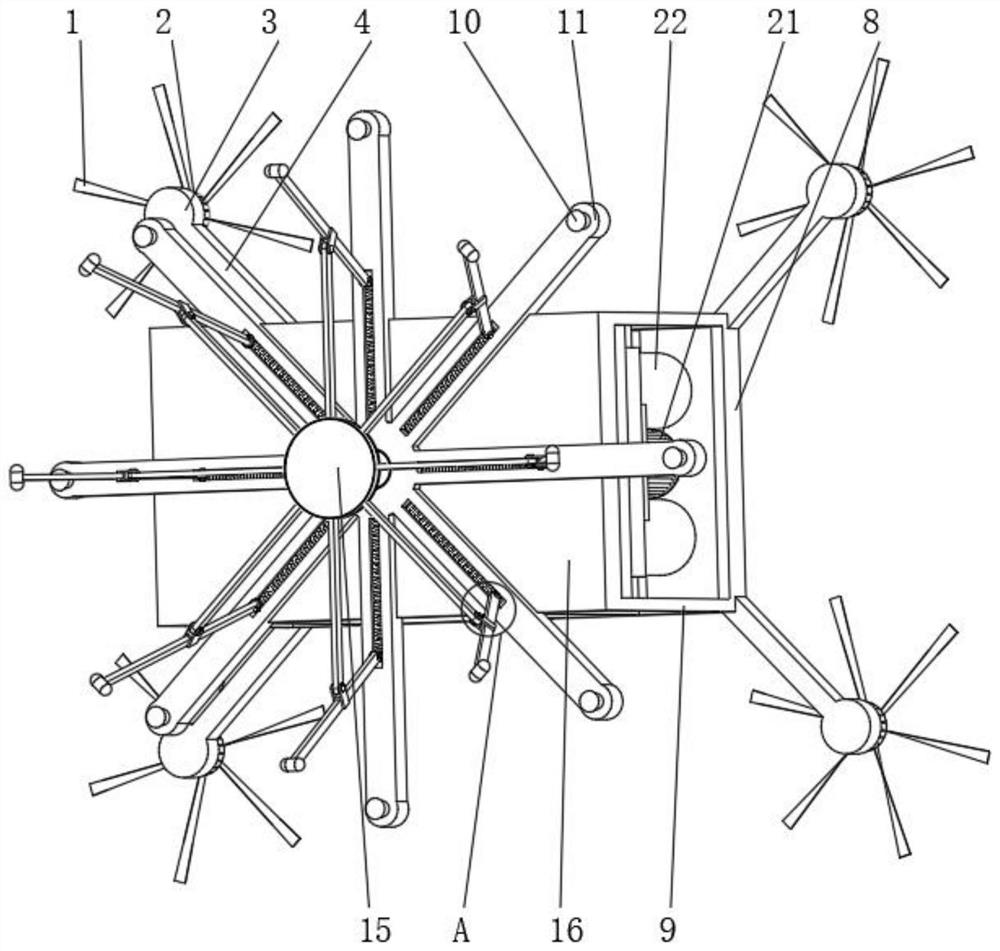

Multi-station expander

InactiveCN102101582ARealize multi-point feedingGuaranteed uptimeConveyor partsEngineeringMaterial supply

The invention discloses a multi-station expander. The expander is characterized by comprising a body device, a driving device, a material supply device, a conveying device and a feeding device, wherein the body device is controlled by the driving device to change a feeding site; the material supply device is used for conveying a material to the feeding device through the conveying device; the body device comprises a body; a wheel set below the body is connected with a track; the driving device comprises a variable frequency driving system and a flat towing line; the material supply device comprises a suspending bracket and a cable vehicle track; the conveying device comprises a head drum, a tail drum, a conveying belt, a suspending roller set, an upper roller set and a lower roller set; the suspending roller set is arranged on the suspending bracket; the upper roller set and the lower roller set are arranged on the body; and the feeding device comprises a feeding funnel, a separator and a separation funnel. The multi-station expander is important bulk material conveying and transferring equipment, so that the function of multi-point feeding can be realized, matched equipment such as an iron remover, a sampler, a large block remover and the like can be simultaneously arranged, and different functional requirements can be met.

Owner:SHANGHAI KEDA HEAVY IND GROUP

Shunt down method of fixed bed Fischer-Tropsch synthesis process

ActiveCN102161609BReduce adverse effectsReduced risk of cokingHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionNitrogenRaw material

The invention provides a shunt down method of a fixed bed Fischer-Tropsch synthesis process. The shunt down method comprises the following steps: when a device is shunted down after a fixed bed Fischer-Tropsch synthesis reaction is finished, firstly, maintaining the temperature of a catalyst bed layer to be unchanged; leading nitrogen from the inlet of a reactor, and simultaneously, cutting off raw material gas for feeding; maintaining the amount of a circulating gas to be unchanged; after replacing to the required condition, gradually reducing the pressure of a reactor, and then gradually reducing the temperature of the catalyst bed layer; and when the temperature of the bed layer is reduced to less than100 DEG C, gradually completing shunt down. Compared with the prior art, by using themethod in the invention, the side influence to the catalyst bed layer in the shunt down process is reduced while stable shunt down is achieved, thereby proving a good guarantee for subsequent reworking and catalyst unloading.

