Multi-station expander

A telescopic machine, multi-station technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of inability to achieve multi-point feeding, inability to separate at the same time, no iron remover, etc., to achieve compact structure and occupy space Small, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

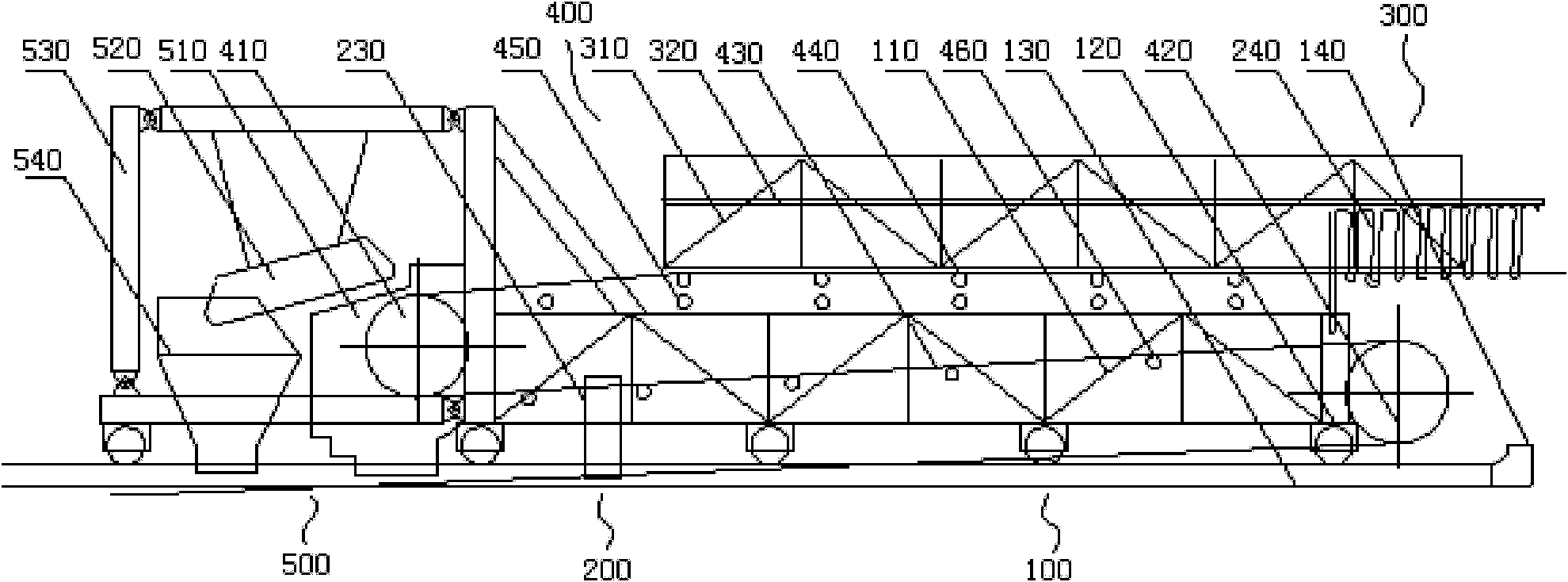

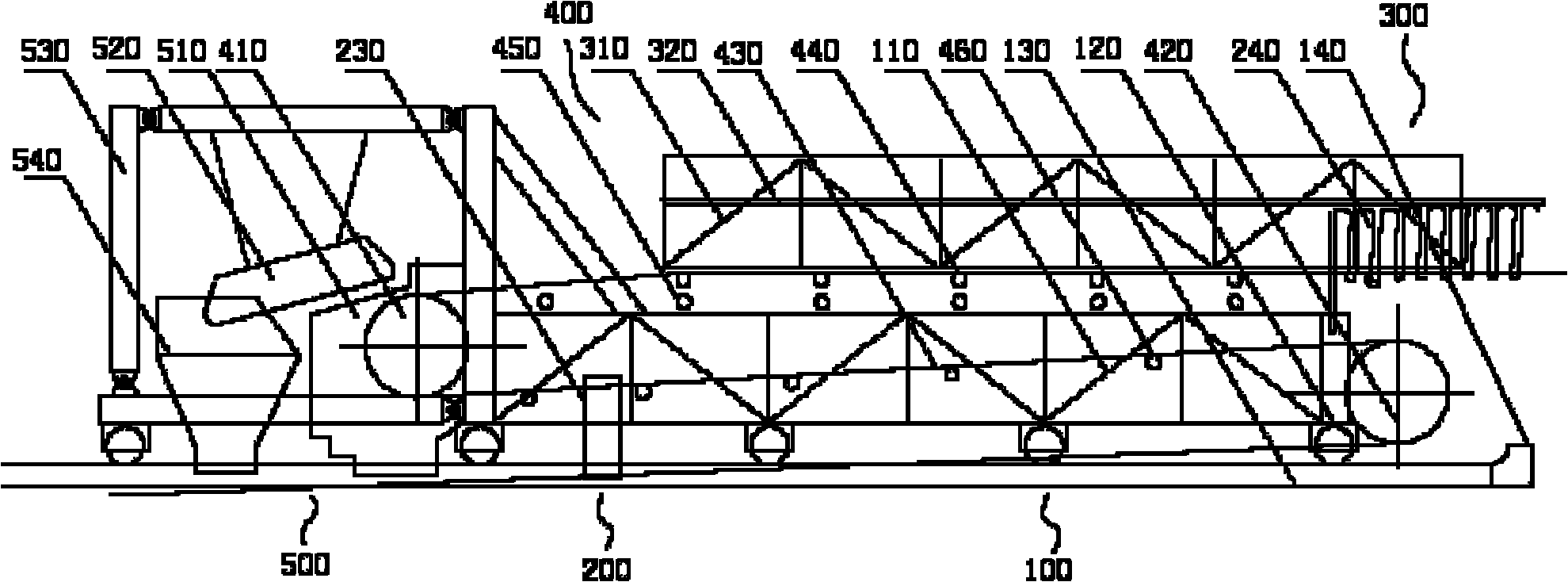

[0039] A multi-station telescopic machine, such as figure 1 As shown, it includes: a vehicle body device 100 ; a driving device 200 ; a feeding device 300 ; a conveying device 400 ; and a feeding device 500 . The vehicle body device is controlled by the driving device and changes the feeding point; the feeding device transfers the material to the feeding device through the conveying device.

