Patents

Literature

36results about How to "Reduced risk of coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crude benzene hydrorefining process

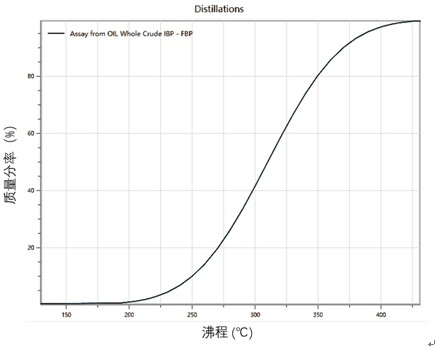

ActiveCN103274885AAvoid high temperature polymerization coking to block the systemHigh outputHydrocarbon purification/separationHydrocarbonsCatalytic reformingDistillation

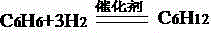

The present invention provides a crude benzene hydrorefining process, which comprises: sequentially carrying out a liquid phase catalysis pre-hydrogenation reaction, a gas phase catalysis pre-hydrogenation reaction and a main catalysis hydrogenation reaction on crude benzene, and then carrying out extraction rectification on the material obtained from the main hydrogenation reaction to obtain distillates of various distillation ranges. Compared with the process in the prior art, the process of the present invention has the following characteristics that: the catalysis hydrogenation process is adjusted into the three stage catalysis hydrogenation technology, heavy benzol pre-separation is not required before catalysis hydrogenation, and unsaturated olefin in the crude benzene is subjected to hydrogenation at a low reaction temperature of 130-140 DEG C to prepare saturated olefin in the liquid phase catalysis reforming pre-hydrogenation step so as to avoid occurrence of system clogging due to high temperature polymerization coking of easy high temperature polymerization unsaturated olefin contained in the crude benzene in the subsequent step. In addition, heavy benzol in the crude benzene can be subjected to hydrogenation to prepare mixed aromatic hydrocarbons, wherein the mixed aromatic hydrocarbons can be used as excellent blending components, and material output values and added values are increased.

Owner:湖北巨邦石油化工有限公司

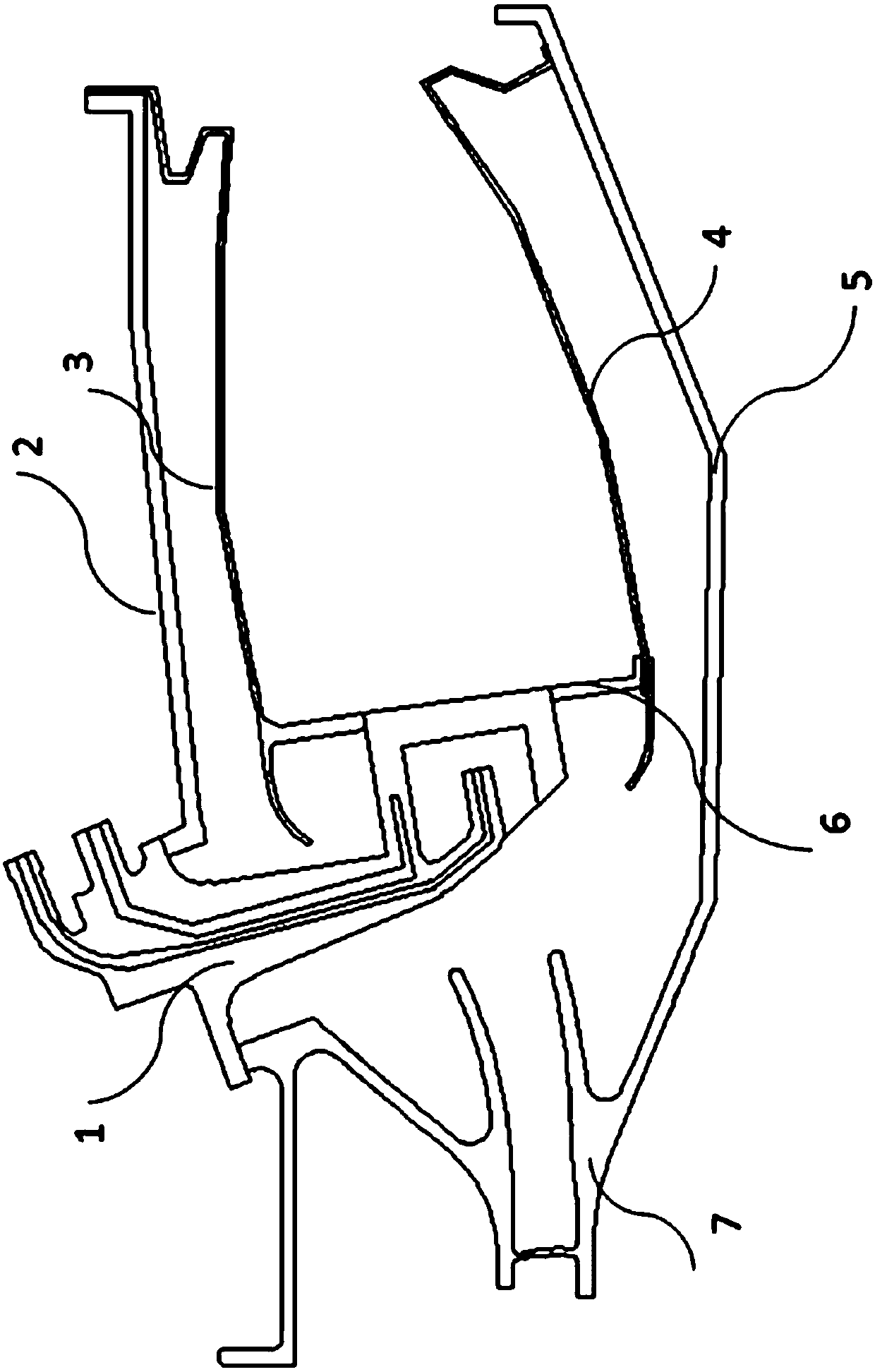

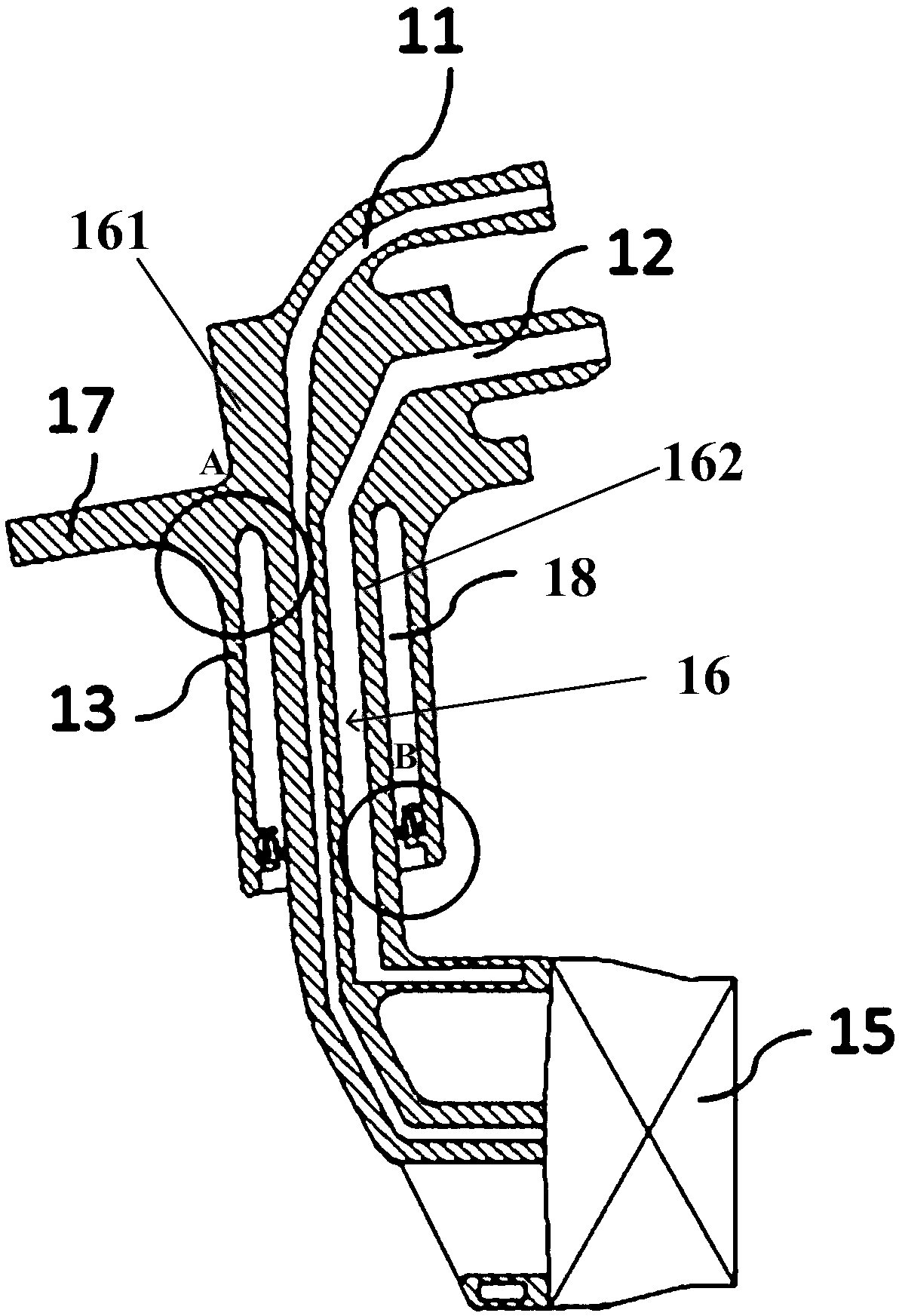

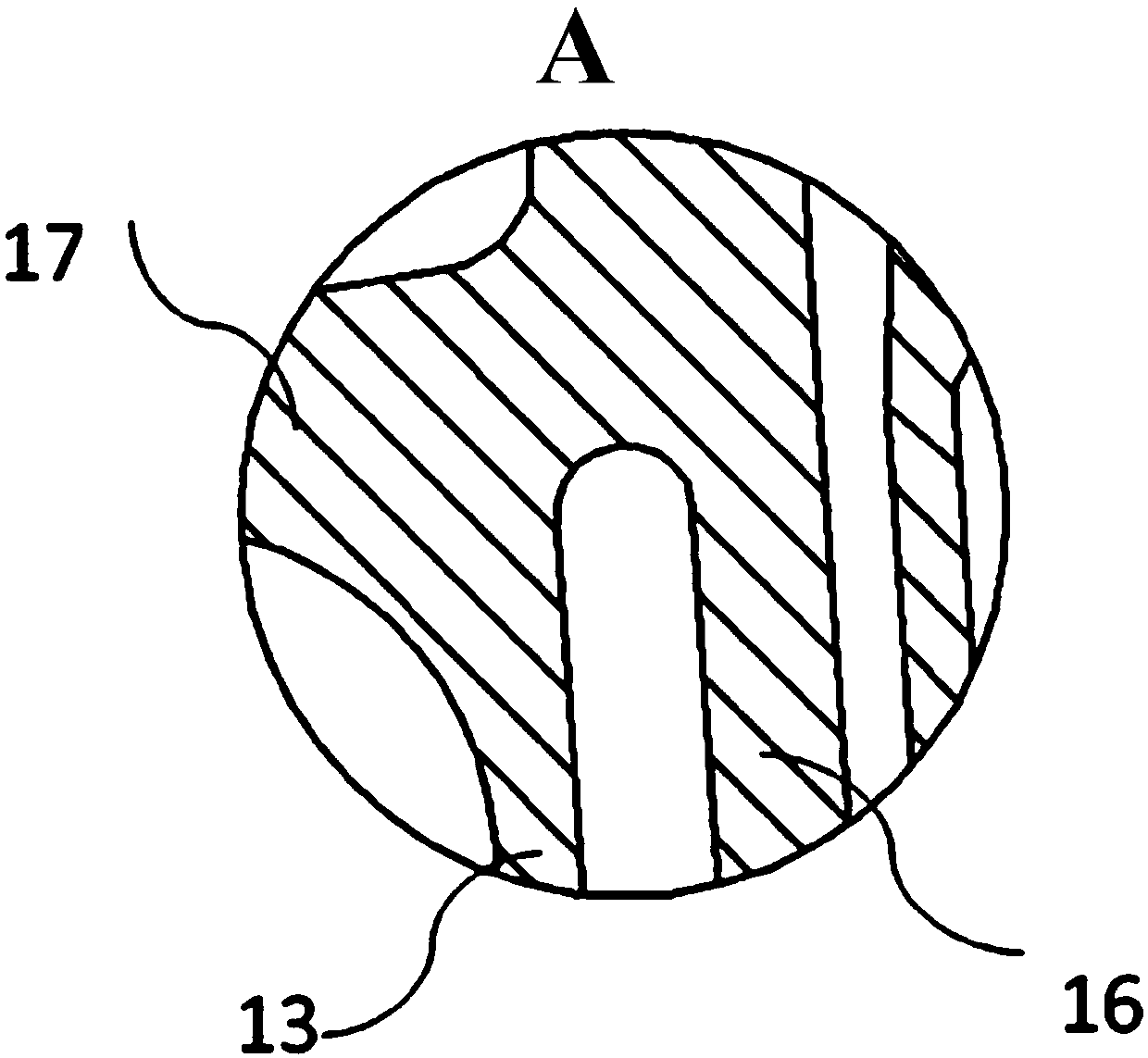

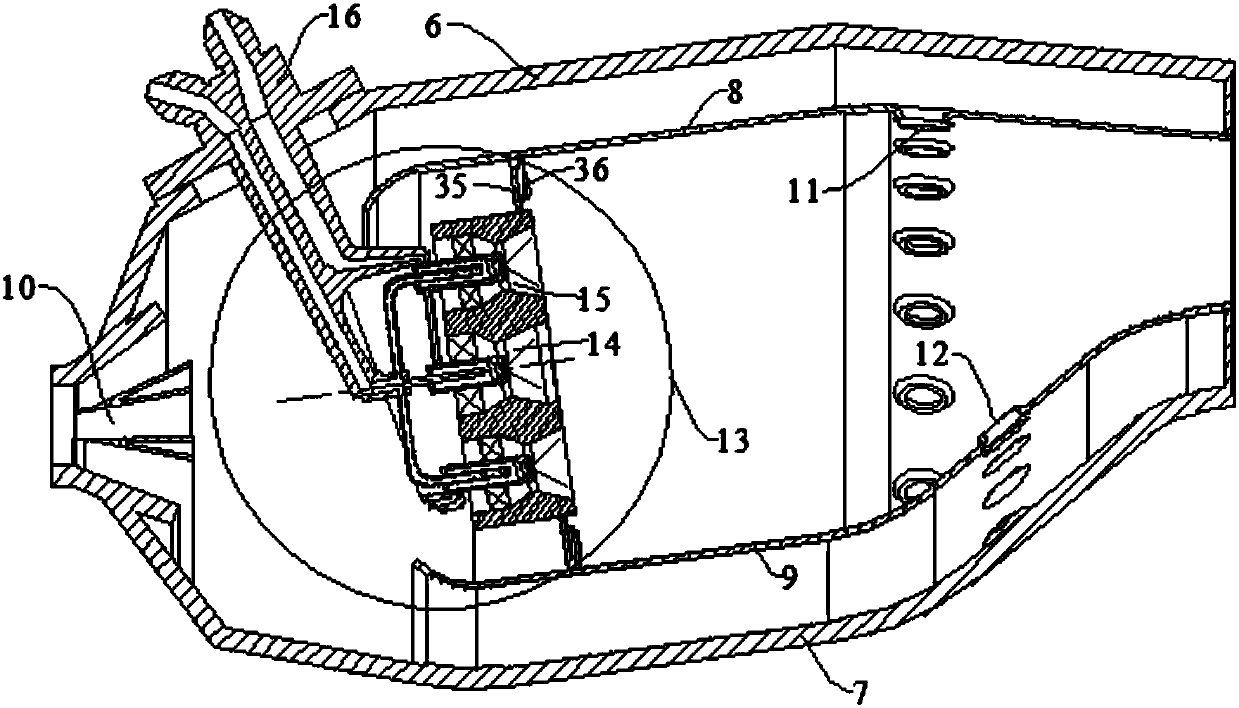

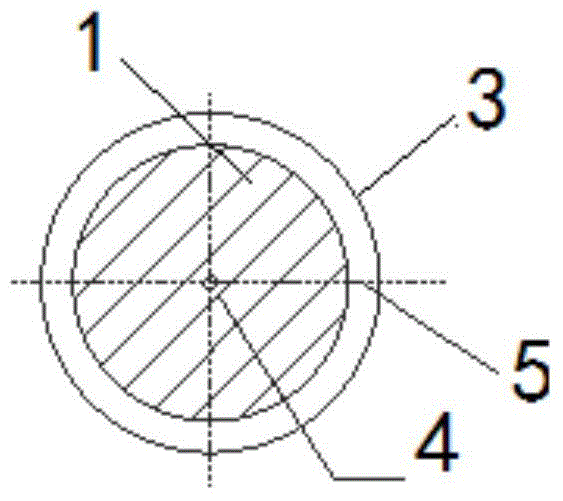

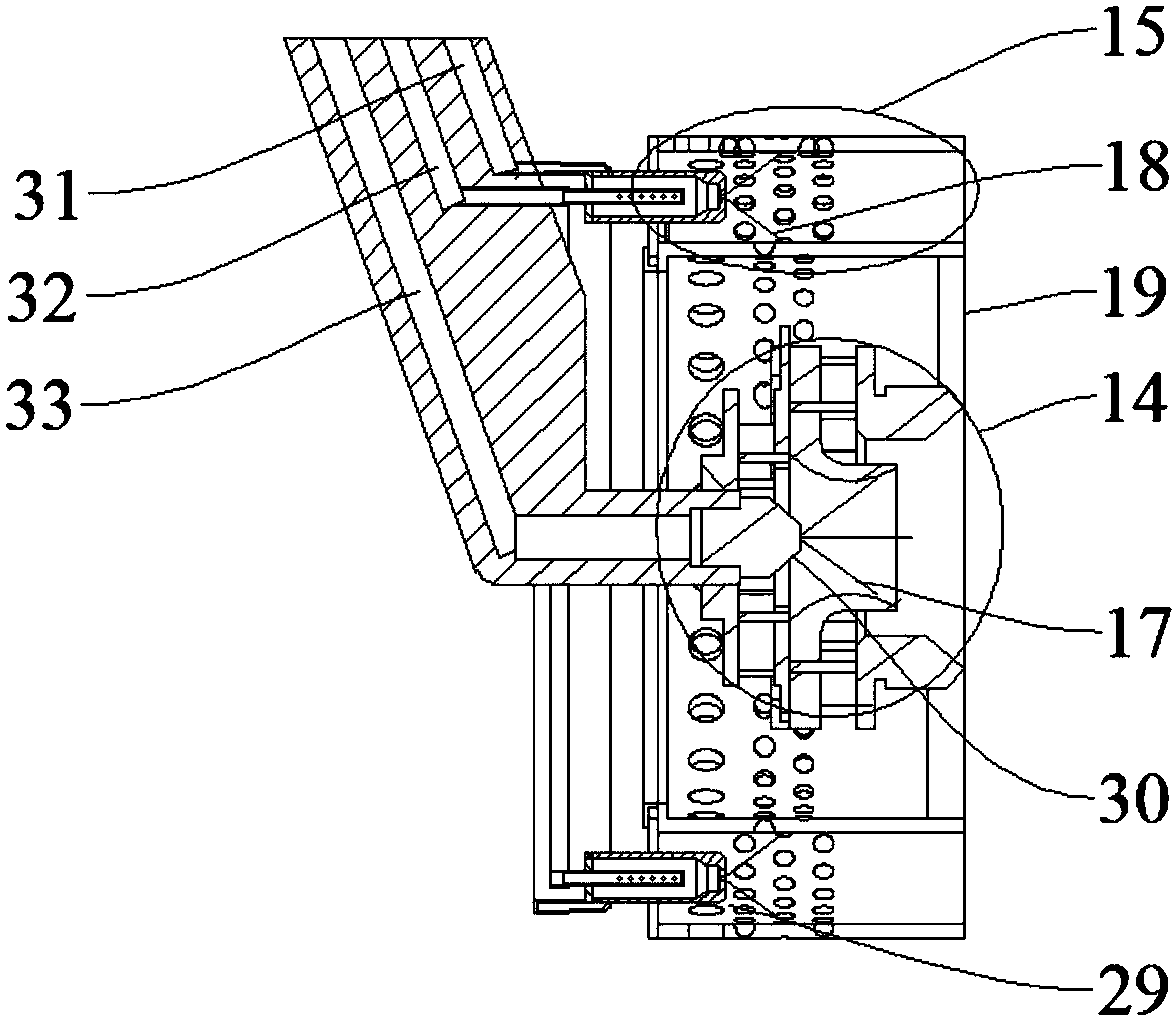

Aero-engine fuel nozzle structure

ActiveCN110726158AAct as thermal protectionAvoid cokingContinuous combustion chamberEngineeringAero engine