Owner:CHINA PETROLEUM & CHEM CORP +1

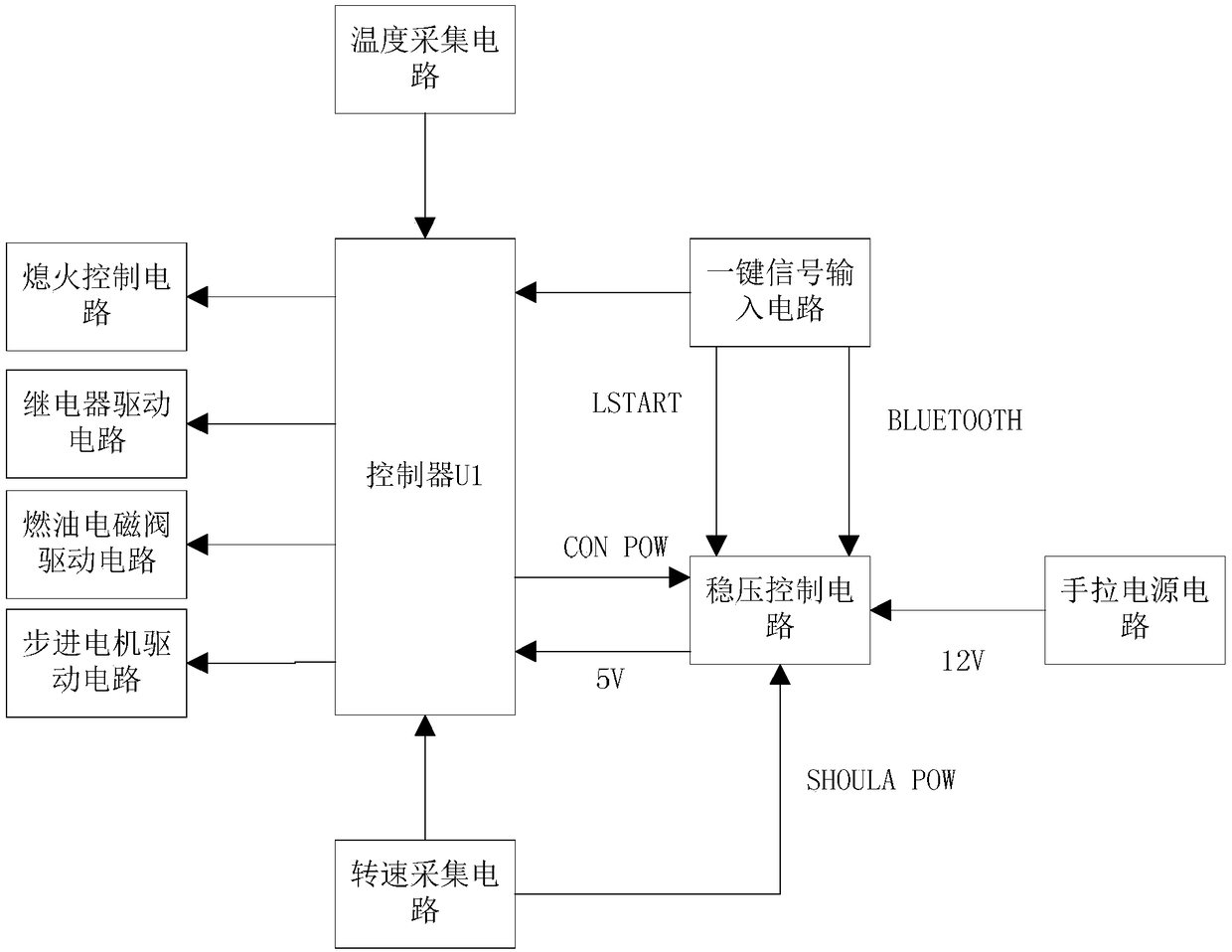

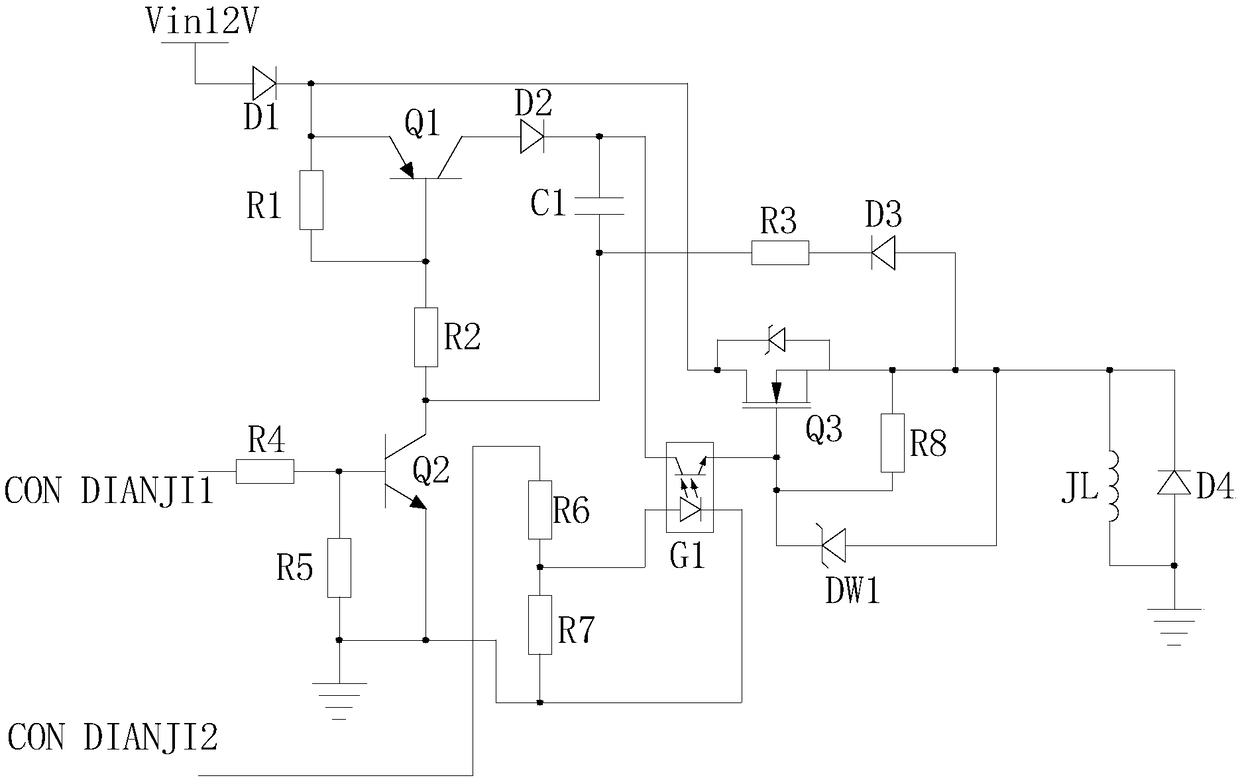

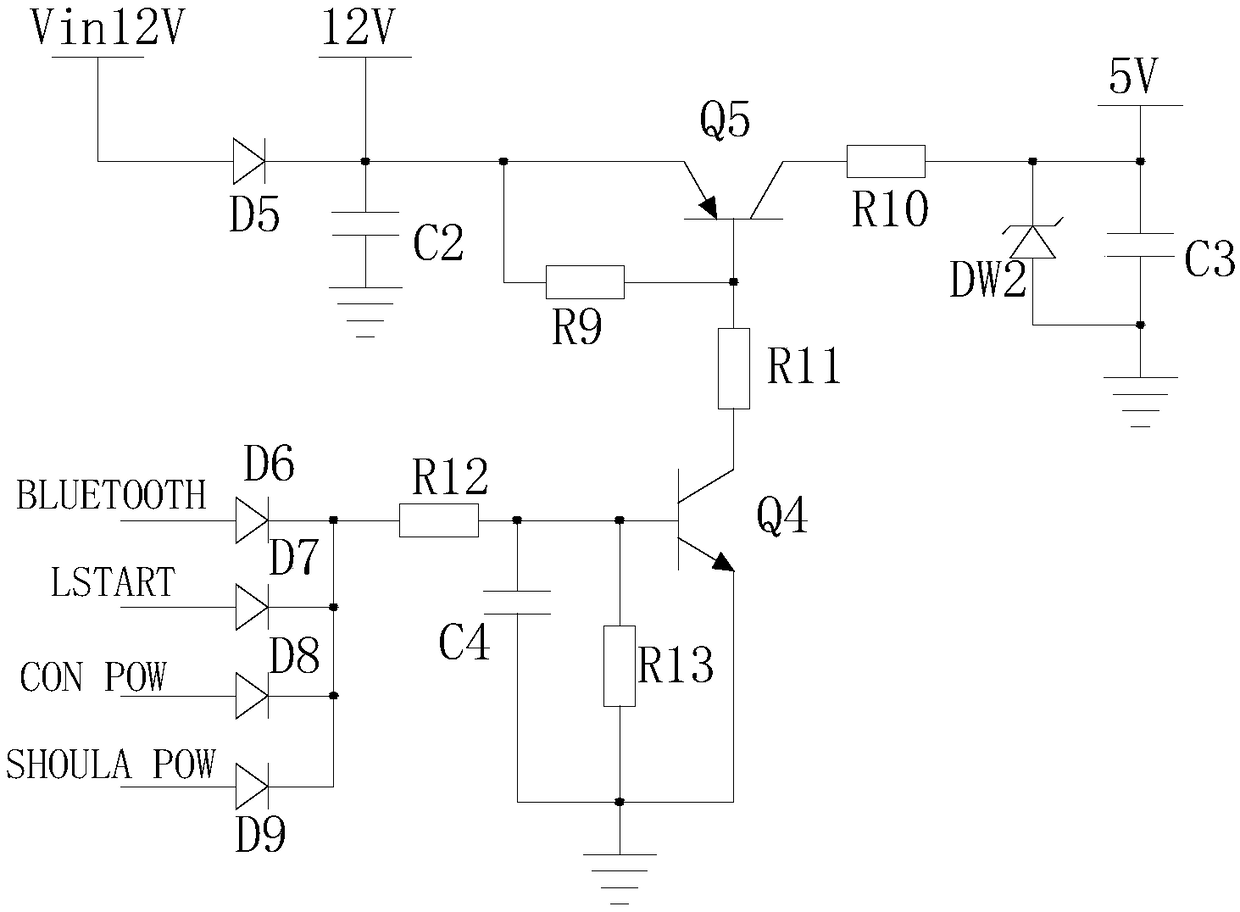

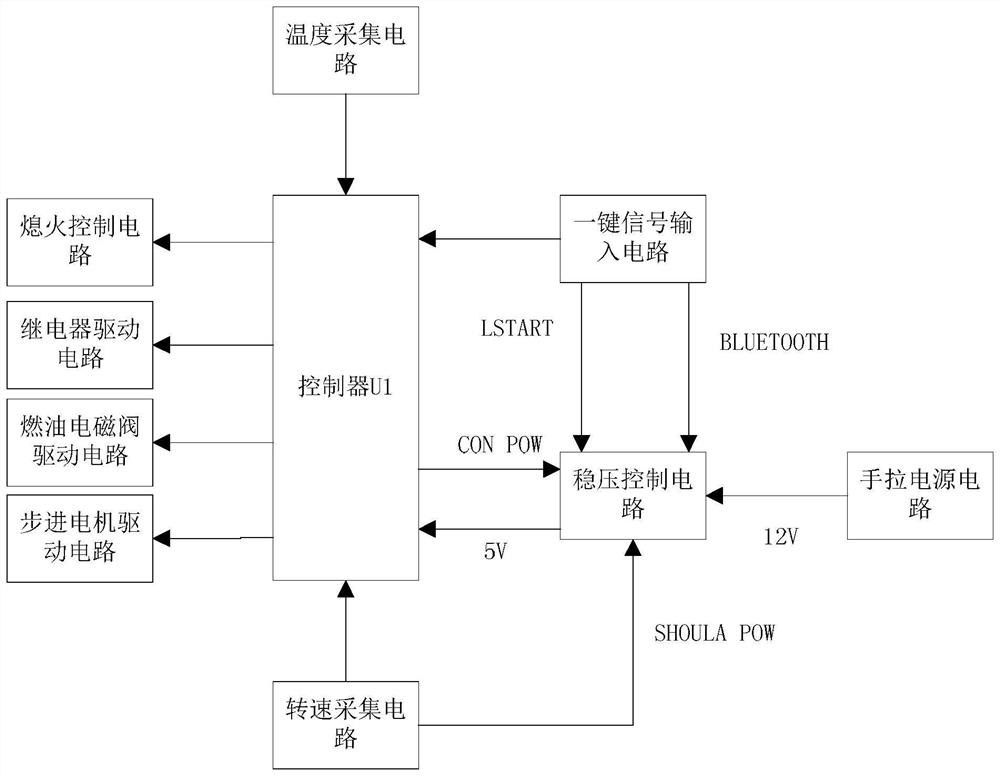

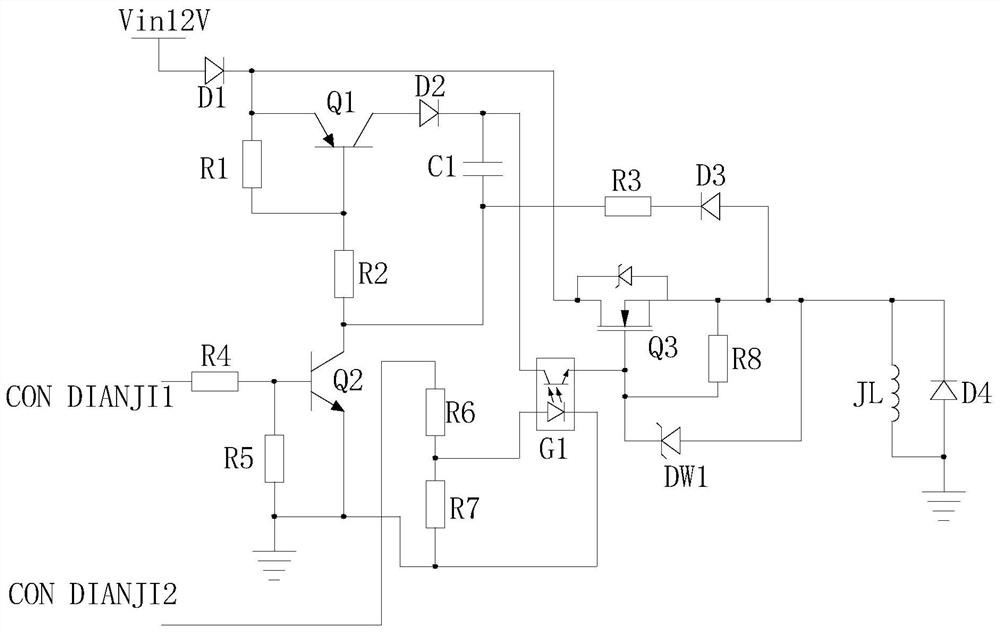

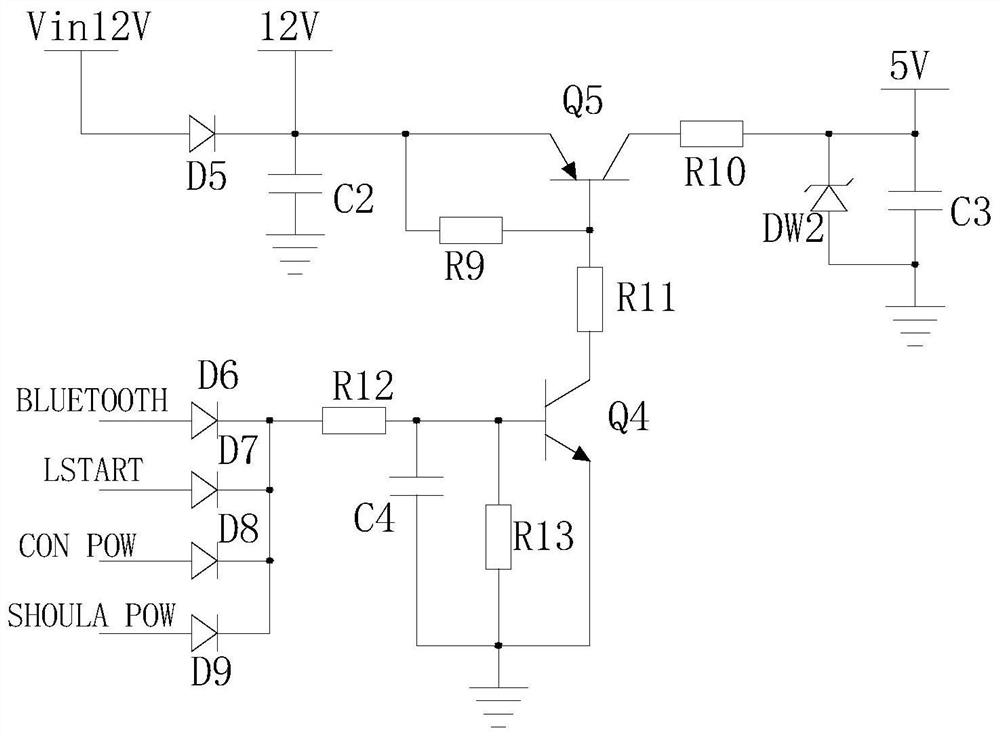

Generator one-key start-stop control system

ActiveCN109488508AStart successfully and stableImprove adaptabilityInternal combustion piston enginesElectric motor startersThree-phaseStart button

The invention provides a generator one-key start-stop control system, which includes a one-key signal input circuit, a temperature acquisition circuit, a rotating speed acquisition circuit, a controller U1 and a start-stop execution circuit. The input end of the one-key signal input circuit is connected with a Bluetooth receiving module and a start button, and used for receiving a Bluetooth start-stop signal or a key start-stop signal and inputting the signals to the controller U1; the input end of the temperature acquisition circuit is connected with a temperature sensor, and used for receiving a temperature signal of an engine of a generator detected by the temperature sensor and transmitting the signal to the controller U1; the input end of the rotating speed acquisition circuit is