Stranding cage type spiral conveyor

A screw conveyor and twisted cage technology, which is applied in the field of powder conveying system in thermal power plants, can solve the problems of unsuitable for super long-distance conveying materials, poor neutrality, poor energy saving and environmental protection effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described below in conjunction with specific embodiments.

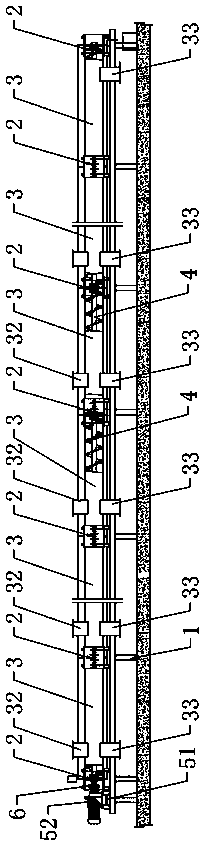

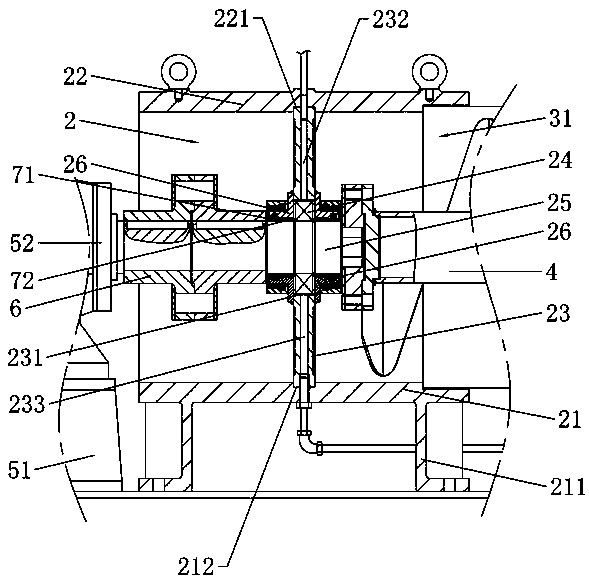

[0030] Such as figure 1 and figure 2 As shown, a twisted cage screw conveyor includes a frame 1, the upper end of the frame 1 is equipped with at least three embedded bearing seats 2 arranged at intervals from front to back, and two adjacent embedded Between the bearing housings 2, there is an intermediate box 3 arranged horizontally along the front-to-back direction and having an "O" shape in the vertical section. Each intermediate box 3 is provided with an intermediate conveying cavity that completely penetrates along the front-to-back direction. Room 31.

[0031] Further, the embedded bearing housing 2 includes a lower bearing housing body 21 in the shape of a semi-circular arc, an upper bearing housing body 22 located directly above the lower housing body 21, the upper end edge of the lower bearing housing body 21 and the upper bearing housing body 22 The lower edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com