The invention discloses an aero-engine fuel nozzle structure. The fuel nozzle structure comprises a sleeve shell and an oil conveying part, wherein the oil conveying part comprises a first oil conveying part and a second oil conveying part, one end of the second oil conveying part is integrally connected with the first oil conveying part, and the other end of the second oil conveying part is connected with an auxiliary vortex device, the sleeve shell is integrally formed with the oil conveying part, a sleeve is arranged outside the second oil conveying part and is extended to the second oil conveying part from the boundary of the first oil conveying part and the second oil conveying part, a semi-closed air heat insulation cavity is provided with the radial space between the second oil conveying part and the sleeve, and elastic pieces which are in contact with the opposite side walls of the air heat insulation cavity are arranged on the open side of the air heat insulation cavity. The fuel nozzle structure has the advantages of stable and reliable structure, long service life and the like.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

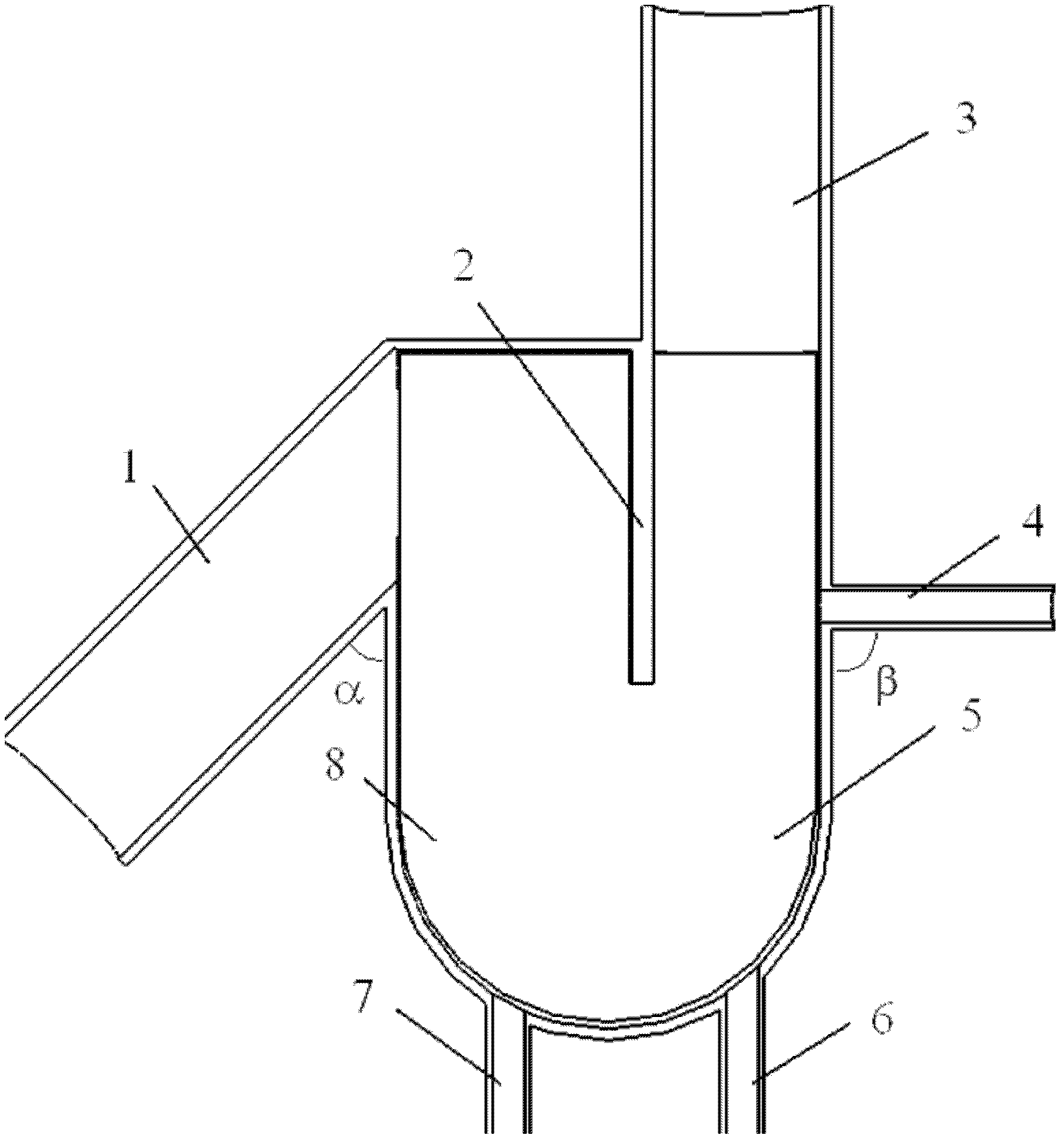

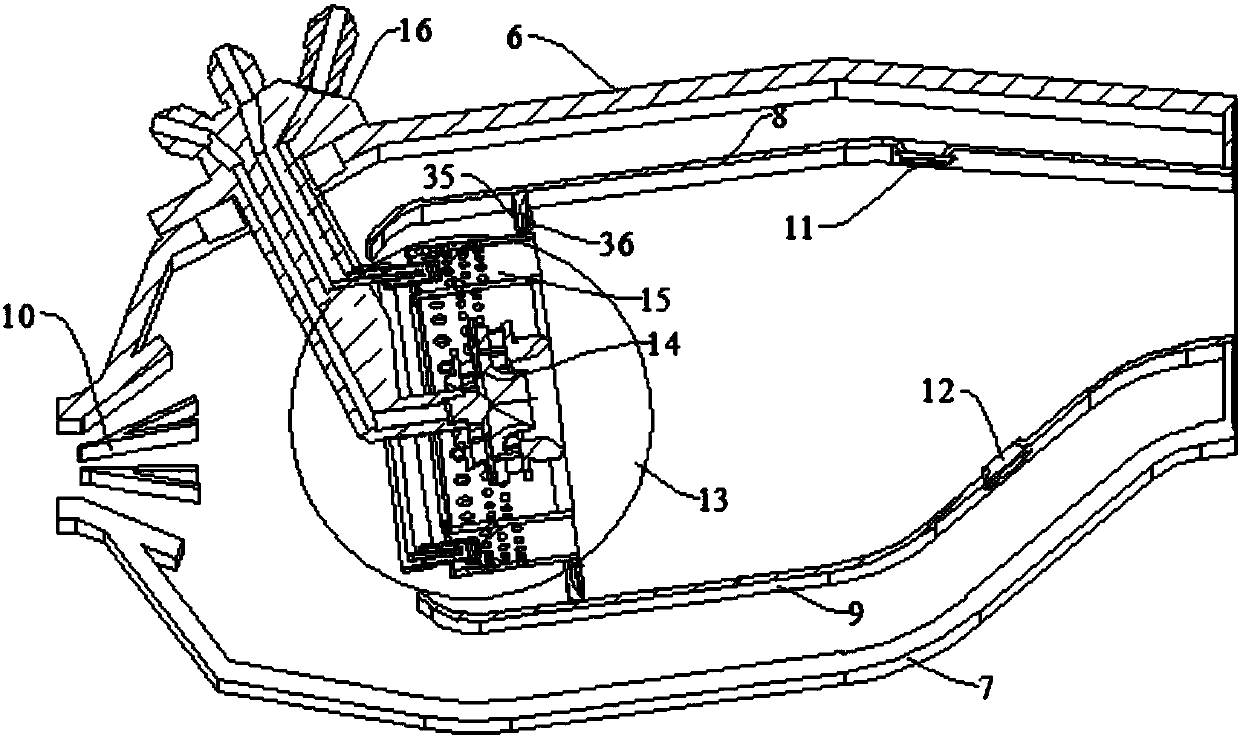

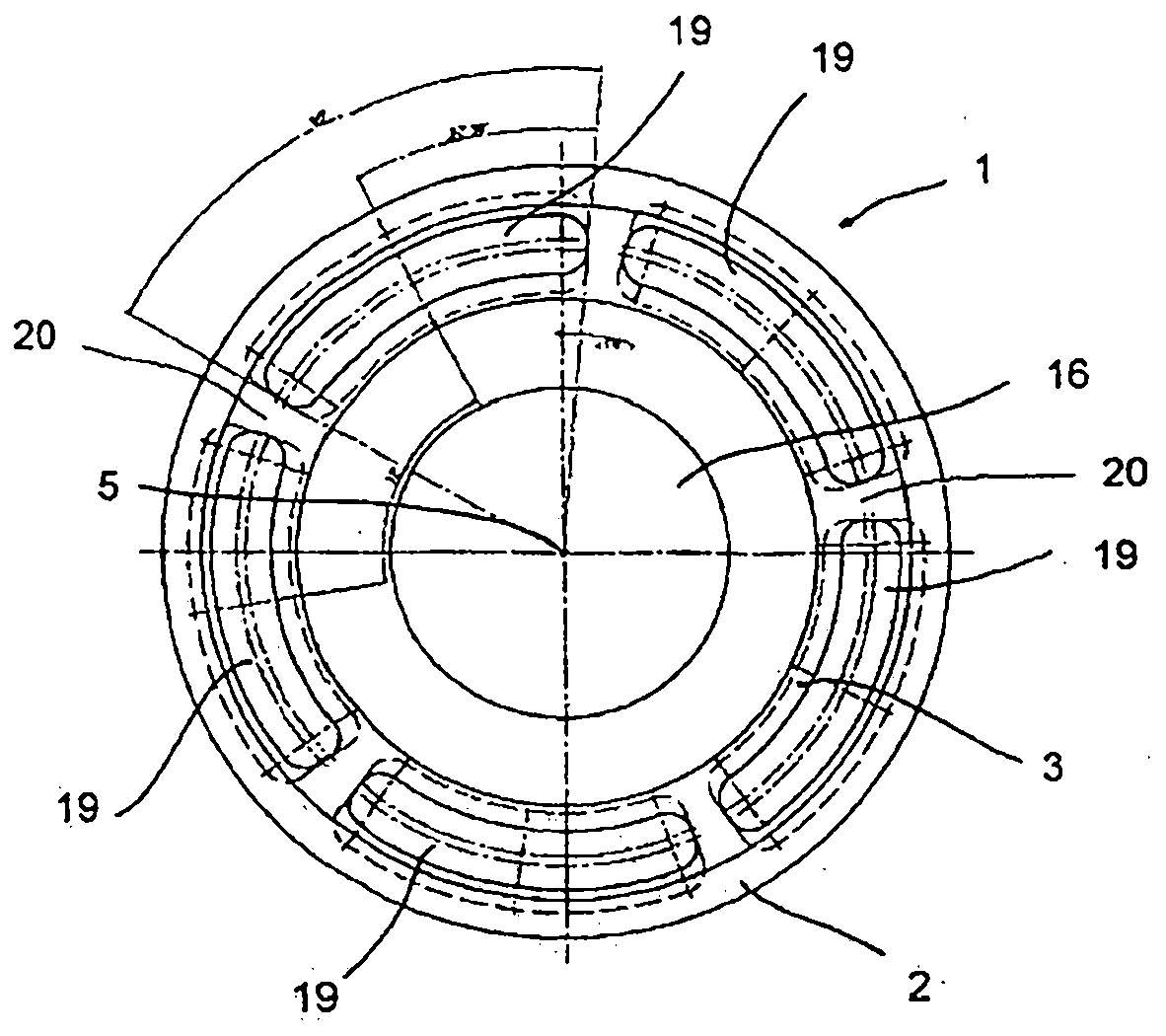

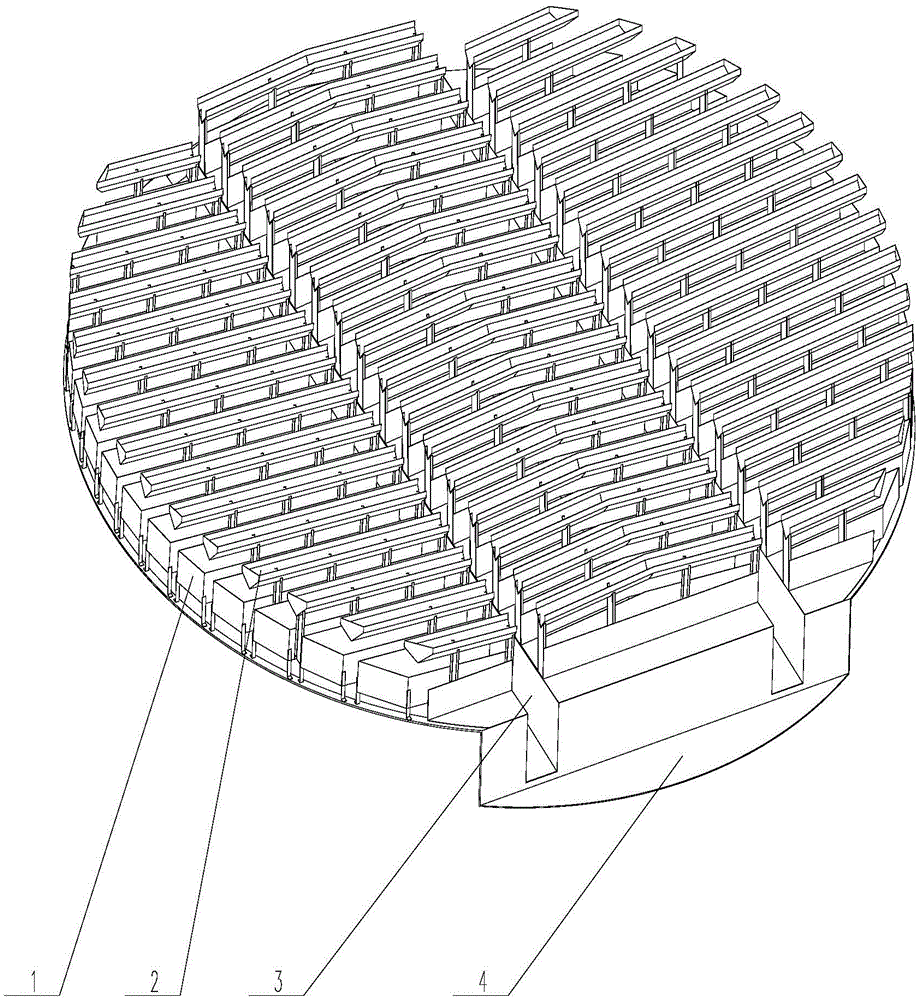

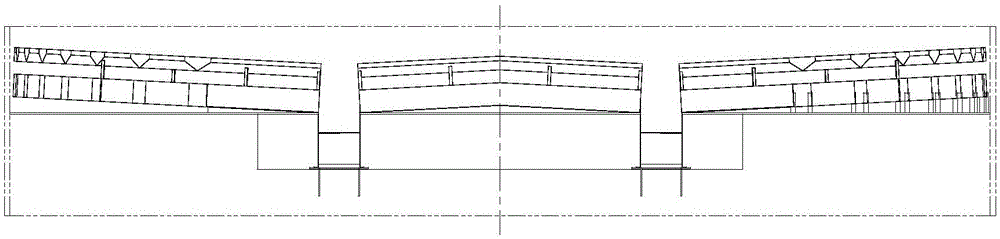

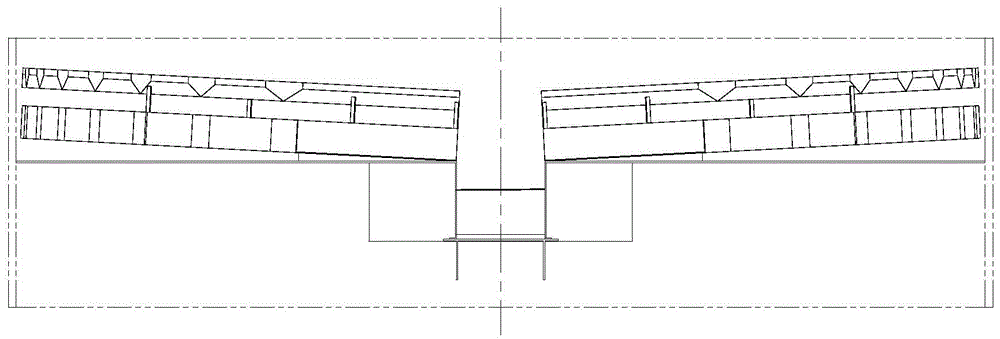

Circular-arc-shaped U valve material returning device for high-density circulating fluidized bed utilizing B-class particle

ActiveCN103216825AImprove stabilitySolve the problems of local flow dead angle, poor fluidization and poor regulationFluidized bed combustionApparatus for fluidised bed combustionCombustionHigh density

The invention discloses a circular-arc-shaped U valve material returning device for a high-density circulating fluidized bed utilizing the B-class particle, which relates to the technology of the circulating fluidized bed. The device mainly consists of an air supply system, a main bed system, a gas-solid separation system, a material returning system and a test system, wherein the air supply system mainly consists of air compressors; the material returning system consists of a dipleg and a circular-arc-shaped U valve material returning device; and the circular-arc-shaped U valve material returning device is provided with three wind paths. According to the circular-arc-shaped U valve material returning device disclosed by the utility model, the problems of local flowing dead corner, unsmooth fluidization and poor regulation of the traditional right-angle U valve material returning device are solved, the coking risk in the U valve material returning device is lowered, the operation stability of the high-density circulating fluidized bed is improved, and therefore, a foundation is laid for researching and developing the combustion and gasification technology of the high-density circulating fluidized bed.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