connected to a three-phase power line of the generator, and used for collecting the rotating speed of the engine and outputting the rotating speed to the controller U1; the controller U1 is used for receiving the start-stop signal output by the one-key signal input circuit, receiving the temperature and rotating speed signals, and controlling the start-stop execution circuit according to the temperature and speed signals; and the start-stop execution circuit is used for receiving a control signal output by the controller U1 to perform the start-stop action. According to the generator one-key start-stop control system, a key or Bluetooth mode is used for starting or stopping the engine of the generator, so as to convenient to control; and furthermore, stability of the whole generator one-key start-stop control system is good, and stability of the starting and stopping processes of the engine of the generator can be ensured.

Owner:LONCIN MOTOR

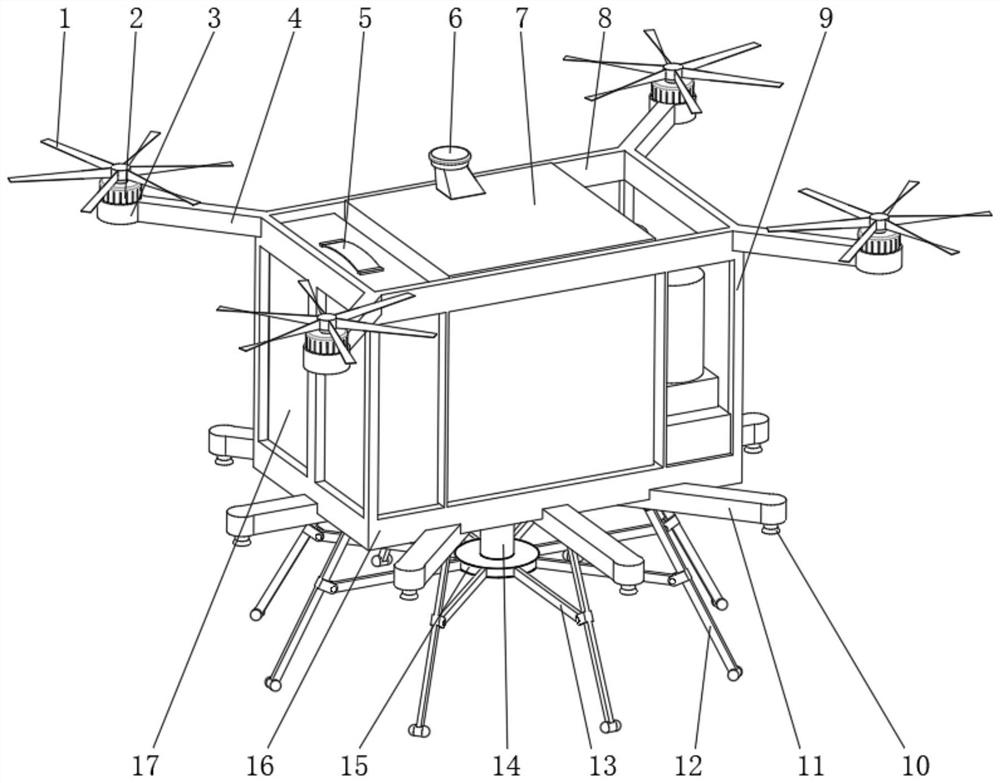

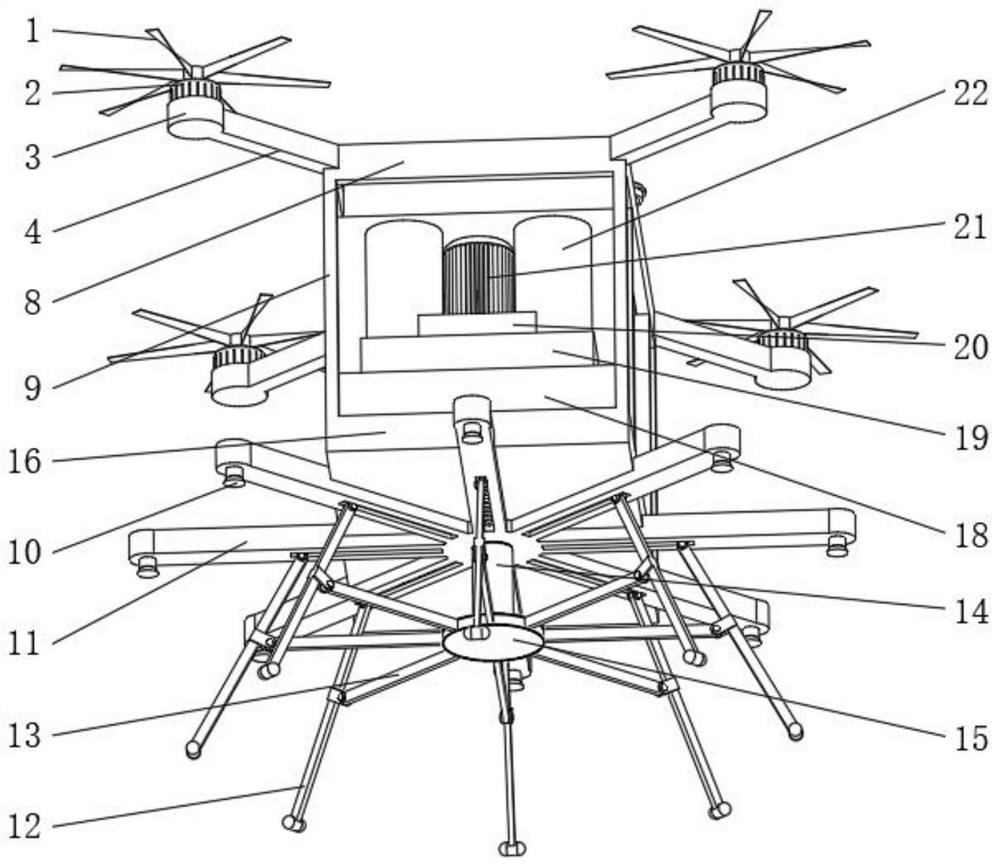

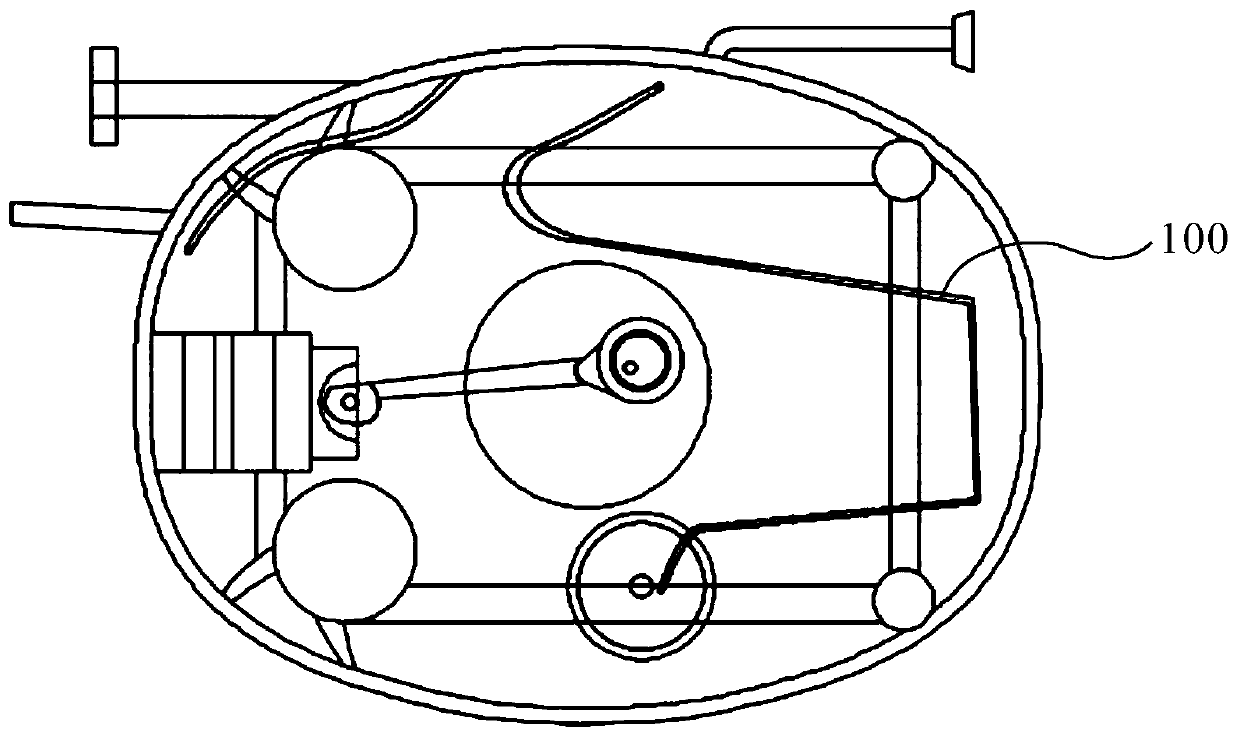

Micro-vibration plant protection unmanned aerial vehicle

PendingCN112544597AGuaranteed synchronicityReduce vibrationAlighting gearInsect catchers and killersElectric machineryAutomotive engineering

