A method of automatic bait feeding and uniform discharge

An automatic baiting and uniform technology, which is applied in applications, climate change adaptation, fish farming, etc., can solve the problems of low feed utilization rate, fish fry being squeezed and injured, falling into the bottom of the pond, etc., to achieve uniform feed distribution and improve utilization rate, beneficial effect on growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

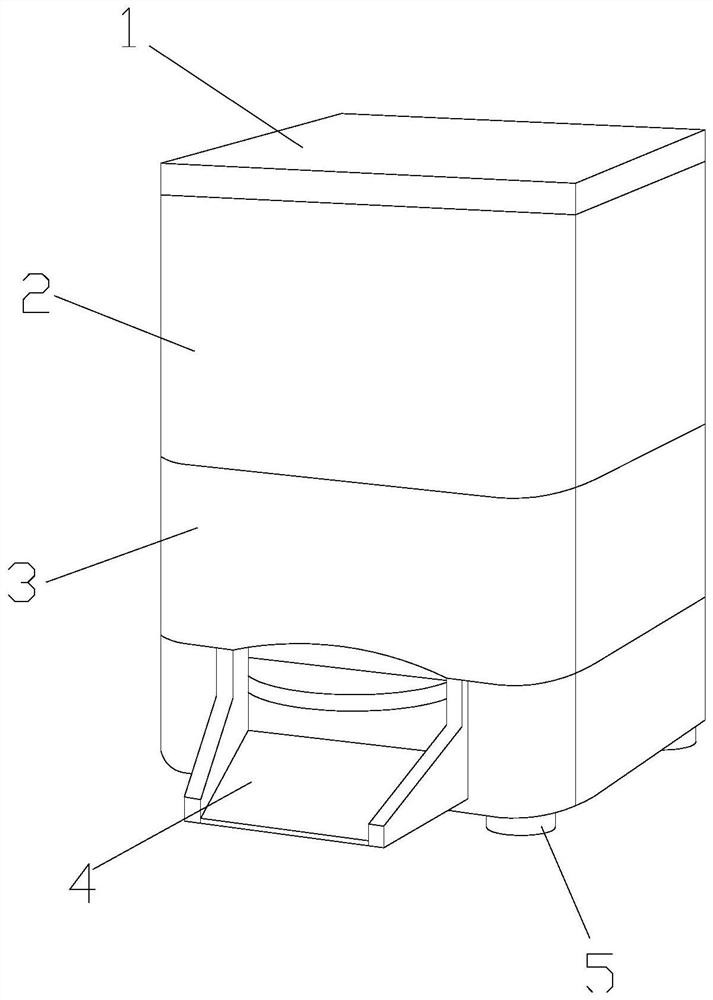

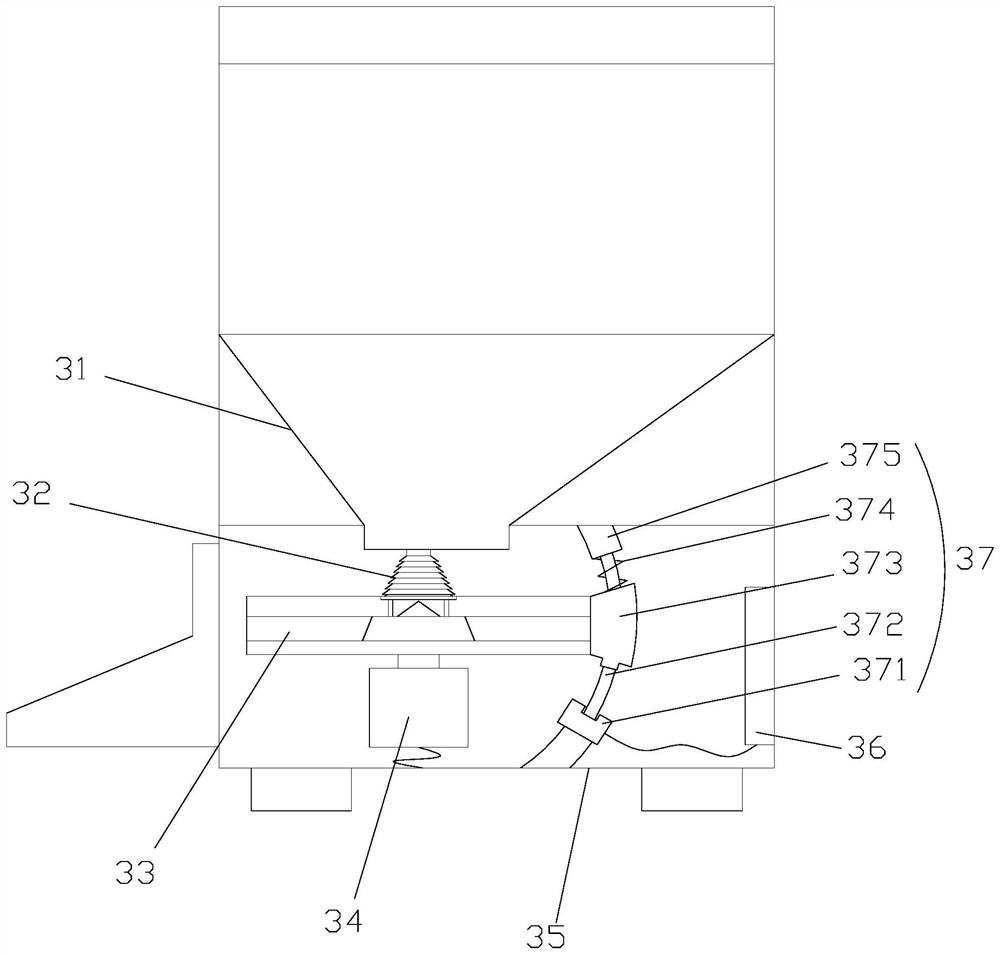

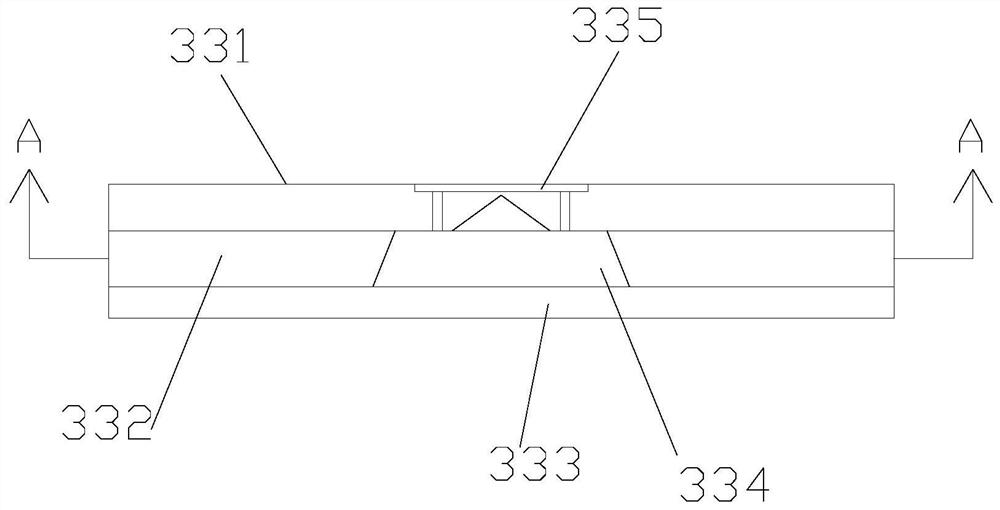

[0032] see Figure 1-Figure 2, the present invention provides an automatic bait feeder for fish ponds with centrifugal and uniform discharge, the structure of which includes a feed sealing cover 1, a feed storage box 2, a feeding mechanism 3, a hopper 4, and non-slip supporting feet 5, and the feed storage box 2 is a hollow rounded rectangular structure and is installed above the feeding mechanism 3. The anti-slip supporting feet 5 are cylindrical structures and are provided with four vertically installed on the four corners of the bottom surface of the feeding mechanism 3. The discharge hopper 4 is located on the feeding mechanism 3. In the middle of the front, the feed sealing cover 1 is installed above the feed storage box 2 and the bottom surface of the feed sealing cover 1 is connected with the top of the feed storage box 2 through screw fit. Centrifugal feeding device 33, drive motor 34, feeder housing 35, controller 36, feeding angle adjustment device 37 are composed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com