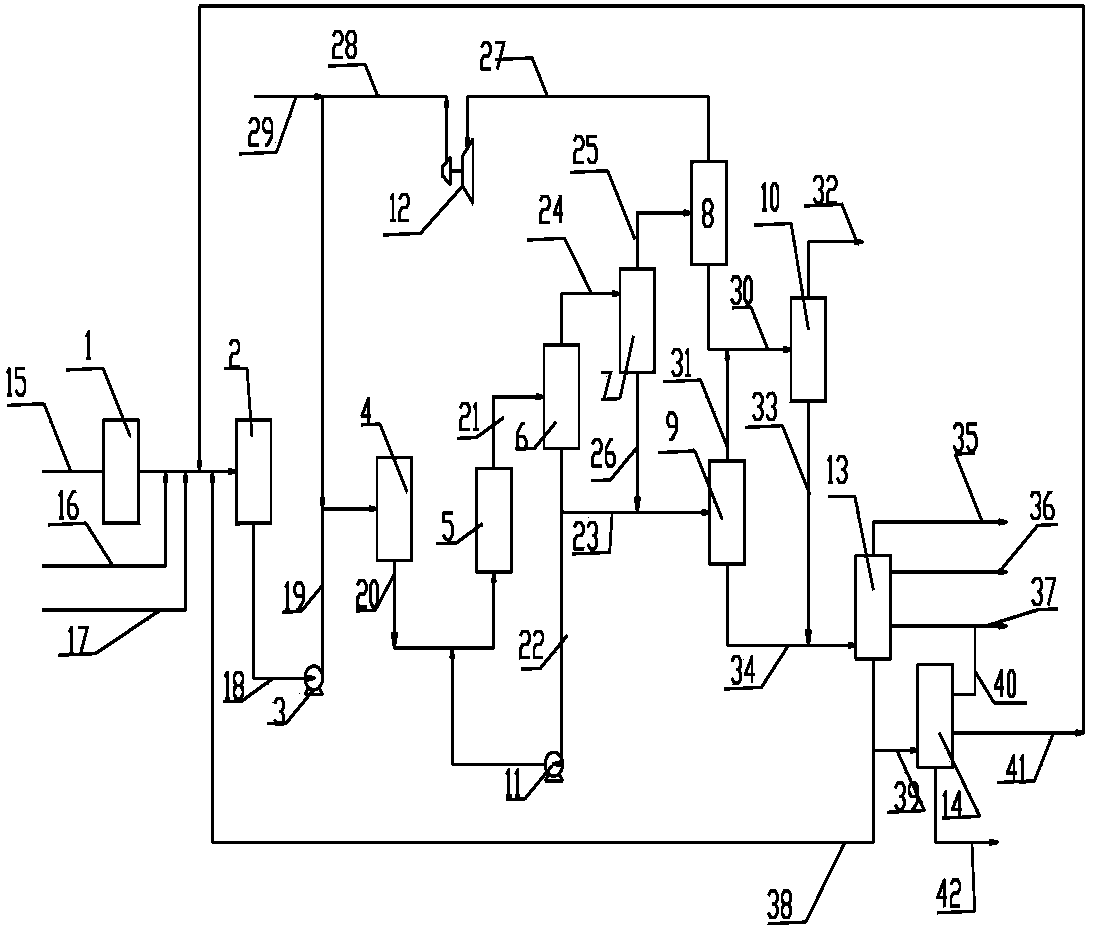

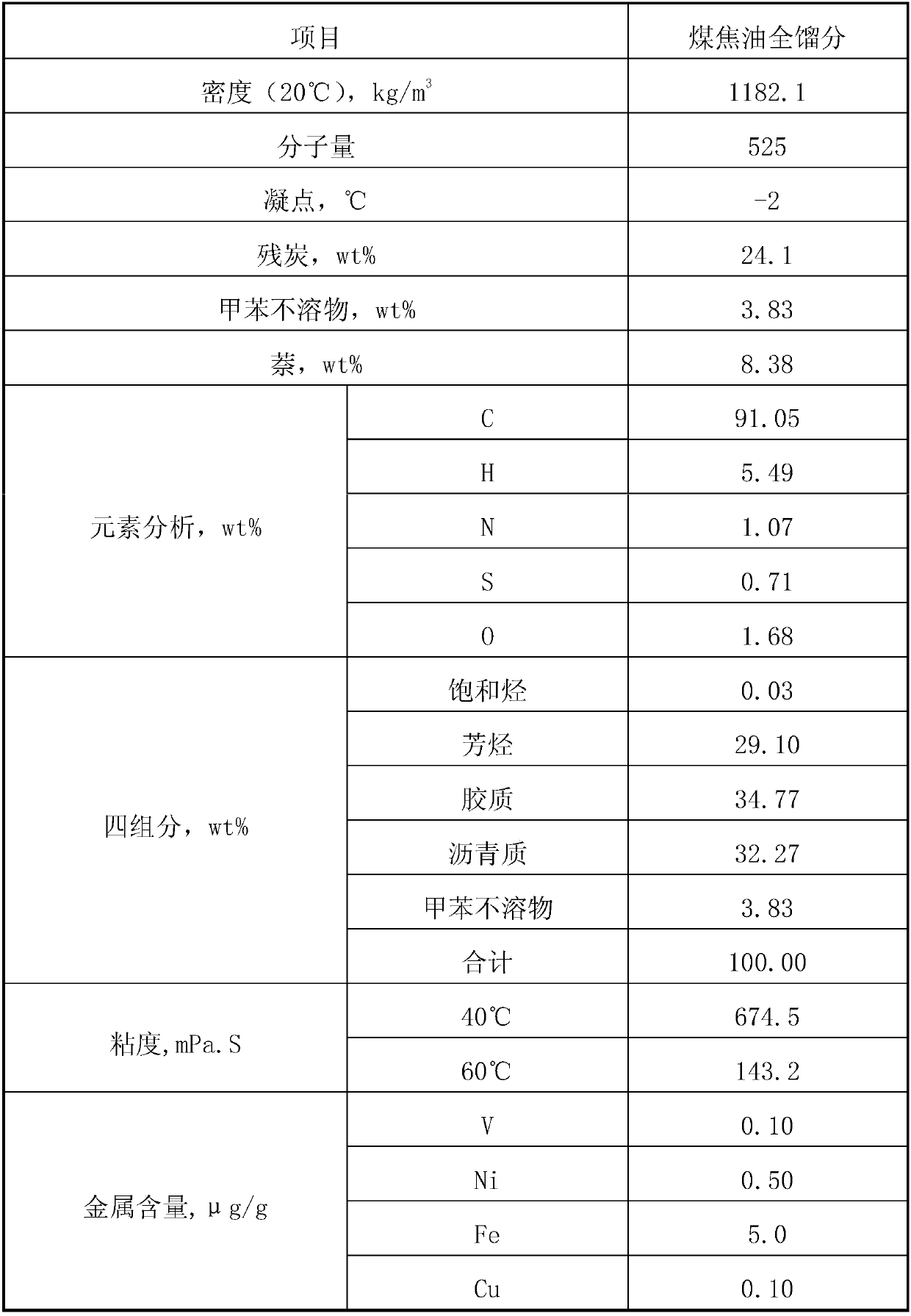

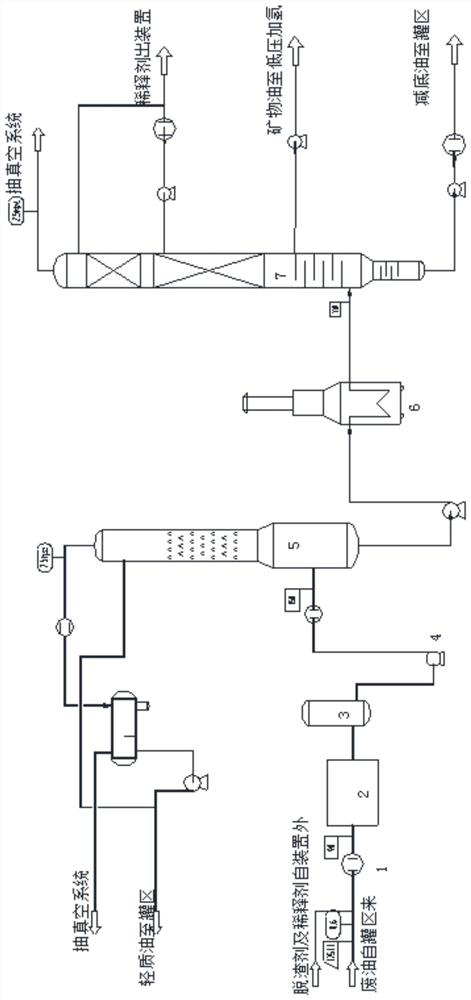

A kind of coal tar suspended bed hydrocracking method

ActiveCN106701178BSimple structureGuaranteed long-term operationHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenSlurry

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

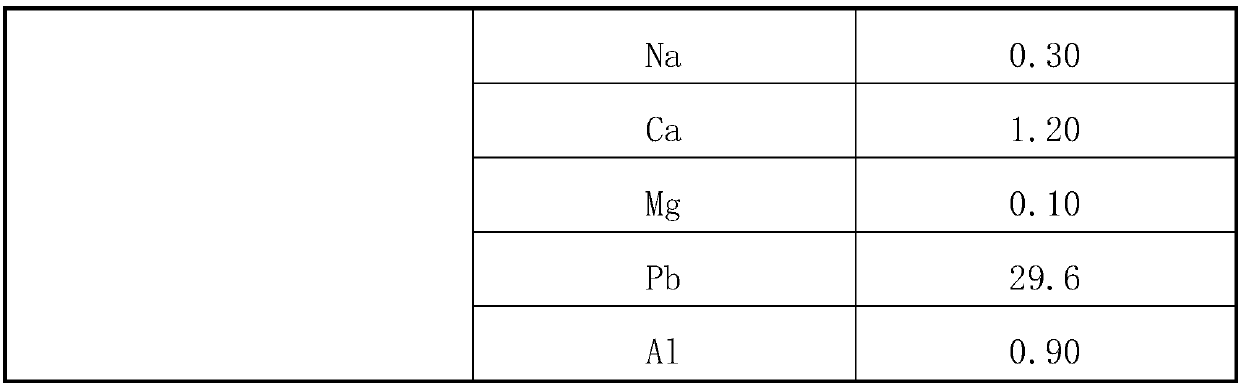

Anti-coking oil collecting tank for passing vaporized oil

ActiveCN104623923ASolve the problem of high temperature cokingIncrease collection speedVacuum distillationFractional distillationFuel tankPulp and paper industry

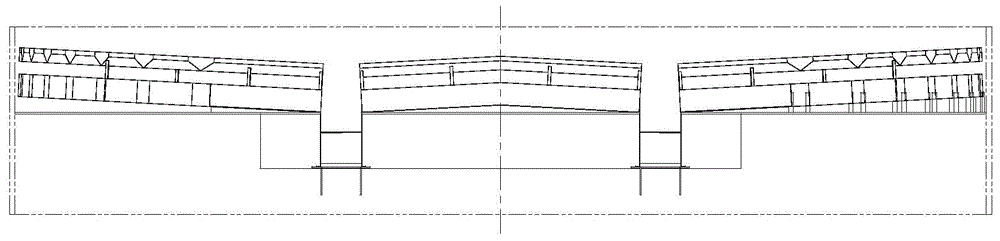

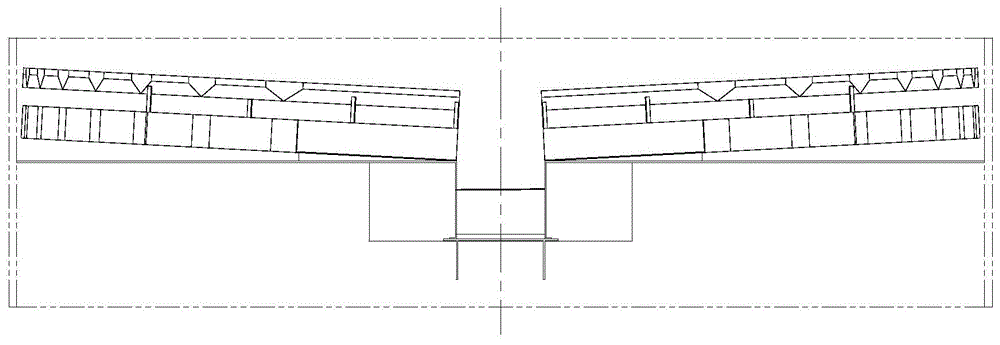

The invention relates to an anti-coking oil collecting tank for passing vaporized oil. Each liquid collecting tank is composed of one or more members with a square tank structure; one end of the liquid collecting tank close to the tower wall is overlapped on a support ring, the other end is overlapped on the edge of a liquid collecting channel, the end overlapped on the support ring is higher than the end overlapped on the liquid collecting channel, and thus the liquid collecting tank is inclined to the liquid collecting channel. The liquid collecting tank in the middle part uplifts, the two ends of the middle liquid collecting tank are respectively overlapped on two neighbored liquid collecting channels, and the middle liquid collecting tank is inclined to the second liquid colleting channel. A liquid baffle plate is in a square tank shape or a triangular tank shape and is fixed above a gap between the liquid collecting tanks through a rib plate or a support plate so as to form a gas channel. The liquid collecting channel has a square tank shape structure, the oil collecting tank comprises one or more liquid collecting channels, one end of the liquid collecting channel is overlapped on a withdrawal hopper, and the bottom plate is inclined to the withdrawal hopper. The number of withdrawal hopper is one or two, and the bottom plate of the withdrawal hopper is inclined to the withdrawal opening. The provided oil collecting tank can reduce the stay time of liquid in the oil collecting tank, reduces the flow resistance, prevents the happening of coking, and guarantees the normal operation of towers at a high temperature.

Owner:PETROCHINA CO LTD +1

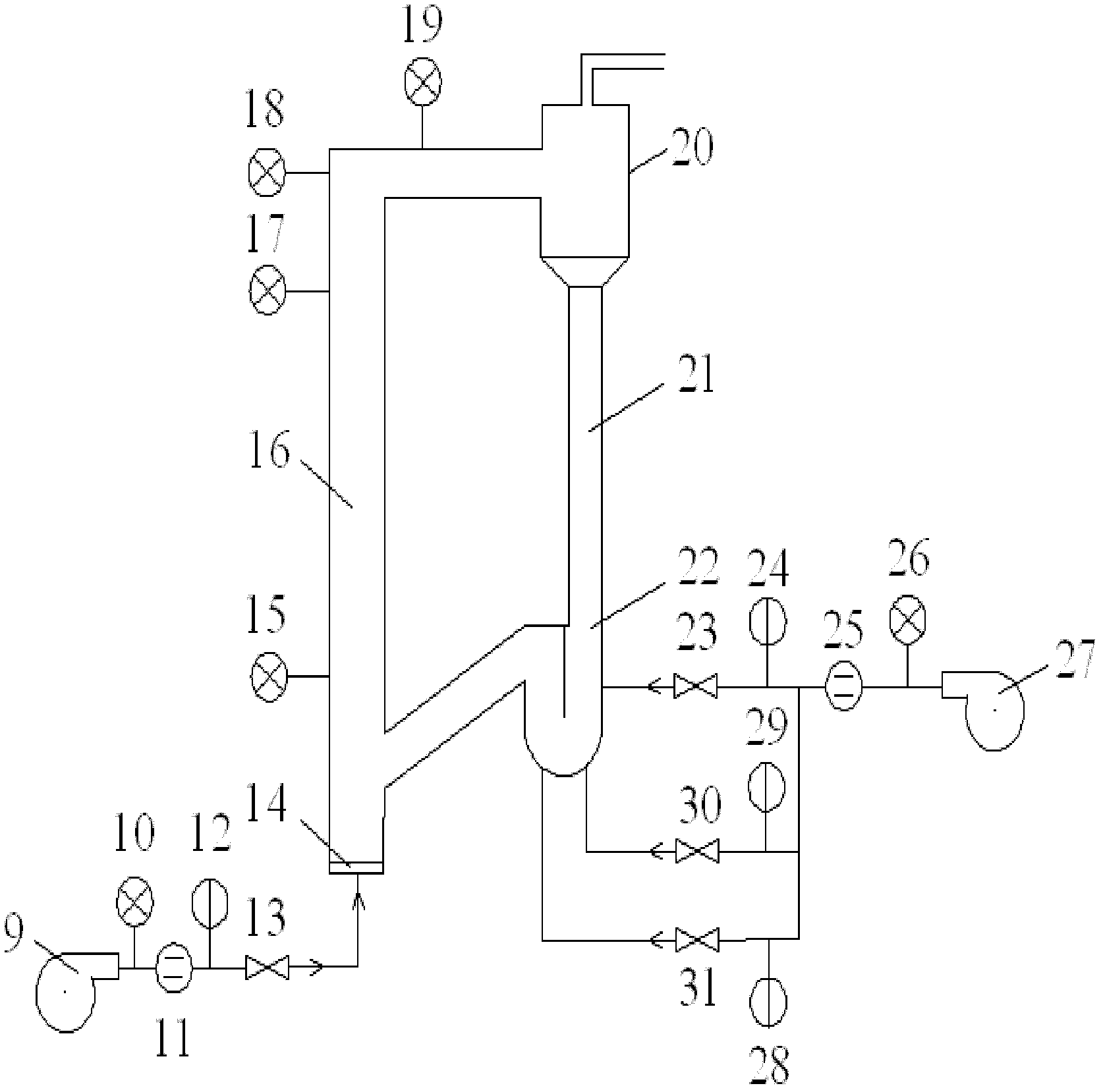

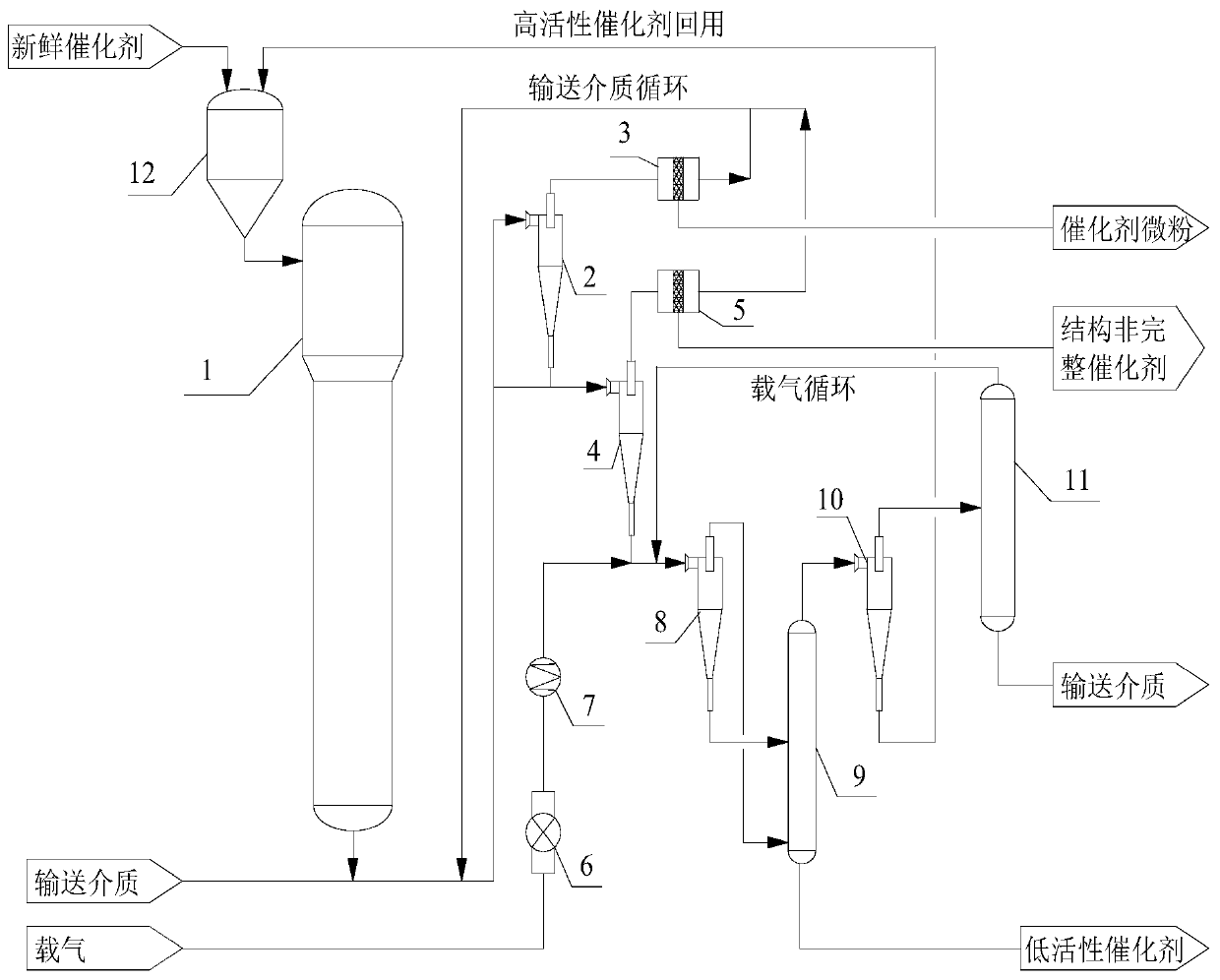

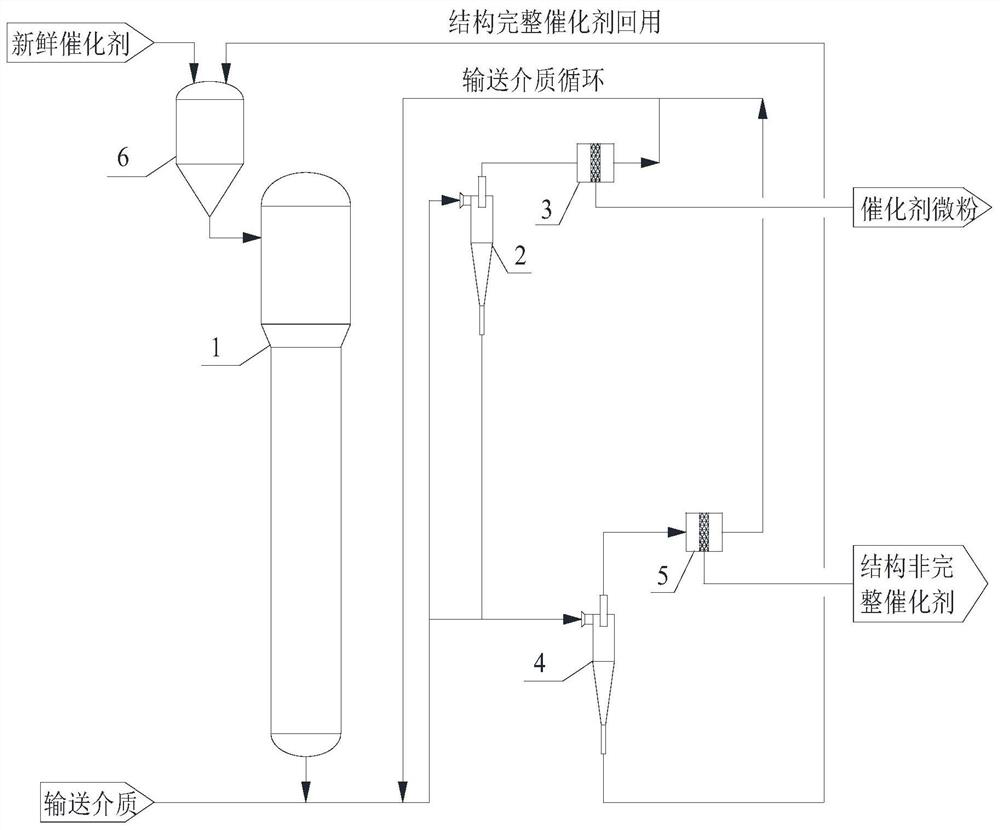

Method and device for removing particles in biomass pyrolysis liquid fluidized bed reactor

ActiveCN110026135AReduced risk of cokingLow running costFeed devicesTreatment with moving solid particlesBiomassChemistry