The invention discloses a micro-vibration plant protection unmanned aerial vehicle, and relates to the technical field of plant protection unmanned aerial vehicles. The micro-vibration plant protection unmanned aerial vehicle comprises a top frame and a bottom plate, a middle column is fixedly connected to the middle of the bottom of the bottom plate, a middle disc is fixedly connected to the bottom of the middle column, and a spring box is fixedly connected to one side of the top of the bottom plate. According to the micro-vibration plant protection unmanned aerial vehicle, by arranging a power box, two plunger pumps can be driven to work at the same time through a pesticide pump motor, so that the synchronism of the two plunger pumps is guaranteed, by arranging the spring box, when a vibration reduction plate is affected by the plunger pumps, vibration can be weakened through vibration reduction springs, and the purpose of reducing vibration is achieved; and by arranging a pesticidespraying rod, a landing spring can be arranged in the pesticide spraying rod, a sliding block is jacked tightly through the landing spring, when the unmanned aerial vehicle lands, due to the fact thatthe bottoms of foot rods are not connected, the unmanned aerial vehicle can stop stably on a bumpy road surface, meanwhile, the landing spring is compressed to achieve the effect of reducing vibration, and the purpose of stopping the unmanned aerial vehicle stably is achieved.

Owner:河南正大航空工业股份有限公司

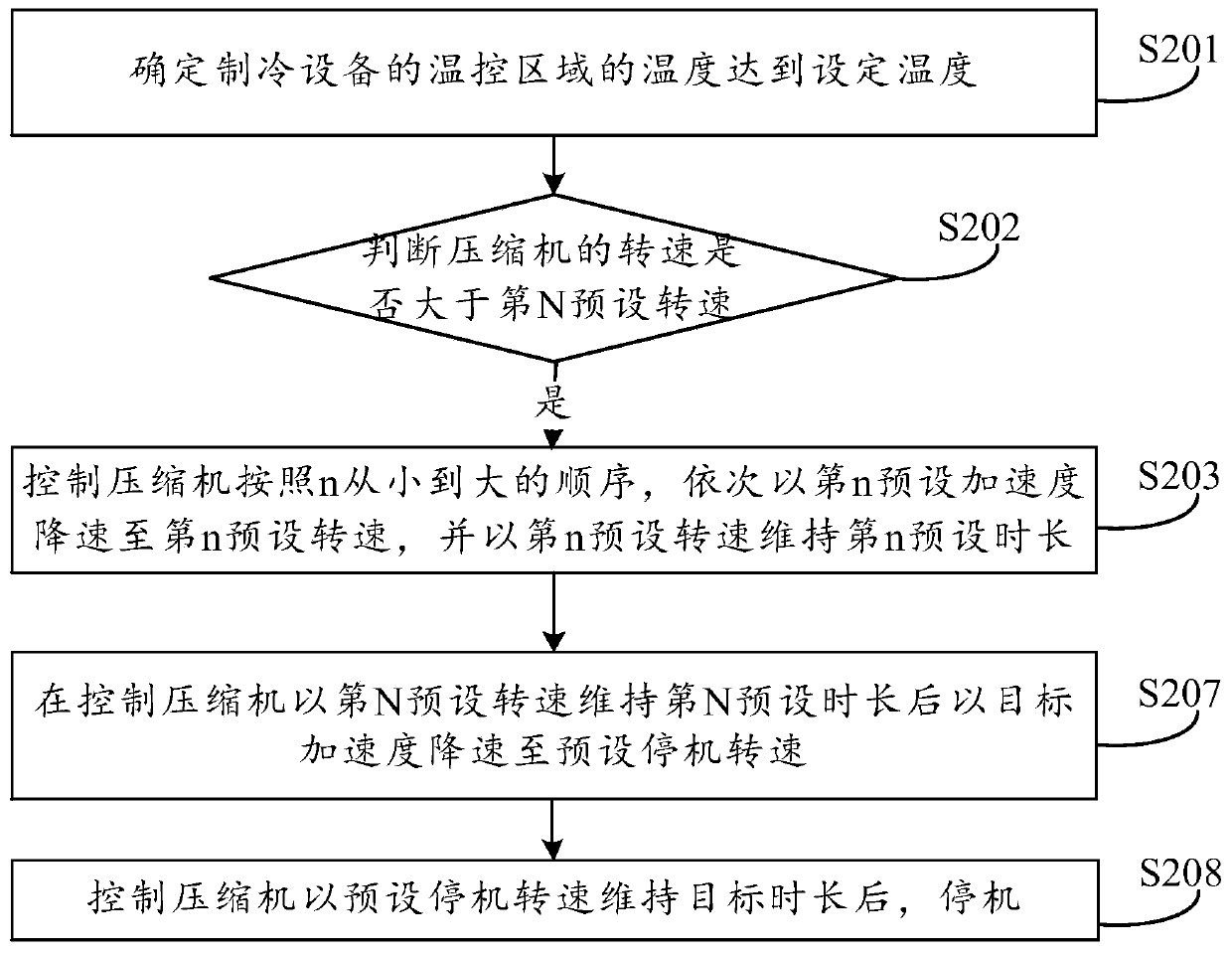

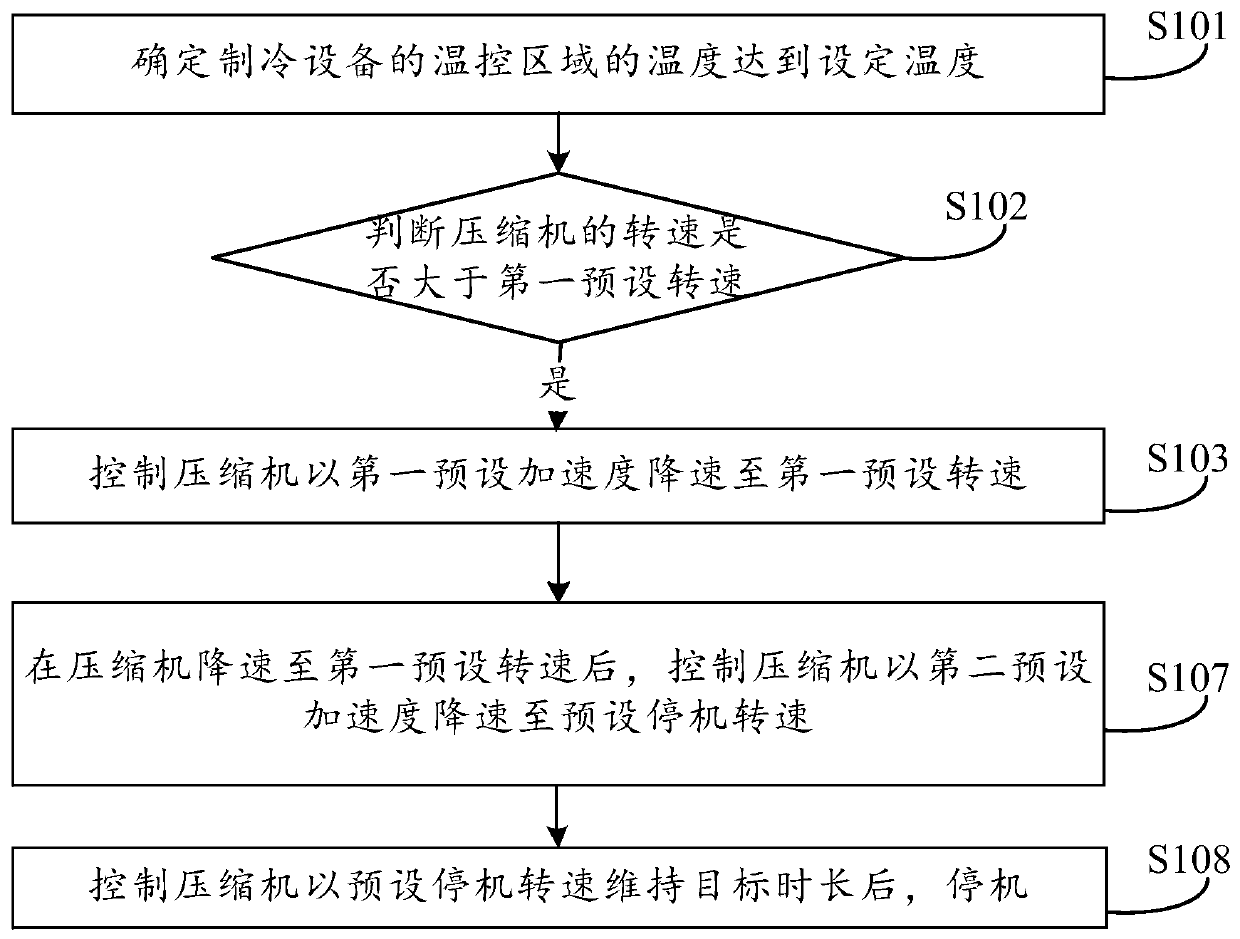

Refrigeration equipment and shutdown control method of compressor of refrigeration equipment

ActiveCN110953777AStable speedResolve jitter fromRefrigeration safety arrangementTemperature controlNoise generation

The invention provides refrigeration equipment and a shutdown control method of a compressor of the refrigeration equipment, and relates to the field of compressor control. According to the refrigeration equipment and the shutdown control method of the compressor of the refrigeration equipment, the shutdown stability of the compressor is improved, and the problem that noise is generated due to thefact that the compressor shakes when the compressor is shut down in a high-rotating-speed state can be solved. The refrigeration equipment comprises a compressor, a temperature detection device and acontrol device; the temperature detection device is used for detecting the temperature of a temperature control area of the refrigeration equipment; the control device is configured to control the compressor to be decelerated to a first preset rotating speed at a first preset acceleration if it is determined that the rotating speed of the compressor is greater than the first preset rotating speedwhen a shutdown instruction is received or the detection temperature of the temperature detection device reaches a set temperature; then the compressor is controlled to be decelerated to a preset shutdown rotating speed at a second preset acceleration; the second preset acceleration is smaller than the first preset acceleration; and the compressor is controlled to to stop after maintaining the target duration at the preset stop rotating speed.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