[0040] The vehicle body device 100 includes: a vehicle body 110 , a wheel set 120 , a rail 130 , a bump stop 140 , an inspection platform and a walkway 150 .

[0041] A wheel set 120 is provided below the vehicle body 110 , and the wheel set 120 is connected to the track 130 ; thus the vehicle body 110 moves along the track 130 .

[0042] A limit stopper 140 is provided on the edge of the track 130 .

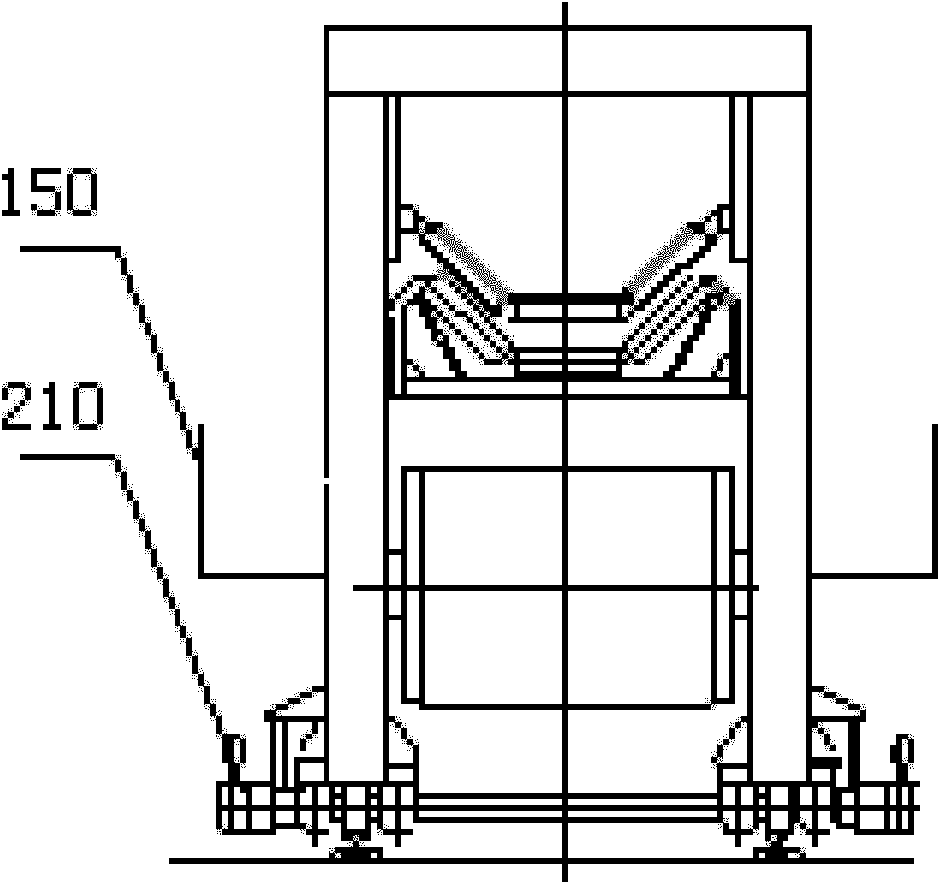

[0043] An inspection platform and a walkway 150 are arranged on the outside of the vehicle body 110 . see figure 2 , It is more convenient for staff to install, overhaul and maintain, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com