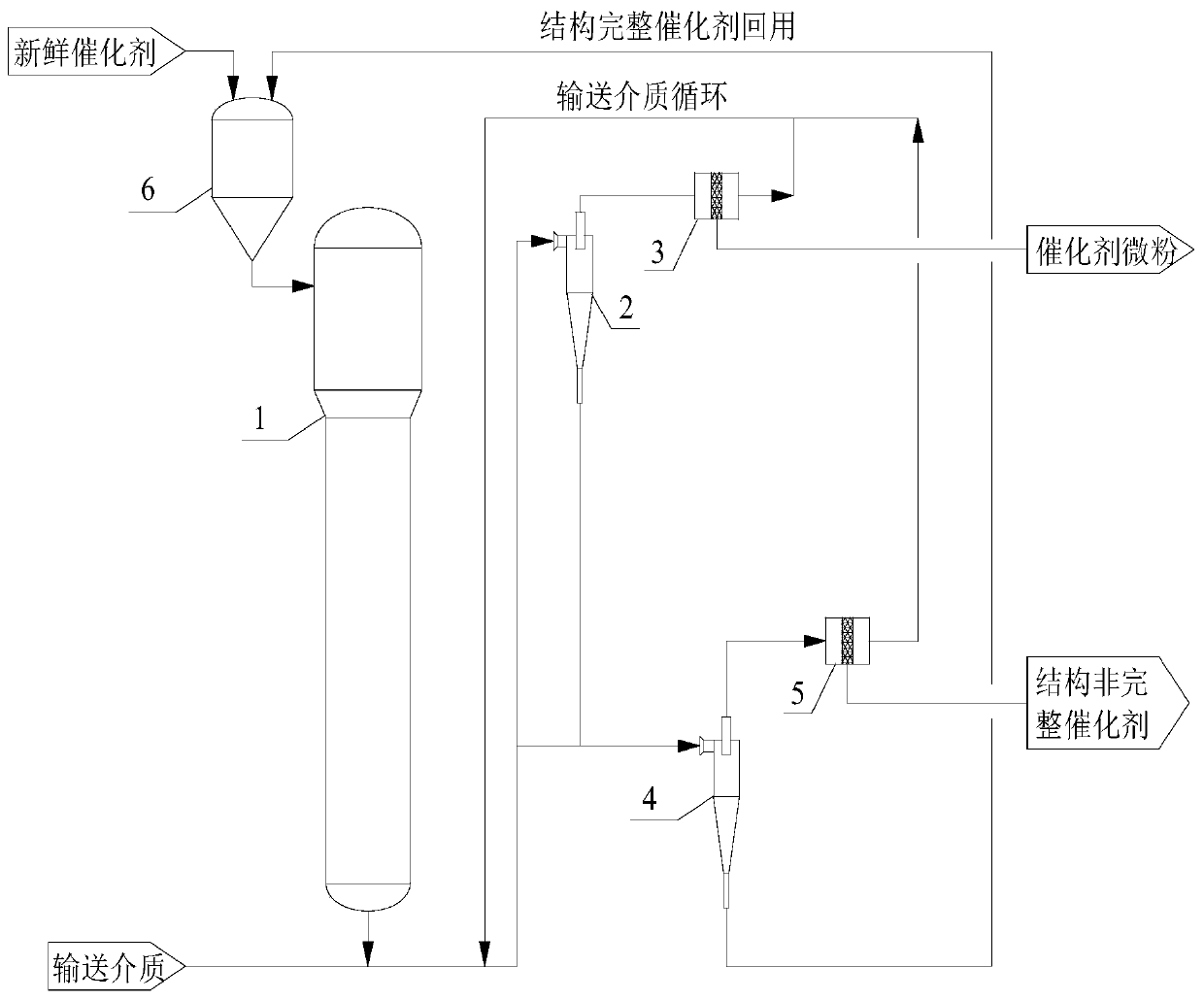

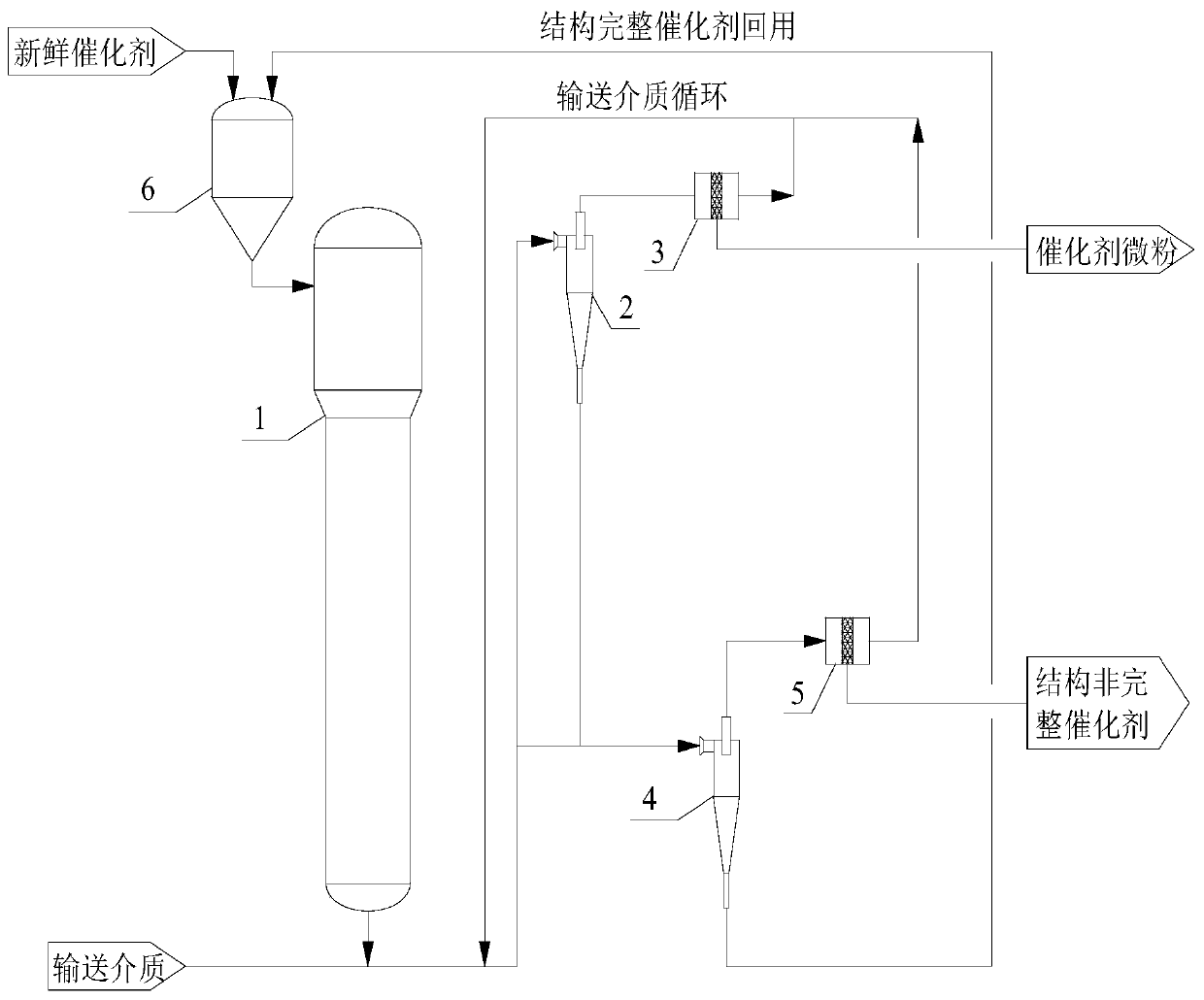

The invention discloses a method and device for removing particles in a biomass pyrolysis liquid fluidized bed reactor. The method comprises the following steps: A) performing primary cyclone classification to realize classification of catalyst micropowder and catalyst particles; b) performing primary filtration to separate the catalyst micropowder from conveying oil; c) performing secondary cyclone classification to realize classification of a structurally incomplete catalyst with a structurally complete catalyst; d) performing secondary filtration to separate the structurally incomplete catalyst from conveying oil; and E) mixing the structurally complete catalyst and a fresh catalyst, and adding the formed mixture into a reactor for use. The invention further provides a device for removing particles in the biomass pyrolysis liquid fluidized bed reactor. According to the method and device disclosed by the invention, the requirements of realizing particle classification and realizing the drying reduction of a separated catalyst are met, the foaming and collision of a reactor bed caused by catalyst micropowder are effectively avoided, and the coking risk is reduced.

Owner:HENAN BUF BIOENERGY CO LTD +2

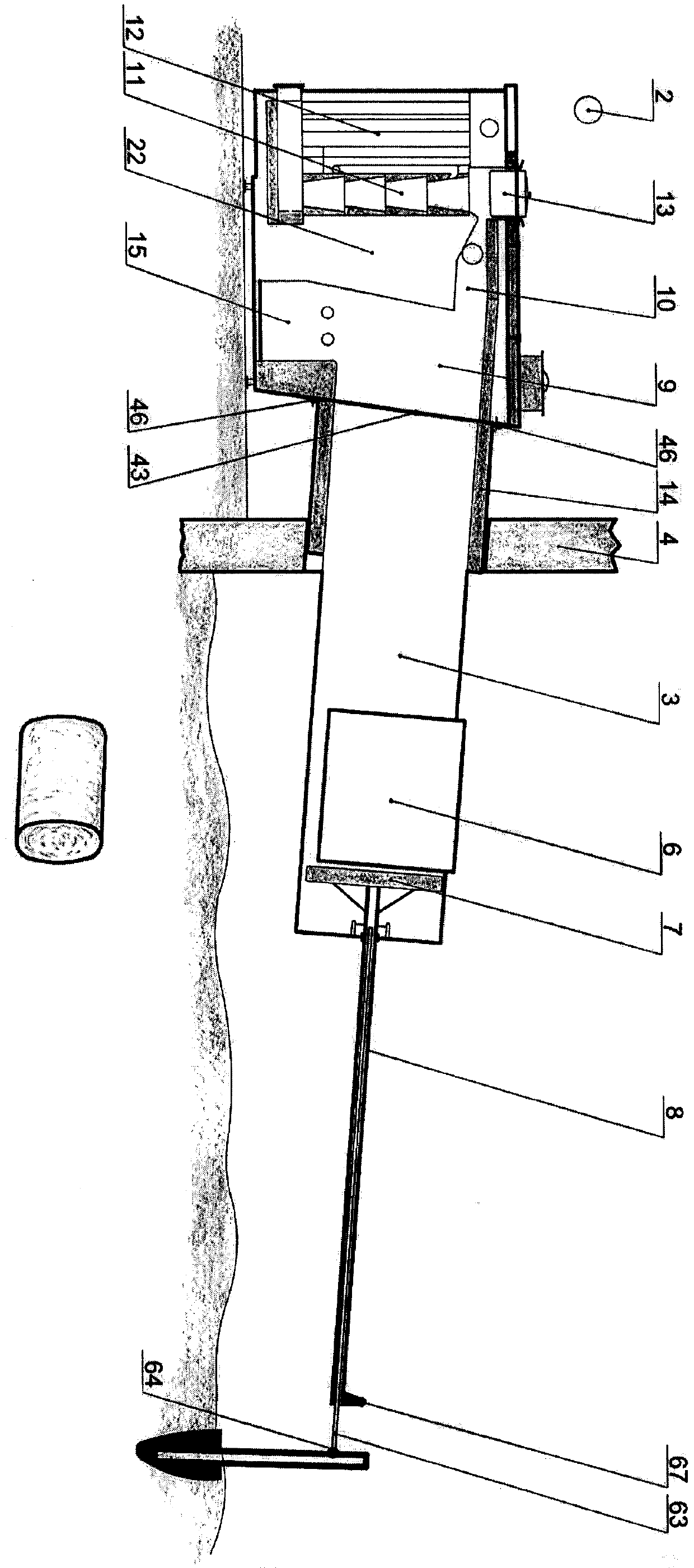

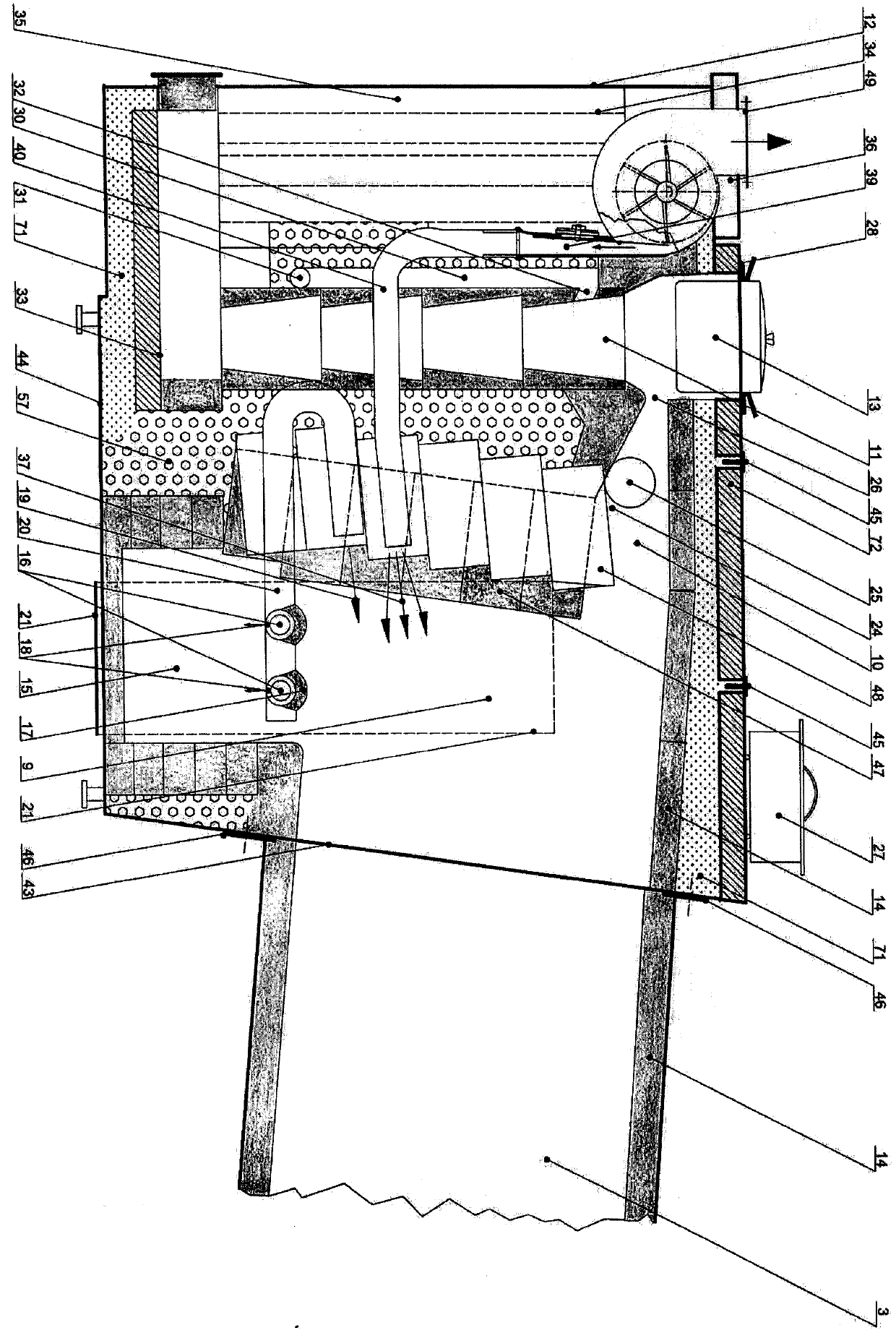

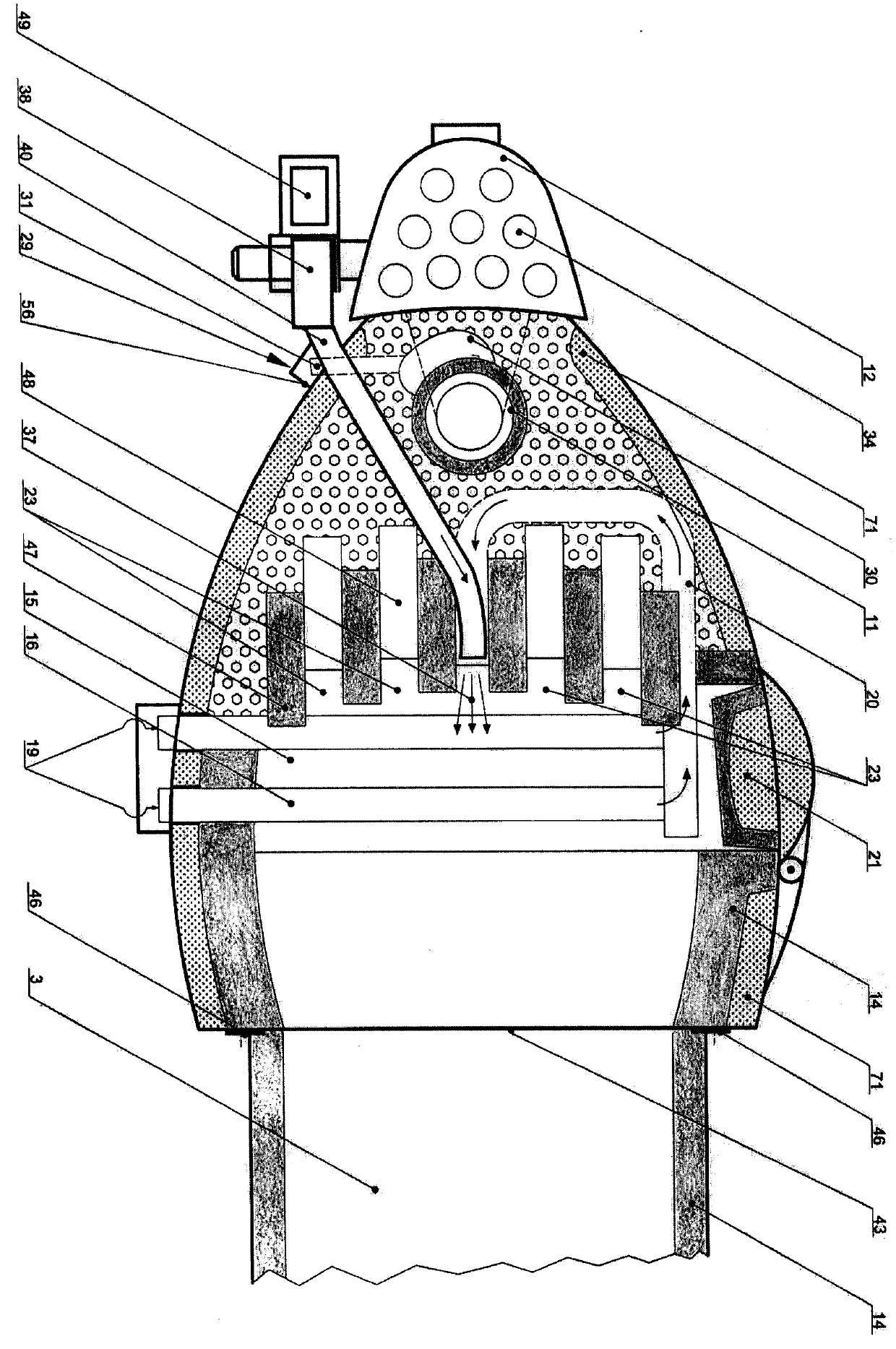

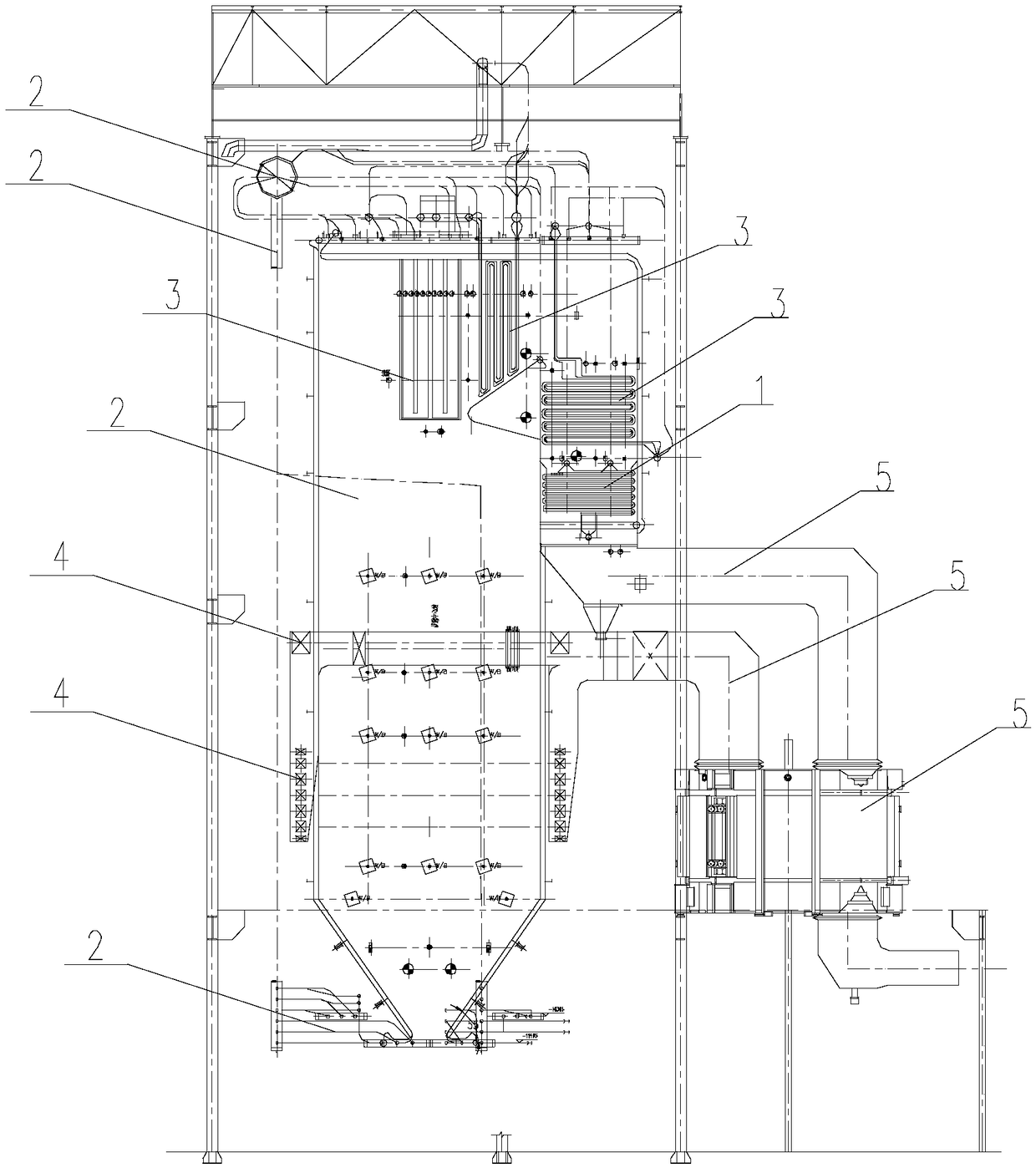

Boiler for small house, with automatic feeding device and adopting bundled straw fuel

ActiveCN111006200ALower oxygen levelsReduced risk of cokingSolid fuel combustionCombustion technology mitigationThermodynamicsCombustion chamber

The invention discloses a boiler for a small house, with an automatic feeding device and adopting bundled straw fuel. The boiler is mainly formed by a straw bale combustion unit 1 and the automatic feeding device 3. The straw bale combustion unit 1 is formed by an outer pressure-resisting wrapping layer, a ceramic component wrapped in the outer pressure-resisting wrapping layer and the like. By means of a ceramic heat storage area 22 in a combustion chamber 9, due to indented refractory bricks, it is guaranteed that an upward flue gas channel 23 is smooth all the time, flue gas is sucked out from a pre-combustion chamber 10 at the top of the combustion chamber, and the pre-combustion chamber 10 comprises an ignition channel 25 used for helping ignition. The inner cross section of a vortexafter-combustion chamber 11 can be contracted and enlarged several times, and therefore pressure pulses are generated in flue gas, and flue gas jet flow 37 pressurized in the combustion chamber 9 is blown to a straw bale 5 so as to strengthen gasification combustion. The automatic feeding device 3 with a sliding shield 7 is driven by a winch 65 and a pulley. By means of the boiler, the straw balecan be combusted quite thoroughly, plant ash is used as fertilizer, and the boiler has high value.