A damper opening and closing angle changing mechanism of a hinge

ActiveCN106761110BPrecise positioningImprove stabilityBuilding braking devicesWing accessoriesControl theoryShock absorber

Owner:伍志勇

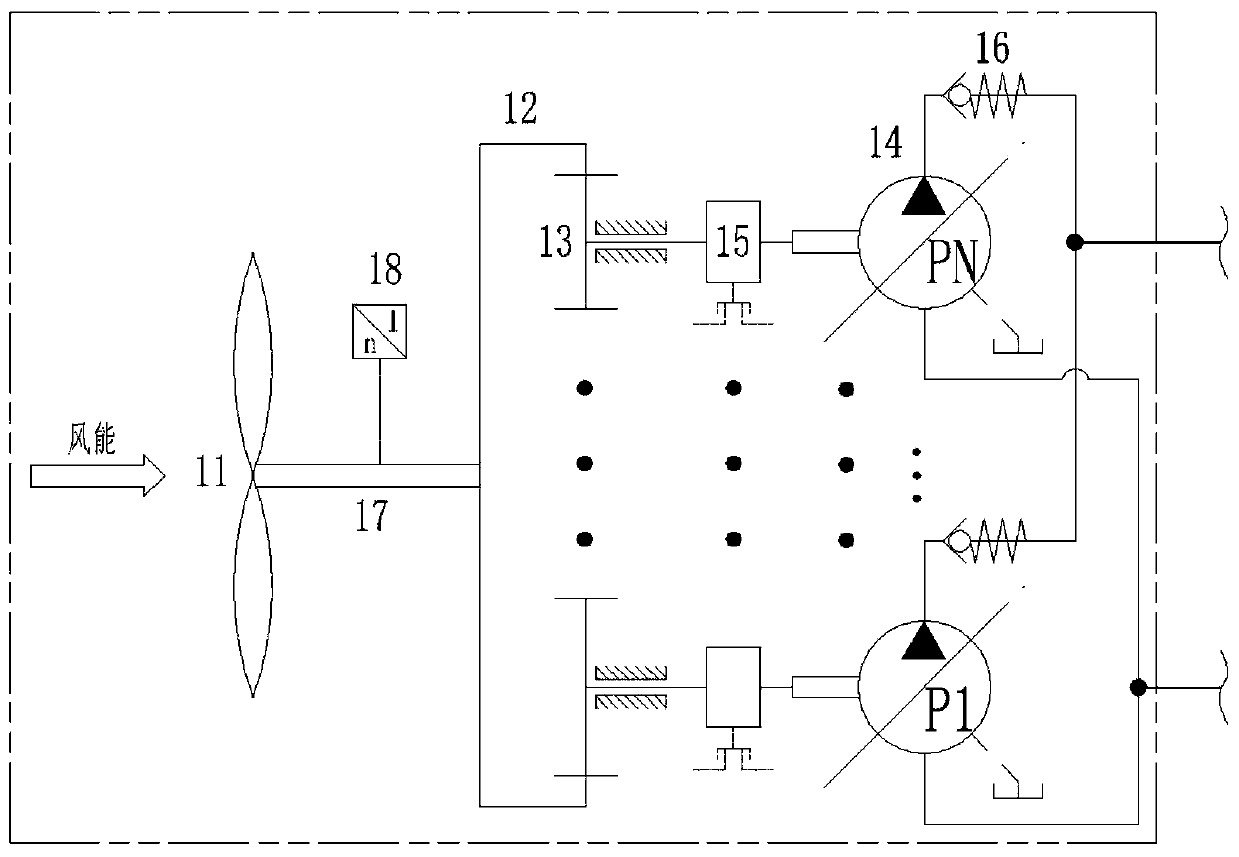

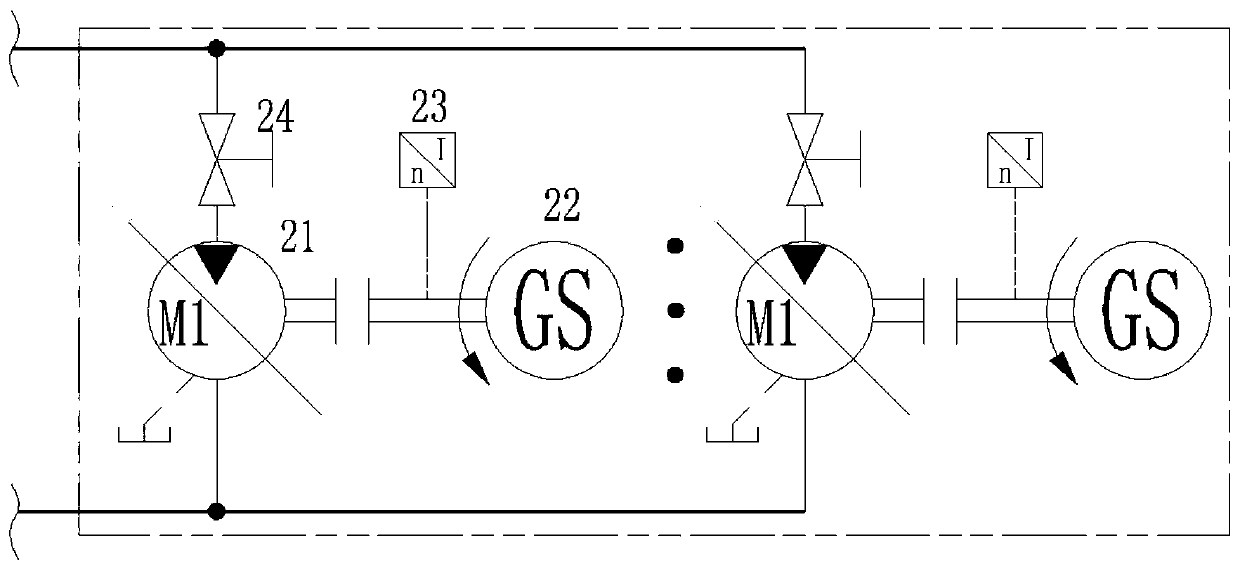

Hydraulic energy storage type wind generation set

PendingCN111350633AImprove power adaptabilityLow wind thresholdWind motor controlWind energy with garvitational potential energyHydraulic motorHydraulic pump

The invention discloses a hydraulic energy storage type wind generation set. The hydraulic energy storage type wind generation set at least comprises a power source set, a power generation set and anenergy storage set; the power source set comprises a wind wheel, a gear ring in transmission fit with the wind wheel, a plurality of planet wheels engaged with the gear ring and constant-pressure variable hydraulic pumps with the power input ends in transmission fit with the planet wheels; clutches are arranged between the constant-pressure variable hydraulic pumps and the planet wheels, the powergeneration set comprises a plurality of hydraulic motors and power generators, and the power generators are matched with the rated power of the hydraulic motors and are driven by the hydraulic motors; and the energy storage set is used for storing energy when the clutches are closed but no power generation demand exists, and energy is released to drive the power generation set to generate power when the clutches are disconnected. According to the hydraulic energy storage type wind generation set, the number of the constant-pressure variable hydraulic pumps can be selected through connected ordisconnected of the clutches, the number of the constant-pressure variable hydraulic pumps is adaptively matched and operated according to the magnitude of wind power, the adaptability of the generator power and the wind wheel power is high, it is effectively guaranteed that the hydraulic power is matched with the generator power, and the wind energy utilization rate and the power generation quality are improved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Integrated optimization mechanism for damping hinge

ActiveCN107100469AEffort-saving opening and closingOpen and close smoothlyBuilding braking devicesWing accessoriesEngineeringControl theory

An integrated optimization mechanism for damping a hinge comprises a retaining element, a first connection arm element and a second collection arm element all of which are in hinged fit. A damper is arranged between the retaining element and the first connection arm element, one end of the damper is rotationally arranged on the retaining element, and the other end of the damper slides on the first connection arm element in a limiting manner, the second connection arm element is provided with an action part, and when the hinge is opened or closed, the first connection arm element, the second connection arm element and the damper are linked relative to the retaining element. When the hinge at least is closed by a certain angle, the second connection arm element acts on the damper through the action part and drives the damper to slide on the first connection arm element in a limiting manner, and the damper is compressed and produces damping force so that damping closing of the hinge can be achieved. The integrated optimization mechanism has the beneficial effects that the structure is simple and reasonable, safety and reliability are achieved, production and achievement are easy, adjusting is quick, operation is convenient, the service life is long, and in the opening and closing process, labor is saved, smoothness is achieved, collision is small and noise is low, and practicality is high.

