Feed flowing feeding device for aquaculture

An aquaculture and feed technology, applied in applications, fish farming, motor vehicles, etc., can solve problems such as low efficiency and labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

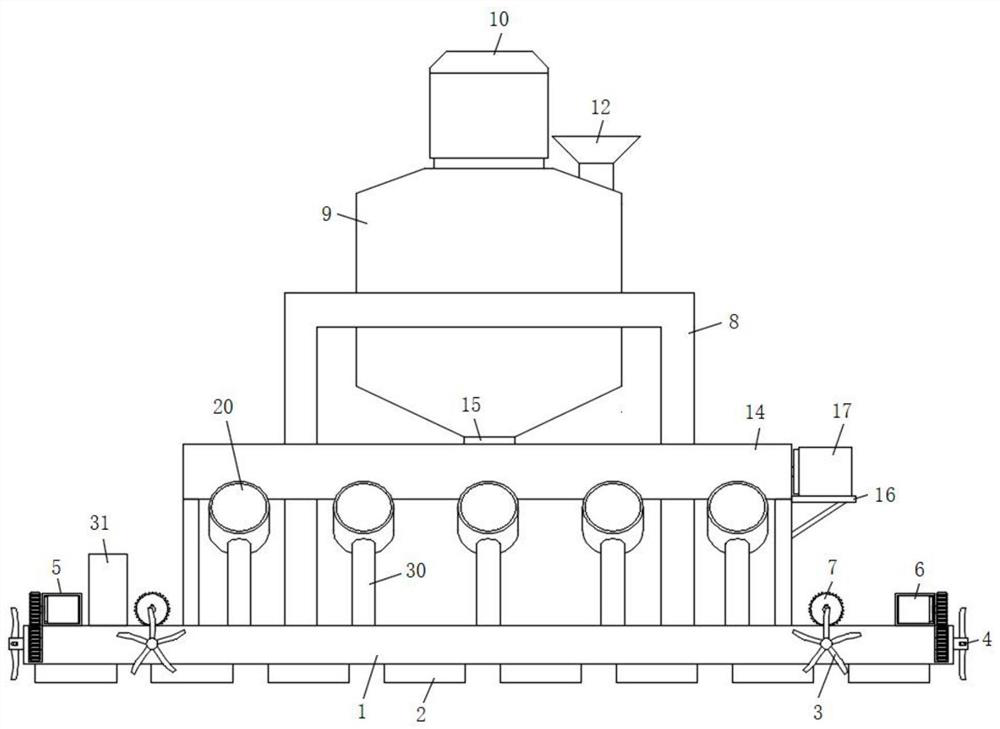

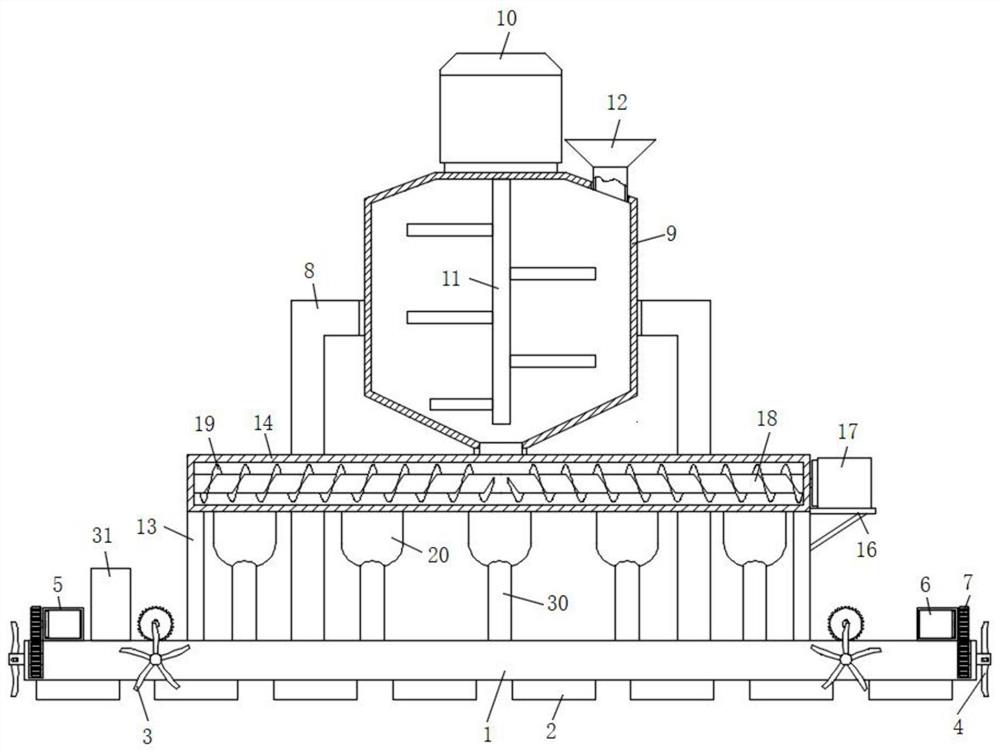

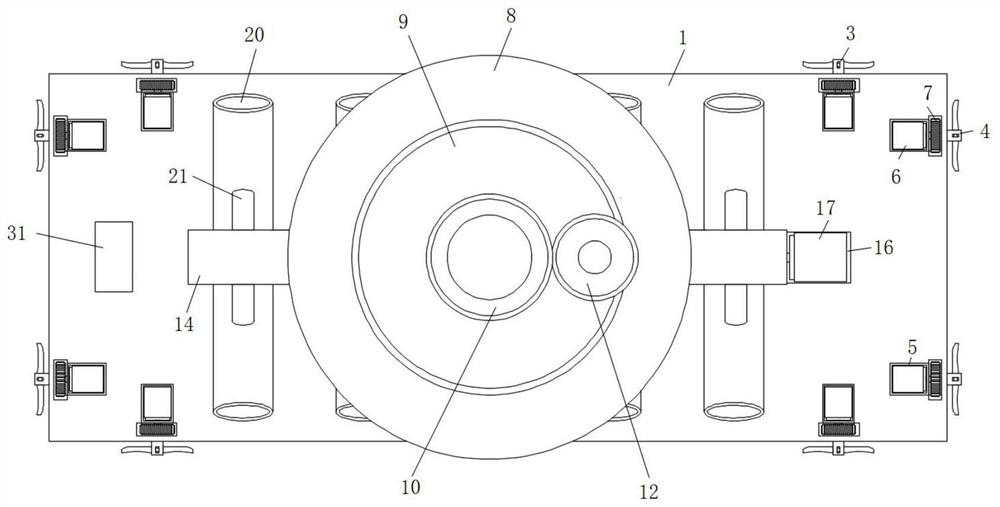

[0030] Example 1

[0031] refer to Figure 1-5A feed flow feeding device for aquaculture comprises a base 1, a suspension block 2 is fixedly connected to the bottom surface of the base 1, a reversing propeller 3 is rotatably installed at the front and rear ends of the base 1, and a propeller 4 is rotatably installed on both side walls of the base 1 , the upper ends of the reversing propeller 3 and the propulsion propeller 4 are provided with a sealing box 5 near the center of the base 1. The inner bottom surface of the sealing box 5 is fixed with a servo motor 6 through screws. The output end of the servo motor 6 is connected to the reversing The propeller 3 and the propeller 4 are connected by rotation through the gear set 7, and a mounting frame 8 is also welded at the center of the top surface of the base 1. The center of the top surface of the mounting frame 8 is provided with a cylindrical groove, and the inner wall of the cylindrical groove is fixed by screws. The mater...

Example Embodiment

[0033] Embodiment 2

[0034] like Figure 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the lower end of the ejection sheet 27 is also fixedly connected to a limiting plate 32 on the side close to the center of the base 1 , and the limiting plate 32 is slidably connected to the side wall of the ejection barrel 20 .

[0035] In this embodiment, a limiting plate 32 is also slidably connected between the lower end of the ejection piece 27 and the side wall of the ejection material cylinder 20 , so that the ejection piece 27 is more stable when ejected.

Example Embodiment

[0036] Embodiment 3

[0037] like Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the output end of the receiver 31 is electrically connected to the control end of the servo motor one 6, the servo motor two 10, the servo motor three 17 and the servo motor four 25, and is electrically connected with the control terminal of the servo motor one 6, the servo motor two 10, the servo motor three 17 and the servo motor four 25 The receiver 31 is also equipped with a remote controller, and a wireless connection is adopted between the remote controller and the receiver 31 .

[0038] In this embodiment, the receiver 31 is also equipped with a remote controller, and the remote controller and the receiver 31 are connected wirelessly, which facilitates the forward, backward and reverse operations of the control device, and greatly improves the stability of the device operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com