Owner:黑龙江赫尔特生物质能源发展有限公司

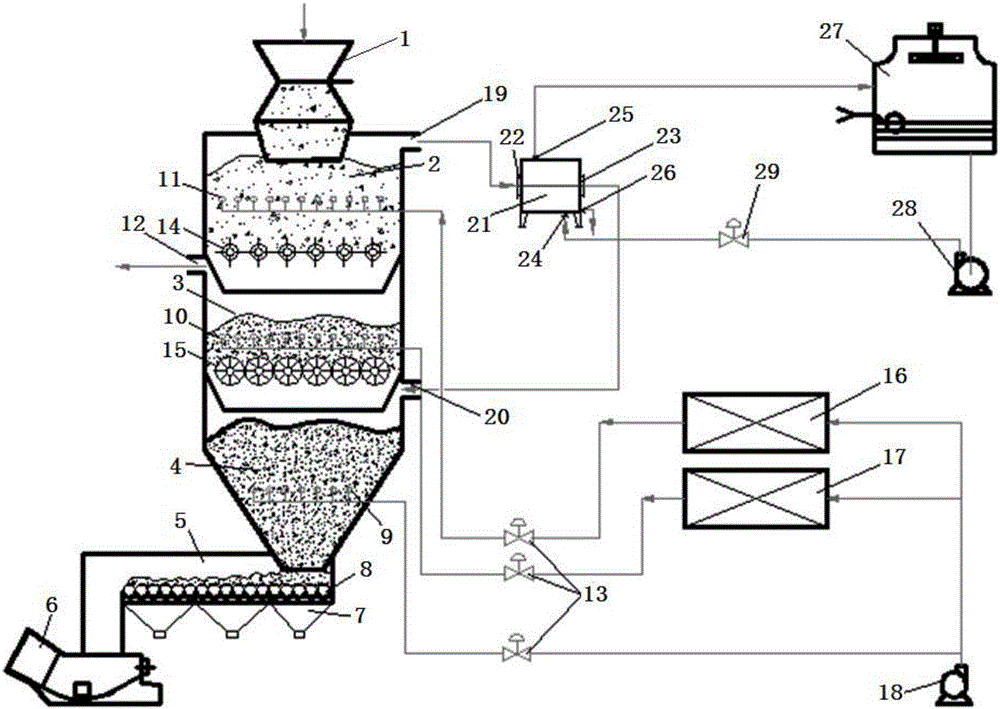

Dehumidification, pyrolysis and gasification device for household garbage, and use method thereof

InactiveCN106678814AControl dwell timeImprove processing efficiencyIncinerator apparatusAir preheaterRetention time

The invention discloses a dehumidification, pyrolysis and gasification device for household garbage, and a use method thereof. The dehumidification, pyrolysis and gasification device for the household garbage comprises a garbage treatment tower, a condensation dehumidifier, a high-temperature air preheater, a low-temperature air preheater and an air blower, wherein the garbage treatment tower is sequentially provided downwards with a drying and pyrolysis chamber, a pyrolysis and gasification chamber and a roasting chamber in the longitudinal direction; and the garbage enters from the upper end of the drying and pyrolysis chamber, the generated damp-hot smoke sequentially passes through the condensation dehumidifier and the roasting chamber, the damp-hot smoke entering the roasting chamber enters the pyrolysis and gasification chamber under the action of a negative pressure, then a water-gas reaction is carried out, and a pyrolysis gas outlet is formed in one end of the pyrolysis and gasification chamber. According to the dehumidification, pyrolysis and gasification device for the household garbage, and the use method thereof which are disclosed by the invention, the retention time of the household garbage in a space can be controlled through adjusting the rotation speed of a grate bar; the heat value of a pyrolysis gas is increased while a water content in the pyrolysis gas is reduced, the risk of coking of a material layer on the rotaring grate bar of the pyrolysis and gasification chamber can also be lowered, and a carbon content in ash residue is lowered; and the household garbage with the water content of greater than 60% can be treated through using the device disclosed by the invention.

Owner:长沙超梵环境科技有限公司

Coal blending method and coal blending system

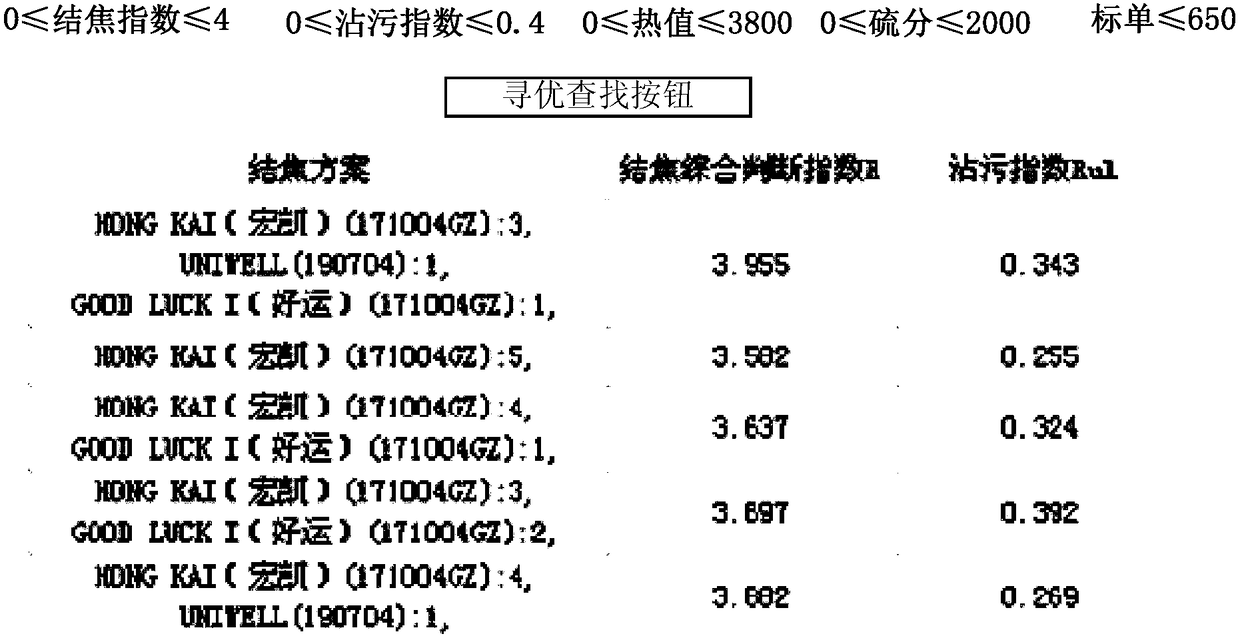

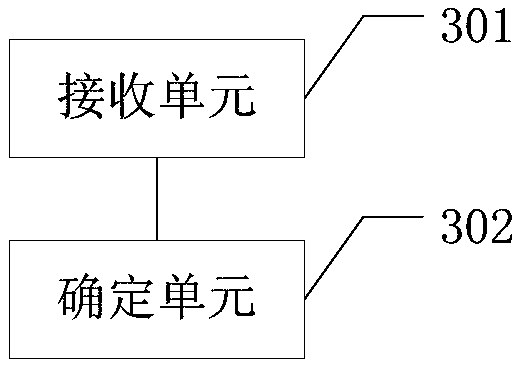

An embodiment of the invention discloses a coal blending method and a coal blending system. The method includes: receiving user configuration information including coal type information and coking indexes; determining coal blending schemes according to the user configuration information and a preset cokeability optimizing module which internally includes a corresponding relation between the cokingindexes and the coal blending schemes. The coal blending method and the coal blending system are used for determining the coal blending schemes according to the coking indexes to reduce coking risksof boilers.

Owner:GUANGZHOU CR THERMOELECTRICITY CO LTD

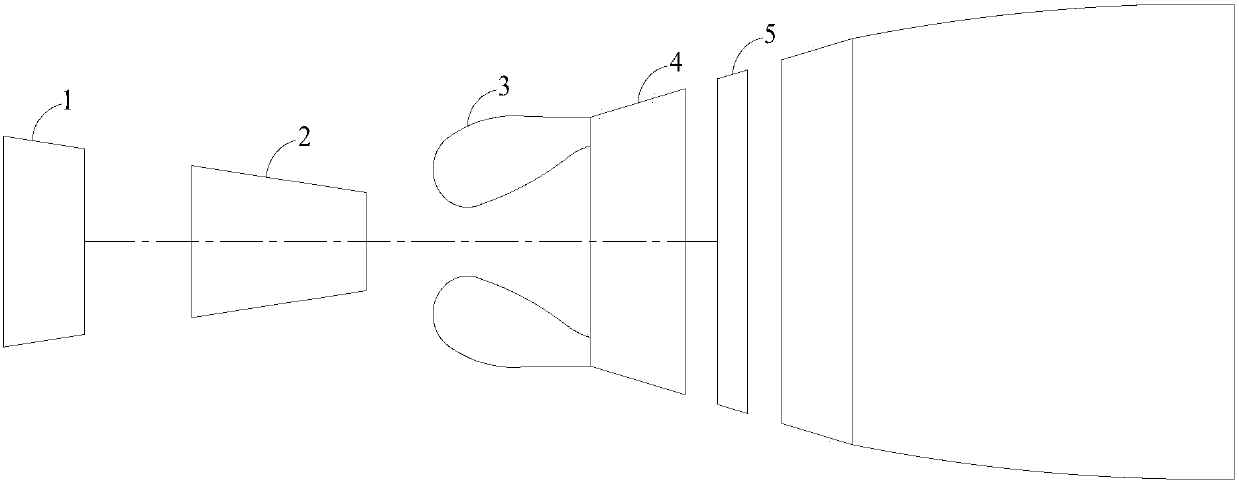

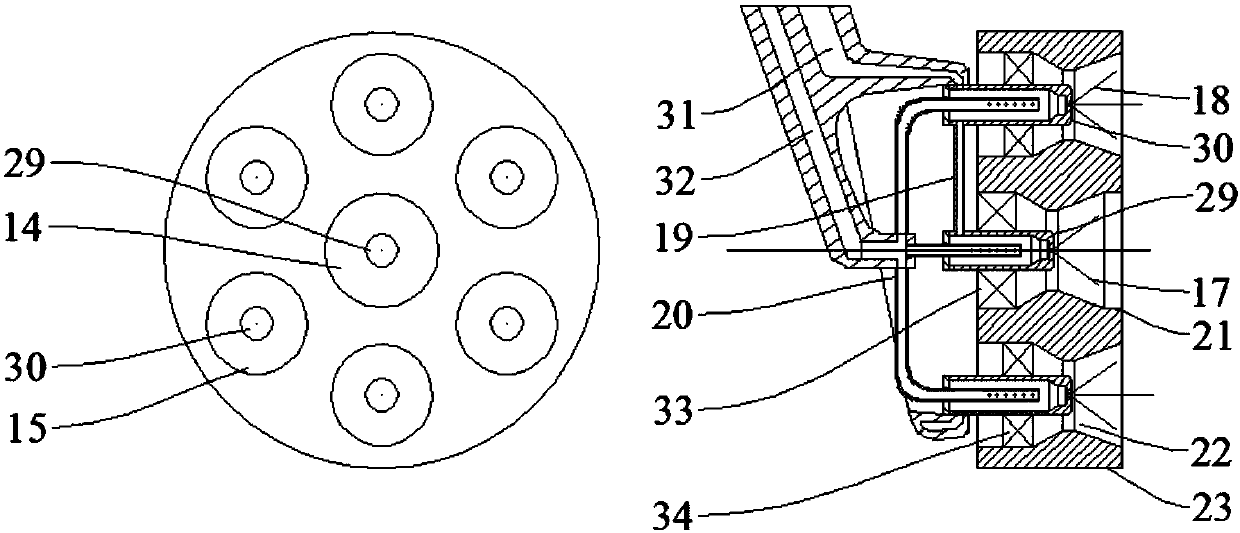

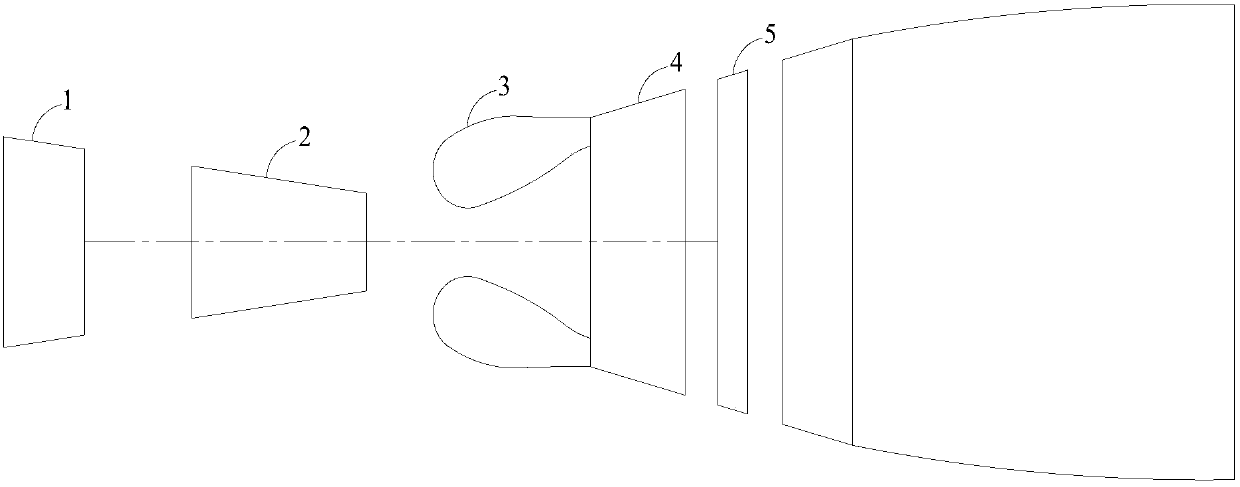

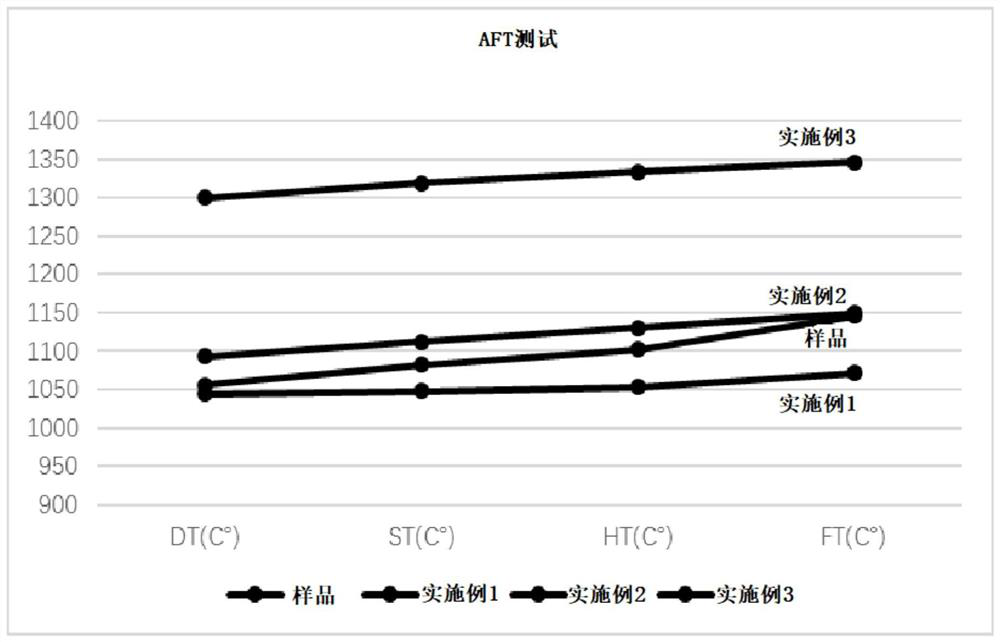

A Lean Oil Direct Injection Low Pollution Combustion Chamber Using Bubble Atomizing Nozzles

ActiveCN105716119BReduced risk of cokingImprove uniformityContinuous combustion chamberCombustion chamberCombustor

The invention discloses a lean direct injection low-emission combustor adopting effervescent atomizers. A single-ring cavity structure is adopted in the combustor. The lean direct injection low-emission combustor comprises a diffuser, a combustor outer case, a combustor inner case, a flame tube outer wall, a flame tube inner wall and combustor heads. Fuel oil is atomized into liquid mist which is extremely thin and extremely uniform through the multiple effervescent atomizers, and the liquid mist is directly injected into the combustor for combustion. A staged combustion structure is adopted in the combustor. A sinking design is adopted in a center precombustion stage, and the flame stabilizing function is played; and the flame is stabilized depending on the precombustion stage for primary combustion stages of the periphery of the precombustion stage, and the primary combustion stages start to work according to the needs of the working conditions. The lean direct injection technology is adopted in the low-emission combustor, the fuel oil is injected into the combustor through the multiple effervescent atomizers, and the spatial distribution uniformity of the fuel oil is increased; and the fuel oil is injected through the special effervescent atomizers, and therefore the fuel oil has the good atomizing quality, fuel oil atomizing and mixing are facilitated, distribution uniformity of the fuel oil is further increased, and the combustor has the great potential in reducing pollution emission.