Owner:伍志勇

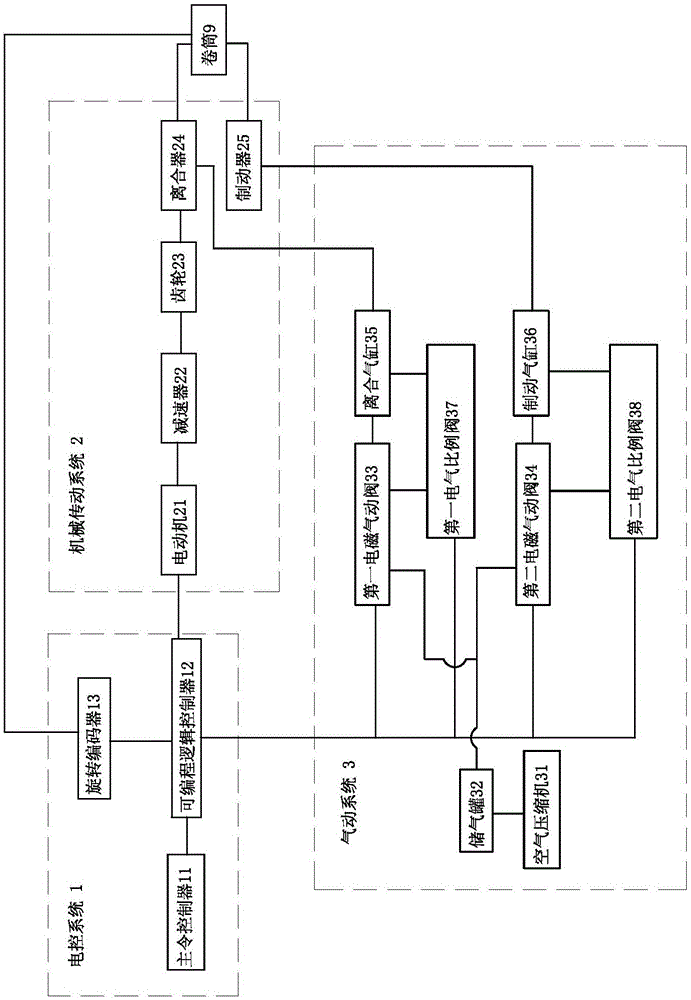

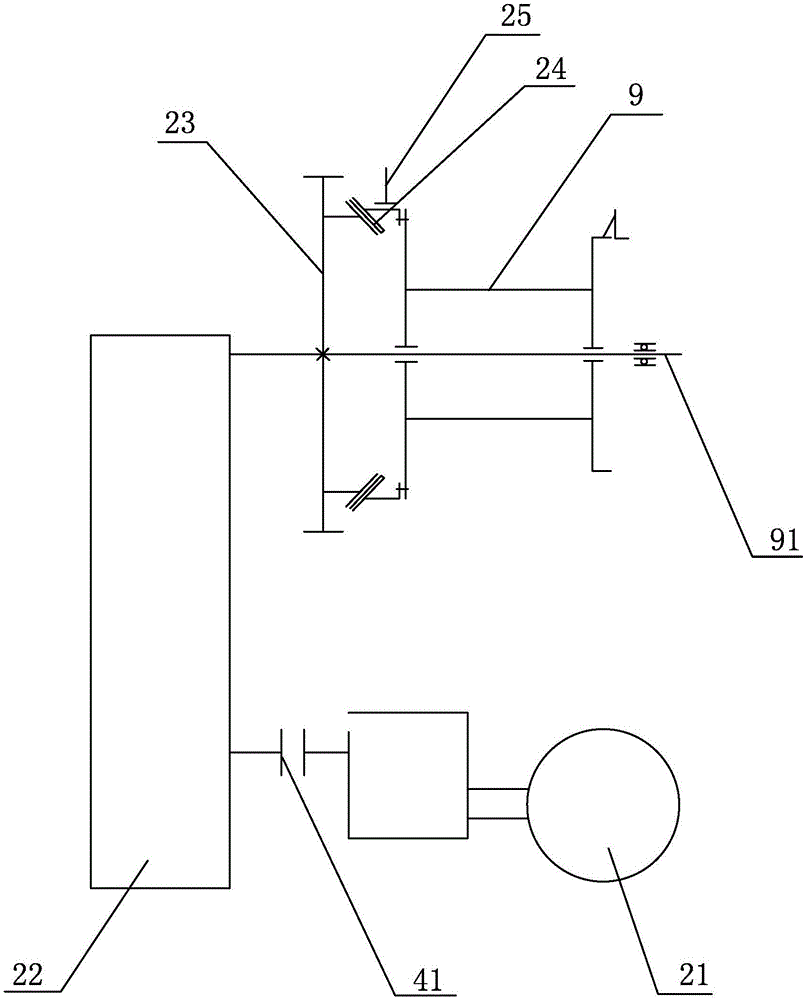

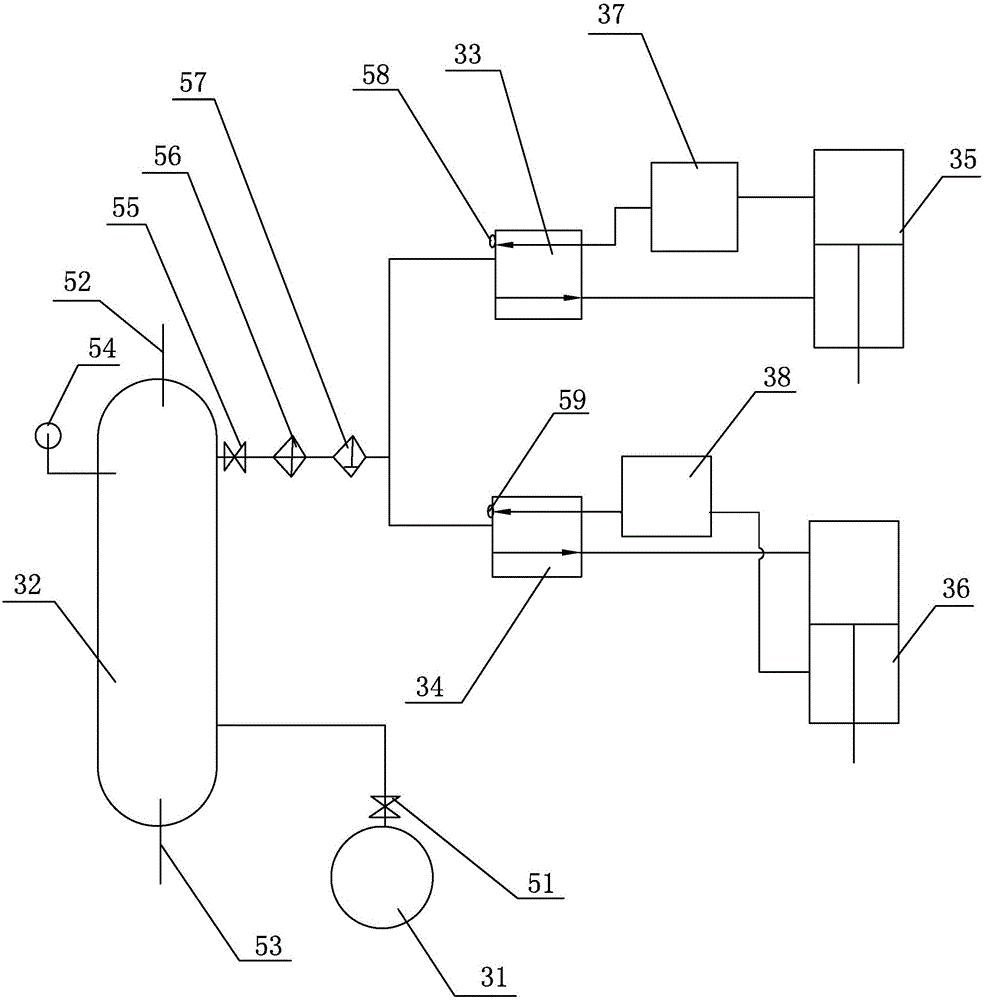

An automatic control system for plastic drainage board insertion equipment

ActiveCN103832939BSimple structureEasy to use and maintainGearing controlWinding mechanismsAutomatic controlReduction drive

The invention discloses an automatic control system of plastic drainage board inserting equipment. The automatic control system comprises an electric control system and a mechanical transmission system. The electric control system comprises a master controller, a programmable logic controller and a rotary encoder. The mechanical transmission system comprises a motor, a speed reducer, a clutch and a brake. The master controller controls the programmable logic controller. The rotary encoder is connected with a winding drum of a winch. The output end of the rotary encoder is connected with the input end of the programmable logic controller. The programmable logic controller controls the motor which is connected with the clutch through the speed reducer. The programmable logic controller controls engaging or disengaging of the clutch. The programmable logic controller controls releasing or using of the brake. The automatic control system has the advantages of being simple in structure, convenient to use and maintain, stable in running and stopping, quick in action response and good in operability, safety and adaptability, and meanwhile the working efficiency and the construction quality of the plastic drainage board inserting equipment can be effectively improved.