Owner:BEIHANG UNIV

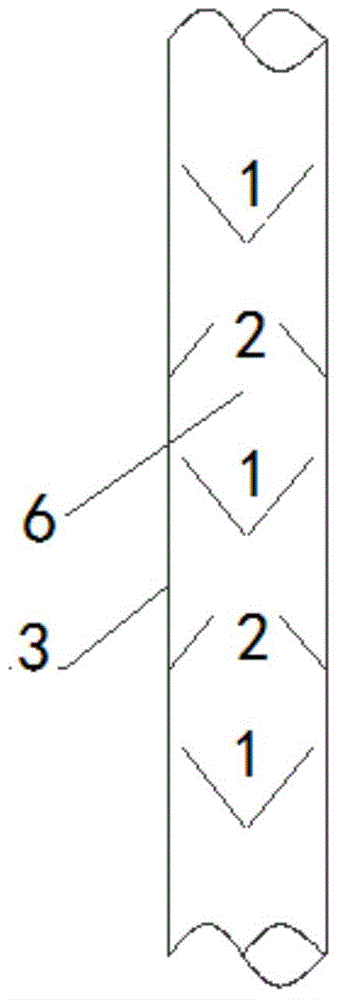

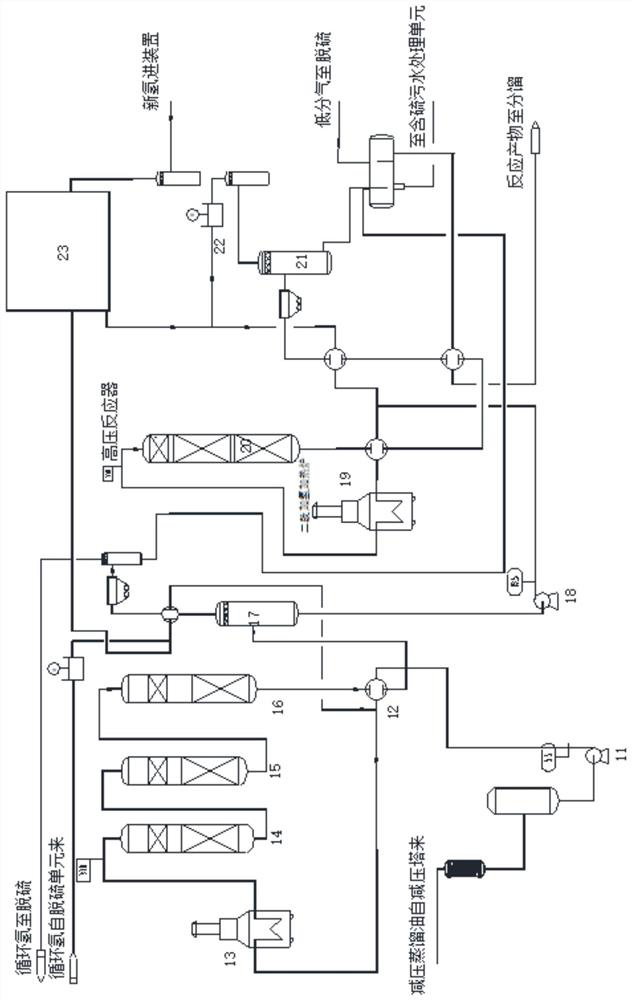

Reactor internal-part with high light oil yield, low back-mixing and long-term operation and technological method thereof

ActiveCN104650955AReduce lossEasy to remove oilThermal non-catalytic crackingShortest distanceEngineering

A reactor internal-part with high light oil yield, low back-mixing and long-term operation and a technological method thereof belong to the technical field of oil refining equipment. Odd-number trays and even-number trays are all inclined a certain degree. The odd-number trays are V-shaped plates with small holes at the center, and there is a long distance between the external edge and a visbreaking tower body; and the even-number trays are inverted V-shaped plates with large holes at the center, and there is a shorter distance between the external edge and the visbreaking tower body. When reaction materials pass through two sides of the odd-number trays, speed will be gradually raised such that the reaction materials pass through intervals between the tower plates and the reactor wall at a high speed. When speed reaches the maximum, the reaction materials leave the even-number trays from the center. Through the gradually-narrowing intervals between the odd-number trays and the tower body, flow velocity of a fluid continuously increases, thus scouring the side wall of the tower body to the maximum so as to avoid back-mixing caused by low flow velocity at the side wall. Reaction raw oil passes through the odd-number trays and the even-number trays in order, successively speeds up at the side wall and center of the reactor, and finally passes through all the trays to go out of the reactor.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Shunt down method of fixed bed Fischer-Tropsch synthesis process

ActiveCN102161609BReduce adverse effectsReduced risk of cokingHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionNitrogenRaw material

The invention provides a shunt down method of a fixed bed Fischer-Tropsch synthesis process. The shunt down method comprises the following steps: when a device is shunted down after a fixed bed Fischer-Tropsch synthesis reaction is finished, firstly, maintaining the temperature of a catalyst bed layer to be unchanged; leading nitrogen from the inlet of a reactor, and simultaneously, cutting off raw material gas for feeding; maintaining the amount of a circulating gas to be unchanged; after replacing to the required condition, gradually reducing the pressure of a reactor, and then gradually reducing the temperature of the catalyst bed layer; and when the temperature of the bed layer is reduced to less than100 DEG C, gradually completing shunt down. Compared with the prior art, by using themethod in the invention, the side influence to the catalyst bed layer in the shunt down process is reduced while stable shunt down is achieved, thereby proving a good guarantee for subsequent reworking and catalyst unloading.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for recycling waste mineral oil

InactiveCN112457881ASolve the blockageSolve corrosiveTreatment with hydrotreatment processesPtru catalystDistillation

The invention discloses a method for recycling waste mineral oil. Settling pretreatment, reduced pressure distillation and hydrofining are adopted as a process route for recycling the waste mineral oil. A centrifugal process is added in reduced pressure distillation, a diluent and a deslagging agent are introduced, partial pressure of a reduced pressure system is reduced while impurities are removed, and the diluent is recycled. High-pressure and low-pressure two-stage hydrogenation is adopted for hydrofining. The technology solves the problems of coking of a waste mineral oil distillation pretreatment furnace tube, blockage of a vacuum tower, serious corrosion of hydrogenation equipment, coking of a hydrogenation catalyst bed layer, blockage of a hydrogenation reaction material outlet pipeline and the like in the prior art. The process is scientific and reasonable in technology, stable in long-period operation, efficient, environmentally friendly, high in product quality and obvious in economic benefit.

Owner:CHANGLING PETRO CHEM ENG DESIGN

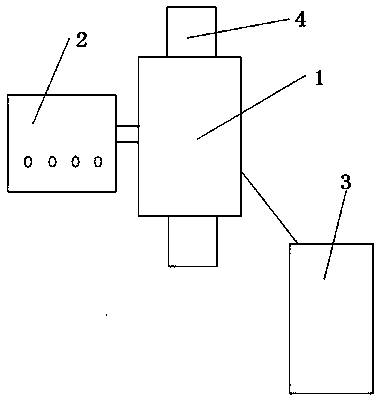

Scrap iron separation and collection system and method applied to intermediate storage type pulverizing system

A scrap iron separation and collection system applied to an intermediate storage type pulverizing system comprises a scrap iron separator, a control cabinet used for controlling the scrap iron separator and a scrap iron collector used for collecting scrap iron, and the control cabinet is electrically connected with the scrap iron separator. The invention further relates to a scrap iron separationand collection method applied to an intermediate storage type pulverizing system. A control cabinet is used for controlling the working time of an electromagnet, the working time is 3-5 minutes, scrapiron in the pulverized coal is magnetized and adsorbed, and the scrap iron in the pulverized coal is adsorbed to the adsorption wall outside the electromagnetic coil. By means of the principle that the electromagnet loses power and magnetism, scrap iron on the adsorption wall is released through outage, automatically slides to a scrap iron collecting pipe under the action of gravity and is collected into the scrap iron collector through a scrap iron collecting descending pipe. According to the invention, the abrasion of a primary air pipe can be greatly reduced, and the coking risk of the water wall of a boiler can be reduced.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +1

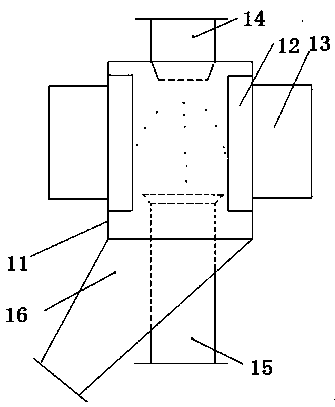

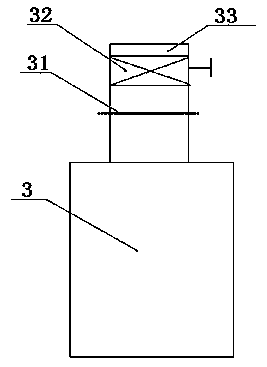

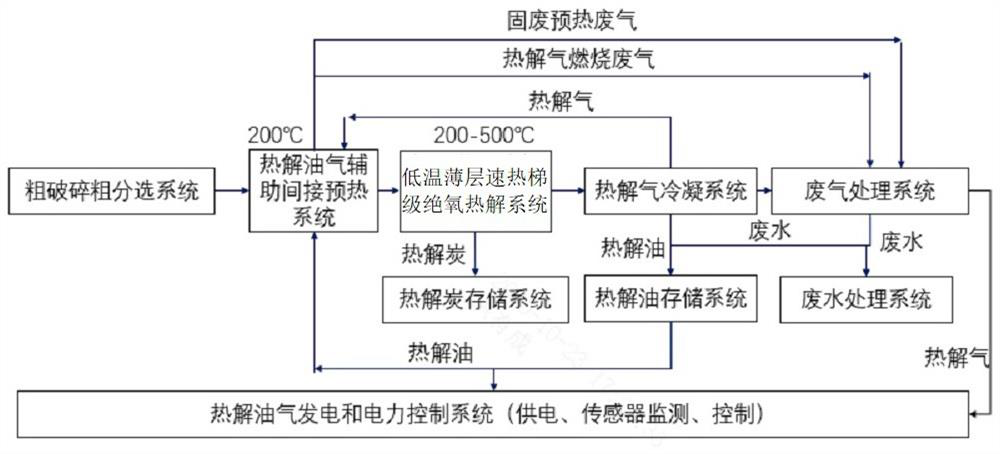

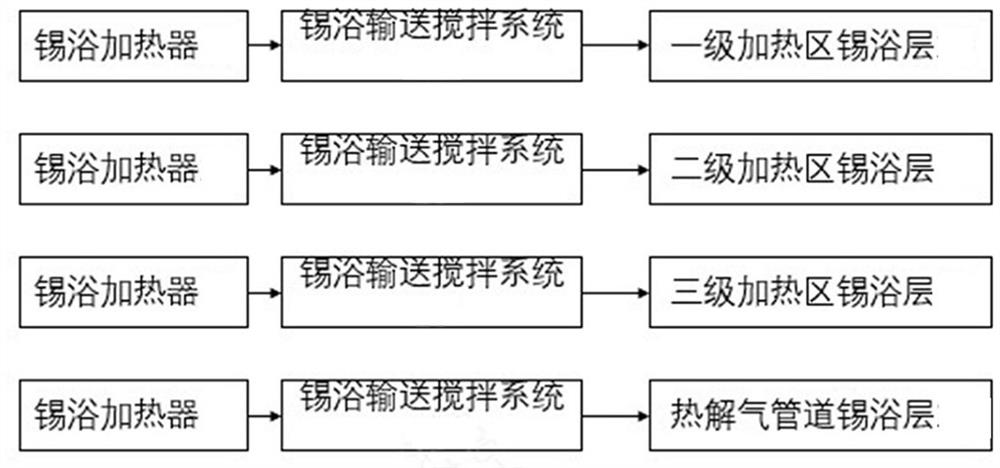

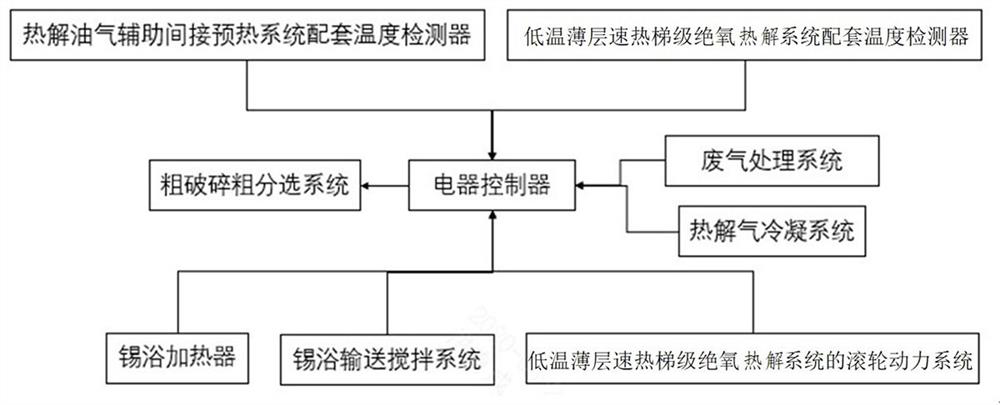

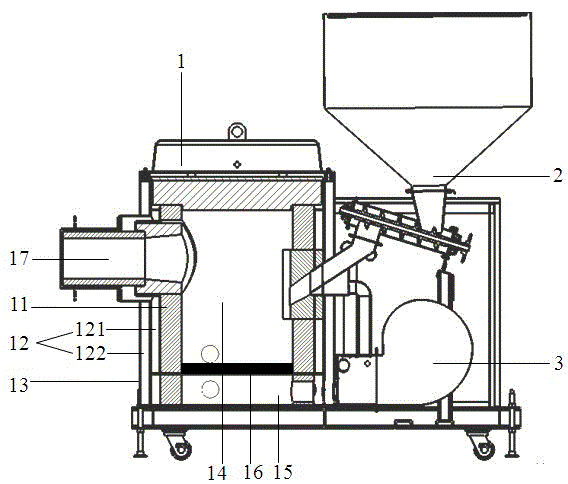

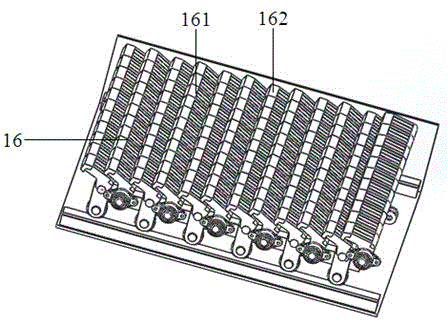

Low-temperature thin-layer quick-heating cascade anaerobic pyrolysis system and solid waste pyrolysis system based on system

PendingCN112393247AAvoid wastingAvoid deformation lossIncinerator apparatusThermodynamicsControl system

The invention discloses a low-temperature thin-layer quick-heating cascade anaerobic pyrolysis system which comprises a solid waste extrusion conveying system, a heating temperature control system anda heat preservation device. The solid waste extrusion conveying system and the heating temperature control system are arranged in the heat preservation device; pyrolysis gas outlets are formed in theheat preservation device; the solid waste extrusion conveying system is used for extruding and thinning the solid waste before conveying the solid waste; and the heating temperature control system isused for heating and pyrolyzing the extruded and thinned solid waste. According to the low-temperature thin-layer quick-heating cascade anaerobic pyrolysis system provided by the invention, the solidwaste is subjected to paving, extruding, thinning and heating, and then quickly heated and pyrolyzed; and particularly, roller sealers are arranged to form sub heating areas, so that the system has the advantages of being low in heating temperature, low in operation cost, high in heating speed, not prone to coking, high in adaptability and the like.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

Combustion furnace structure of biomass combustion machine

InactiveCN105020698AImprove insulation effectIncrease temperatureSolid fuel combustionCasings/liningsCombustion chamberEngineering

The invention provides a combustion furnace structure of a biomass combustion machine, and provides a combustion furnace configured with a reciprocating grate and a double-layer insulating jacket structure. The combustion furnace comprises a fire-resistant concrete lift, a heat insulating jacket layer, and a metal outer cylinder from inside out. The heat insulating jacket layer is in a double-layer jacket structure. The heat insulating jacket layer comprises a water-cooling jacket layer and an air cooling jacket layer from inside out. The combustion furnace is internally provided with a combustion chamber and a settling chamber. The reciprocating grate is arranged between the combustion chamber and the settling chamber. The reciprocating grate is formed by a movable grate and a fixed grate. A side of the combustion furnace is provided with a nozzle, and the other side is connected with a feeding system and an air supply system. Continuous motion of the reciprocating grate can make generated coking be cleared away to the settling chamber in time, preventing coking hidden danger, reducing manual decoking times, reducing labor intensity, and saving operation cost. The double-layer insulating jacket structure is beneficial for furnace body heat insulation and improves combustion efficiency.

Owner:天津市双鑫锅炉辅机有限公司

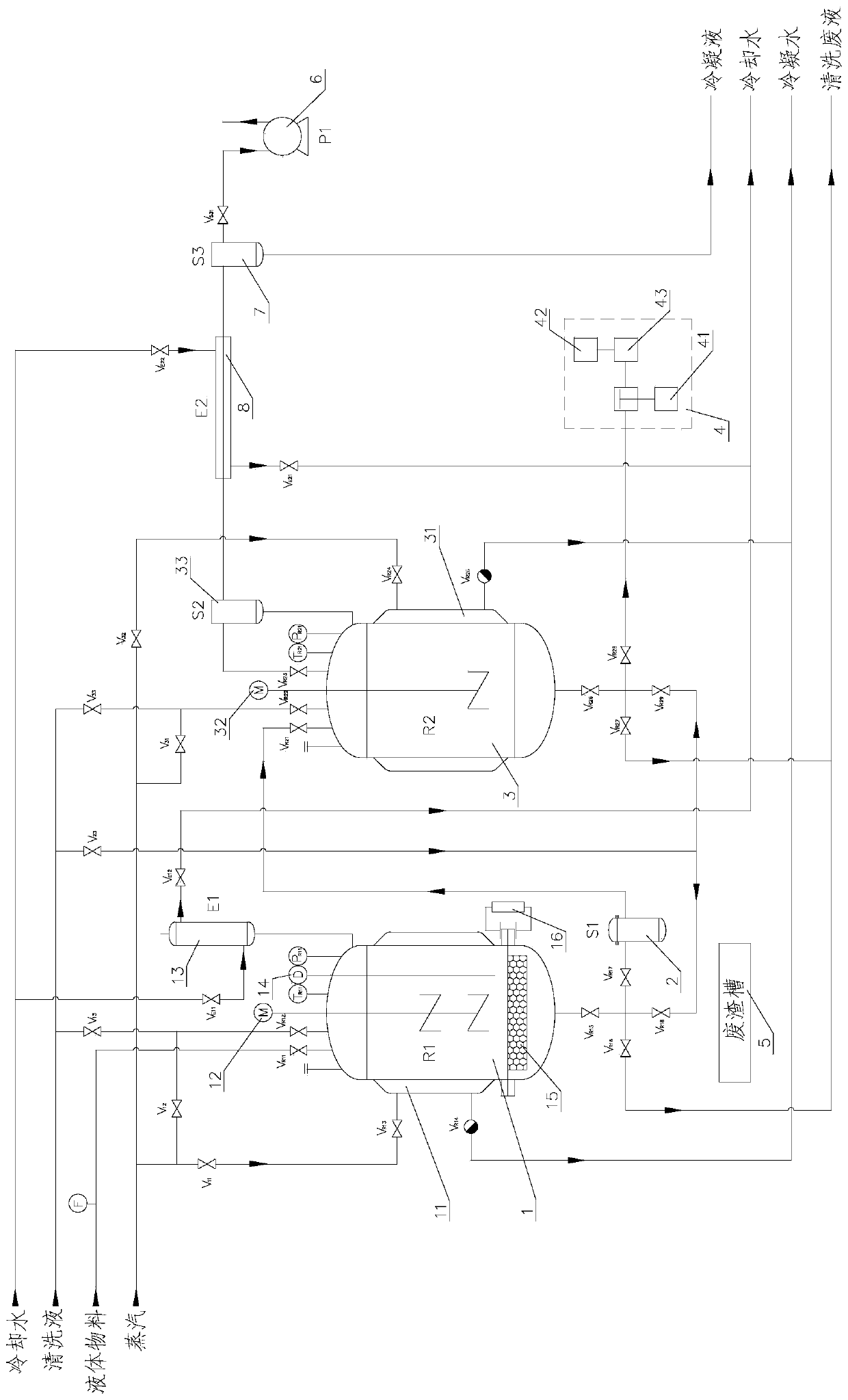

Complete device for industrial production of paste and application of device

InactiveCN110292531AReduce contentReduce accumulationPharmaceutical product form changeDomestic articlesProduct gasProcess engineering

The invention relates to a complete device for industrial production of paste (concentrated decoctions) and application of the device. The complete device comprises an extraction tank (1), a precise filter (2), a concentration tank (3), an automatic packaging machine (4), a waste residue tank (5), a vacuum pump (6), a condensate recovery tank (7), a condenser (8) and an on-line cleaning CIP and high-temperature steam sterilization system. A liquid material enters the extraction tank (1) and is extracted, then the liquid material is input into the concentration tank (3) after being filtered bythe precise filter (2), concentrated gas sequentially passes through the condenser (8), the condensate recovery tank (7) and the vacuum pump (6) and then is discharged, the concentrated liquid is a paste product, and the paste product enters an automatic packaging machine (4) for packaging. Compared with the prior art, the device is suitable for industrial and large-scale production, and has the advantages of being high in extraction speed, high in extraction efficiency, controllable in concentration temperature, capable of reducing the coking risk and the like.