Owner:ZHEJIANG RECLAIM NINGBO HONGYANG CONSTR

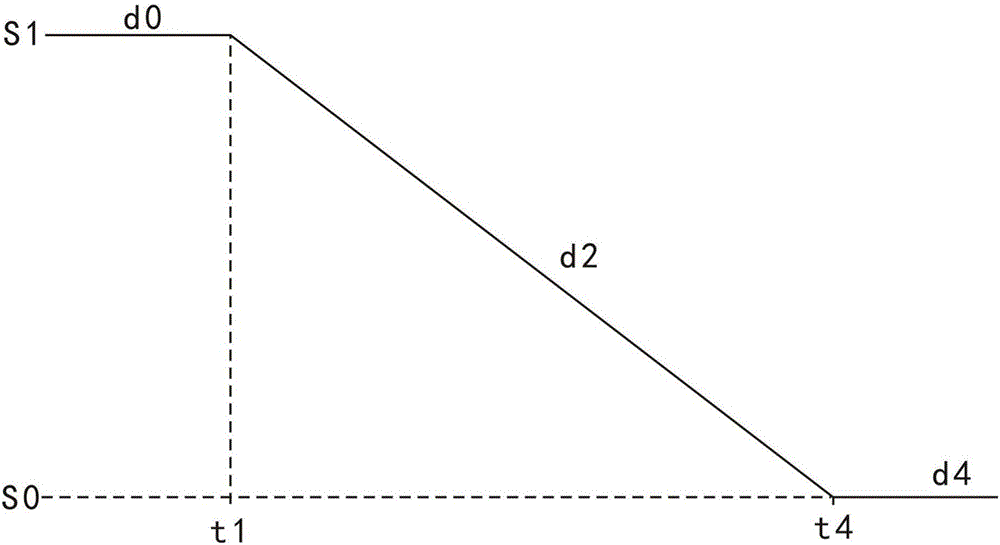

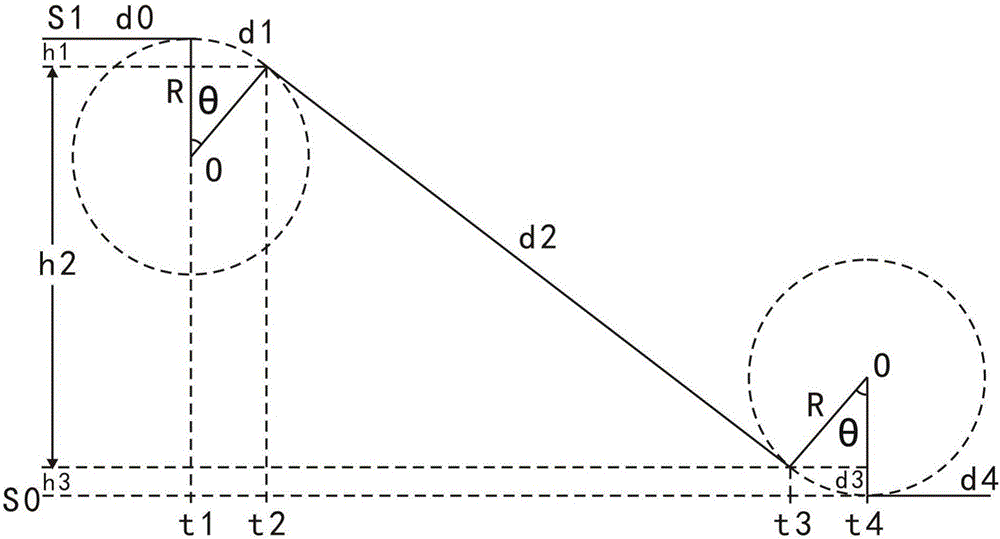

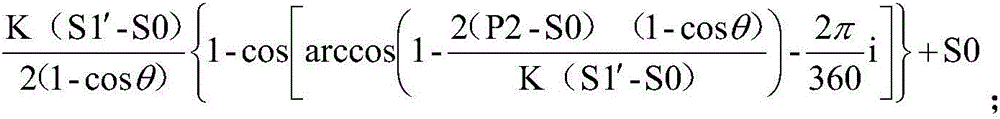

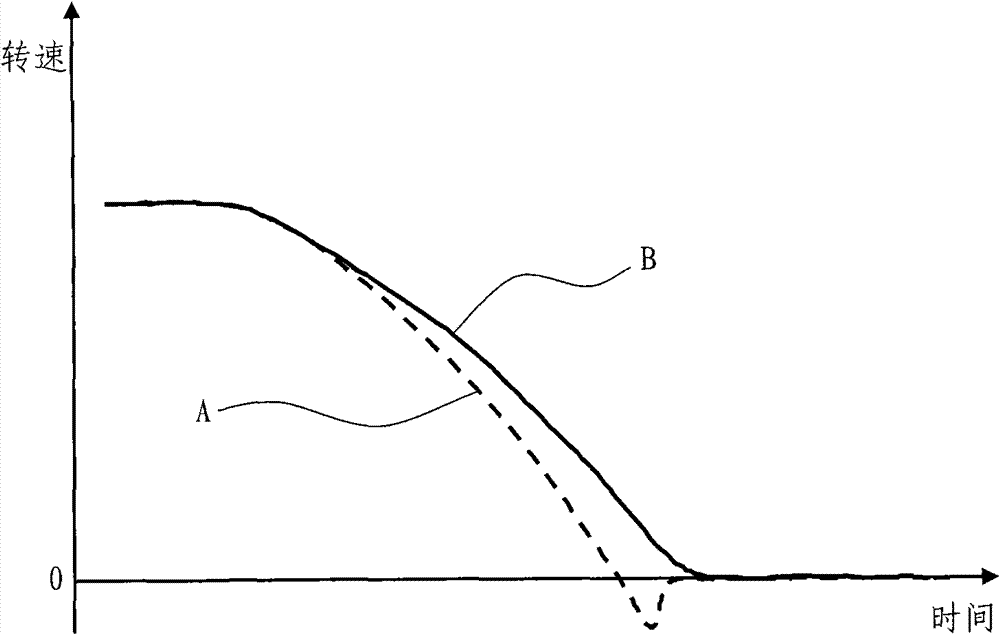

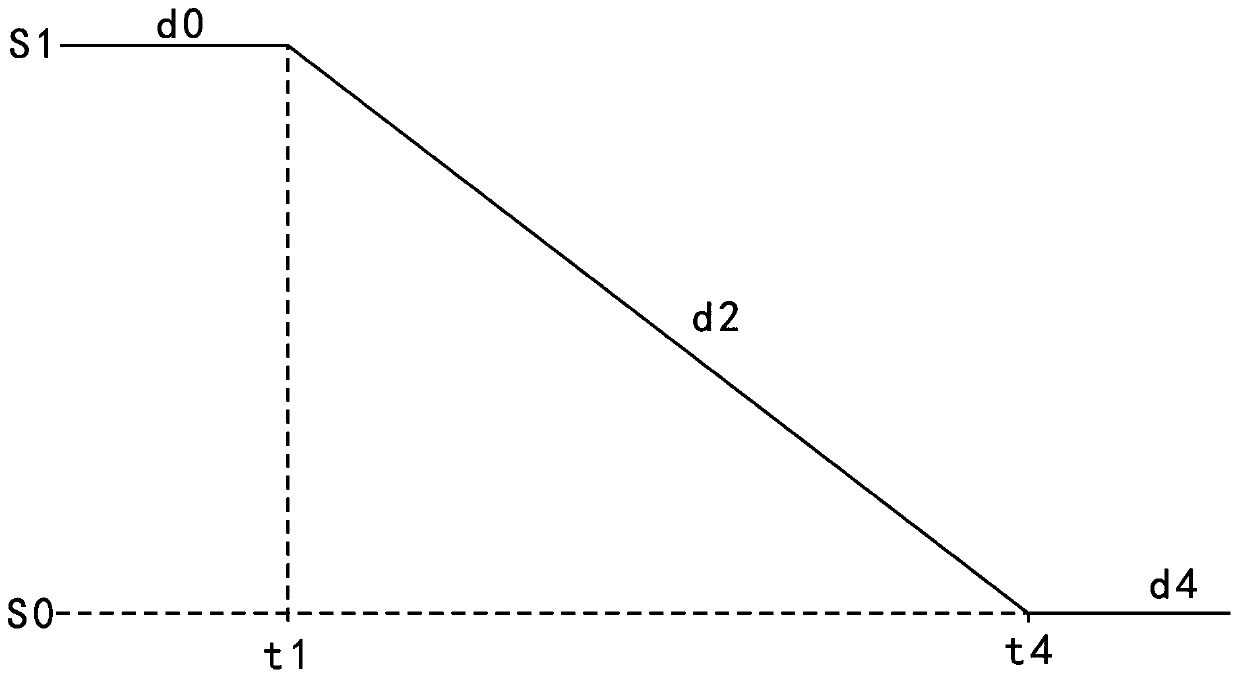

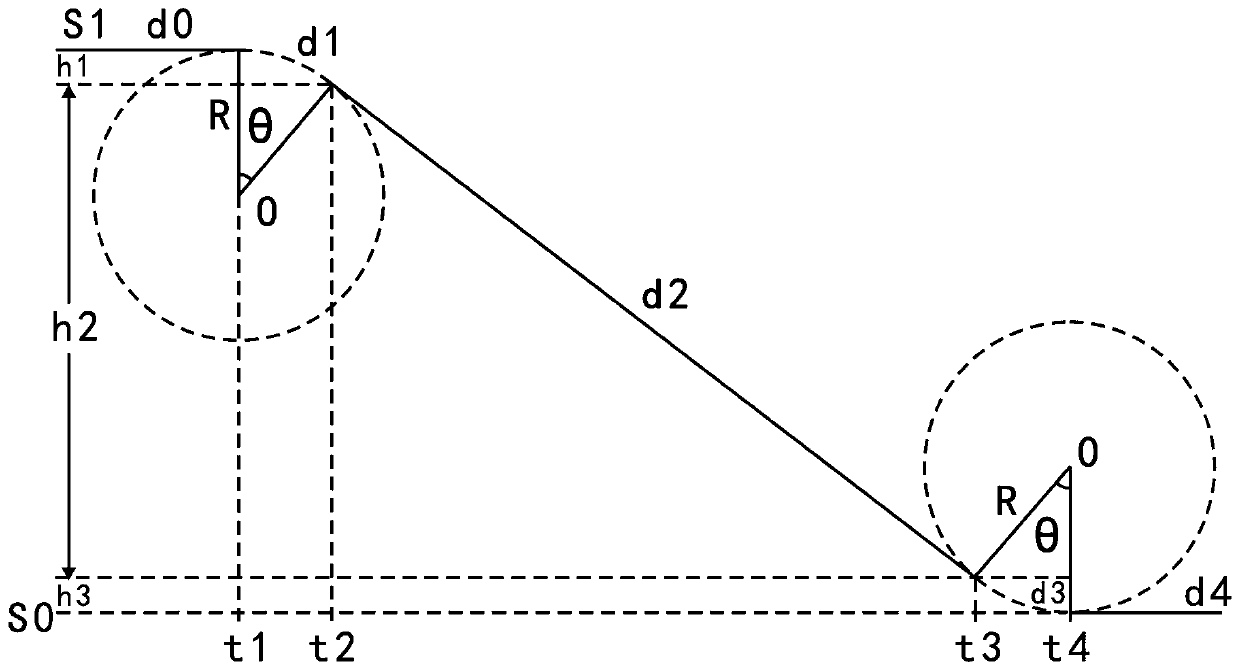

Method for establishing halt instruction curve of host computer of centrifugal dynamic flight simulator

ActiveCN106681174ASolve the vibrationSolve the impactSimulator controlFlight simulatorComputer science

The invention discloses a method for establishing a halt instruction curve of a host computer of a centrifugal dynamic flight simulator. The method comprises the following steps of: establishing an initial curve, wherein a rotating speed of the hose computer before the starting of the halting moment is indicated by a first segment, a target halting rotating speed after the ending of the halting moment is indicated by a third segment and an oblique line segment connected between the first segment and the third segment is arranged as a second segment; redefining the three segments and adding or reducing two segments at corners; and correcting the initial curve, thereby acquiring an optimized halt instruction curve. The method disclosed by the invention is suitable for the centrifugal dynamic flight simulator, can be utilized to stably and quickly halt at any moment and under any states and can be used for effectively solving the problems of vibration and shocking of the host computer in the halting process of the centrifugal dynamic flight simulator so as to guarantee the safety of the pilot.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Constant voltage frequency ratio control system and constant voltage frequency ratio control method of multi-motor driving belt conveyor

ActiveCN103112702BThe output frequency is the sameConsistent output torqueControl devices for conveyorsFrequency changerMotor drive

The invention discloses a constant voltage frequency ratio control system of a multi-motor driving belt conveyor, wherein each motor is controlled through an independent frequency converter, a primary frequency converter and each secondary frequency converter are connected through a communication line, and each frequency converter can detect active current. Startup procedures of a constant voltage frequency ratio control method of the multi-motor driving belt conveyor include multiple steps, wherein a step a is that startup signals are received and broadcasted; a step b is that the multi-motor driving belt conveyor is started in a constant voltage frequency ratio control mode; a step c is that the secondary frequency converters are in operation; a step d is that whether the active current is in an allowed range is detected; and a step e is that frequency of each secondary frequency converter is adjusted. Operation procedures of the constant voltage frequency ratio control method of the multi-motor driving belt conveyor include multiple steps, wherein a step g is that operation frequency and the active current are broadcasted; a step h is that the active current is judged; and a step i is that the frequency is adjusted. Shutdown procedures of the constant voltage frequency ratio control method of the multi-motor driving belt conveyor include multiple steps, wherein a step j is that shutdown signals are received and broadcasted, and a step k is that the multi-motor driving belt conveyor is stopped in the constant voltage frequency ratio control mode. Through the constant voltage frequency ratio control system and the constant voltage frequency ratio control method of the multi-motor driving belt conveyor, all the motors basically have the same output torque, and therefore the problem that the motors are at the same rotating speed but have different output torque due to the facts that rotary drums are different in size and the sizes of belt wrap angles are not constant is solved, and the multi-motor driving belt conveyor is enabled to be started and stopped stably and can operate with high efficiency.