Owner:SHANGHAI RES INST OF CHEM IND

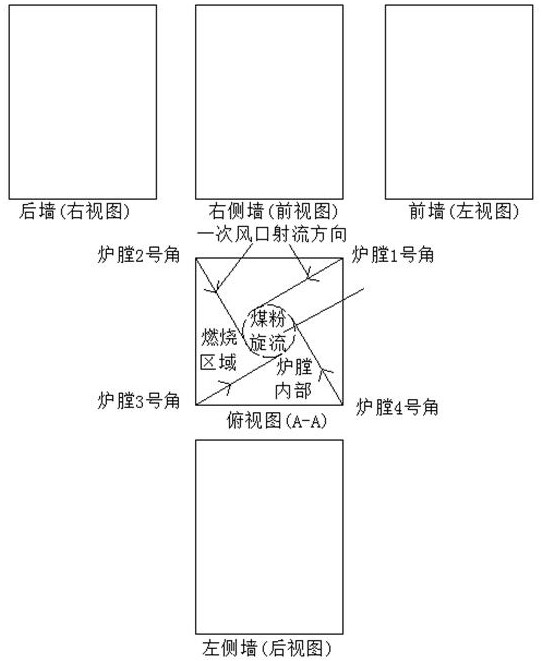

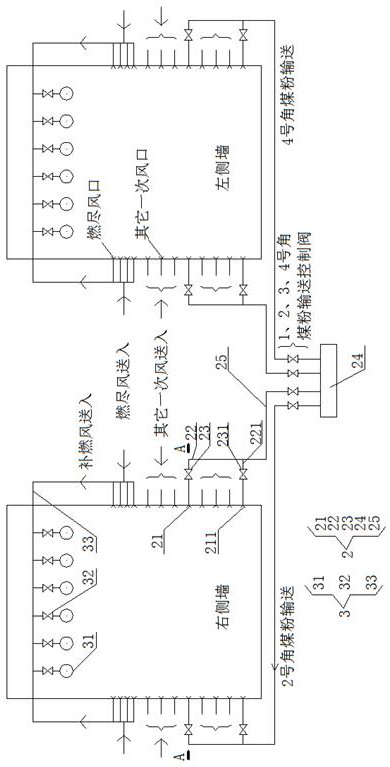

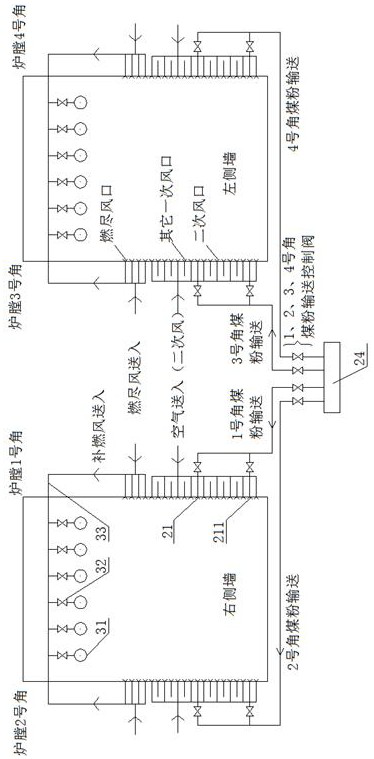

Low-low-nitrogen combustor for large and medium-sized pulverized coal boilers under wide-load operation, and using method

PendingCN112413570AIncrease concentrationReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelAir volumeThermodynamics

The invention discloses a low-low-nitrogen combustor for large and medium-sized pulverized coal boilers under a wide load condition, and a using method. A primary air system which can meet the requirement that the interior of the cross section of a hearth at the position is always a high-concentration pulverized coal area and is stable in combustion and free of coking under any load / coal type working condition is arranged in the middle of a hearth combustor in the vertical direction; an afterburning air system which can be used for spraying air into the internal space of the cross section of the hearth is arranged at the upper part of the hearth combustor; during operation under a low-load working condition, a middle hearth space can remain enough pulverized coal concentration, and forms an anoxic high-temperature combustion area, and a large amount of carbon monoxide is generated to fully inhibit generation of thermal nitric oxide; and in the upper afterburning air area, an upper hearth forms an oxygen-enriched relatively-low-temperature combustion area through regulation and control of the afterburning air volume, and the temperature is lower than the temperature generated by thethermal nitric oxide, so that high-concentration carbon monoxide is fully combusted. The method has remarkable energy-saving and environment-friendly benefits during low-load operation of the large and medium-sized boilers.

Owner:NANJING INST OF TECH

A low-pollution combustor using bubble atomizing nozzles in the main combustion stage

ActiveCN105823087BReduced risk of cokingImprove uniformityContinuous combustion chamberAviationCombustion chamber

Owner:BEIHANG UNIV

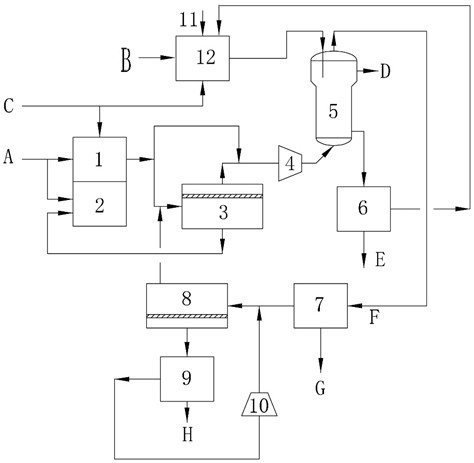

Regeneration method and regeneration device for biomass pyrolysis liquid fluidized bed exhaust catalyst

InactiveCN110093180AAvoid foaming and collisionsReduced risk of cokingCatalyst regeneration/reactivationTreatment with moving solid particlesLow activityAirflow

The invention discloses a regeneration method and a regeneration device for a biomass pyrolysis liquid fluidized bed exhaust catalyst. The regeneration method comprises the following steps of: A) performing primary cyclone classification to remove micro powder in the exhaust catalyst; B) performing secondary cyclone classification to remove structurally incomplete catalyst particles in the catalyst; C) performing cyclone autorotation to remove a conveying medium carried by a complete structure catalyst; D) performing gas flow acceleration sorting to realize the classification of a high-activity catalyst and a low-activity catalyst; and E) mixing the high activity catalyst and a fresh catalyst and adding into a reactor for utilization. The regeneration device comprises a biomass pyrolysis liquid fluidized bed reactor, a primary cyclone classifier, a primary filter, a secondary cyclone classifier, a secondary filter, a pulsating airflow generator, a cyclone autorotator, a sorter, a cyclone separator and a gas purification tower. The regeneration device can meet the separation and classification requirements of the micro powder, the catalyst with the incomplete structure, and low activity catalyst particles in the exhaust catalyst of the hydrogenation reaction of a biomass pyrolysis liquid.

Owner:HENAN BUF BIOENERGY CO LTD +2

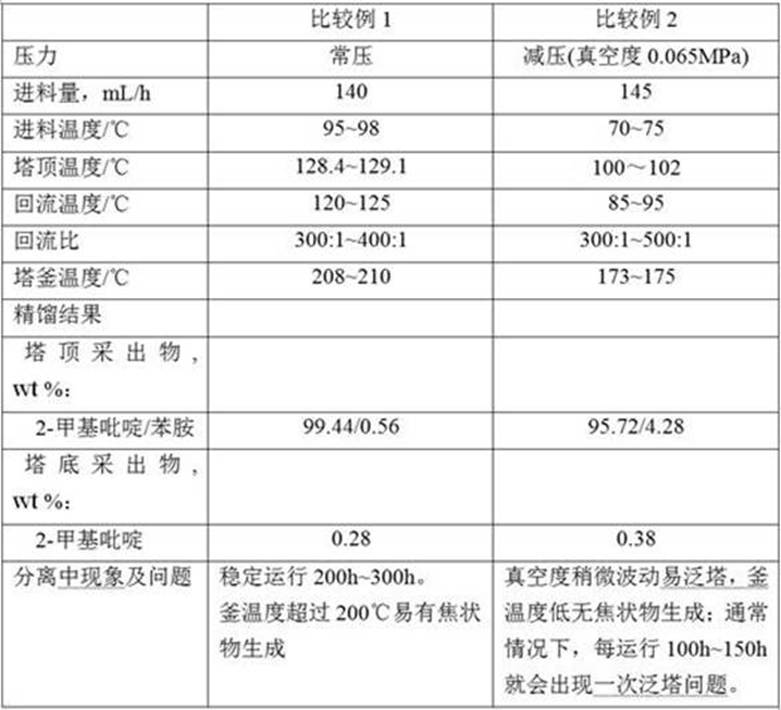

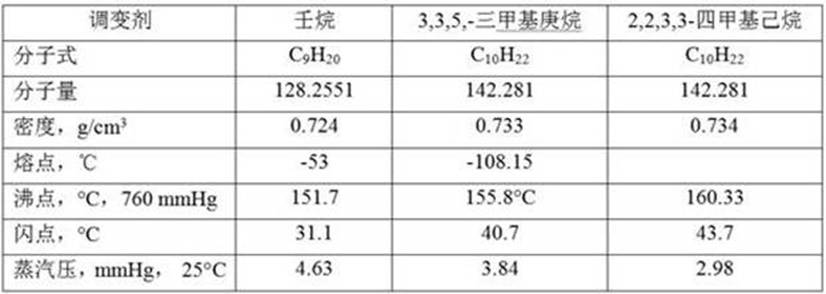

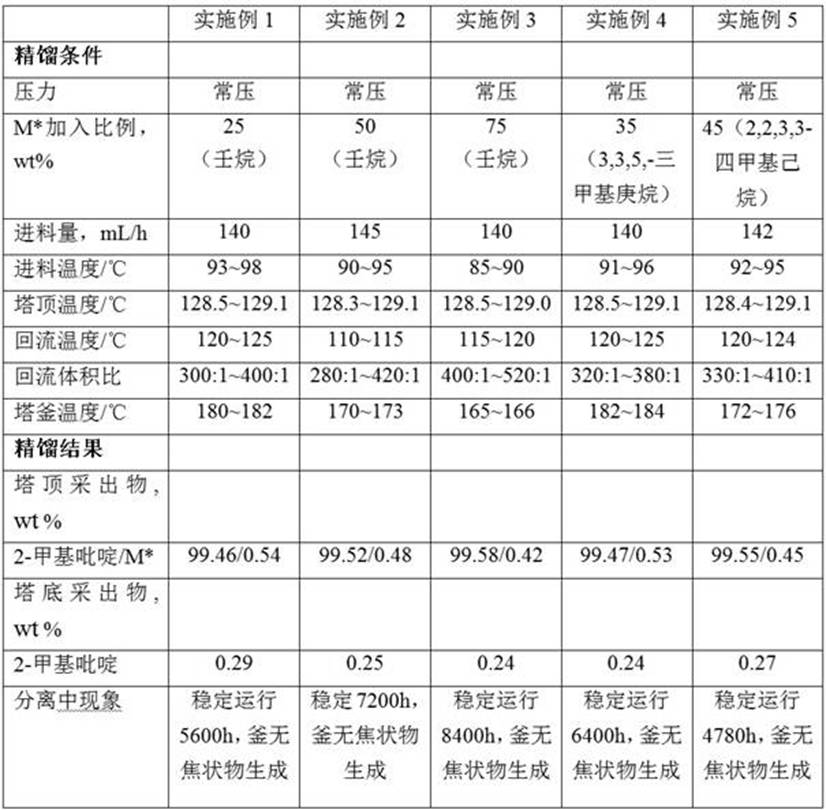

Separation method of 2-methylpyridine

PendingCN114685362AAdjustable temperatureReduce the temperatureAmino compound purification/separationMethylpyridiniumProcess engineering

The invention discloses a method for separating 2-methylpyridine. The method comprises the following steps: selecting a modulation agent M, wherein the modulation agent is a non-polar substance; the boiling point of the modulating agent is 130-183 DEG C; adding the modulating agent M into a separation raw material of a 2-methylpyridine separation tower according to a certain proportion; the obtained separation raw material enters a 2-methylpyridine separation tower, rectification is carried out under the rectification condition, and 2-methylpyridine with the increased concentration is obtained on the tower top. The method provided by the invention realizes the purposes of operation under normal pressure and reduction of the temperature of the tower kettle, and reduces the risk of coking of the tower kettle at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method and device for removing particles from a biomass pyrolysis liquid ebullated bed reactor

ActiveCN110026135BAvoid foamingAvoid collisionFeed devicesTreatment with moving solid particlesPtru catalystPhysical chemistry

The invention discloses a method and device for removing particles in a biomass pyrolysis liquid ebullating bed reactor. The method comprises the following steps: A) primary cyclone classification to realize the classification of catalyst micropowder and catalyst particles; B) primary filtration Realize the separation of catalyst fine powder and transport oil; C) two-stage cyclone classification realizes the classification of structurally incomplete catalyst and structurally complete catalyst; D) two-stage filtration realizes the separation of structurally incomplete catalyst and transport oil; E) structurally complete catalyst and Fresh catalyst is mixed and added to the reactor for utilization. The invention also provides a particle removal device in the ebullated bed reactor of biomass pyrolysis liquid. The invention can meet the requirements of realizing the classification of particles and realizing the drying reduction of the separated catalyst, effectively avoiding the foaming and collision of the reactor bed caused by the fine powder of the catalyst, and reducing the risk of coking.

Owner:HENAN BUF BIOENERGY CO LTD +2

Natural gas hydrogen production and biomass liquefaction combined treatment system and process

ActiveCN112300823AHigh activityQuality improvementHydrogenLiquid hydrocarbon mixture productionHydrogen productionTreatment system

The invention discloses a natural gas hydrogen production and biomass liquefaction combined treatment system and process. The treatment system comprises a natural gas reforming hydrogen production unit, a synthesis gas proportion adjusting membrane separator, a synthesis gas compression unit, a biomass raw material pretreatment unit, a biomass liquefaction reactor, a carbon dioxide separation unit, a light hydrocarbon concentration membrane separator and a light hydrocarbon recovery unit. The invention further provides a treatment process adopting the treatment system. According to the combined treatment system, the biomass liquefaction reaction unit and the natural gas reforming hydrogen production unit are organically combined, the natural gas reforming hydrogen production unit can adjust the property of hydrogen required by liquefaction at any time according to different biomass raw materials, a water gas shift reaction unit and a hydrogen purification unit in the natural gas reforming hydrogen production unit are omitted, synthesis gas generated by the natural gas reforming hydrogen production unit is directly used in the biomass catalytic liquefaction process, the hydrogen cost is greatly reduced, and the hydrogen utilization rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crude benzene hydrorefining process

ActiveCN103274885BAvoid high temperature polymerization coking to block the systemHigh outputHydrocarbon purification/separationHydrocarbonsCatalytic reformingDistillation

The invention provides a crude benzene hydrogenation refining process, which is obtained by sequentially performing liquid-phase catalytic pre-hydrogenation reaction, gas-phase catalytic pre-hydrogenation reaction and main catalytic hydrogenation reaction on crude benzene, and then extracting, rectifying and main hydrogenation reaction material, obtained distillates of each distillation range; compared with the prior art, the present invention adjusts the catalytic hydrogenation process to a three-stage hydrogenation technology, and does not need to pre-separate heavy benzene before catalytic hydrogenation; In the hydrogenation process, the unsaturated olefins in the crude benzene are hydrogenated into saturated hydrocarbons at a relatively low reaction temperature of 130~140°C, so as to avoid the unsaturated hydrocarbons contained in the crude benzene that are easy to polymerize at high temperatures in the subsequent process. In the case of high-temperature polymerization coking and blockage of the system; the method can hydrogenate heavy benzene in crude benzene to obtain mixed aromatics, which can be used as high-quality blending components of gasoline and diesel, and the output value and added value of materials can be improved.