Owner:XINFENGGUANG ELECTRONICS TECH CO LTD

Integrated optimization mechanism of damping hinge

ActiveCN107100469BEffort-saving opening and closingOpen and close smoothlyBuilding braking devicesWing accessoriesControl theoryShock absorber

An integrated optimization mechanism for damping a hinge comprises a retaining element, a first connection arm element and a second collection arm element all of which are in hinged fit. A damper is arranged between the retaining element and the first connection arm element, one end of the damper is rotationally arranged on the retaining element, and the other end of the damper slides on the first connection arm element in a limiting manner, the second connection arm element is provided with an action part, and when the hinge is opened or closed, the first connection arm element, the second connection arm element and the damper are linked relative to the retaining element. When the hinge at least is closed by a certain angle, the second connection arm element acts on the damper through the action part and drives the damper to slide on the first connection arm element in a limiting manner, and the damper is compressed and produces damping force so that damping closing of the hinge can be achieved. The integrated optimization mechanism has the beneficial effects that the structure is simple and reasonable, safety and reliability are achieved, production and achievement are easy, adjusting is quick, operation is convenient, the service life is long, and in the opening and closing process, labor is saved, smoothness is achieved, collision is small and noise is low, and practicality is high.

Owner:伍志勇

Emergency oil supply system for steam turbine generator set

InactiveCN106979038ASmooth shutdownEnsure safetyMachines/enginesEngine componentsFuel tankAlternating current

The invention discloses an emergency oil supply system for a steam turbine generator set. The system comprises a centrifugal pump arranged between a main oil tank and a lubricating oil mother pipe through an oil pipeline, and the centrifugal pump is driven by a diesel engine connected with the centrifugal pump; a check valve preventing lubricating oil from flowing reversely is arranged in the portion, between the centrifugal pump and the lubricating oil mother pipe, of the oil pipeline; manual valves are arranged in the portions, located at the two ends of the centrifugal pump, of the oil pipeline respectively. The emergency oil supply system is applied to the steam turbine generator set to serve as a spare oil supply system, can supply lubricating oil to the steam turbine generator set when an alternating-current lubricating oil pump and a direct-current lubricating oil pump both cannot be started, it is guaranteed that the set can be stopped smoothly, vicious accidents of bearing burnout due to oil breakoff and shaft grinding are avoided, and a reliable guarantee is provided for the safety of the set.

Owner:河北建投能源科学技术研究院有限公司

Halt control method and system of hybrid power vehicle

The invention discloses a halt control method and system of a hybrid power vehicle. The halt control method comprises the steps of: judging a reversal-preventing control entry condition; if according with the reversal-preventing control entry condition, controlling an engine to prevent from reversing, wherein the control step comprises the procedures of detecting in real time to obtain an engine rotating speed signal of reflecting a rotating speed of an engine; comparing the rotating speed signal of the engine with a preset ideal rotating speed of the engine to obtain a rotating speed difference; calculating the rotating speed difference through a PID controller to obtain a theoretical target motor output torque, calculating according to the theoretical target motor output torque to obtain an actual target motor output torque needing being implemented by a motor, sending a command for implementing the actual target motor output torque to the motor; and implementing the actual target motor output torque by the motor, and acting the torque implemented by the motor to the engine. Therefore, the reversal of the engine before automatic halt can be prevented.

Owner:SAIC MOTOR

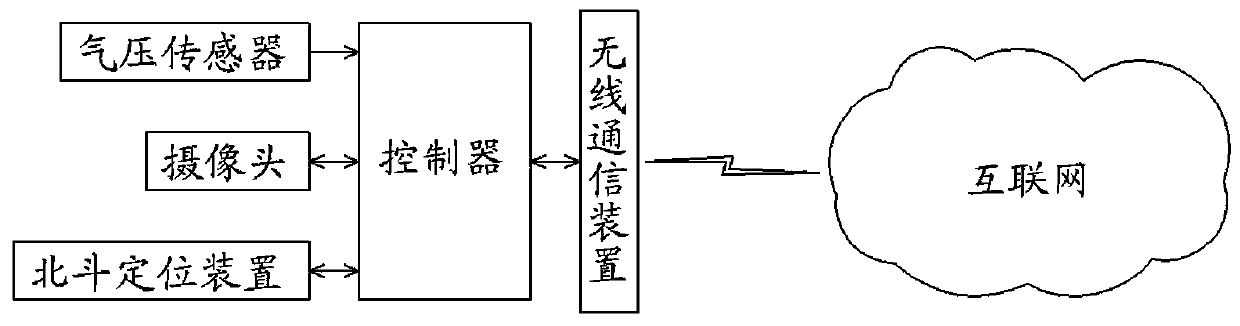

Relay type unmanned aerial vehicle power transmission and distribution line inspection system and method

InactiveCN110963037AEasy to useImprove work efficiencyAircraft componentsHelicopter landing platformElectrical batteryUncrewed vehicle

The invention discloses a relay type unmanned aerial vehicle power transmission and distribution line inspection system and method, and relates to the technical field of electric power overhaul. The system comprises an unmanned aerial vehicle and a charging platform, the charging platform is a platform device which is arranged on a tower and used for landing and charging of the unmanned aerial vehicle. The charging platform comprises a landing platform used for parking the unmanned aerial vehicle and a charging device used for charging the unmanned aerial vehicle, a groove is formed in the landing platform, a boss is arranged at the bottom of the unmanned aerial vehicle, the boss matches the groove in an inserted mode, the unmanned aerial vehicle is parked in the groove through the boss, and the charging device is connected with a battery of the unmanned aerial vehicle and charges the battery of the unmanned aerial vehicle; the method is based on a platform device and an unmanned aerial vehicle, and the unmanned aerial vehicle flies in one way relative to the platform device in each inspection process; by means of the unmanned aerial vehicle, the landing platform, the charging device, the groove, the boss and the like, low-cost patrolling of the power transmission and distribution line is achieved.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +1

Generator one-button start-stop control system

ActiveCN109488508BStart successfully and stableImprove adaptabilityInternal combustion piston enginesElectric motor startersControl systemControl signal

Owner:LONCIN MOTOR

A method for making a shutdown command curve of a centrifugal dynamic flight simulator main engine

ActiveCN106681174BSolve the vibrationSolve the impactSimulator controlFlight simulatorComputer science

The invention discloses a method for establishing a halt instruction curve of a host computer of a centrifugal dynamic flight simulator. The method comprises the following steps of: establishing an initial curve, wherein a rotating speed of the hose computer before the starting of the halting moment is indicated by a first segment, a target halting rotating speed after the ending of the halting moment is indicated by a third segment and an oblique line segment connected between the first segment and the third segment is arranged as a second segment; redefining the three segments and adding or reducing two segments at corners; and correcting the initial curve, thereby acquiring an optimized halt instruction curve. The method disclosed by the invention is suitable for the centrifugal dynamic flight simulator, can be utilized to stably and quickly halt at any moment and under any states and can be used for effectively solving the problems of vibration and shocking of the host computer in the halting process of the centrifugal dynamic flight simulator so as to guarantee the safety of the pilot.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

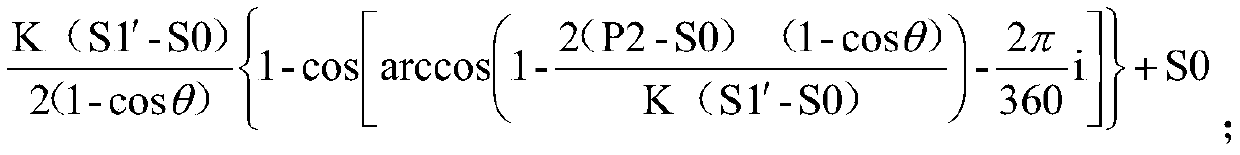

Mining plate-scraper control system and control method thereof

ActiveCN103475277ASmooth startSmooth shutdownMotor/generator/converter stoppersMultiple dynamo-motor startersDisk controllerTransformer

The invention discloses a mining plate-scraper control system and a control method thereof. The system includes a main circuit connected with a three-phase power supply, a total power switch arranged at one end of the main circuit, a controlled-device main motor and a controlled-device auxiliary motor, which are arranged at the other end of the main circuit, a speed reducer connected with the controlled-device main motor, a controllable soft-starting device arranged on the main circuit, a control transformer with a primary winding installed on the main circuit between the total power switch and the controllable soft-starting device, a pilot assembly connected with a first secondary winding of the control transformer, a relay device connected with a second secondary winding of the control transformer, a controllable soft-starting-device controller and a master switch, which are connected with the relay device, a PC control panel controlling work of the system and a bidirectional thyristor assembly connected with the PC control panel, wherein the bidirectional thyristor assembly is connected with the controlled-device main motor. The mining plate-scraper control system is small in size and capable of meeting installation requirements in narrow space in a pit.

Owner:HUNAN COAL MINE MACHINERY CO LTD

Variable damper

InactiveCN101705976AVariable dampingConstant damping effectSpringsShock absorbersControl theoryPiston

The invention discloses a variable damper which comprises a baseboard, an isolation spring, a damping cylinder, a damper regulator, damping medium, a piston, a sealing ring and a top board; the isolation spring is fixedly arranged between the baseboard and the top board; the damping cylinder is arranged on the baseboard and filled with damping medium; the piston is arranged in the damping cylinder; the sealing ring is arranged at the opening of the damping cylinder and seals the gap between the piston and the damping cylinder; the extending end of the piston is fixedly connected with the top board; the lateral side of the damping cylinder is provided with a pipeline; and the damper regulator is arranged at the middle of the pipeline. The damping effect of the inventive variable damper is variable and can be meticulously and continuously regulated, thus satisfying requirements of various occasions with frequent vibration working condition variation.

Owner:钟活明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com