Owner:湖北巨邦石油化工有限公司

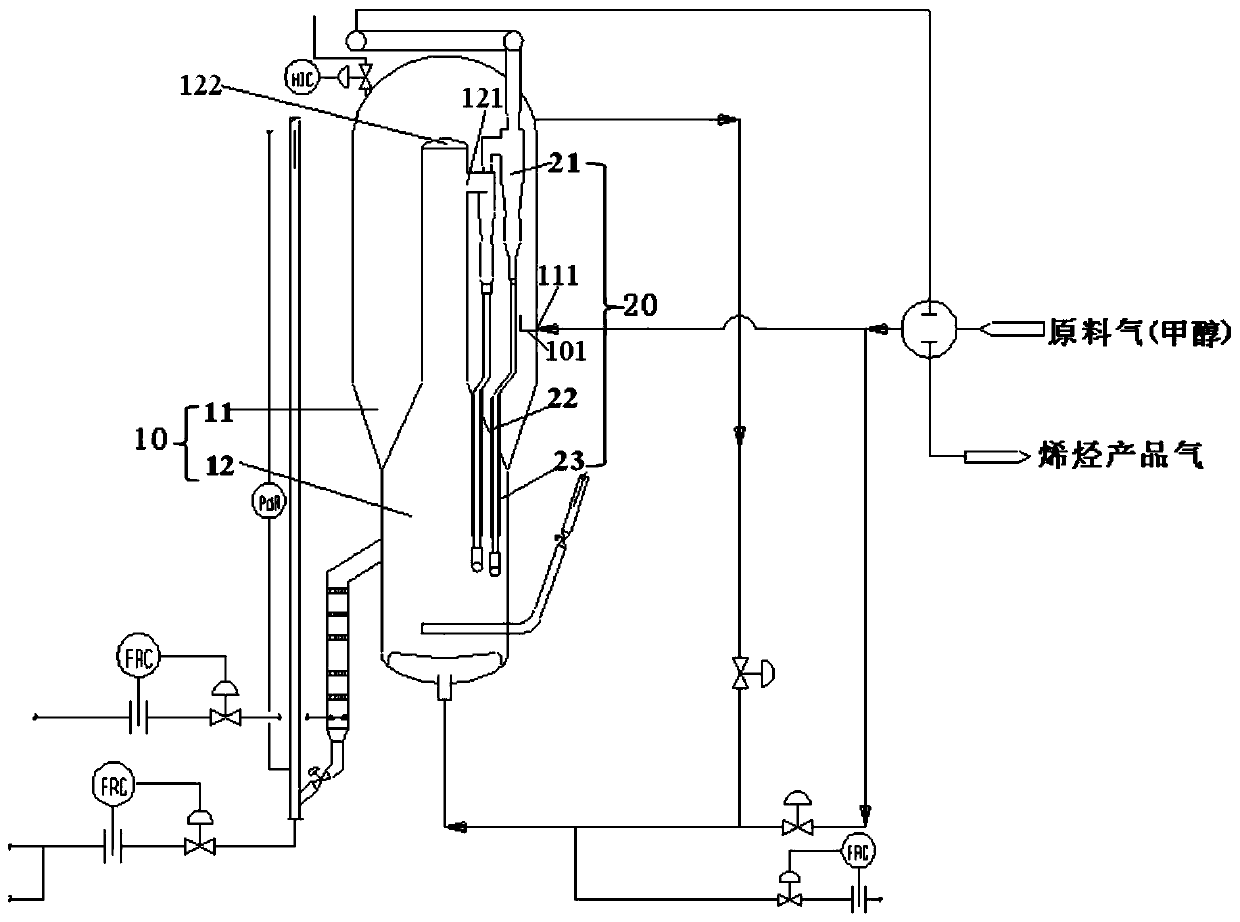

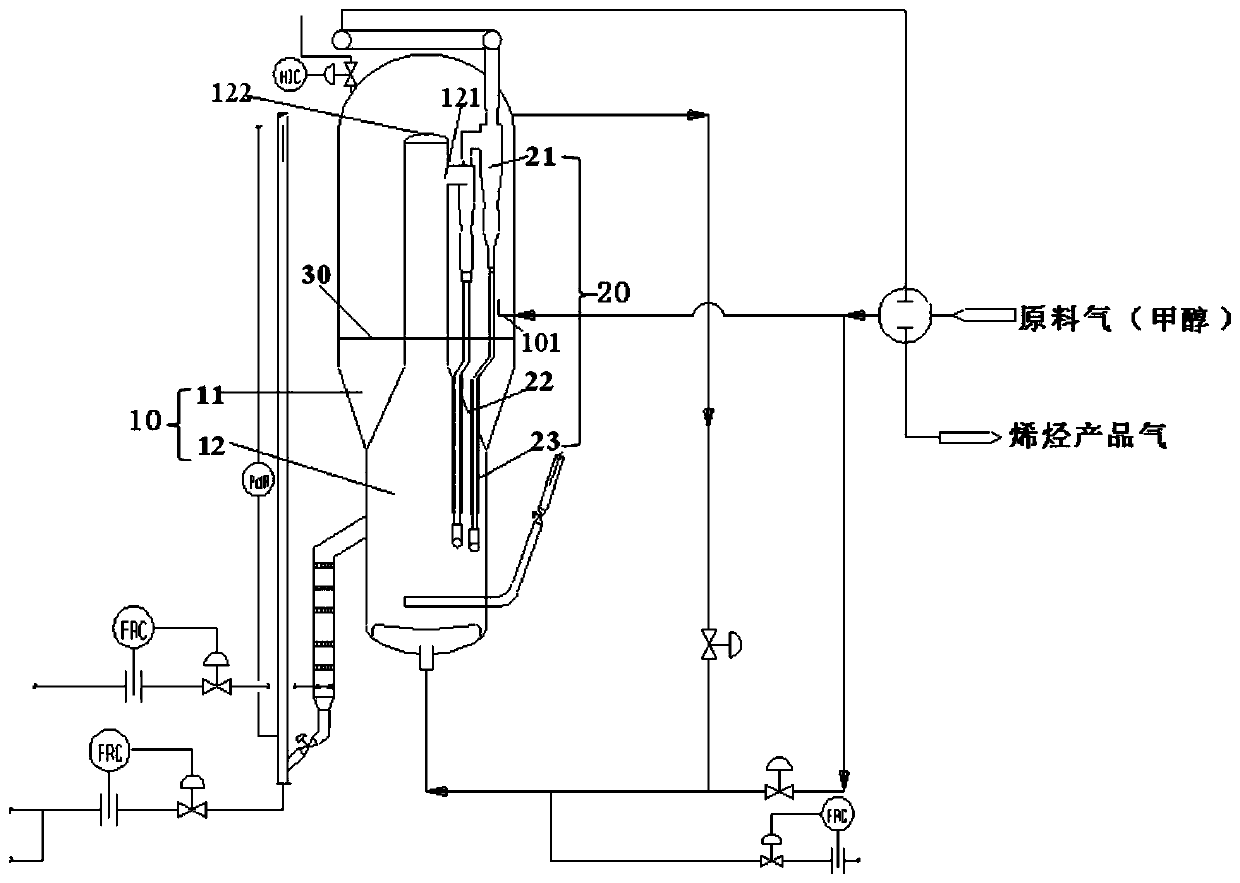

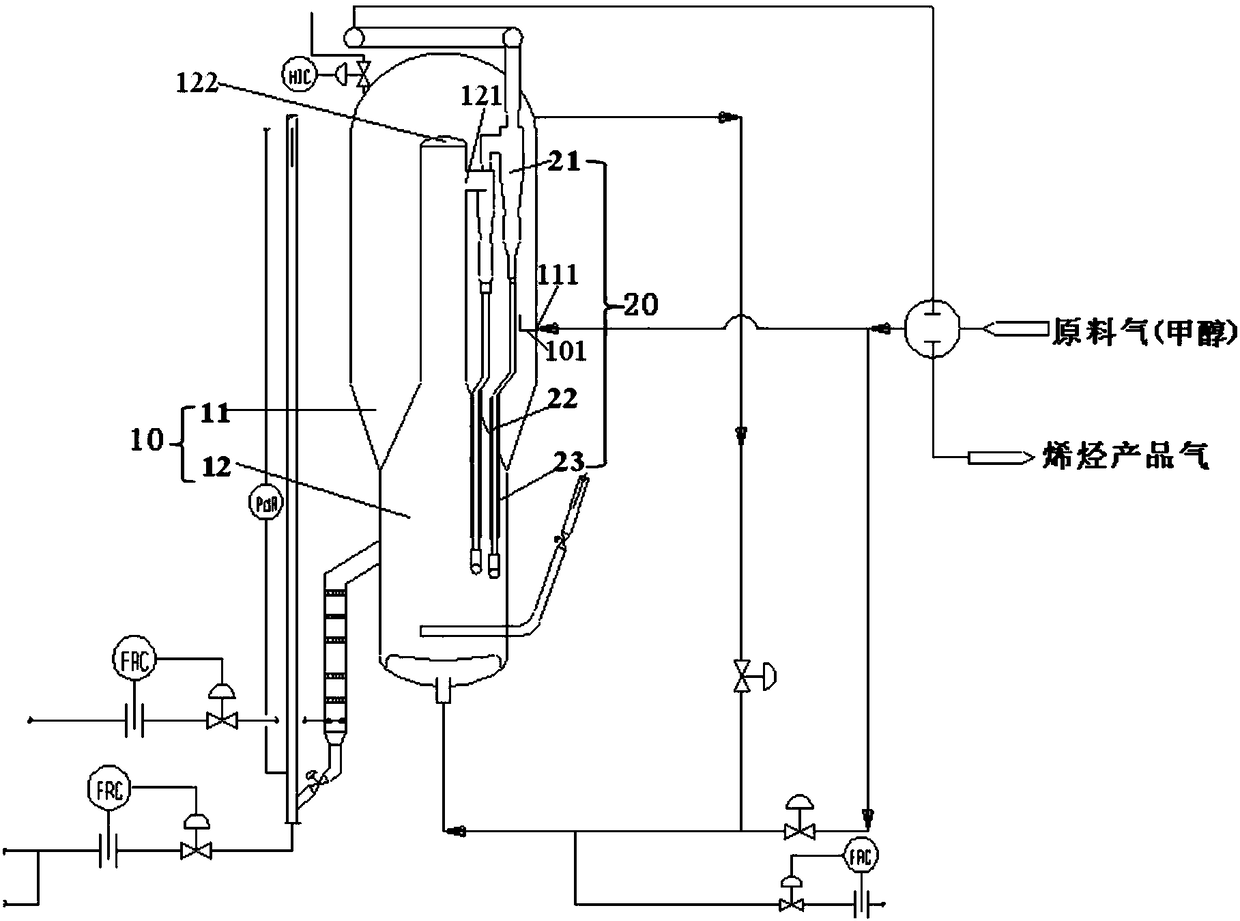

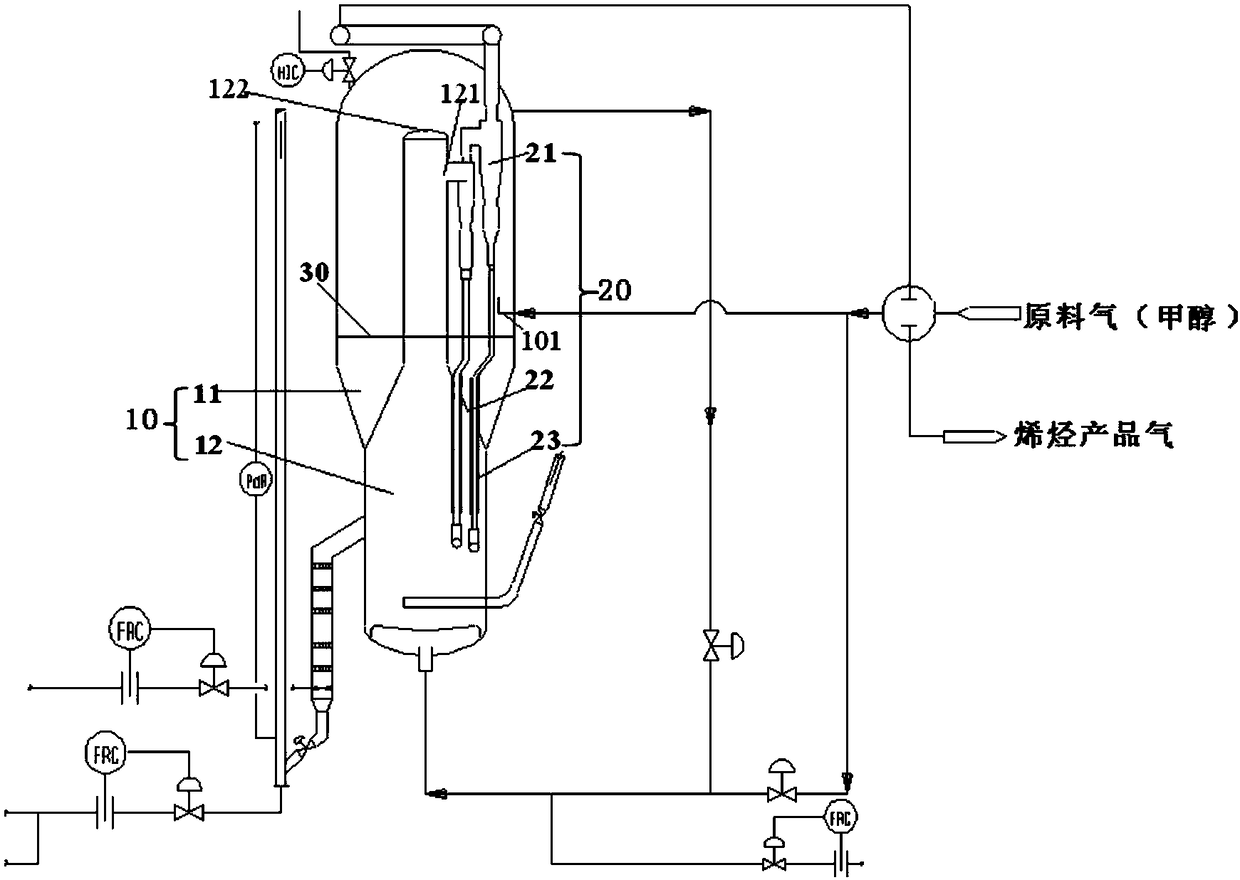

Methanol to olefins reaction system

ActiveCN108404818BHigh selectivityReduce energy consumptionHydrocarbon from oxygen organic compoundsChemical/physical processesThermodynamicsPhysical chemistry

The invention provides a methanol to olefin (MTO) system. The MTO reaction system comprises an MTO reactor and a gas-solid separator. The gas-solid separator is provided with an olefin outlet and is arranged in the MTO reactor. The olefin outlet is communicated with the inlet end of the gas-solid separator. The MTO reactor and the gas-solid separator form a heat exchanging structure, which is usedto cool the separated olefin gas from the gas-solid separator. Methanol gas can absorb the heat of high temperature olefin gas in the olefin product system in the gas-solid separator; the heat exchanging between the olefin gas and the MTO reactor is realized; the temperature of olefin gas is reduced, the coking of heat exchangers in subsequent flow paths is inhibited, and the heat exchanging effect is improved. Furthermore, methanol is heated by the heat of olefin gas, and the selectivity of MTO reactions is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

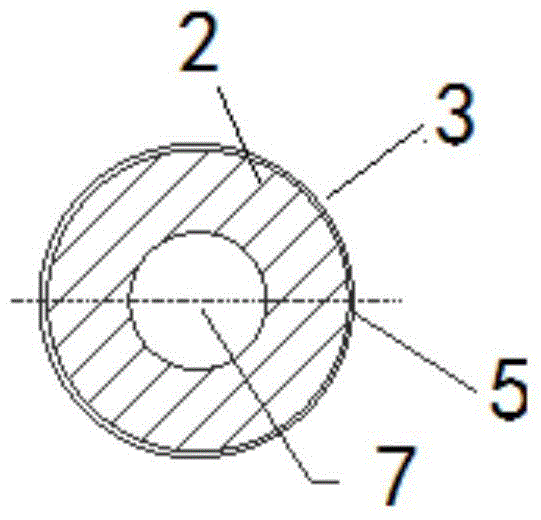

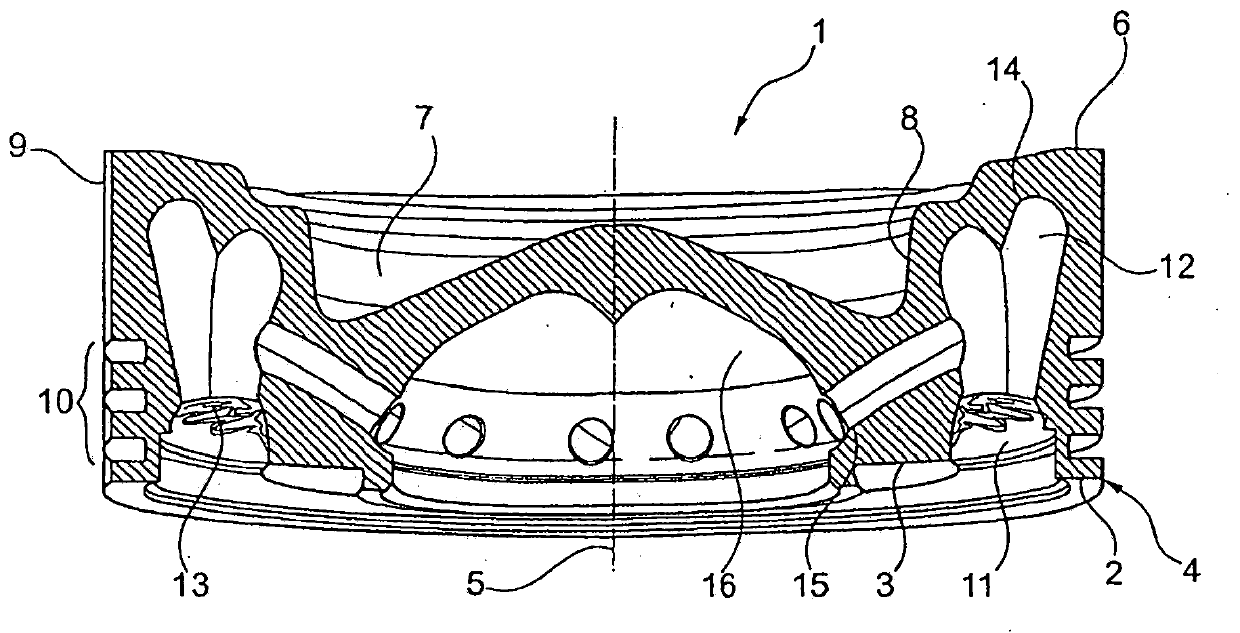

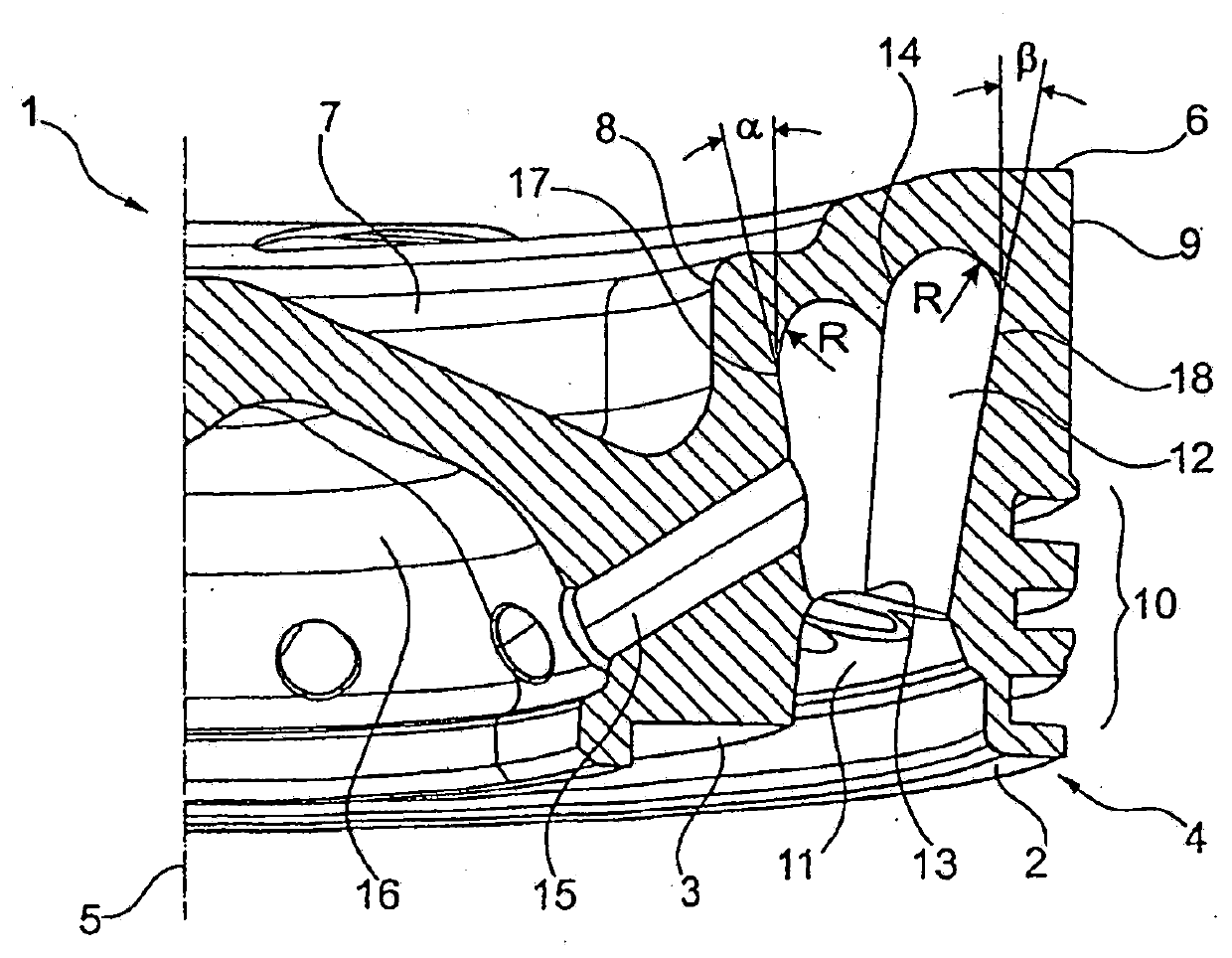

Piston upper part with enlarged cooling chamber for assembled or welded pistons

ActiveCN102859165BMeet emission requirementsReduce intensityFoundry mouldsMachines/enginesCombustion chamberPiston ring

A liquid cooled piston of an internal combustion engine includes a piston lower part and piston upper part which has a combustion chamber recess. These piston components are supported via joining lands which are spaced apart radially and together form a dividing plane, and are joined together with a material-to-material fit. In order to receive piston rings, the piston upper part has a ring area and includes an annular cooling channel which extends into the piston lower part and is connected to an inner cooling space via connecting channels. The cooling channel is adjoined by recesses which are oriented in the direction of a piston head, are configured as a blind hole and widen conically starting from the cooling channel as far as a recess bottom. The recess bottom can be of a pronounced undulating enlarged surface or a finely undulating configuration.

Owner:KOLBENSCHMIDT AG

Medium-pressure boiler is suitable for burning xinjiang quasi-east coal

PendingCN108775572AReduce heat loadReduced coking tendencySteam superheatersSteam boilersCombustion systemCombustion

The medium-pressure boiler is suitable for burning xinjiang quasi-east coal, and relates to a medium-pressure boiler. According to the boiler, the problem that an existing quasi-east coal boiler is used for generating coking of an integral part of the boiler is solved, the problems that the boiler is exploded and the furnace stopping phenomenon is frequently caused due to contamination are solved.The combustion system is located at an angle part defined by a water-cooled wall system in the hearth, four-angle tangential combustion is formed in the hearth through flames, a tail flue and a boiler top shed are defined by the ceiling ladle wall superheater, a low-temperature superheater and a coal economizer system are arranged in a rear vertical shaft of the tail flue, a separation screen superheater is arranged at the top of the hearth, a last-stage superheater is arranged in a flue at the upper part of an outlet of the hearth outlet, the transverse pitch range of the separation screen superheater is 500mm to 700 mm, the transverse pitch range of the low-temperature superheater and the transverse pitch range of the last-stage superheater are both 150mm to300 mm, and a hearth area, aradiation heating surface and a convection heating surface are provided with a plurality of soot blower. The medium-pressure boiler is suitable for burning xinjiang quasi-east coal.

Owner:HARBIN BOILER

Methanol to olefin (MTO) reaction system

ActiveCN108404818AHigh selectivityReduce energy consumptionHydrocarbon from oxygen organic compoundsChemical/physical processesProduct systemReaction system

The invention provides a methanol to olefin (MTO) system. The MTO reaction system comprises an MTO reactor and a gas-solid separator. The gas-solid separator is provided with an olefin outlet and is arranged in the MTO reactor. The olefin outlet is communicated with the inlet end of the gas-solid separator. The MTO reactor and the gas-solid separator form a heat exchanging structure, which is usedto cool the separated olefin gas from the gas-solid separator. Methanol gas can absorb the heat of high temperature olefin gas in the olefin product system in the gas-solid separator; the heat exchanging between the olefin gas and the MTO reactor is realized; the temperature of olefin gas is reduced, the coking of heat exchangers in subsequent flow paths is inhibited, and the heat exchanging effect is improved. Furthermore, methanol is heated by the heat of olefin gas, and the selectivity of MTO reactions is increased.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

An anti-coking over-vaporized oil collection tank

ActiveCN104623923BShort stayAvoid resistanceVacuum distillationFractional distillationFuel tankPulp and paper industry

The invention relates to an anti-coking oil collecting tank for passing vaporized oil. Each liquid collecting tank is composed of one or more members with a square tank structure; one end of the liquid collecting tank close to the tower wall is overlapped on a support ring, the other end is overlapped on the edge of a liquid collecting channel, the end overlapped on the support ring is higher than the end overlapped on the liquid collecting channel, and thus the liquid collecting tank is inclined to the liquid collecting channel. The liquid collecting tank in the middle part uplifts, the two ends of the middle liquid collecting tank are respectively overlapped on two neighbored liquid collecting channels, and the middle liquid collecting tank is inclined to the second liquid colleting channel. A liquid baffle plate is in a square tank shape or a triangular tank shape and is fixed above a gap between the liquid collecting tanks through a rib plate or a support plate so as to form a gas channel. The liquid collecting channel has a square tank shape structure, the oil collecting tank comprises one or more liquid collecting channels, one end of the liquid collecting channel is overlapped on a withdrawal hopper, and the bottom plate is inclined to the withdrawal hopper. The number of withdrawal hopper is one or two, and the bottom plate of the withdrawal hopper is inclined to the withdrawal opening. The provided oil collecting tank can reduce the stay time of liquid in the oil collecting tank, reduces the flow resistance, prevents the happening of coking, and guarantees the normal operation of towers at a high temperature.

Owner:PETROCHINA CO LTD +1

Anti-coking agent for hazardous waste incineration line and preparation method of anti-coking agent

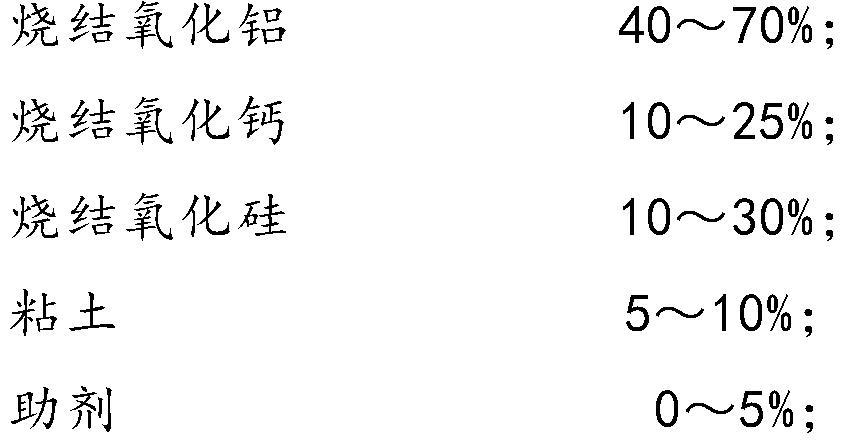

The invention discloses an anti-coking agent for a hazardous waste incineration line. The anti-coking agent comprises the following components in percentage by mass: 40-70% of sintered alumina; 10-25% of sintered calcium oxide; 10%-30% of sintered silicon oxide; 5-10% of clay; 0-5% of an auxiliary agent; wherein the sum of the mass percentages of the components is 100%. The anti-coking agent provided by the invention can increase the melting temperature of the hazardous waste material, reduce the coking risk and improve the operation state of a hazardous waste incineration line.

Owner:SCIP SITA WASTE SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com